enware EL450 Assembly instructions

I00303_Mar19

Call 1300 369 273

www.enware.com.au

Enware Australia Pty Limited

9 Endeavour Rd Caringbah NSW 2229 Australia

Ph: 02 8536 4000 info@enware.com.au

EL450

Wall Mounted Hand Held

Drench Hose

NOTE: THIS DOCUMENT IS TO BE LEFT ONSITE WITH FACILITY MANAGER AFTER INSTALLATION

Installation, Operating and Maintenance Instructions

WALL MOUNTED HAND HELD DRENCH

HOSE – SINGLE OUTLET

2 Call 1300 369 273 www.enware.com.au

contents

Technical Data 3

Installaon Compliance 3

Installaon 4

Components 5

Operang Instrucons 6

Troubleshoong 6

Service and Maintenance 7

Warranty 8

www.enware.com.au Call 1300 369 27 3

technical data

Inlet Connecon ½” BSP Female

Minimum Water Supply

Line Size

DN15

Minimum Working

Pressure

40 kPa

Recommended Maximum

Working Pressure

500 kPa

Minimum Flow Rate 6 Lpm

Suggested Flushing Water

Temperature

Tepid

16°C min - 38°C max

Acvaon Squeeze trigger handle

For use with potable water only

Before proceeding with installaon ensure all operang and dimensional specicaons are suitable for

the intended installaon.

This product is a supplemental equipment to provide immediate ushing to support plumbed and self-

contained emergency eye wash and shower equipment but does not replace them.

Refer to AS4775 and ANSI Z358.1 for installaon guidelines of Supplemental Equipment – Drench Hose.

Enware products are to be installed in accordance with the Plumbing Code of Australia (PCA), AS/

NZS3500 and instrucons provided. Installaons not complying with above may void the product and

performance warranty provisions.

Supply Lines

Ensure all supply lines are ushed thoroughly to

remove debris prior to the installaon of this

product. Strainers (40 mesh) are recommended if

debris is an ongoing problem.

Supply Pressure

A Pressure Reducon Valve may be required to

comply with recommended maximum supply

pressure.

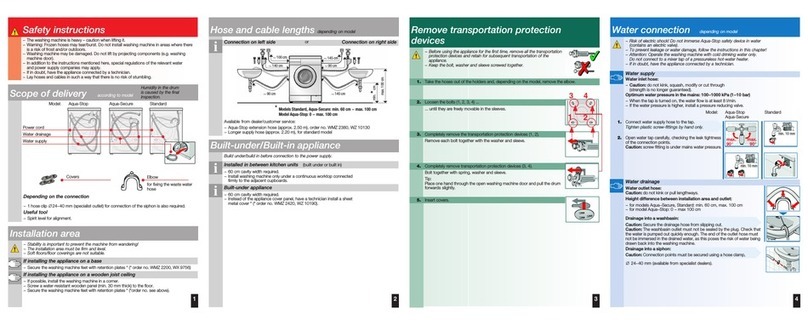

installation compliance

50

65

80

3.75 m LONG HOSE

1/2" BS

P

80

175

Flushing Fluid Temperature

Flushing Fluid Temperature: Tepid.

Suggested temp range 15.6 °C – 37.8 °C

Refer to AS4775 for installaon guidelines of

Supplemental Equipment – Drench Hose

NOTE: Enware Australia advises:

1. Due to ongoing Research and Development,

specicaons may change without noce.

2. Component specicaons may change on

some export models.

4 Call 1300 369 273 www.enware.com.au

installation

1. Set out and Rough-in:

Provide a 1/2” BSP male ng for water inlet,

allowing approximately 12mm of thread proud

from nished wall.

2. Prior to installaon, ush the line thoroughly

to remove debris. Once the line is clear of

debris, proceed to next step. A pressure

reducon valve may be required to comply

with recommended water supply pressure.

3. Apply thread tape onto the 1/2” BSP male

thread on wall. Screw wall mount on and

ghten rmly.

4. Apply thread sealing tape onto male thread of

chrome elbow and screw to wall mount rmly.

A 1/2” BSP male ng can be screwed on

loosely to the other side of the elbow to gain

leverage and ghten with a spanner. Ensure the

elbow is facing straight down.

5. Apply thread sealing tape onto thread of hose

assembly, and screw onto the elbow with a

spanner.

6. Locate the bracket, and once the hand held eye

wash is in the desired posion, mark holes for

the bracket on wall. Drill the holes and secure

bracket using appropriate wall xings/ anchors.

7. Turn water supply on and test all joints and

connecons for leaks. Grab the trigger gun and

squeeze the handle to test for correct operaon

and water ow. If there is any problem refer to

Troubleshoong on page 6.

8. Hook the hand trigger gun onto bracket.

Flip the outlet cap back on so no dust

accumulates on the outlet. Installaon is

now complete.

34

6 mm

17

42

Holes on

Bracket

www.enware.com.au Call 1300 369 27 5

components

4

5

6

7

9

8

2

1

10

DESCRIPTION PRODUCT CODE

1Wall Mount

2Elbow Swept ½” BSP MF C/P

4Outlet Shroud and Dust Cap

5Aerator 13 Lpm

6Rubber Washer

5, 6 Aerator and Washer ESPE015

4, 5, 6 Outlet ESPE016

7Wall Bracket FS071

8Trigger Gun

9Hose Assembly 1/2” Nylex Self Store ESPE011

10 Aerator Key 672282

6 Call 1300 369 273 www.enware.com.au

operating instructions

Instrucons for all emergency equipment should

be readily accessible to maintenance and training

personnel.

1. Squeezing the trigger acvates the drench hose.

2. Grab the trigger gun up from the bracket,

squeeze the trigger to start water ow, and

apply to body parts needing treatment.

3. To stop the water ow, simply release the

trigger.

4. To keep the water ow to stay on, slide the

holding ring over the trigger handle while

squeezing the trigger.

When servicing ensure that the water supply is turned OFF before disassembling the product.

troubleshooting

SQUEEZE TO TURN ON

RELEASE TO TURN OFF

USE HOLDING

RING TO KEEP

TRIGGER ON

PROBLEM CAUSE RECTIFICATION

Trigger Spray does

not turn o

Debris fouling ball seang

washer or stainless steel ball

Dismantle and clean SBA

Seang washer damaged or

spring broken

Replace components using spare part kit (Enware

Part Code FS077NS) or replace SBA (Enware Part

Code FS721S)

Piston jammed in open

posion

Remove dome and piston from SBA. Clean piston

assembly and re-grease piston o-rings

No ow from trigger

spray outlet

Water supply turned o Turn water on

Seang o/ring damaged Replace o-ring using spare part kit or replace SBA

Debris fouling inlet or outlet

ports of SBA

Dismantle and clean SBA and outlet aerator.

Replace if necessary

Water discharge

from top of trigger

spray dome

Piston o-rings worn Replace o-rings and re-grease spindle with

service kit or replace SBA

www.enware.com.au Call 1300 369 27 7

service and maintenance

TRIGGER SPRAY GUN MAINTENANCE

It is recommended that the trigger spray acon

be periodically serviced. The maintenance

interval will depend on the frequency of use

of the product, water quality and the general

environment.

Occasionally the handle screws should be checked

for ghtness, and a visual inspecon made of all

other connecons on the assembly including the

trigger spray and hose, and the wall bracket xing

to the wall to ensure they are secure, and ghten

if necessary.

CLEANING

Enware Product should be cleaned with a so damp cloth using only mild liquid detergent or soap and

water. Do not use cleaning agents containing a corrosive acid, scouring agent or solvent chemicals. Do

not use cream cleaners, as they are abrasive. Powder coated surfaces should only be cleaned with a cloth

and clear water or mild detergent. Use of unsuitable cleaning agents may damage the surface. Any damage

caused in this way will not be covered by warranty.

If re-greasing spindles always use a silicon based potable water approved lubricant such as Hydroseal ‘O’

Ring Lubricant or Molykote 111 silicone based grease.

The drench hose needs to be acvated weekly for a period long enough to verify operaon and ensure the

ushing uid is available (AS4775 and ANSI Z358.1).

NOTE: the intent is to ensure that there is a ushing uid supply at the head of the device, to clear the

supply line of any sediment build up that could prevent uid from being delivered to the head of the device,

and to minimize microbial contaminaon due to sing water. Hose condion and outlets should also be

checked for damage or wear.

The equipment should be inspected and tested annually to ensure correct operaon. Aerator outlet should

be dismantled with aerator key, checked for any debris, and cleaned or replaced. Hose condion and outlets

should also be checked for damage or wear, and all connecons and joints checked for leaks.

SBA FS721S

SERVICE KIT

FS077NS

FS790

CLEANING TRIGGER SPRAY

1. Using two (2) phillips head screw drivers, undo the

locking screws from the handle and remove handle.

2. Using a 26mm spanner remove the cover dome

and red bre washer from the spring loaded acon.

Clean the inside of the cover dome. Use a dilute

soluon of CLR if necessary. Remove all scale, grease

and any other residues.

3. Lightly grease the inside of the dome.

4. Pull out the piston from the SBA (stung box

assembly) and clean any scale or residues from the

spindle and buon. Be careful not to damage the

O-rings.

5. Lightly grease the piston o rings and push the piston

back into the SBA.

6. Depress piston to start water ow. Release piston

and check for leaks and that the water ow stops.

If there is no ow, or water does not stop, refer to

the trouble shoong guide. If the problem persists,

service kits or replacement SBA may be required.

7. With the red bre body washer located over the SBA,

screw the cover dome back down onto the SBA.

8. Replace the handle and secure it with the hinge

screws.

9. Re-test trigger spray for correct operaon.

8 Call 1300 369 273 www.enware.com.au

product warranty for Australia Eecve 1 September 2014

Enware Australia Pty Limited (ACN 003 988 314)

(“we” or “us”) warrants that this product (also referred

to as “our goods”) will be free from all defects in

materials and workmanship for 24 months* from the

date of purchase. Our liability under this warranty is

limited at our opon to the repair or replacement of

the defecve product or part, the cost of repair of the

defecve product or part or the supply of an equivalent

product or part, in each case if we are sased the

loss or damage was due to a defect in the materials or

workmanship of the product or part. All products must

be installed in accordance with the manufacturer’s

instrucons, the PCA, and AS/NZS3500 including any

other applicable regulatory requirements.

exceptions

This warranty does not apply in respect of any damage

or loss due to or arising from:

a) Failure by you or any other person to follow any

instrucons for use (including instrucons and direcons

relang to the handling, storage, installaon, ng,

connecon, adjustment or repair of the product)

published or provided by us;

b) Failure by you or any other person responsible for

the ng, installaon or other work on the product

to follow or conform to applicable laws, standards

and codes (including the AS/NZ 3500 set of Standards,

all applicable State and Territory Plumbing Codes,

the Plumbing Code of Australia and direcons and

requirements of local and other statutory authories); or

c) Any act or circumstance beyond our control including

faulty installaon or connecon, accident, abnormal use,

acts of God, damage to buildings, other structures or

infrastructure and loss or damage during product transit

or transportaon.

making a claim

To make a claim under this warranty you must

nofy us in wring within 7 days of any alleged defect

in the product coming to your aenon and provide

us with proof of your purchase of the product and

completed the Online Product Service and Warranty

Form available on website www.enware.com.au.

All nocaons and accompanying forms must be sent

to us marked for the aenon of the Enware Australia

Pty Limited, 9 Endeavour Road, Caringbah NSW 2229.

We can also be contacted by telephone (1300 369 273)

or by email (inf[email protected]om.au).

Your costs in making a claim under this warranty,

including all freight, collecon and delivery costs, are

to be borne and paid by you. We also reserve the right

at our cost to inspect any alleged defect in the product

wherever it is located or installed or on our premises.

*Condional warranty: 1 Year parts and labour on

complete assembly. Aer 1 year, a further 1 year parts

only warranty is applicable.

other conditions

Except as provided or referred to in this document, we

accept no other or further liability for any damages

or loss (including indirect, consequenal or economic

loss) and whether arising in contract, tort or otherwise.

Any benets available to you under this warranty are in

addion to any non-excludable rights or remedies you

may have under applicable legislaon, including as a

“consumer” under the Australian Consumer Law. To that

extent you need to be aware that: Our goods come with

guarantees that cannot be excluded under the Australian

Consumer Law. You are entled to a replacement or

refund for a major failure and for compensaon for any

other reasonably foreseeable loss or damage. You are

also entled to have the goods repaired or replaced if

the goods fail to be of acceptable quality and the failure

does not amount to a major failure.

Table of contents

Popular Washer manuals by other brands

Hotpoint Ariston

Hotpoint Ariston AQUALTIS AQ9F 49 U Instructions for installation and use

Miele

Miele PG 8528 Installation and operating instructions

Bosch

Bosch WAW32899SN Instruction manual and installation instructions

Admiral

Admiral W10092687 Cycle descriptions

Daewoo

Daewoo DWF-805M Service manual

Aqua

Aqua ECO WASH instruction manual