Enwork Equilibrium User manual

Equilibrium

Revision B 11/07/16

Conference Table

Installation Instruction

12900 Christopher Drive Lowell, MI 49331

800.815.7251 www.enwork.com

Specifications subject to change without notice. 3

Equilibrium End User Agreement

Enwork Equilibrium table bases must be installed directly onto a four inch

minimum thickness concrete floor using factory provided hardware.

Warning and Indemnity Agreement

Failure to install on four inch thick concrete floor or failure to follow installation

instructions may cause table to function improperly and could lead to personal

injury and or structural damage. Do not, under any circumstance, install on a

concrete floor less than four inches thick.

Equilibrium assembled can weigh up to 1,700 pounds supported in a three and a

half square foot area. It is the responsibility of the dealer to verify that the

location for Equilibrium is suitable and is properly installed. End user agrees that

the installation shall not be modified and the location of the table base shall not

be moved without assistance from an Enwork Dealer.

It is the responsibility of the dealer and end user to adhere to and follow any

local or state building, electrical and accessibility codes.

Enwork is not responsible for any structural failures or personal injuries or

property damage due to improper installation or improper use of product. End

user agrees to defend, indemnify and hold harmless Enwork from any claims of

any nature or type arising out of unauthorized modification or movement of the

table base or any other improper use of the product.

Note: Installation requires at least two people.

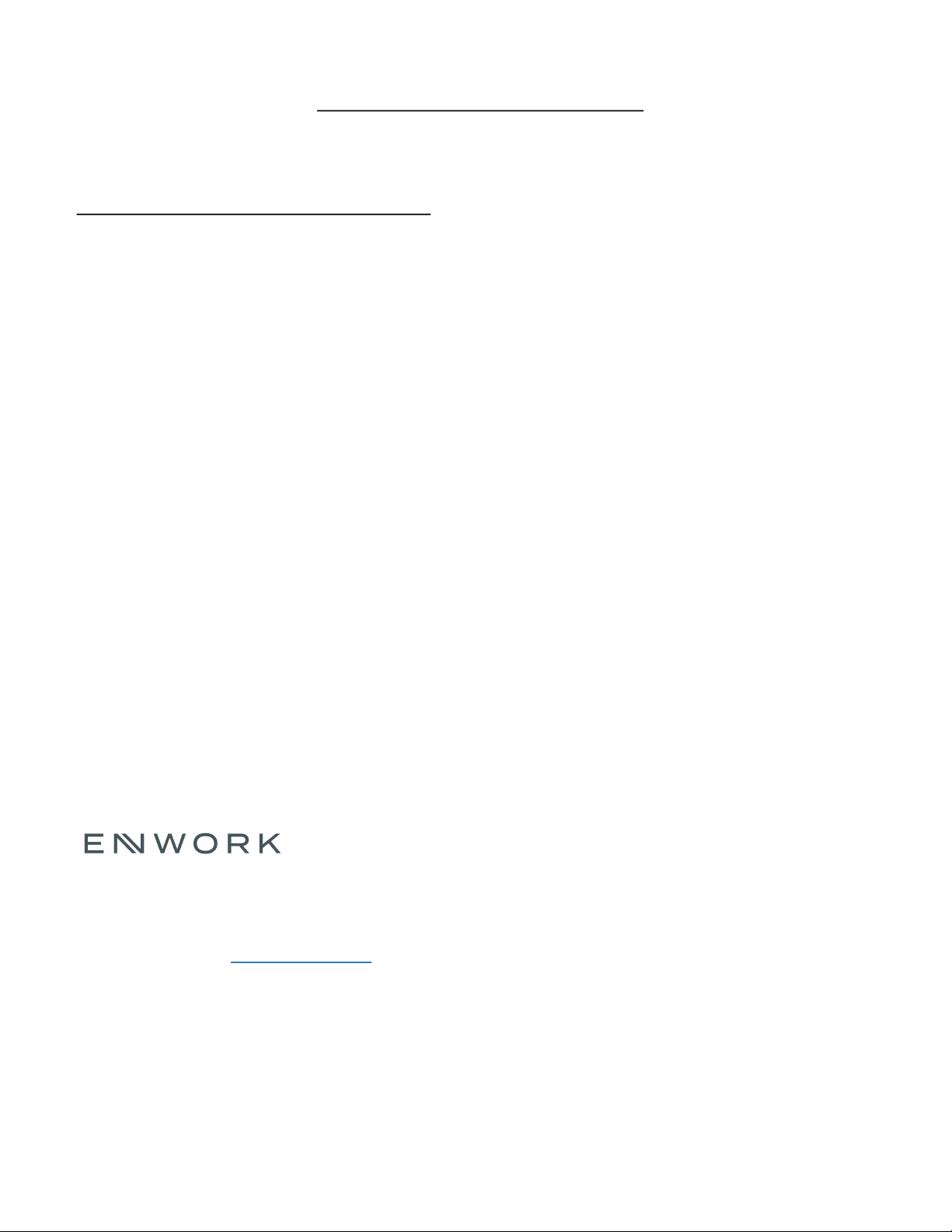

1) Tools and Supplies Required

INSTALLATION INSTRUCTION

4

Tape Measure Drill / Hammer Drill ½” Diameter

Masonry Drill Bit

Adjustable Wrench Socket Wrench

5/8” Socket

3/4” Socket

Level Phillips Drive

Utility Knife Marker Roll of Tape Vacuum

Hammer or Mallet

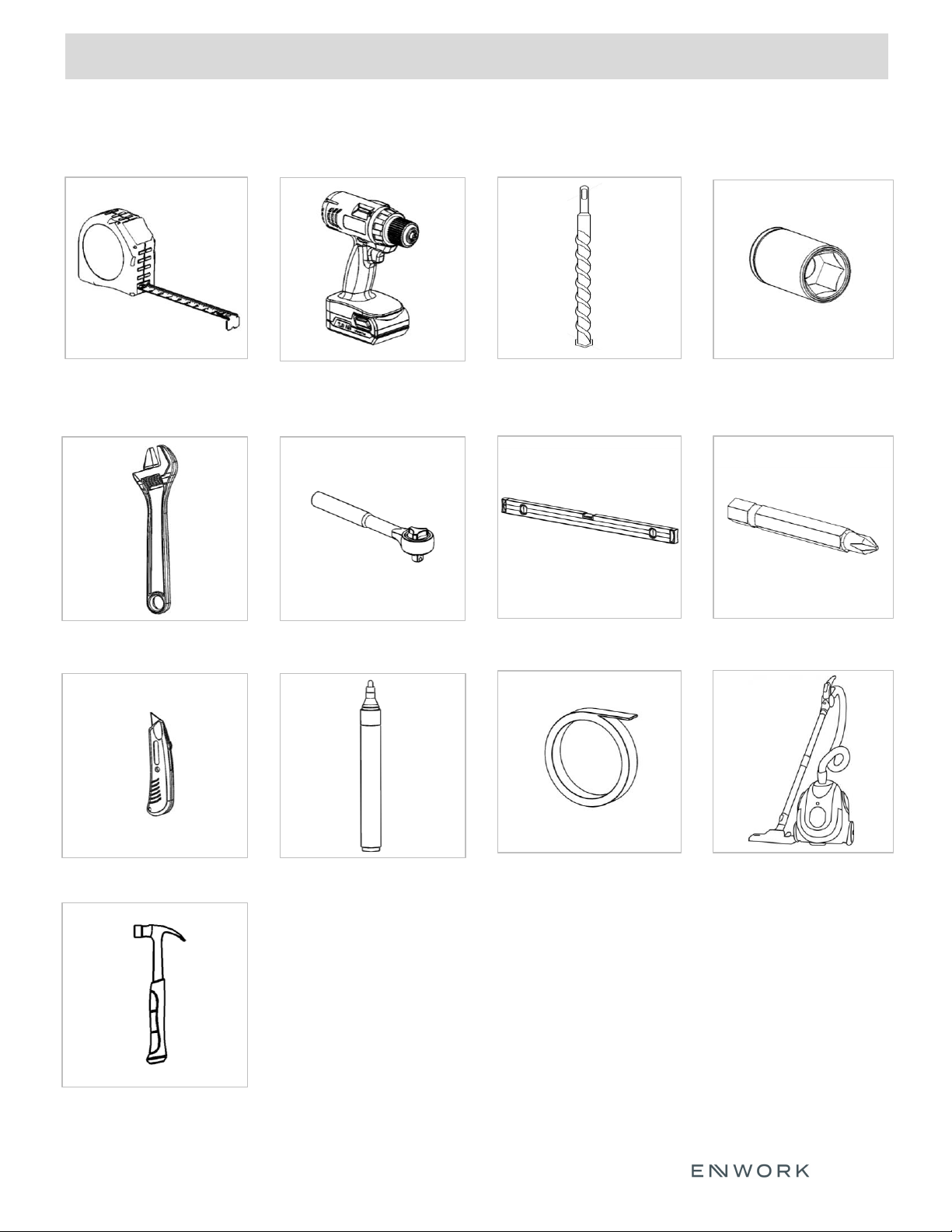

2) Parts and Fasteners Included

INSTALLATION INSTRUCTION

5

Aluminum Shim (Pack) ½” x 3 ¾” Concrete Stud ½” – 13 Hex Nut

¾” – 10 x 1 ¼” Hex Bolt 3/8” – 16 x 1 1/2” Flange Hex

Bolt

3/8” – 16 Flange Hex Nut

3/8”-16 x 2” Flange Hex Bolt #10 x 1 ¼” Pan Head Phillips 3/8” x 1” Flat Washer

2) Parts and Fasteners Included

INSTALLATION INSTRUCTION

6

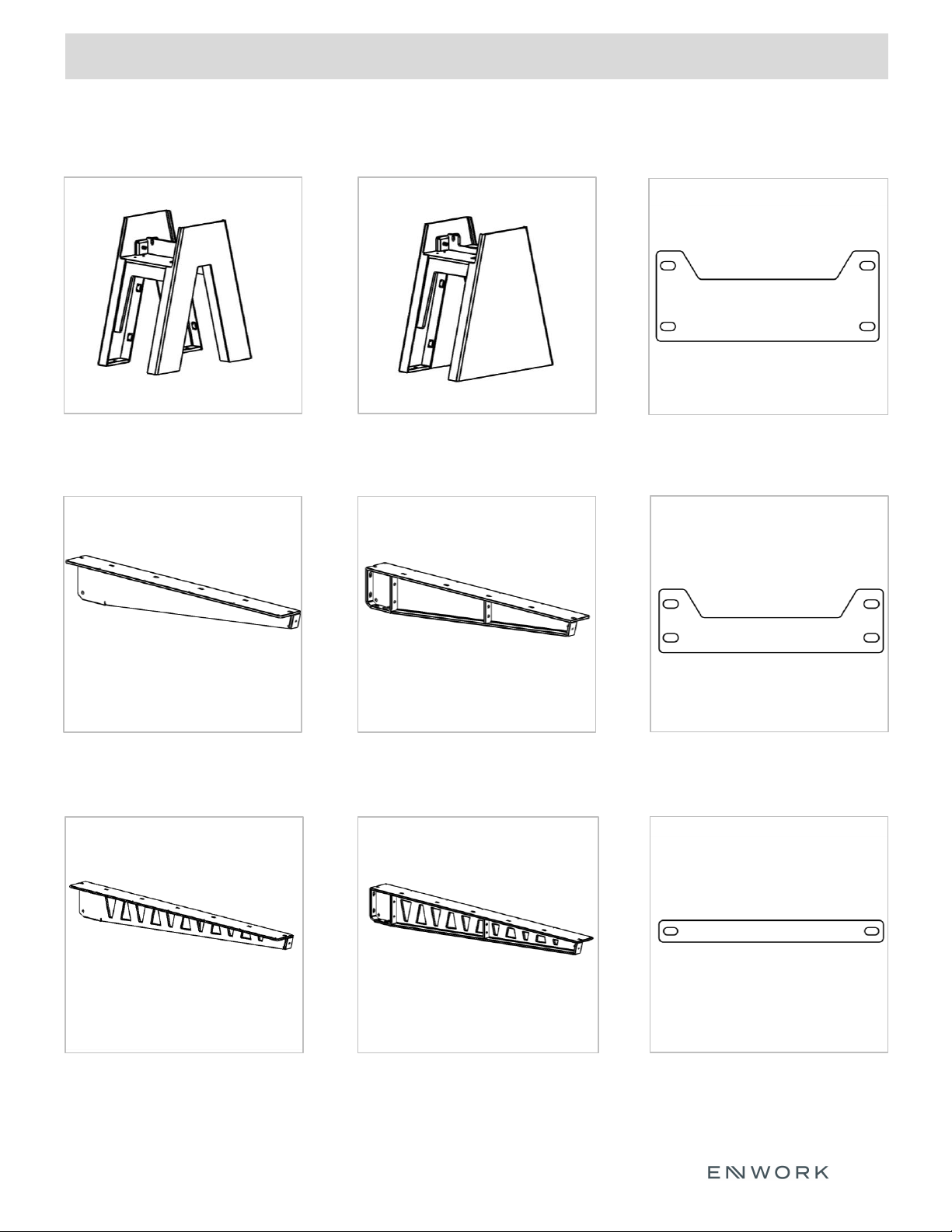

Right Side Top Support w/ Truss Design

EQM-2130-xx-R

or

EQM-2131-xx-R

End Tie Plate

EQM-1227

Left Side Top Support

EQM-2122-xx-L

or

EQM-2123-xx-L

Right Side Top Support

EQM-2122-xx-R

or

EQM-2123-xx-R

Mid Tie Plate

EQM-1228-1

or

EQM-1228-2

Inverted V Base

EQV296 / EQV298

EQV426 / EQV428

Triangle Base

EQT296 / EQT298

EQT426 / EQT428

Center Tie Plate

EQM-1229-1

or

EQM-1229-2

Left Side Top Support w/ Truss Design

EQM-2130-xx-L

or

EQM-2131-xx-L

2) Parts and Fasteners Included

INSTALLATION INSTRUCTION

7

Trough Cover End Cap

EQM-1247-xx

OR

EQM-1267-xx

Trough Cover

EQM-1248-xx

Left Hand Inner Leg Cover

EQM-2126-(1,2,3,4)-LH

all EQV style bases and EQTxxxI bases

Right Hand Inner Leg Cover

EQM-2126-(1,2,3,4)-RH

All EQV style bases and EQTxxxI bases

Base End Cover

EQM-1264-(1,2,3,4)

EQTxxxE bases

Center Spacer

EQM-1230

(OPTIONAL)

Oasis Mini Extension Kit

EQH-5007

Includes Qty 8, 3/8”-16 x 2 ¼”

Flange Bolts

For use with Oasis Mini

Mounted over bases

EQV296 / EQV426

EQT296 / EQT426

3) Assembly:

INSTALLATION INSTRUCTION

8

3

Installing the Base

3) Assembly:

INSTALLATION INSTRUCTION

9

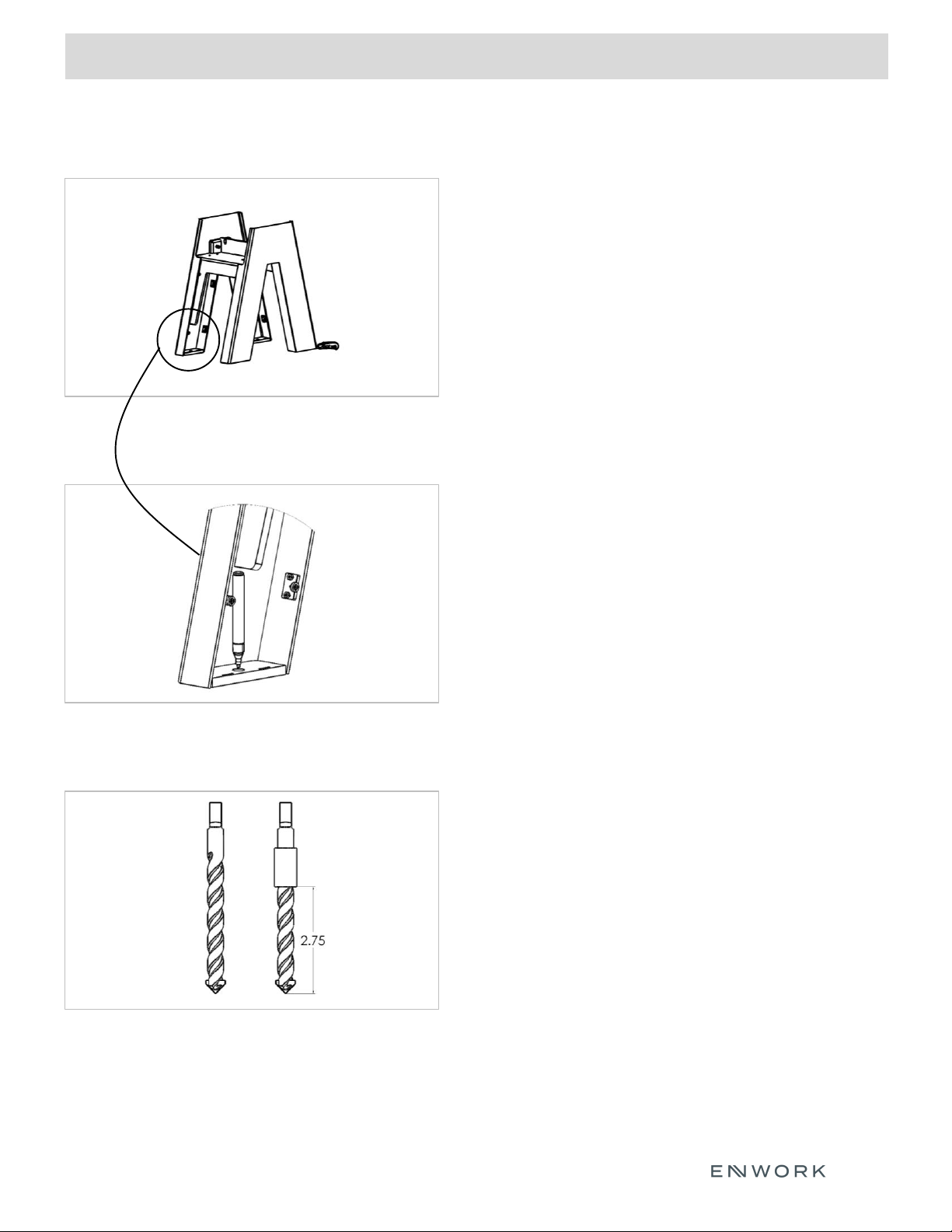

Fig. 3.1

Fig. 3.2

Fig. 3.3

3.1.1) Place base in final location for installation

3.1.2) Using a utility knife, cut away carpet in the four

leg locations.

3.1.3) Once all four leg location carpet cuts are

complete, move base and remove cut carpeting.

Note: Base must sit directly on concrete floor.

3.2.1) With carpet removed, replace the base in it’s

final position on the concrete.

3.2.2) Using a permanent marker, mark the anchor

hole locations.

Note: Hold the marker vertically and

spin the marker around the hole to get

the best result.

3.3.1) Measure 2 ¾” from the bottom of the ½”

diameter concrete drill bit and wrap drill bit with

tape creating a visual depth gauge.

Installing the Base continued

3) Assembly:

INSTALLATION INSTRUCTION

10

Fig. 3.4

Fig. 3.5

Fig. 3.6

3.4.1) Remove the base.

3.4.2) Drill marked hole locations to 2 ¾” deep.

3.4.3) Vacuum out the drilled holes to remove

dust that may prevent anchor from seating

properly.

3.5.1) Replace the base over final location.

3.5.2) Check that base is level. If base is level in two directions

skip to step 3.6.

3.5.3) If base is not level, use the included shims and place

shims on the outer corners as shown in Fig 3.5 until base

is level in two directions.

3.6.1) Place one washer and one hex nut onto

provided concrete anchor so that the hex nut is

flush with the top of the anchor.

3.6.2) Insert anchor with washer and nut through the

Base hole into the drilled floor hole. Using a hammer

or mallet pound anchors into drilled holes until anchor

washer and hex nut make contact with the base foot pad.

3.6.3) Use ¾” socket to tighten anchor hex nuts.

3.6.4) Double check all anchor hex bolts to ensure they are

tight.

Installing the Base continued

3) Assembly:

INSTALLATION INSTRUCTION

11

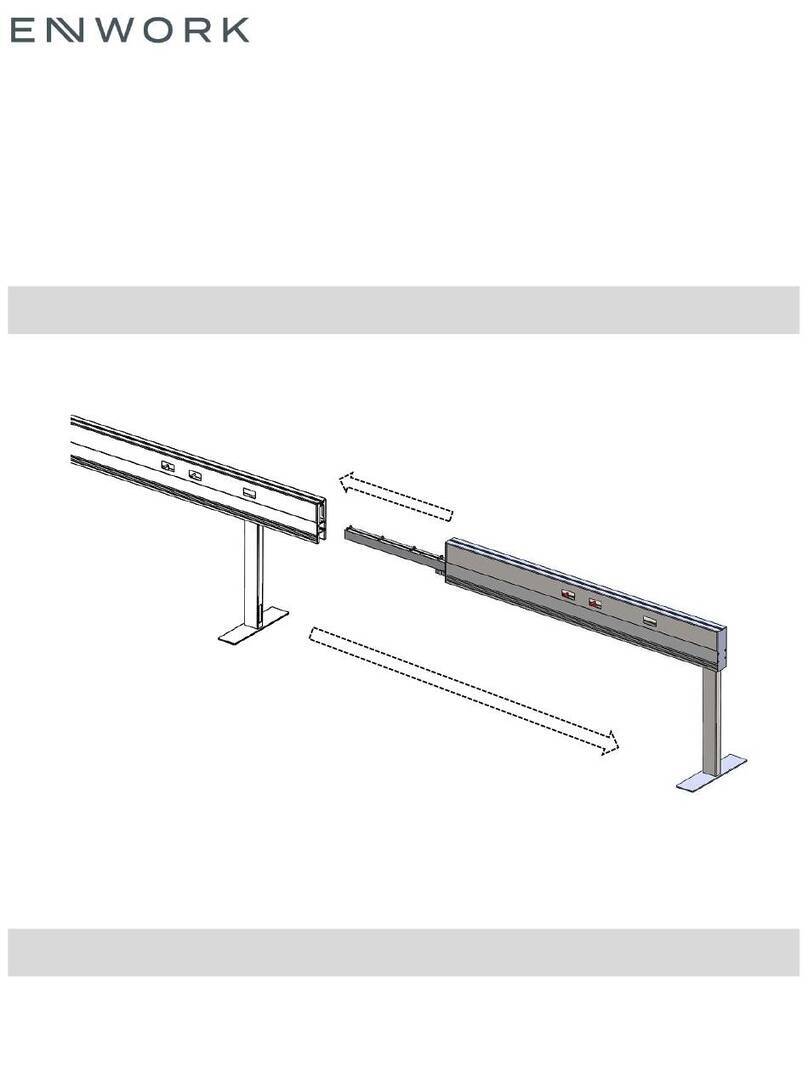

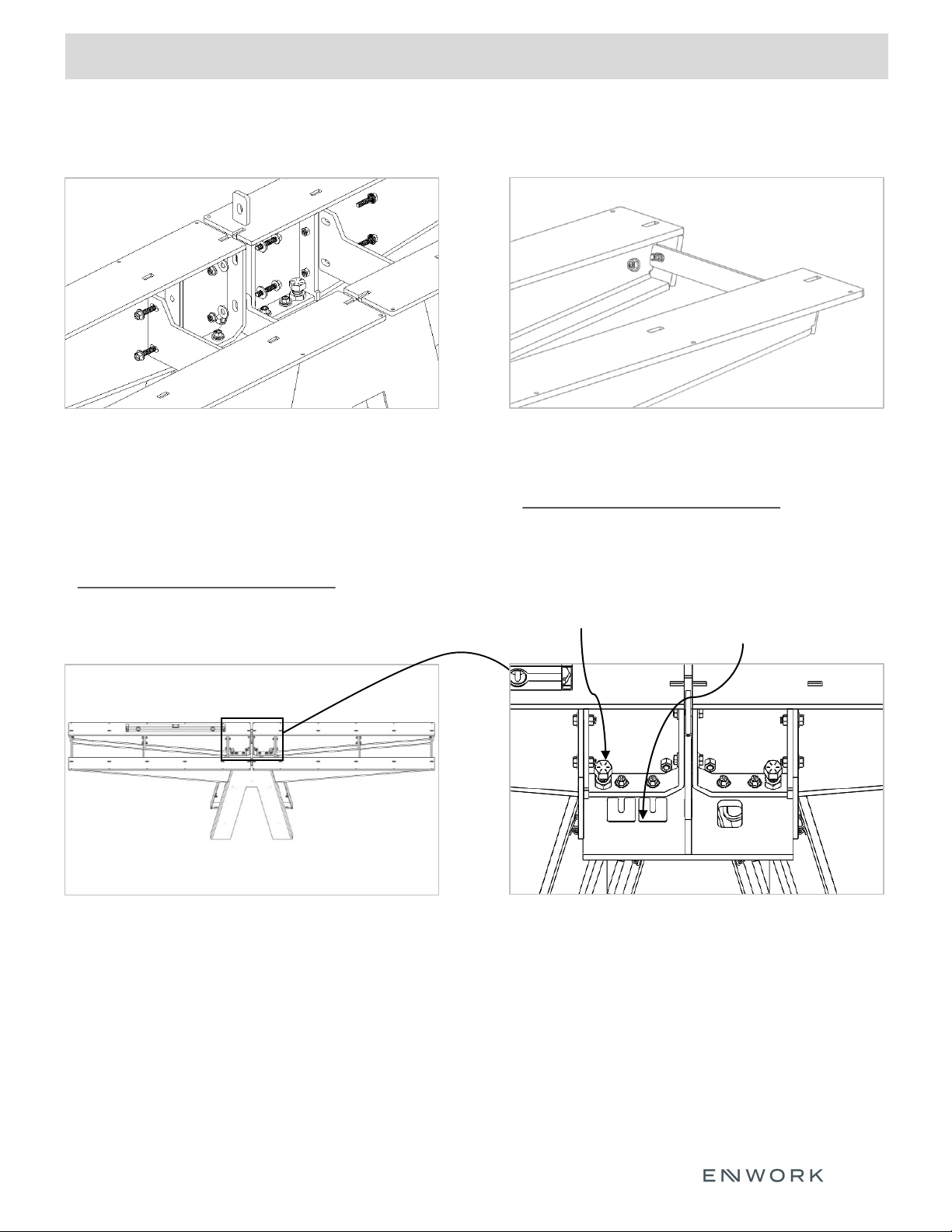

Fig 4

Installing Top Supports

3) Assembly:

INSTALLATION INSTRUCTION

12

Fig. 4.1

4.1.1) Left side top support shown.

Fig. 4.3

4.3.1) Loosely thread qty 1: ½” – 13 hex nut

onto the base pivot bolt.

4.3.2) Loosely thread qty 2: 3/8”-16 x 1 ½”

flange bolts with flat washers through the

bottom top support slot holes into the base

top plate.

4.3.3) Loosely thread qty 1: 3/4”-10 x 1 ¼” hex bolt

into the top support hex nut.

4.3.4) Repeat for all four top supports.

Note: Do not tighten any hardware yet.

Installing Top Supports continued

Fig. 4.2

4.2.1) Place top support on base top plate.

4.2.2) Slide top support towards the side wall

of base so that the pivot hole on the top

support slide onto the pivot bolt on base.

Note: Top support arms will slope downward from

the base. Leveling of top support arms is

done in the following steps.

Fig. 4.4

4.4) Tie plate and spacer layout.

4.5) Notch side up.

MID TIE PLATE

CENTER TIE PLATE

CENTER SPACER

END TIE PLATE

3) Assembly:

INSTALLATION INSTRUCTION

13

Fig. 4.5

4.5.1) Loosely install 3/8”-16 x 2” flange hex bolts

with flat washers, both sides and 3/8”-16

flange hex nut through both top supports and

center spacer.

4.5.2) Loosely install 3/8”-16 x 1 ½” flange hex bolts

through tie plates into top support bolt plates.

Note: Do not tighten any hardware yet.

Fig. 4.7

4.7.1) Using an adjustable wrench, turn the

¾” hex leveling bolt to clockwise to raise

the top support arm to level.

4.7.2) Once top support is level, use a combination

of different shim thicknesses to fill the gap

between the bottom of the top support arm

and base top plate.

Installing Top Supports continued

Fig. 4.6

4.6.1) Loosely install 3/8”-16 flange nut onto end tie

plate bolt.

Note: Do not tighten any hardware yet.

Fig. 4.8

4.7.3) With shims in place, turn the leveling bolt

counter clockwise to lower the arm onto the

shims.

4.7.4) With arm resting on shims, check level. If

arm dropped below level, raise arm with

leveling bolt and add more shims.

Hex leveling bolt Shim

3) Assembly:

INSTALLATION INSTRUCTION

14

Fig. 4.9

4.9.1) Push shims under the top support arm as far as

as they will go for full support.

Note: Sandwich thinner shims between thicker shims

to help prevent binding when pushing shims

under arm.

Note: Weight of top support arm must be sitting on

shims, not the leveling bolt. Ensure leveling

bolt is not under load.

Fig. 4.11

4.11.1) With arm level, tighten only the bolts

indicated in Fig. 4.11 on all arms.

Note: Order of operation when tightening bolts is

critical to the level of the top support arms.

Installing Top Supports continued

Fig. 4.10

4.10.1) Level top support arms front to back at the

at the end of the arm as shown in Fig. 4.10.

Fig. 4.12

4.12.1) With all arms level, use shims as shown

in Fig. 4.12 to fill the gap between center

spacers and top support arms.

Tighten

3) Assembly:

INSTALLATION INSTRUCTION

15

Fig. 4.13

4.13.1) Measurement between arms should be 10”.

Fig. 4.15

4.15.1) Install trough end cap and covers to ensure

fit between top support arms.

4.15.2) Trough cover flange sits on the bottom of

the top support arm.

4.15.3) Peel double sided tape backer from trough

end cap flange. Align outside face

of end cap to end of top support arms and

adhere to top support arm flange.

Note: Adhesive tape needs pressure during

application to achieve a strong bond.

Installing Top Supports continued

Fig. 4.14

4.14.1) Looking down the edge of the table, ensure

that top supports are straight.

Note: Ensure arms are straight, non aligned arms

will cause issue with trough installation.

Fig. 4.16

4.16.1) With top support arms level and straight

tighten tie plate bolts and center spacer

bolts.

10”

Tighten

3) Assembly:

INSTALLATION INSTRUCTION

16

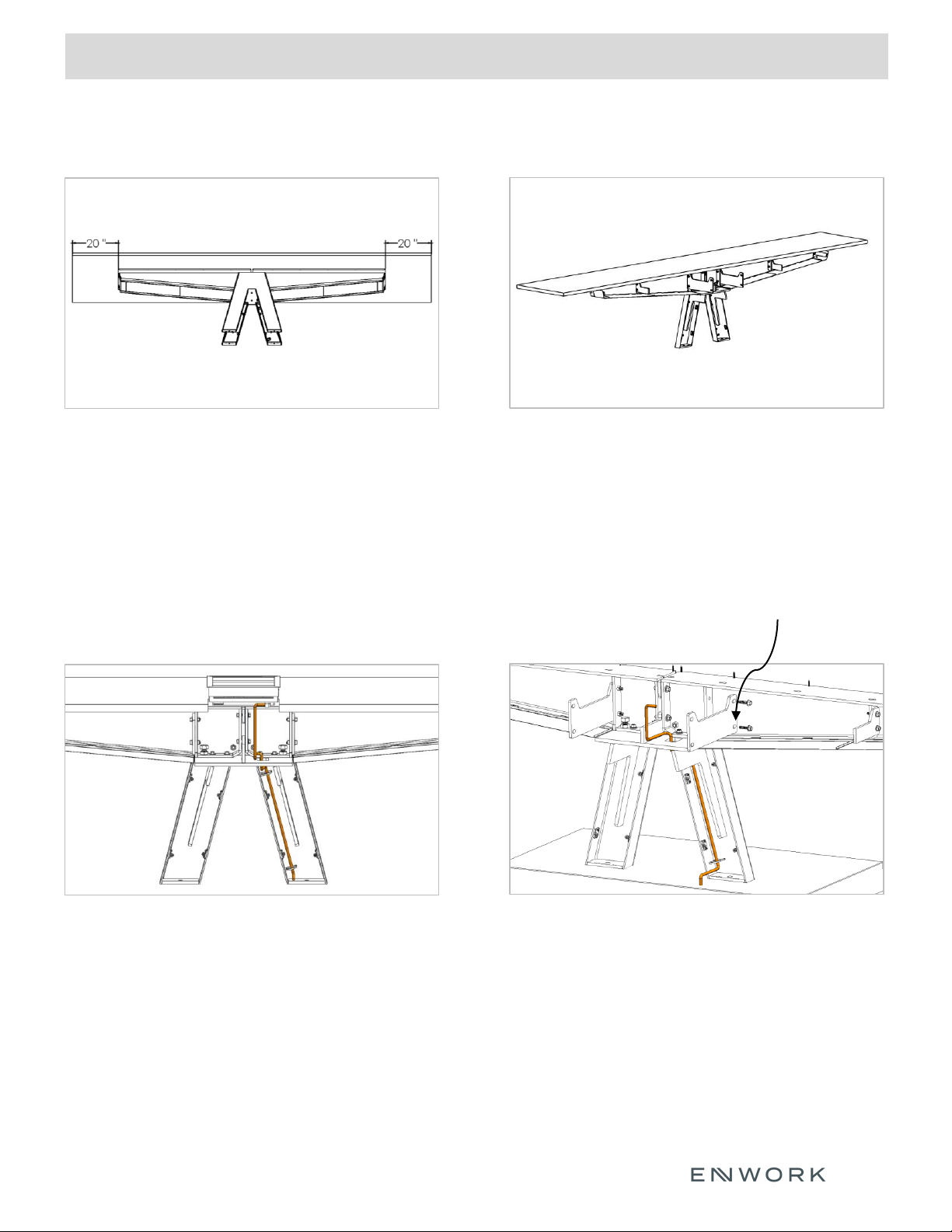

Fig. 5.1

5.1.1) Center surface on base. For multi piece tops,

attach tight joint fasteners.

Fig. 5.3

5.3.1) Power / Data routes thru base top plate

cutout.

5.3.2) Power / Data cables are held in right side

of leg with integrated hooks.

Installing surface and power

Fig. 5.2

5.2.1) If surface has power and data cutouts

check that they are unimpeded by top

tie plates.

5.2.2) Secure surface to base using included

Screw 1.

Fig. 5.4

5.4.1) It may be necessary to remove the center

tie plate to access center power.

Remove the four center tie plate bolts by

turning them counter clockwise.

5.4.2) Replace center tie plate when done.

Center tie plate

3) Assembly:

INSTALLATION INSTRUCTION

17

Fig. 6.1

Fig. 6.2

Fig. 6.3

6.1) Fig. 6.1 is base with inner leg cover option.

6.2.1) Inside leg covers are installed by placing

the hook on the back of leg cover into the

slot at the base of the leg.

6.2.2) Preinstalled magnets hold the leg cover

in place.

6.3.1) Fig. 6.3 shows optional end cover.

6.3.2) Installs between base legs, attaches to preinstalled magnets.

6.3.3) Fig. 6.3 shows power routing hole down for power infeed

access outside of base.

6.3.4) If power access is inside the base, flip the end cover so that

routing hole is up.

Installing leg covers

Base leg slot Cover hook

Optional end cover

3) Assembly:

INSTALLATION INSTRUCTION

18

Fig 7.1

Fig 7.1) If an Oasis Mini power unit is installed over the base (EQV296 / EQV426 / EQT296 / EQT426 models

only). The Oasis Mini Extension kit must be used as shown. This extension kit allows the use of the

Oasis Mini attachment brackets to be used so that the power unit can be secured to the

work surface.

Optional Oasis Mini Extension Kit

Optional Oasis Extension Bars

3/8”-16 x 2 ¼” Flange Bolt

Other manuals for Equilibrium

2

Table of contents

Other Enwork Desktop manuals

Popular Desktop manuals by other brands

HP

HP Presario SR5400 - Desktop PC Guida alla risoluzione dei problemi e alla manutenzione

CompuLab

CompuLab IPC2 owner's manual

Lenovo

Lenovo ThinkCentre M78 manual

HP

HP dx7200 - Microtower PC Quick setup guide

Control Data

Control Data Cyber 170 Series Operator's guide

Euphonix

Euphonix Avid SC264 installation manual