EPAX ROPAX RPM 7700 VII Installation instructions

RPM 7700 - VII

174 18

FO-09-39 Version 01

Machine type

Serial no.

Year of manufacture

Operating manual no.

14641 Arminta Street • Panorama City, CA 91402 • Toll Free: 800.220.6776

Original operating manual

Ropax™

JUMBO MOBILE COMPACTOR

®

Lathen

GERMANY

German engineering

and design by

Built in

collaboration with

Van Nuys, CA

EPAX Systems, Inc., 14641 Arminta Street • Panorama City, CA 91402 • Toll Free: 800.220.6776

BERGMANN

Machines for waste management for over 50 years

BERGMANN from its world headquarters in Lathen Germany provides a wide range

of waste compaction equipment which delivers dramatic reductions in waste disposal

costs for users.

Highly popular Bergmann Systems. which are available in North America via an

exclusive distribution agreement with Epax Systems, include:

• BERGMANN Roto Compactors - a compact solution for the compaction of

waste directly at the work site. Marketed by Epax in North America as ROPAX

ROTO COMPACTORS.

• BERGMANN Roll-Packers - for compacting waste in open top containers. Ideal

for a wide variety of manufacturing, retail and construction waste including

wooden or plastic pallets, wooden or cardboard boxes, spools, packaging

materials, appliances and other bulk waste. Marketed by Epax in North America

as ROPAX ROLLING COMPACTORS.

®

Lathen

GERMANY

German engineering

and design by

Built in

collaboration with

Van Nuys, CA

Table of contents

30. 01

1. Intended use.................................................................................................................. 1.01

1.1 Preface................................................................................................................ 1.01

1.2 Basic information................................................................................................. 1.02

1.3 Information on this operating manual.................................................................. 1.02

1.4 Intended use ....................................................................................................... 1.03

2. Introduction.................................................................................................................... 2.01

2.1 Machine overview ............................................................................................... 2.01

2.2 Operating keyboard overview ............................................................................. 2.02

2.3 Joystick overview ................................................................................................ 2.03

2.4 Function description ............................................................................................ 2.04

2.5 Technical data ..................................................................................................... 2.05

2.5.1 Technical description ............................................................................... 2.05

2.6 Checks prior to start ............................................................................................ 2.07

2.7.1 Run-in period........................................................................................... 2.07

2.7.2 Daily checks ............................................................................................ 2.07

3. Basic safety information ................................................................................................ 3.01

3.1 Explanation of symbols and notes ...................................................................... 3.01

3.2 Basic safety rules ................................................................................................ 3.02

3.2.1 Organizational measures ......................................................................... 3.02

3.2.2 Safety and protective devices .................................................................. 3.03

3.2.3 Hazards caused by electrical energy ....................................................... 3.05

3.2.4 Hazards caused by hydraulic energy....................................................... 3.05

3.2.5 Depressurizing the machine .................................................................... 3.06

3.2.6 Hazards caused by misuse...................................................................... 3.06

3.2.7 Maintenance and service ......................................................................... 3.06

3.2.8 Information for emergencies .................................................................... 3.07

3.2.9 Safety and precautionary measures in public areas................................ 3.07

3.2.10 The safety devices/guards ....................................................................... 3.08

4. Commissioning/start-up................................................................................................. 4.01

4.1 The assembly...................................................................................................... 4.01

4.2 The disassembly ................................................................................................. 4.01

4.3 The commissioning/start-up ................................................................................ 4.01

4.3.1 Checks prior to entering........................................................................... 4.02

4.3.2 Doors and windows.................................................................................. 4.02

4.3.3 Adjusting the driver’s seat........................................................................ 4.03

4.3.4 Adjusting the steering column.................................................................. 4.04

4.4 The travel path adjustment.................................................................................. 4.05

5. The driving and compaction operation .......................................................................... 5.01

5.1 Starting up the diesel engine............................................................................... 5.01

5.1.1 Daily checks............................................................................................. 5.01

5.1.2 Start-up .................................................................................................... 5.02

Table of contents

4

5.2 The driving mode ................................................................................................ 5.03

5.3 Measures to take if the Jumbo Mobile Compactor tips over ............................... 5.05

5.4 Precautionary measures in different weather situations ..................................... 5.05

5.4.1 At high outdoor temperatures .................................................................. 5.05

5.4.2 At low outdoor temperatures.................................................................... 5.06

5.5 The compaction mode......................................................................................... 5.07

5.5.1 Preparation .............................................................................................. 5.07

5.5.2 The compaction process.......................................................................... 5.08

6. The electrical equipment ............................................................................................... 6.01

6.1 General information............................................................................................. 6.01

6.2 The electrical control system............................................................................... 6.02

6.2.1 Setting the running time on the display.................................................... 6.03

6.3 The electrical equipment of the diesel engine..................................................... 6.04

6.4 The path measuring system................................................................................ 6.05

6.5 The multi-functional display................................................................................. 6.05

6.6 The lighting.......................................................................................................... 6.06

6.7 The windscreen wipers ....................................................................................... 6.06

6.8 The cab ventilation / heater................................................................................. 6.07

6.9 Thedieselparticulatelter .................................................................................. 6.08

7. The additional equipment.............................................................................................. 7.01

7.1 The container moving unit........................................................................ 7.01

7.2 Additional EMERGENCY STOP hit buttons............................................. 7.02

7.3 Theashinglightduringmachineoperation ............................................ 7.02

7.4 The central lubrication pump.................................................................... 7.03

7.5 The safety barrier..................................................................................... 7.03

7.6 The electric drive...................................................................................... 7.04

7.7 The wheel position display....................................................................... 7.04

7.8 The air conditioning system ..................................................................... 7.05

7.9 The reversing camera system.................................................................. 7.05

7.10 The selector switch for ‘3 container lengths’............................................ 7.06

7.11 The lighting system .................................................................................. 7.06

7.12 The hydraulic oil heater............................................................................ 7.07

7.13 The main battery switch........................................................................... 7.08

7.14 Theemergencyreextinguishinghose ................................................... 7.08

7.15 The heated wing mirrors .......................................................................... 7.08

8. The hydraulic unit.......................................................................................................... 8.01

8.1 General information............................................................................................. 8.01

8.2 Hydraulic oil type................................................................................................. 8.01

8.3 Oil change and engine overview ......................................................................... 8.02

9. The gear unit ................................................................................................................. 9.01

9.1 General information............................................................................................. 9.01

9.2 Gear oil type........................................................................................................ 9.01

9.3 Changing the oil in the gear unit ......................................................................... 9.01

10. Technical data ............................................................................................................... 10.01

11. Machine dimensions...................................................................................................... 11.01

0. 02

Table of contents

5

12. Towing and transport..................................................................................................... 12.01

12.1 Towing ................................................................................................................. 12.01

12.2 Short-circuiting the travel drive............................................................................ 12.01

12.3 The transport....................................................................................................... 12.02

12.4 Loading the Jumbo Mobile Compactor onto a transport vehicle ........................ 12.02

12.5 Loading by crane................................................................................................. 12.02

12.6 Independent driving onto a transport device....................................................... 12.03

12.7 Lashing the Jumbo Mobile Compactor in place .................................................. 12.03

12.8 Securing the Jumbo Mobile Compactor .............................................................. 12.03

13. Maintenance and care................................................................................................... 13.01

13.1 General information............................................................................................. 13.01

13.2 Filling with diesel fuel .......................................................................................... 13.01

13.3 Maintenance and inspection list .......................................................................... 13.02

13.4 Checking the screw connections......................................................................... 13.03

13.5 Lubricating the bearing points ............................................................................. 13.03

13.5.1 General information ............................................................................... 13.03

13.5.2 Lubricating the bearing points for compacting mode ............................. 13.04

13.5.3 Lubricating the bearing points for driving mode..................................... 13.04

13.5.4 Lubricating the bearing points of the container hook ............................. 13.05

14. Troubleshooting............................................................................................................. 14.01

15. Lubricant chart............................................................................................................... 15.01

16. Warranty and liability ..................................................................................................... 16.01

16.1 Obligations of the owner/user ............................................................................. 16.01

16.2 Acceptance based on accident prevention regulations....................................... 16.01

16.3 Warranty and liability........................................................................................... 16.01

16.4 Copyright............................................................................................................. 16.01

17. CE Declaration of Conformity........................................................................................ 17.01

0. 03

1. Introduction

66

1. 01

1.1 Introduction

This operating manual describes the operation and maintenance of the Epax Systems Jumbo Mobile

Compactor. It provides the operating and maintenance personnel with the required information for safe

and hazard-free use, proper maintenance/inspection, cleaning and care as well as adherence to the

technical safety regulations of the Epax Systems Jumbo Mobile Compactor.

Compliancewiththespecicationscontainedinthisoperatingmanualensures:

• the correct, safe and proper operation of the Epax Systems Jumbo Mobile Compactor

• the proper maintenance, cleaning and care of the Epax Systems Jumbo Mobile Compactor

• adherence to the required technical safety regulations

If required, the owner/user of the Epax Systems Jumbo Mobile Compactor must supplement the

operating manual with instructions and regulations on environmental protection and national accident

prevention regulations.

Ensure that the operating manual is always in the Epax Systems Jumbo Mobile

Compactor.

The operating manual must be read and used by all persons working with or on the Epax Systems

Jumbo Mobile Compactor, e.g. in the context of:

- operation,includingmake-ready,malfunctionrecticationduringoperation,care,

removalofauxiliarymaterialsandoperatinguidsaswellasdisposalofthemachine

- service work (inspection, maintenance, care)

- transport

This operating manual does not contain instructions for extensive service work.

Have this work carried out by an approved expert.

71. 02

1.2 Basic information

It is not permitted to use the Epax Systems Jumbo Mobile Compactor on public roads. As its maximum

speed is 6 km/h, it does not require registration.

Each new user must receive instruction prior to using the vehicle

for the rst time.

Information on using the operating manual:

• Thoroughly read the operating manual prior to start-up

• Comply with all safety information

• Adhere to any regulations valid at the location of use

• Adhere to the regulations of the employer’s liability insurance associations (VGB)

• Always leave the operating manual in the Jumbo Mobile Compactor and ensure that it remains in a

clean and tidy condition.

If it is not possible to reliably prevent danger to persons or material during the intended work, this danger

is indicated by pictographs. The Epax Systems Jumbo Mobile Compactor is described in the driving

direction,meaningalldirectionspecicationsareindicatedbasedonthedrivingdirection.

1.3 Information on this operating manual

All technical information in this operating manual refers to serial models tested under central European

operating conditions and describes the standard functions of these models. The equipment and its

functionmodesaswellastheaccessoriesaredeterminedbythespecicmodelandtheproductoptions

aswellascountry-specicrequirementsofthecountryofsale.Figuresmayshowproductswhichare

not mentioned or are not available as serial products.

Thedescriptions,gures,weightsandtechnicaldataisnon-bindingandareinaccordancewiththestate

of the art at the time of printing. Due to changes in design, equipment, appearance and technology, we

reservetherighttomakechangeswithoutpriornoticationbasedontheconstantfurtherdevelopment

of the products.

Please always observe all safety information in this operating manual as well as the legal regulations

and requirements of the employer’s liability insurances at the location of use.

Although we took the greatest possible care to avoid these, this operating manual may contain

deviationsfromguresordimensions,errorsincalculations,misprintsorincompleteinformation.For

this reason, we do not assume any liability for the correctness and completeness of our information in

this operating manual. We guarantee the fault-free function of our product in the context of our general

terms and conditions. We do not assume any further warranties. Any liability beyond what is indicated in

our general terms and conditions is excluded.

8

1.4 Intended use

1. 03

Use other than that intended can risk the lives of the operating personnel

and other persons or cause injuries

or extensive property damage.

This machine is a mobile waste compactor only designed for compacting materials and waste in open

containers and therefore only intended for this purpose. Any other or further use is regarded as use other

than that intended. Epax Systems does not assume any liability for damage resulting from the above.

The intended use also includes

• adherence to all information included in the operating manual,

• adherence to inspection and maintenance work and

• refraining from making any attachments or conversions to the machine

• any other or further use of the Epax Systems Jumbo Mobile Compactor is prohibited:

- Lifting and transporting persons

- Lifting and transporting loads using equipment not intended for this purpose

- Useafterimpropermalfunctionrectication/repair

The basic prerequisite for safe handling and malfunction-free operation of the machine is being aware of

the basic safety information and safety rules.

This operating manual contains the most important information on how to use the machine in

accordance with the safety regulations.

This operating manual must be made

available to the operator and must be kept

in a safe location.

Read and observe the entire

operating manual, including all details.

Duetoconstantdevelopment,technicalinformation,guresanddimensionsmaydeviate.

When ordering spare parts, always indicate the factory number, page of the spare parts list and the

specicitemwithitsitemnumber.

Type plate:

92. 01

2.1 Machine overview

All gures, drawings, etc.

are based on standard versions

and may deviate.

Container

Pendulum arm

Cranked arm

Engine bonnet

Compaction roller

Hazard area Hydraulic unit

Connection hook for container

(additional option)

Maintenance doors

Diesel tank

Diesel engine

Driver’s cab with

control panel

10

2. 02

2.2 Operating keyboard overview

1

2

3

4

5

6

7

12

13

6

14

15

8 9 10 11 6

16 17 18 19

1 Malfunction 8 Display, engine 15 Release for roller operation

2 Travel path adjustment 9 Fuel display 16 Front light

3 Grease container empty 10 EMERGENCY STOP 17 Rear light

4 Windscreen wiper water 11 Multi-function display for driving mode 18 Joystick

5 Mains operation 12 START 19 Horn

6 Spare 13 Ignition lock

7 Cab ventilation / heating 14 Windscreen wipers

112. 03

2.3 Joystick overview

Sliding switch

green and yellow button

Driving mode Roller mode

Sliding switch in mid-position:

- 0 position

- automatic parking brake active

Sliding switch in front position:

- driving mode active

- automatic parking brake deactivated

- lifting/lowering container hook active (up: green button; down: yellow button)

Sliding switch in back position:

- roller mode active

- automatic parking brake active

- lifting/lowering compaction roller active (up: green button; down: yellow button)

- travel length setting possible (see chapter 4.4)

12

2. 04

As you probably know from your own experience, great volumes of waste and refuse are still disposed of in

open containers. Loose collection leads to low effective volumes and frequent transport for disposal. Your

containerllsupquickly,wastematerialsrollaroundinthecontainerandthecostofwastedisposalishigh.

The Epax Systems Jumbo Mobile Compactor, which is placed next to open containers as an additional unit,

providessignicantadvantagesforwastedisposal.Itwillhelpyoureducethenumberofdisposaltransport

runstoanefcientminimum,whileallowingyoutokeepyouroldwastedisposalsystem.

TheJumboMobileCompactoristheworld’srstmobilecompactionunitcapableofgrippingwasteand

recyclablematerialsinopencontainers,shreddingthemandcompactingthemefciently.Evenlargevolumes

of bulky waste can be reduced to a minimum of its initial volume within barely any time at all.

Itisnolongernecessarytoshred,cut,tearorfoldhigh-volumellingmaterials,astheEpaxSystemsJumbo

MobileCompactorimmediatelyattenseverythinginlayersfromthebottomupassoonasitisinserted.

The continuous roller movements and constant breaking up of material structures results in an extremely

highcompactionrate,allowingthecontainertoholdthree,fourorevenvetimestheusualvolume.

The unit’s mobility permits continuous compaction in a practically unlimited number of containers, with both

compaction from the unloading and the loading side of the container being possible.

The Jumbo Mobile Compactor is driven by a 3-cylinder diesel engine, making compaction possible

independently of any external energy supply and allowing the Jumbo Mobile Compactor to move from one

container to the next.

As an option, the Jumbo Mobile Compactor is also available with a connection hook, making it possible to

move containers with rollers and connection hooks on suitably level and paved surfaces. The maximum

permissible weight of the container is 10t.

You have decided to purchase a Jumbo Mobile Compactor, a system which combines the unique advantages

of the Epax Systems Jumbo Mobile Compactor, which has been used with great success in commerce and

industry for years, with the advantages of a mobile unit.

Thiscombinationleadstosignicantcostsavingswheredisposal,personnelandspaceisconcerned.

2.4 Function description

13

2.5 Technical data

2.5.1 Technical description

The Epax Systems Jumbo Mobile Compactor consists of the frame, the drive wheels and the steering axle.

The frame contains all drive and control units of the Epax Systems Jumbo Mobile Compactor.

The electrical control system and the drive unit are located in the frame.

Drive

A diesel engine is used to drive the steering and operating hydraulics and the hydraulics used for driving

mode.

The driving hydraulics drive the wheel motors, which transmit power to the front axle.

In the rear, the steering axle is mounted on a ring mount.

Brakes

The travel drive is simultaneously used as a service brake. It affects the front axle. The brake is actuated

using the center position of the joystick (locking position). A switch is used to also activate the parking brake.

Steering

A fully hydraulic steering system using 2 double-acting cylinders and a ring mount is used for steering.

Vehicle frame

The vehicle frame contains the electrical control system and the drive unit

Hydraulic system

The Epax Systems Jumbo Mobile Compactor is equipped with two hydraulic systems supplied from a

hydraulic oil tank:

• hydrostatic travel drive

• steering and operating hydraulics

The hydrostatic travel drive consists of a variable axial piston pump driven by the two wheel motors. The

variableaxialpistonpumpisange-connectedtothedieselengine.

Adjustmentisautomaticandinnitelyvariable,butload-dependent.Thetravelspeedisbasedontheunit’s

load. The joystick is used to start driving. The variable pump is controlled based on the speed of the Epax

Systems Jumbo Mobile Compactor. The higher the load on the Epax Systems Jumbo Mobile Compactor,

the lower the ideal utilization of the overall capacity. The joystick can also be used to affect the control in

such a way that the Epax Systems Jumbo Mobile Compactor is slowed down to a halt.

2. 05

14

2. 06

The steering and operating hydraulics are supplied with oil by a triple hydraulic gear pump. The gear pump

is connected to the variable pump of the travel drive.

Thehydraulicsystemisequippedwithpressurelimitationvalves,ltersandanoilcooler.

Electrical system

The electrical system has an operating voltage of 12 Volt. The consumers and their supply lines are

equipped with fuses.

Equipment

Thecranked arm, cylinderholding xture, pendulum arm, lifting cylinder and compaction roller form a

compaction unit.

Factory signs

A factory sign is permanently attached to the Jumbo Mobile Compactor on the right-hand side of the chassis

frame(g.10).

It contains the following information:

• Manufacturer

• Year of manufacture

• Factory no.

• Type

• Motor power

• Operating weight

• Permissible total weight

In addition, the factory no. is engraved in the engine mount.

Moreover, the following parts of the Jumbo Mobile Compactor have their own type plate:

• the diesel engine

• the variable axial piston pump (hydraulic travel pump)

• the oil motor (hydraulic travel motor)

• the axles

15

2.6 Checks prior to start

2.6.1 Run-in period

During the engine run-in period, always check the following items:

1. Replacetheengineoilandoillteraftertherst50operatinghours(see“ENGINEOIL”inthe

chapter containing recurrent maintenance work in the engine operating manual. For further

information, also refer to the engine OM).

2. If temperatures are low, do not start up the machine until the engine has heated up completely.

2.6.2. Daily checks

To prevent malfunctions, it is highly important to keep the engine in the best possible operating

condition. For this reason, check the following items prior to each use:

To prevent accidents:

• After inspection and maintenance work, reinstall the dismantled safety shield

(see engine operating manual).

• Prior to all inspection and maintenance work, always shut down the engine, allow it to cool off and

ensure that the engine is in a horizontal position.

• Keepdustorfuelfromthebattery,cableconnection,soundabsorberandenginetopreventare.

Clean these parts daily prior to starting the engine. Pay particular attention to the exhaust pipe and

thehotexhaustgasestoavoidre.

Control and warning lights

Danger of accidents due to malfunction! If a red control light lights up while the engine is running, immediately

shut down the engine. Remedy the error (see chapter 13). Do not continue working with the Jumbo Mobile

Compactor until the error has been remedied.

Immediately turn off the engine, if one of the lights marked with this * symbol in the adjacent table is lit.

2. 07

1616

3.1 Service

The ROPAX™ JUMBO ROLLING COMPACTOR is designed to give you reliable service and superior

performance for many years. To realize the best performance and the safest operation of your ROPAX™

Jumbo Rolling Compactor, everyone involved in its operation and service should read and thoroughly

understand the contents of this manual and follow all of its instructions and warnings.

Management responsibly involved in its installation, operation and service also should read and understand

the most current version of the following applicable standards:

• ANSI Standard No. Z245.2, “Stationary Compactors Safety Requirements” a copy of which is

supplied with your compactor.

• OSHA 29 CFR, Part 1910.147, “The control of hazardous energy (lock-out/tag-out)”

ALL SERVICE OR REPAIR PROCEDURES DESCRIBED IN THIS MANUAL SHOULD BE

PERFORMED ONLY BY AUTHORIZED, FULLY TRAINED PERSONNEL.

Any service or repairs that go beyond the scope of this manual should be performed only by

factory authorized personnel.

17

17

17

3.2 Lock-Out and Tag-Out Instructions

FOREWORD: Before entering any part of the compactor, be sure that

all sources of energy have been shut off, all potential hazards have

been eliminated, and the compactor is locked-out and tagged-out in

accordance with OSHA and ANSI requirements.

Thespeciclock-outandtag-outinstructionsmayvaryfromcompanytocompany(i.e.multiplelocksmay

be required, or other machinery may need to be locked out and tagged-out). The following instructions are

provided as minimum guidelines.

INSTRUCTIONS

1. If the ROPAX™ Jumbo Rolling Compactor is operable, raise the drum to its maximum elevation.

2. Remove the container from the compactor.

3. Open the front door of the compactor.

4. Turnthe“KEY”switchtothe“OFF”positionandremovethekeyandkeepitinyourpossession.

5. Turnthefuseddisconnectswitch“OFF”andpadlockitwithakeyedpadlock.Removethekeyandtake

it with you.

6. In addition to the padlocking, place an appropriate, highly visible, warning tag on the disconnect lever.

Thetagshouldprovideawarningsuchas:“Danger:donotoperateequipment.Personworkingon

equipment.Warning:Donotenergizewithoutthepermissionof(Nameofindividual)”.

7. After locking and tagging the ROPAX™ Jumbo Rolling Compactor, try to start and operate the compactor

(as outlined in the Operation Manual) to make sure the lock-out and tag-out is effective. You may begin

to service the compactor after you have determined that the lock-out and tag-out is effective.

ELECTRICAL: the panel box contains high voltage components. Only authorized service personnel should

be allowed inside the box. Authorized service personnel should be allowed inside the box only after the

compactor has been locked-out and tagged-out.

HYDRAULIC: Stored hydraulic energy must be released from the compactor hydraulic circuit for complete

lock-out and tag-out. Make sure that this energy has been released by manually depressing the solenoid

valve pin located in the center of each coil of the directional control valve on the power unit.

18

3. 01

3.1 Explanation of symbols and notes

The following symbols are used for danger in the operating manual and on the machine:

This symbol signals a potential danger for life and health of persons.

Non-adherence to this information can result in injuries or even death.

This symbol signals a potentially dangerous situation.

Non-adherence to this information can result in minor injuries or damage to

property.

This symbol signals important circumstances.

This symbol warns of dangerous voltage.

This symbol indicates that the operating personnel must have read

and understood the operating manual.

This symbol indicates that the machine must be disconnected from

the electrical grid, the engine must be turned off and secured against

being switched on prior to maintenance and repair work.

This symbol indicates that entering the container and staying under

the raised roller is prohibited.

This symbol warns of hot surfaces.

19

This symbol indicates that the operating personnel must wear hearing

protection.

This symbol warns against opening and removing protective devices/

guards while the engine is running.

3.2 Basic safety rules

The safety and availability of the machine depends on adherence to these

regulations.

The most important requirements are also listed on labels on your machine.

3.2.1 Organizational measures

* The area of use of the Jumbo Mobile Compactor is limited to designated industrial and commercial

areas.

* Ensure that the area of use of the Jumbo Mobile Compactor is not in the area of high-voltage

power lines, slewing cranes, gantry cranes, telephone lines, etc.

* It is not permitted to use the Jumbo Mobile Compactor on public roads.

* In addition to the Jumbo Mobile Compactor operating manual, adhere to the supplied diesel engine

operating manual and, for special additional equipment, e.g. radio, air conditioning system, adhere

to the operating manual of the additional option. This applies in particular to adherence to safety

information and proper as well as timely execution of maintenance work.

* The Jumbo Mobile Compactor may only be operated by persons aged 18 or over.

* Only allow trained and instructed personnel to work with and on the machine. The operating

personnel must have read and understood the operating manual.

* The operating manual must be supplemented with instructions including supervising and reporting

obligations taking into account special features of the owner/user’s operations, e.g. regarding work

organization, work procedures or personnel employed.

* Personnel being trained, taught, instructed or in the process of an apprenticeship may only operate

the machine or work on it under constant supervision of an experienced, authorized supervisor.

* The operating personnel may not operate the Jumbo Mobile Compactor if they suffer from health

impairments!Moreover,regularandsufcientbreaksarerequired.

* Only operate the machine if all attachment components and all information signs and safety

symbols are attached.

* Operators must wear the required personal protection equipment, such as safety boots, gloves

and hearing protection. It is the owner/user's responsibility to provide this equipment. This applies

particularly for the handling of hazardous materials at the site of operation.

3. 02

20

* The machine may only be moved on paved surfaces such as blacktop, pavement, etc. The maximum

permissible incline is 11% (6.5°). If the machine is operated with the container moving unit as additional

equipment, the max. incline while a container is hooked in is 2%.

* In addition to the operating manual, always adhere to the general and local regulations regarding

accident prevention and environmental protection.

* Do not make any structural changes, additions or conversions without written authorization by HEINZ

BERGMANN. This also applies to welding work on load-bearing parts.

* Properly handle and dispose of all materials used.

* Do not compact large quantities of scrap iron and construction waste or materials subject to special

regulations for disposal according to waste disposal laws.

* Special safety and precautionary measures are required for operating the Jumbo Mobile Compactor

in areas accessible by the public (see chapter 3.2.9).

* Toavoidaccidentsinthedark,theowner/usermustensurethatthemachinehassufcientlighting.

* Only containers which do not exceed the maximum weight of 10t may be moved using the container

moving unit (additional option).

* Only experienced persons may be tasked with attaching loads and guiding crane drivers. The person

guiding the operator must be within sight of the operator or must have voice contact.

* Due to the exhaust fumes of the diesel engine, it is not permitted to operate the Jumbo Mobile

Compactor

in closed spaces / buildings.

* Always adhere to the operating manual when towing, loading and transporting the Jumbo Mobile

Compactor.

* Adheretothespeciedtransportpositionandthepermissiblemax.speedwhentowing.

* Usesuitabletransportandliftingequipmentwithsufcientloadbearingcapacity

* Ifthemachineistobedecommissionedforgood,drainalloperatingandauxiliaryuidsanddispose

of them in an environmentally friendly manner. It must be ensured that recommissioning is impossible.

Dispose of the battery in an environmentally friendly manner and task suitable, specialized companies

with disposing of the remaining machine body.

* If the machine is combined with other machines (e.g. conveyor belts, etc.) the owner/user must issue

a separate risk assessment.

* Theminimumcontainerllinglevelmustbe500mm.Themax.llinglevelmay

be approx. 10cm underneath the top edge of the container. For transport, the owner/user must provide

a covering net or similar.

3.2.2 Safety and protective devices

* Only operate the machine with trained operating personnel in the driver’s cab.

* Only one person at a time may use the driver’s cab and chassis.

* During driving and compaction operation, ensure that nobody is in the hazard area.

* Prior to driving operation, lift the compaction roller as far as possible.

* While the machine is at rest and during the compaction process, ensure that the parking

brake is activated.

3. 03

Table of contents

Popular Trash Compactor manuals by other brands

Euro Shatal

Euro Shatal RP4014-50 operating instructions

Dynapac

Dynapac LP8500 operation & maintenance

MULTIQUIP

MULTIQUIP Mikasa MVH-702DRSC Operation and parts manual

KitchenAid

KitchenAid 9872215B Use and care guide

EarthBin

EarthBin Silo EB500 user guide

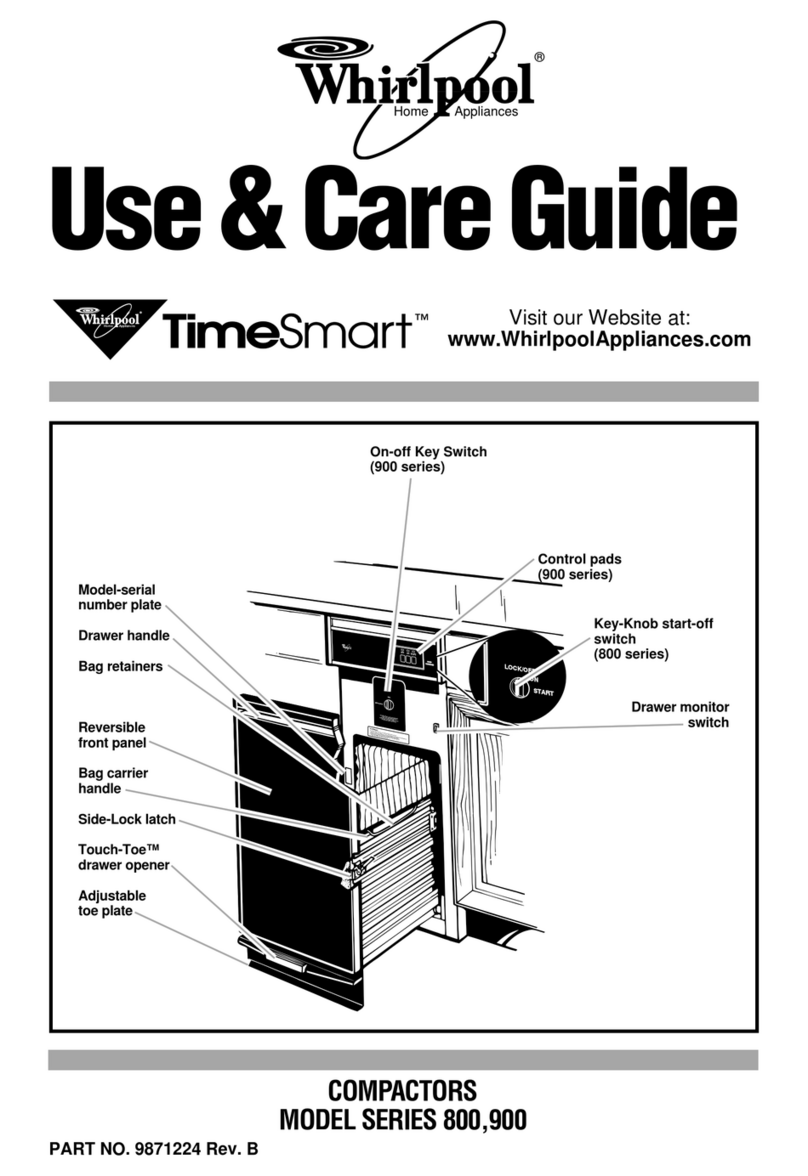

Whirlpool

Whirlpool Trash Masher JTF8500XL user guide

Whirlpool

Whirlpool 800 SERIES Use & care guide

Electrolux

Electrolux EI15TC65HS - Undercounter Trash Compactor Technical & service manual

Electrolux

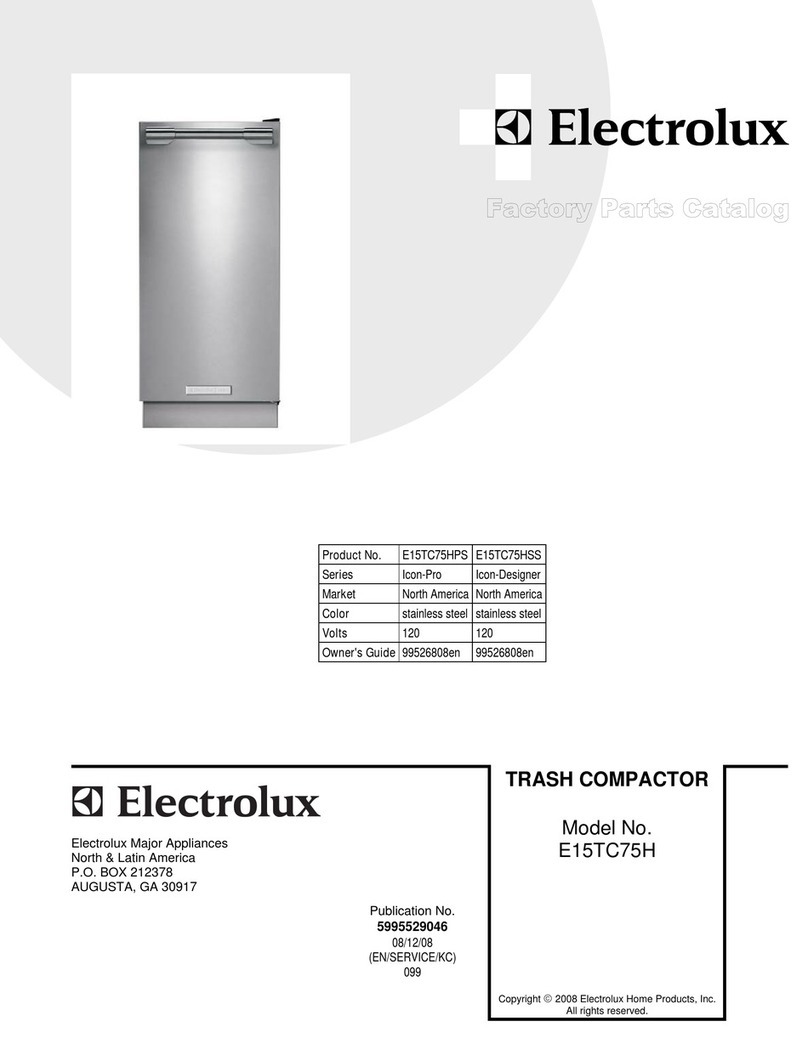

Electrolux E15TC75HSS - ICON Designer Factory parts catalog

Glasdon

Glasdon NEXUS 36G manual

KitchenAid

KitchenAid 9871780B Use and care guide

GE

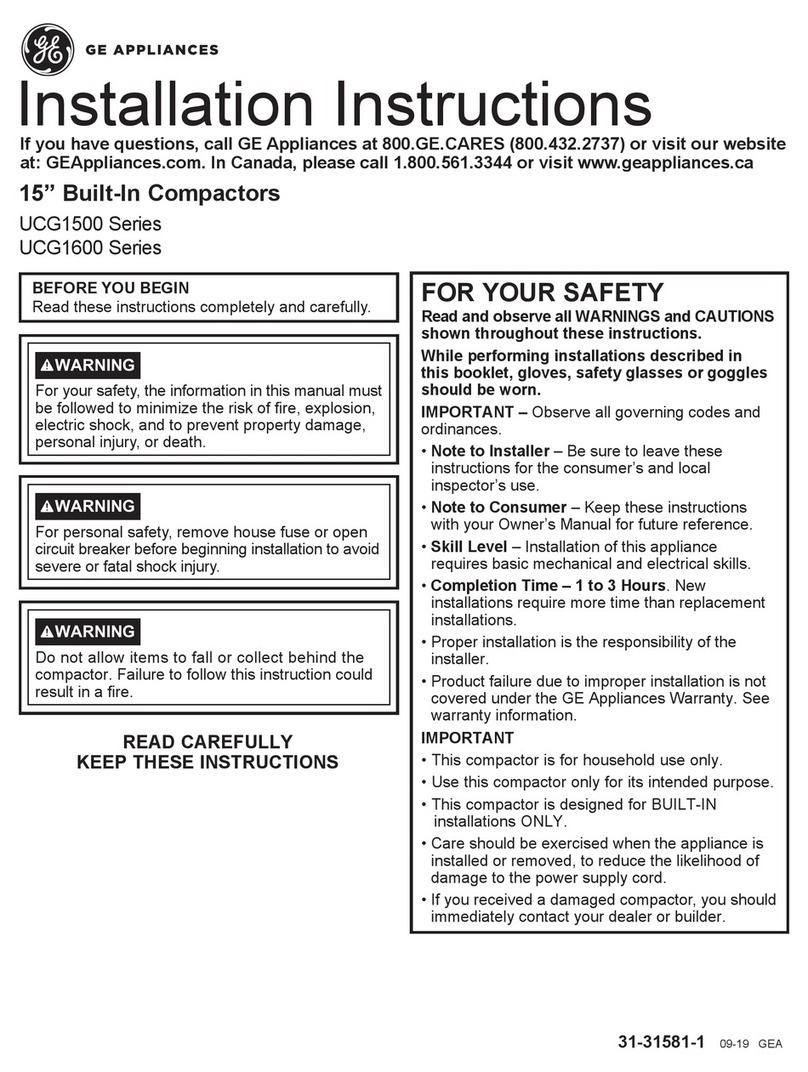

GE UCG1520NSS installation instructions