EPCO 1614 User manual

ENGINEERING

PRODUCTS CO.

12-1-78

P.O. Box

1510

Waukesha,

Wisconsin

53187

48"

SNOWBLOWER FOR POWER KING

MODELS

1614,1618,

2414&

2418

PURPOSE

This

Snow

Blower

, manufactured by

Engineering

Products

Company and Haban

Manufacturing

Company

for

use on

the

Econ-

omy

tractor

, is intended

to

maintain

moderate areas

of

sidewalk,

driveway

and parking lot in

the

safe and

efficient

removal

of

light,

moderate and heavy

snow

cover.

Strict

adherence

to

the

assembly

and operating instructions

will

ensure

that

the

unit

will

have a

long and safe life.

ASSEMBLY

The

Snow

Blower

header is shipped

substantially

assembled

in one box and

the

hitch

in another. Finish assembling

the

unit

according

to

the

diagrams on pages 3, 4, and 5 and

the

following

instructions:

Bolt end

of

HITCH WELDMENT (Item 3) to

the

rear of

the

HEADER ASSEMBLY (Item

8)

using SCREW, 3/

8"

-24NF x 7/

8"

LONG HHC (Item 26) WASHER, 7/

16"

SAE FLAT (Item 31) and

NUT, 3/

8"

-24NF HEX LOCK (Item 18). Be sure

that

the

WASHERS

are over

the

slots

in

the

HEADER.

Bolt LIFT

ARM

LINK (Item 12) to HITCH

WELDMENT

(Item 3).

There are

two

holes on

this

end

of

the

LINK.

The

upper

hole

(marked

"D")

is

for

the

Power

King

1614

&

1618

models. The

lower

hole (marked

"C")

is

for

the

Power

King

2414

&

2418

models.

Run SCREW, 7/

16"

-20NF x 2-1 /

2"

LONG HHC (Item 29)

through

the

LINK,

then

through a WASHER, 7/

16"

SAE FLAT (Item 31)

through

the

tube welded

to

the

bottom

of

the

HITCH

WELDMENT

through

another

WASHER, (Item 31) and

into

NUT, 7/

16"

-20NF

HEX LOCK (Item 19). This

joint

must be free to turn.

Slide female SLIP ASSEMBLY (Item

150)

into

male SLIP

AS-

SEMBLY (Item 152). Slide Sections

of

the

PTO

GUARDS (Items

187

and 188)

together

and

mount

to HEADER

flange

and

GUARD

BRACKET using

hardware

(Items

165, 185,

187

,

189,

190,

191,

192)

.

Assemble LIFT LINK (Item 11) as

shown

on page 3. It is very

important

that

the

KEYS (Item 34),

the

LIFT LINK BRACKET,

(Item 2),

the

SPRING (Item 16) and

the

WASHER (Item 32) be

in

the relative positions

shown

. This

arrangement

allows

the

HEADER

to

trip

up

when

a solid

object

is

struck and

therefore,

avoids

damage

to

the

HEADER, HITCH, and LIFT. The

length

of

the

LINK

is adjusted

for

the

various model

tractors

by placing

the

KEYS

and PINS in

the

appropriate locations. See

Diagram

on page 3.

Attach

the

LIFT LINK

to

lift

arm

on

Lift

Weldment

(Item 5) using

BOLT 7/

16"

x

2"

LONG BLANK (Item 23), SPRING (Item 15),

WASHER, 7/

16"

SAE FLAT (Item 31) and

KEY

#9

LARGE QUICK

CHANGE (Item 34).

Attach

the

CHUTE CRANK BRACKET (Item 1

0)

to

the

right

hand side

of

the

tractor

flywheel

housing.

Two

holes are provided

there

for

this

purpose. Use SCREW, 3/

8"

-24NF x 7/

8"

LONG

HHC (Item 26) and WASHER, 3/

8"

REGULAR LOCK (Item 30).

Place DISCHARGE CHUTE (Item 143) and DEFLECTOR

AS-

SEMBLY (Item 33)

through

the

DEFLECTOR DRIVE CABLE LOOP

(Item

120

and over

the

discharge stack on

the

HEADER.

Tighten

the

four BOLTS (Item

176)

at

the

DISCHARGE CHUTE base. These

BOLTS should

fit

under

the

ring on

the

HEADER

discharge

stack

to prevent

the

DISCHARGE CHUTE

from

coming

off

during

opera-

tion, yet

allow

it

to

rotate freely. Place both

interlocking

loops

of

the CABLE over

the

stud on

the

DISCHARGE CHUTE and

retain

with

WASHER, (Item 1

06)

and BOLT, 1I

4"

-20NC x 1/

2"

LONG

HEX

MACH

(Item

175)

.

The

Snow

Blower

is

now

fully

assembled and ready

for

mount-

ing,

final

adjustments

and operation.

MOUNTING

Mount

Snow

Blower

as

follows

:

Be sure

tractor

is on a level surface, is

not

running

and is

in

neutral. Place HEADER and HITCH ASSEMBLY

in

front

of

tractor

with

LIFT LINK extending

forward

toward

the

rear. Roll

the

tractor

forward

until HITCH PIVOT ROD is

just

slightly

ahead

of

tractor

rear

hitch

blocks. Leave

tractor

in

neutral

and

lift

rear of HITCH

and roll

tractor

forward

until

PIVOT ROD is in slot

in

rear

hitch

block. Tractor is

most

easily moved by

turning

tire,

either

front

or rear. Raise LIFT WELDMENT

until

bar

is

in

slot

of

tractor

front

hitch

block. Rotate HITCH LATCH

into

pos1t1on

and

retain

with

BOLT 3/

8"

x

2"

LONG BLANK (Item 22) and

KEY

, #11 ,

SMALL

QUICK CHANGE (Item 35).

Attach

rear end of LIFT LINK

to

tractor

lift

arm

using BOLT

7/

16"

x

3"

LONG BLANK (Item 24), SPRING (Item 15), WASHER

(Item 31) and

KEY

(Item 34). LIFT LINK should have already been

assembled

to

proper

length

referencing

the

diagram

on page 3.

Disconnect

the

Electromagnetic Clutch

wires

and

retaining

chain. Place BELT (Item 14) over clutch and

into

front

groove.

Reconnect

chain

and

wires.

It is desireable

to

wrap

the

wires

once

around

the

chain

when

reconnecting

to

avoid its rubbing on

the

engine screen and BELT

during

operation

.

Run BELT

down

around DRIVE SHAFT SHEAVE and around

IDLER SHEAVE.

Adjust

BELT

tension

by

turning

WING NUT so

that

about

1"

of

thread

shows

on BELT TENSIONING ROD. The

BELT

will

stretch

after

operation

begins

and

will

have

to

be re-

adjusted. Stop

engine

before making any adjustments.

Hook end of CRANK ROD (Item

135)

through

the

EYEBOLT

(Item 107) of chute

turning

assembly.

Slide

other

CRANK

ROD

(Item 107)

through

CHUTE CRANK (Item 10) and

into

the

end of

the

other

CRANK ROD.

ADJUSTMENTS

Adjust

SKID SHOES (Item 1

03)

to

the

desired

height

by block-

ing up

the

HEADER, loosening

the

BOLT (Item

131)

and NUT (Item

183), adjusting

Shoe

height, and

retightening

BOLT and NUT.

Adjust

both SHOES

to

the

same level.

If

operation

is

to

take place

on a gravel or stone

driveway

, etc

.,

it is recommended

that

the

SHOES

be

as

low

as possible. Both

the

SCRAPER BLADE (Item

101) and

the

SKID SHOES are subject

to

wear

and are designed

for easy replacement. Replace before

wear

is excessive

to

pre-

vent damage

to

the

auger housing.

A correctly adjusted AUGER CHAIN (Item

121)

will

have a

slight

amount

of

slack.

Adjust

this

CHAIN by loosening NUTS

(Item 161) at

the

HEADER end of

the

universal shaft, loosen

the

JAM

NUT (Item

168)

and

turn

BOLT (Item

150)

to

adjust CHAIN

tension. Clockwise

to

increase

tension,

counter-clockwise

to

decrease tension.

Re-tighten

JAM

NUT and NUTS (Item 161 ).

Check CHAIN periodically

to

maintain

proper

adjustment

. Do

not

run CHAIN

either

too

tight

or

too loose.

The DISCHARGE CHUTE CRANK is located on

the

right

hand

side of

the

tractor

. Turn CRANK to

control

the

direction

of

the

snow

discharge. The CHUTE rotates

thru

a

total

of

about

270°

and

should turn equally

far

in

either

direction

. Overtravel is

prohibited

by a chute stop bolt.

If

the

CHUTE travel is

not

the

same

in

both

directions, check

the

wrap

of

the

CABLE (Item

120)

and

the

TUBE

(Item 118). It should be

wrapped

2-1 / 2

times

around

the

TUBE

in

each direction.

If

the

DISCHARGE CHUTE

will

not

hold

in

a set

position,

tighten

the

NUT (Item 184)

until

the

CHUTE does

hold

its

position. Do

not

overtighten

.

The DEFLECTOR (Item 133) mounted on top

of

the

DISCHARGE

CHUTE

determines

the

distance

snow

is

thrown

.

Moving

the

top

of

the

DEFLECTOR

down

decreases

the

distance

while

raising

the

DEFLECTOR increases it.

/'),.SHUT

OFF

ENGINE

WHENEVER

ANY

ADJUSTMENTS/'),.

·

..

TO

THE

SNOW

BLOWER

ARE

MADE!

..

OPERATION

Before

the

first

snowfall,

the

area in

which

snow

removal is

to take place should be cleared

of

all stones, sticks and

the

like

which

might

be

picked up by

the

auger.

All

obstacles should be

marked to protect

the

tractor

and auger

from

possible collision.

Check

the

tractor

and

Snow

Blower

to

be sure

that

both are

in

good operating condition.

A

light

coat of

wax

or

a coat

of

a silicone spray

lubncant

applied

to

the

inside surfaces

of

the

auger housing

will

prevent

snow

and ice

from

sticking to it. The

wax

or spray should be

applied several

times

during

the

snow

removal season.

Fill gas

tank

out of doors and avoid

spilling

gasoline

over

the

engine. Do

not

fill

tank

while

smoking or

while

engine

is

running

.

Allow

ample engine

warm

up

time

before

starting

snow

re-

moval.

To become

familiar

with

the

controls, operate

the

tractor

and

Snow

Blower

in a clear area before

attempting

to

remove

snow

.

The more

familiar

you become

with

the

Snow

Blower

and its oper-

ation,

the

better

results you

will

have.

For best results,

snow

should be removed as soon as possible

after it falls.

Do

not

remove

any

guards

or

covers

while

operating

the

tractor and

Snow

Blower

.

Also

do

not

operate

with

any

guards

removed.

The auger speed is

directly

related to

engine

speed. For

maxi-

mum

snow

removal and discharge,

maintain

high

engine

RPM (full

throttle). It is advisable

to

operate

the

tractor

at

a very

slow

ground speed

for

safe and

efficient

snow

removal. A

tandem

trans-

mission is

highly

recommended.

If

the

snow

cover is

extremely

deep, raise

the

Header

to

its

highest position and

drive

forward

until

the

tractor

tires

reach

the

unblown

snow

. Do

not

drive

onto

this

snow.

Back up,

lower

header, and drive

forward

again. In

this

manner

the

deepest

snow

can

be

removed.

The use

of

tire

chains

and

wheel

weights

is

recommended

for

extra

traction

especially

when

heavy

snows

or

icy

conditions

occur.

Whenever

possible discharge

snow

downwind

.

Do

not

attempt

to

remove ice or hard packed frozen

snow.

Always

overlap each pass

slightly

to assure complete

snow

removal.

A frozen or stuck auger

or

elbow

must be broken loose or

thawed

with

care.

When

attempting

to loosen a

jammed

auger,

shut

off

tractor

engine and remove spark plug

wire.

Never

attempt

to clear

Snow

Blower

at any

time

with

tractor

engine

running.

If

the auger suddenly comes unstuck, you

will

loose your fingers!

A

definite

pattern is required

for

thorough

and

efficient

snow

removal. If

snow

can

be

blown

to

either

side,

start

the

first

pass

in

the

center

of

the

area.

With

each additional pass

alternate

sides

of

the

cleared area and

blow

the

snow

over

the

uncleared area.

If

snow

can be

blown

only

to

one side,

start

at

the

other

side

of

the

area and

blow

the

snow

in

one

direction

only

.

Alternate

the

angle of

the

discharge chute

with

each pass.

Be extremely careful as

the

Snow

Blower

will

throw

objects

other

than

snow. Keep children, adults and

animals away

to avoid

any danger

to

them

both

from

thrown

objects and

from

contact

with

the

rotating auger.

After

the

area has been cleared and

the

Snow

Blower

is

to

be

put away, be sure

that

the

auger housing and discharge chute

are clear of all

snow

and slush, especially slush.

If

the

tempera-

ture drops and

the

slush

or

snow

freezes in

the

header, it

may

become

virtually

impossible

to

clear

it

without

applying heat.

At

the end

of

the

season

the

following

steps are recommended:

Wash

off

any

salt deposit

which

may

have

dried

on

the

Snow

Blower

and housing. Paint or cover exposed metal

with

a

light

coat

of

oil.

Lubricate

the

Snow

Blower

following

the

lubrication

instruc-

tions. The

Snow

Blower

chain

must

be oiled

thoroughly

to

prevent

rust from forming.

Store

Snow

Blower

in a

dry

place.

2

LUBRICATION

Auger Chain:

Lubricate

chain

with

30

weight

oil

every

20

operating hours. Be sure oil reaches inside each

roller

.

Wipe

off

excess oil.

Pivot and Friction Points: To

maintain

smooth and free opera-

tion apply a

few

drops

of

30

weight

oil as required

to

all

friction

and pivot points.

Deflector: Lubricate defector

with

a

water

repellent

grease

as needed.

Bearings: Lubricate Header

Bearings

and

pillow

block bearing

after every

50

hours of operation

with

a good

wheel

bearing grease.

The header grease

fittings

are located on

the

right

side

when

facing

the

front

of

the

header. The

Pillow

Block grease

fitting

is

located on

the

Pillow

Block housing. Be .careful

not

to

overfill

the

bearings.

Also

be sure

to

wipe

the

fittings

clean before greasing

to prevent

dirt

from

being forced

in

the

bearings and

after

they

have been lubricated.

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

P/N

03

·

2102

15·0505

50·0104

50

·

0115

50·0130

50·2502

50·2505

50

·

0110

50

·

0111

50

·

0505

50-4701

50

·

4704

51

-

4705

81

·

0048

83

·

0024

83

·

0124

83

·

0005

84·0110

84

·

0120

84

-

0073

84

·22

60

84

-

1101

84·1111

84·1121

84

·

4012

84

·2

110

83

·

0127

84·2171

84

·2

210

84

·

3020

84

·3

060

84

·

3070

84-4020

84-4031

84-4032

6346

50·0114

80·0505

50

-2

515

50-4708

50·0525

99·0011

09

·

0053

86

·0

061

60

·

0509

84-4011

50·5050

99

·

0252

84

·

0051

84

-3

010

84

·2

030

84

·

2151

84

·2

170

84

·2

010

84

·2

111

84·2220

Read all

safety

rules

on

page

6

before

attempting

to

operate

Snow

Blower.

48"

SNOW

BLOWER PARTS LIST

DESCRIPTION

FiniNG

...

Grease

114"

-

28

short

BRACKET

.. ..... .

Lift

Link

WELDMENT

............

..

.........

.48"

Snow

Blower

Hitch

WELDMENT

........................

Left

Hanger

WELDMENT

.....

..

.....

..

..

.

..

.

..

.48

"

Snow

Blower

Lift

WELDMENT

.............

..

..

......

Gear

Box

Mounting

BRACKET

......................

Bearing

Support

ASSEMBLY

... ..........

..

.48

"

Snow

Blower

Header

ROD

.................

....

.........

..

Hitch

Pivot

Mounting

BRACKET

...... .....

..

......

Chute Crank

LINK

...................

.46"

Universal

Lift

LINK

.........

....

.......

..

.

LiftArm

LATCH

.. ..............

Hitch

BELT

.....

..

....

..

.

.For

Model1978

48

"

Snow

Blower

SPRING

.......

..

.....•............

Compression

1"

Long

SPRING

. ............... .......

Compression

6"

Long

SPRING

..........

Extension

5-3

/

8"

Long

NUT

.. ...........

.3

/8" -

24NF

Hex

Lock

NUT

......•..........•.......

.7

I

16

" -

20NF

Hex

Lock

NUT

............3/ 4" -

16NF

Hex

Slotted

SCREW

.....

..

......

....

.5/

16"-

18NC

x3/8"

Long

SOC

HSS

BOLT

.....................

.3

/8" x2"

Long

Blank

BOLT

............ .... ........

.7

/

16

" x2"

Long

Blank

BOLT

...............................

.7

/

16

" x3"

Long

Blank

KEY

.................................3/

16

"

Square

x 1·7/

16

"

Long

SCREW

............................

.3

/8" -

24NF

x7/8"

Long

HHC

SPACER

............................

Idler

Assembly

SCREW

............................

.7

/

16

" -

20NF

x 1·1/4"

Long

HHC

SCREW

.........•

..

.........

.. ..

.

..

.7

/

16

" -

20NF

x2

·112''

Long

HHC

WASHER

.................

.3

/

8"

Regular

Lock

WASHER

.................

.7

/

16

"

SAE

Flat

WASHER

......3/4"

SAE

Flat

KEY

.... ............5/

32"

x1·1/2"

Long

Cotter

KEY

......

#9

Large

Quick

Change

KEY

.....

..

................

..

.

..

.

..

#11

Small

Quick

Change

ASSEMBLY

...•...

..

......

Pulley

and

Hub

WELDMENT

........................

Right

Hanger

BEARING

...........................3/ 4"

Pillow

Block

GUARD

..............

..

.............

Drive

Shaft

BRACKET

...........................

Header

Drive

Guard

COUPLING

.....................

Drive

Shaft

to

Gear

Box

-

Flexible

SNAP

RING

...... .........

Drive

Shaft

ROD

.................................

Belt

Tightener

SHEAVE

...................•........5" 0.D.

Flat

BRACKET

...........................

Idler

KEY

..

..

..

. .

..

3/

16

"

Square

x7/8"

SHAFT

... ....................

Drive

GUIDE

..............................

Belt

Tightener

Rod

WING

NUT

...........

..

..........

..

Belt

Adjustment

WASHER

.....................

..

...5/

16"

Regular

Lock

SCREW

...........................

5/

16"-

24NF

x7/8"

Long

HHC

SCREW

.........

..

..

........

.3

/8" -

24NF

x2·1/2"

Long

HHC

SCREW

.

.7

/

16

" -

20NF

x1·

112

"

Long

HHC

SCREW

...5/

16

"-

24NF

x 1/2"

Long

HHC

SCREW

.................

.3

/

8"-

16NC

x7/8"

Long

HHC

SCREW

........7/

16

" -

20NF

x

3·1

/ 4"

Long

HHC

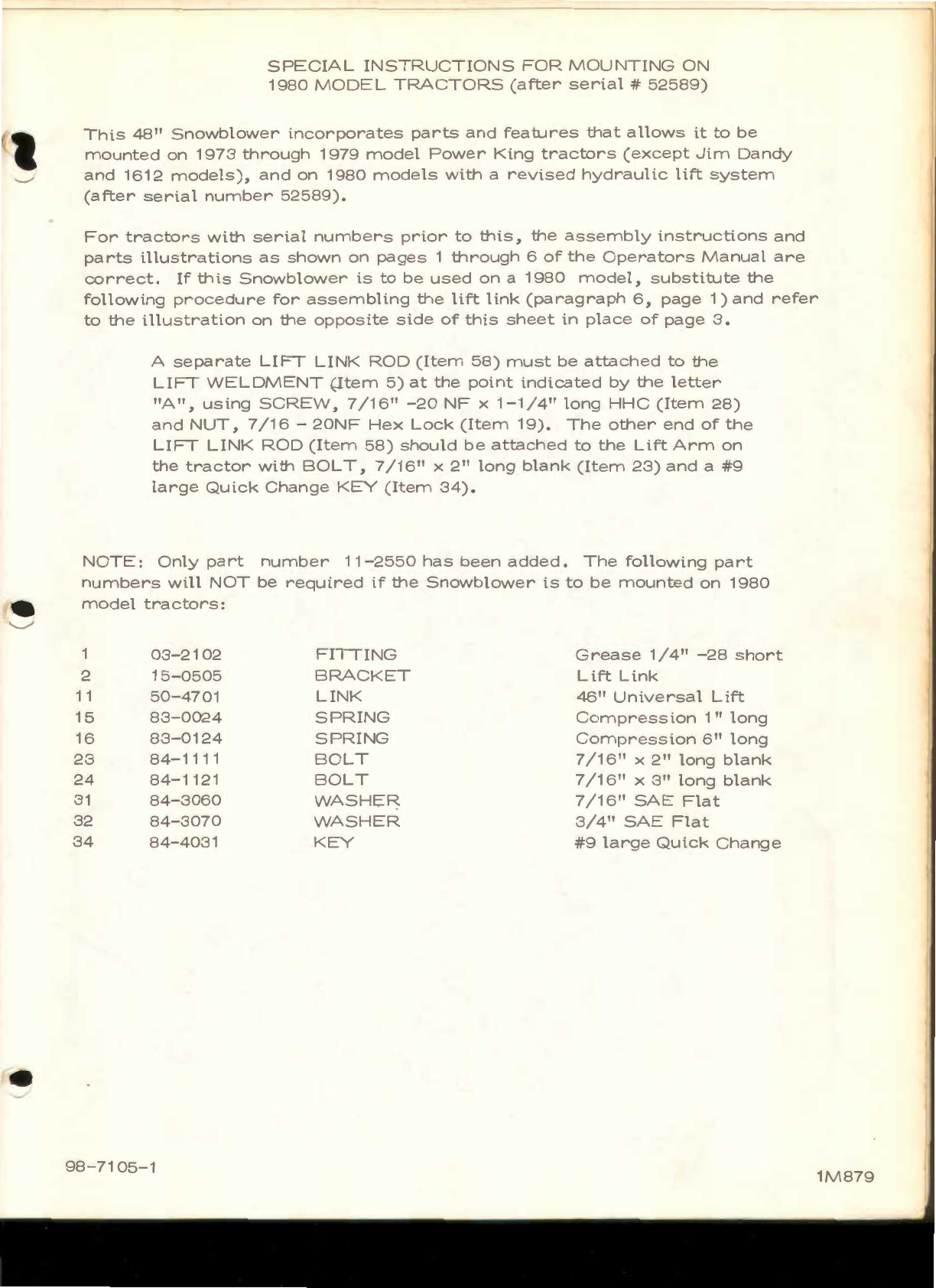

SPECIAL

INSTRUCTIONS

FOR

MOUNTING

ON

1980

MODEL

TRACTORS

(after

serial

#

52589)

This

48

11

Snowblower

incorporates

parts

and

features

that

allows

it

to

be

mounted

on

1973

through

1979

model

Power

King

tractors

(except

Jim

Dandy

and

1612

models),

and

on

1980

models

with

a

revised

hydraulic

lift

system

(after

serial

number

52589).

For

tractors

with

serial

numbers

prior

to

this,

the

assembly

instructions

and

parts

illustrations

as

shown

on

pages

1

through

6

of

the

Operators

Manual

are

correct.

If

this

Snowblower

is

to

be

used

on

a

1980

model,

substitute

the

following

procedure

for

assembling

the

lift

link

(paragraph

6,

page

1)

and

refer

to

the

illustration

on

the

opposite

side

of

this

sheet

in

place

of

page

3.

A

separate

LIFT

LINK

ROD

(Item

58)

must

be

attached

to

the

LIFT

WELDMENT

(Item

5)

at

the

point

indicated

by

the

letter

"A",

using

SCREW,

7/16"

-20

NF

x

1-1/4"

long

HHC

(Item

28)

and

NUT,

7/16

-

20NF

Hex

Lock

(Item

19).

The

other

end

of

the

LIFT

LINK

ROD

(Item

58)

should

be

attached

to

the

Lift

Arm

on

the

tractor

with

BOLT,

7

/16"

x

2"

long

blank

(Item

23)

and

a

#9

large

Quick

Change

KEY

(Item

34).

NOTE:

Only

part

number

11-2550

has

been

added.

The

following

part

numbers

will

NOT

be

required

if

the

Snowblower

is

to

be

mounted

on

1980

model

tractors:

03-2102

FITTING

Grease

1I

4"

-28

short

2

15-0505

BRACKET

Lift

Link

11

50-4701

LINK

46"

Universal

Lift

15

83-0024

SPRING

Compression

1"

long

16

83-0124

SPRING

Compression

6"

long

23

84-1111

BOLT

7

/16"

x

2"

long

blank

24

84-1121

BOLT

7

/16"

x

3"

long

blank

31

84-3060

WASHER

7

/16"

SAE

Flat

32

84-3070

WASHER

3/4"

SAE

Flat

34

84-4031

KEY

#9

large

Quick

Change

98-7105-1

1M879

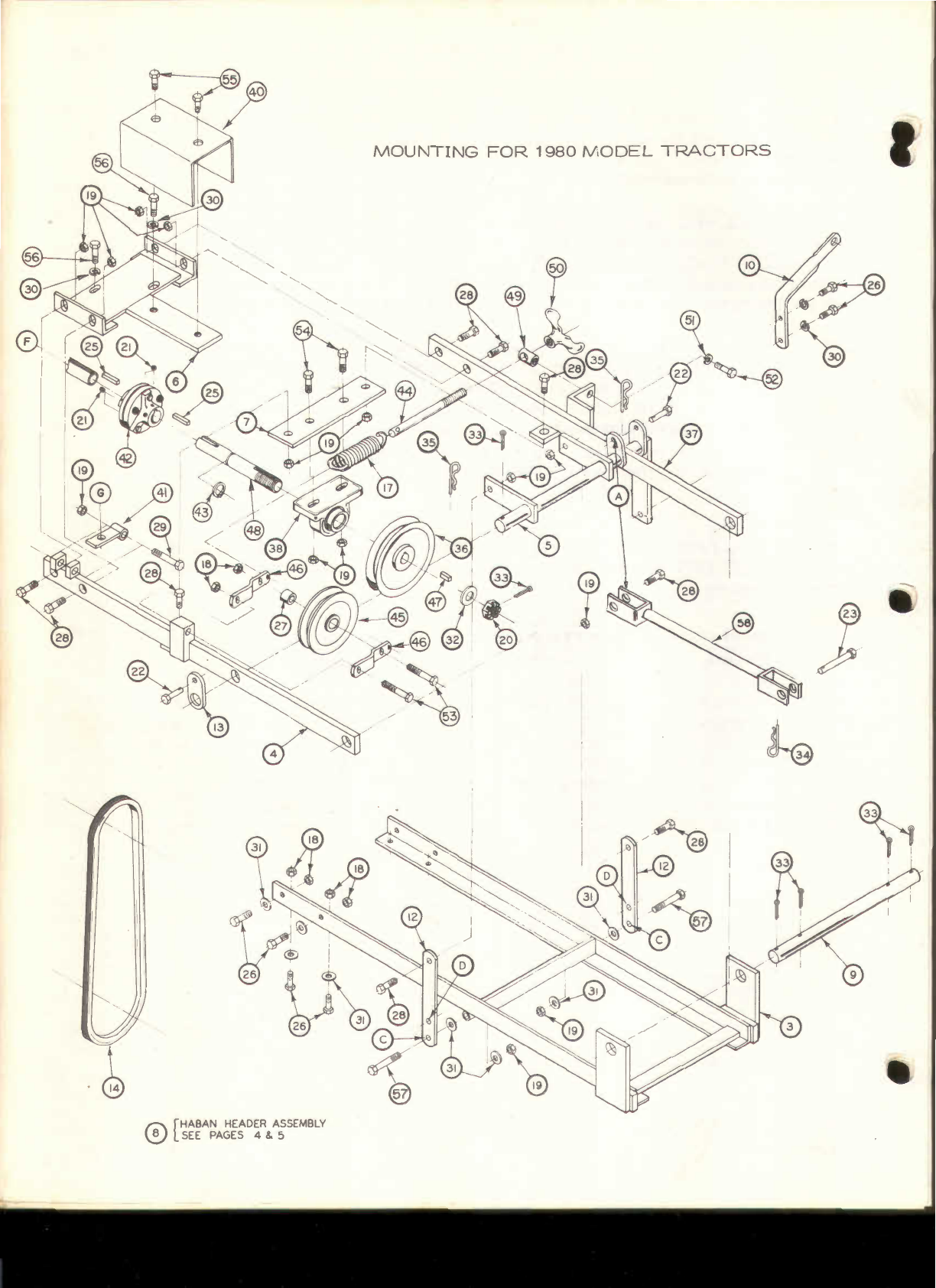

DER

ASSEMBLY

fa\

[HABA~A~g

4 & 5

V::../

SEE

D

EL

T

1980

MO

MOUNTING

FOR

RA

CTORS

37

J

DER

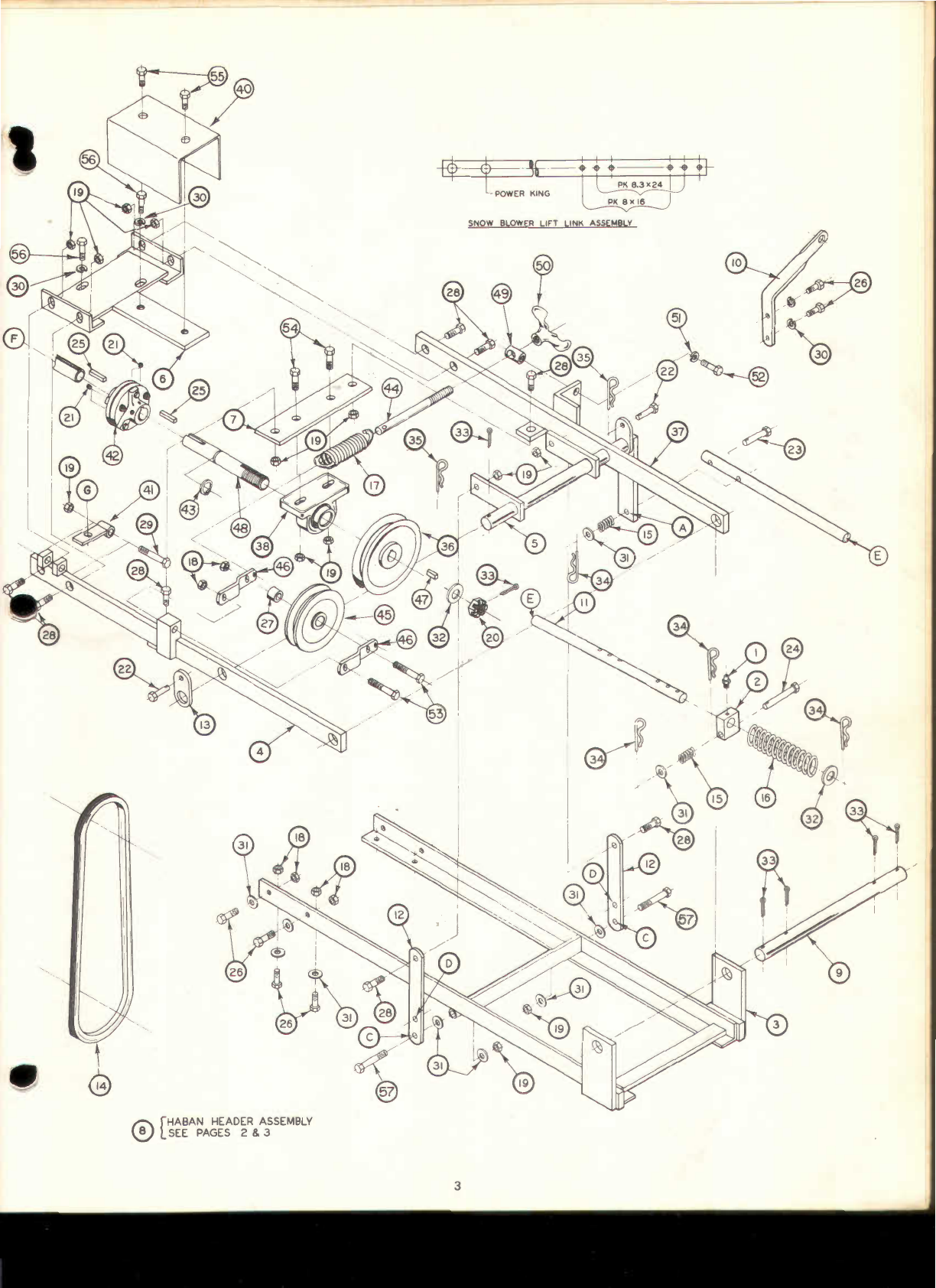

ASSEMBLY

17:\

[HABANPA~ft

2 & 3

\:::.I

SEE

HABAN

48

, HEADER ASSEMBLy

ITEM

P/N

101

3013A

102

3036

103

3045

104

3076

105

3259

106

3903

107

3955

108

4119

109

4143

110

4506

111

4606

112

4607

113

4608

114

4609

115

4610

116

4611

117

4123

118

4742

119

4772

120

5098

121

5101

122

5429

123

5473

124

5474

125

6023

126

6024

121

6340

128

6558

129

7090

130

7091

131

7953

132

3396

133

8197

134

8198

135

8206

136

8236

137•

8287

138

8299

139

11356

140

8362

141

8363

142

8456

143

8585

144

8725

145

9030

146

9032

147

9125

148

9127

149

9129

150

9132

151

9175

152

9177

153

9345

GEARCASE

IS

SHOWN

IN

ITS

MOUNTED ORIENTATION. SEE

AS-

SEMBLY INSTRUCTIONS

FOR

PROPER

INSTALLATION,

HABAN

48"

SNOW

BLOWER

HEADER

PARTS LIST

DESCRIPTION

BLADE

............... .....

Scraper

GUARD

............

..

Chain

SHOE

. .......................

Skid

HOOK

. .......................

Lift

SP,ring

KEY

. ..

..

...................3/16'

Square

x I"

Long

WASHER

..

.....................

Concave

Tooth

EYE

BOLT

.......

.

................

Drive

Tube

NUT

...

..

. .

..

..

.

..

..

...... .....

.1

/

4"-

20NC

HEX

Lock

(84-0010)

WASHER

.............

..

....

..

..

..

.

Auger

WASHER

.........................

.1

-1/2" O.D. x

13

/

32"

I.D.

x .

0511

.

080

BUSHING

.. .........

Gear

Box

GEAR

BOX

.. .......................

Right

Angle

GASKET

..

.....

.

....

...............

Gear

Box

SNAP

RING

..

............

Gear

Box

SNAP

RING

...........

Gear

Box

BEARING

. ............

Gear

Box

FiniNG

.....................

Grease

TUBE

...... ......

....

.

..

.

....

...

Deflector

Drive

WASHER

......

.................

.

13

/

16"

O.D

. x 13/32"

I.D.

x 5/

64"

Thick

CABLE

.........

..

...................

Deflector

Drive

CHAIN

.........

..

...................

Auger

Drive

WASHER

..........................

.1

-11

16"

O.D. x

49

/

64"

I.D.

x0.

0598"

Thick

FLANGE

.. ......

.. .. ..

.....

Bearing

BEARING

...................

Auger

ASSEMBLY

..

.......

..

......

Shaft

and

Gear

ASSEMBLY

..........

....

....

Gear

Box

SLEEVE

..

...........................

Oval

MOLDING

......

..

..................

Deflector

BOLT

........

......................

.1

/

4"-

20NC

x 5/ 8"

Long

Carriage

PLUG

..... .....................

Pipe

BOLT

.....................5/

16"-

18NC

x3/

4"

Long

Carriage

WASHER

.......

..

...

.1-112"

O.

D.

x49/64"

I.D

. x 0.

0598"

Flat

DEFLECTOR

.... ................

Elbow

STRAP

...............

.Locking

ASSEMBLY

. ................

Crank

Rod

U-BOLT

.. ..............

..

Deflector

Drive

SPROCKET

.......................

..

35

Tooth

Auger

STRAP

...

..

......... ...........

....

.Friction

ASSEMBLY

.........

..

....

..

........

Sprocket

and

Bearing

SHAFT

.....

Auger

ASSEMBLY

.

..

.................

Auger

48"

KIT

...

..

................

Chain

Repair

ASSEMBLY

....................

..

...

Elbow

and

Pivot

ASSEMBLY

.........................

Cable

,

Tube

and

Sleeves

SHROUD

...........................

Stack

Drive

ASSEMBLY

.........................

Bracket

and

Tube

ASSEMBLY

.. .. ..

..................

.Jackshaft

Housing

ASSEMBLY

.........................

Jackshaft

Housing

ASSEMBLY

.........................

Jackshaft

and

Sprocket

13

Tooth

BOLT

................................

5/16"-

18NC

x

1-3

/

4"

Long

Sei!Tapping

SPACER

...........................

.Jackshaft

SLIP

ASSEMBLY

...................

Male

End

ASSEMBLY

. ................

Crank

Rod

5

ITEM

P/N

154

9663

155

10440

156

10441

157

10442

158

10444

159

GM-102594

160

GM

-

120214

161

GM-120378

162

GM-120380

163

GM-120384

164

9737

165

GM-120388

166

GM

-

120389

167

GM

-

120915

168

GM

-

124824

169

GM-124829

170

GM-126227

171

GM-126358

172

GM

-

126803

173

GM

-

180024

174

GM

-

178566

175

GM

-

180016

176

GM-180018

177

GM

-

9411507

178

GM-180044

179

GM-180077

180

GM-9428225

181

GM

-

180175

182

GM-271178

183

GM-271184

184

GM-271190

185

GM-9413534

186

GM-9414012

187

10509

188

10395

189

5681

190

10397

191

GM

-

180126

192

GM-180137

193

4409

194

GM-180075

195

GM-180116

196

GM-120382

197

GM-9413447

198

11354

199

11353

DESCRIPTION

DECAL

.............................

Chute

Warning

ASSEMBLY

........................

Header

Housing

48"

ASSEMBLY

.............

..

... .. .

.48"

Auger

Complete

ASSEMBLY

................ .

Stack

Dnve

Complete

SLIP

ASSEMBLY

..........

..

......

.Female

End

SCREW

............................

.3

1

8"

..

-

16NC

x 5/ 8"

Long

AI

Hd

Cp

Pt

Set

WASHER

..................

..

.

..

....5/

16

Med1um

Lock

(84-3010)

NUT

....... .................1/2" -

13NC

Lt

Hex

WASHER

..........................

.1

/4:

Medium

Lock

(84

-

3040)

WASHER

...........................1/2

Med1um

Lock

(84-3110)

ASSEMBLY

.........................

Deflector

and

Decal

WASHER

...........................3/8"

Flat

WASHER

..........................

.7

/

16"

Flat

(84-3060)

BOLT

.... ..... .......

..

......

.3

/

8"-

16NC

x

I"

Long

Carriage

NUT

. .

..

........

..

........

5/16"-

18NC

x

Half

Hex

NUT

.3/8"-

16NC

Lt

Hex

BOLT

........

.3

/

8"-

16NC

x3/

4"

Long

Carriage

BOLT

. .

..

......5/

16"-

18NC

x 1"

Long

Carriage

BOLT

............. .

..

.1/2"-

13NC

x3-1/2"

Long

Carnage

BOLT

..

.....................

.1

/

4"-

20NC

x 1-1/4"

Long

WASHER

......................

.3

/ 8"

Internal

BOLT

............

114"-

20NC

x 1/2"

Long

Hex

Mach

(84-1012)

BOLT

................................1/4" -

20NC

x5/

8"

Long

Hex

Mach

NUT

................................

.3

/

8"

-

16NC

Serrated

Flange

Hex

Lock

BOLT

...............................

.1

/4" -

20NC

x2"

Long

Hex

Mach

BOLT

................................5/

16"-

18NC

x3/ 4"

Long

Hex

BOLT

...............................

.3

/

8"-

16NC

x

I"

Flanged

Hex

Hd

BOLT

...............................

.1/2"-

13NC

x 1-1/

4"

Long

Hex

Mac

NUT

............

.1

/

4"

-

20NC

Hex

with

Lock

Washer

NUT

... .

......................

.5/

16"-

18NC

Hex

with

Lock

Washer

NUT

................................

.3

/

8"-

16NC

Hex

with

Lock

Washer

NUT

...

..

..... ..........

.3

/

8"-

16NC

Hex

Lock

(84-0040)

SCREW

..................

....

.

..

.

..

.1

/

4"-

14

x 1/2"

Long

Self

Tapp1ng

GUARD

.......

..

....

..

..............

PTO

Bottom

GUARD

........................

PTO

Top

SPRING

...........

WASHER

..................

..

.......

Special

Wing

BOLT

...................

..

........

..

.3

/

8"-

16NC

x 1-1/2"

Long

Hex

Mach

BOLT

3/ 8" -

16NC

x

2-3

/

4"

Long

Hex

Mach

SPACER

............................

BOLT

................ .

..

5/

16"-

16NC

x 1/ 2"

Long

Hex

Mach

BOLT

..

..

....

..

..

..

..

.

..

. 3/

8"-

16NC

x 1/2"

Long

Hex

Mach

WASHER

.................

..

.....

..

.3

/

8"

Medium

Lock

Nut

NUT

..... .

..

.............

Deflector

ASSEMBLY

.........................

Idler

Bracket

ASSEMBLY

......... ................

Idler

Bracket

Complete

The

above

parts

and

their

part

numbers

refer

to

parts

which

are

serviced

by

Haban

Manu

-

facturing

Company,

2100

Northwestern

Avenue

,

Racine

,

Wisconsin

53404

. If

replacement

parts

are

needed

please

order

them

directly

from

Haban

.

Parts

which

are

common

to

the

Engineering

Products

Company

system

also

have

their

Engineering

Products

part

number

given

in

parentheses

following

the

part

description

(84-0010)

.

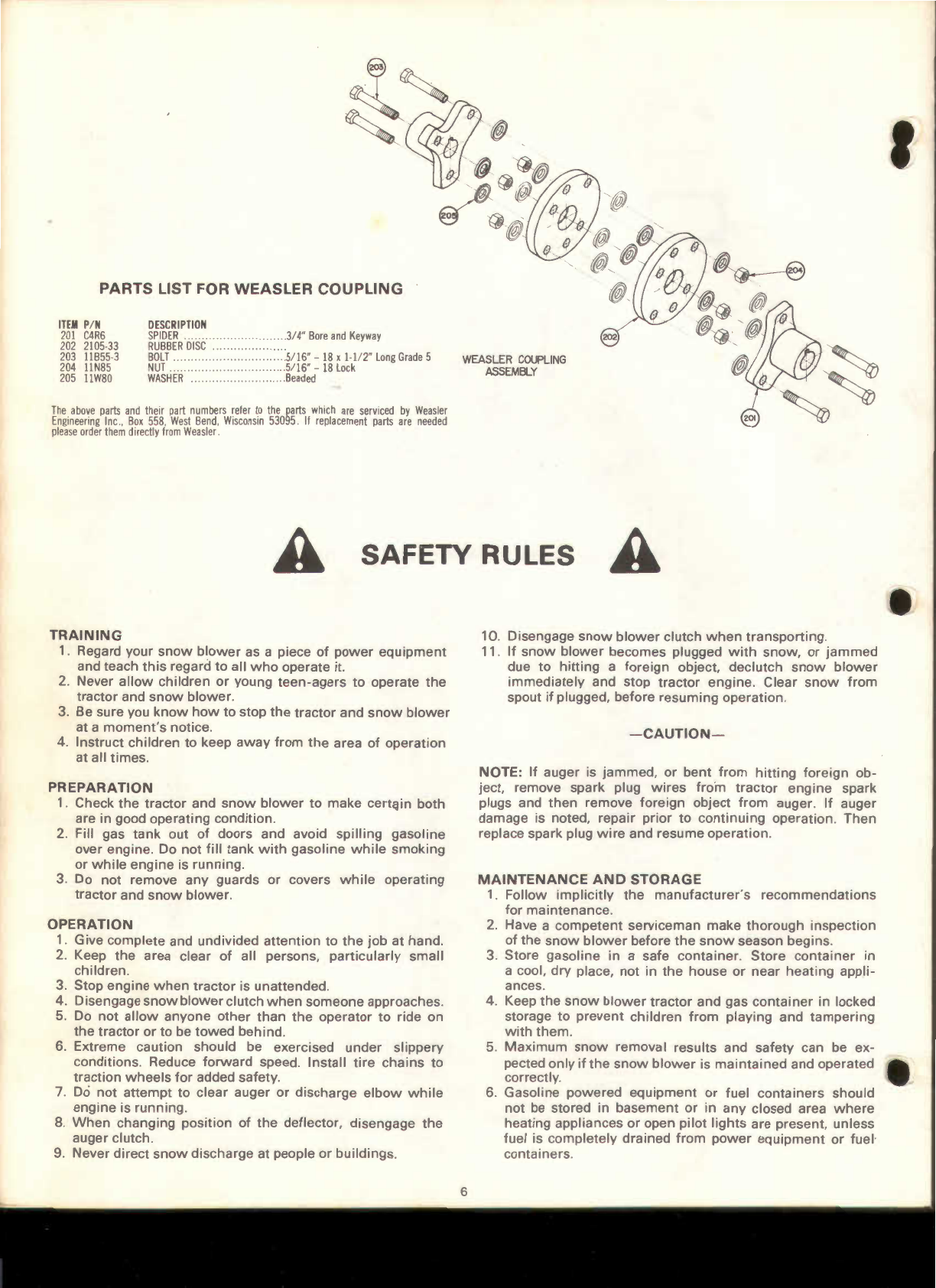

PARTS LIST FOR WEASLER

COUPLING

ITEM

P/N

201

C4R6

202

2105-33

203

11B55

-3

204

11N85

205

11W80

DESCRIPTION

SPIDER

..

..

RUBBER

DISC

BOLT.

NUT.

WASHER

..

.3

/

4"

Bore

and

Keyway

.5/

16"-

18

x

1-112

"

Long

Grade

5

....................5/

16"-

18

Lock

........

.Beaded

The

above

parts

and

their

part

numbers

reler

to

the

parts

which

are

serviced

by

Weasler

Engineering

Inc

.,

Box

558

,

West

Bend,

Wisconsin

53095

.

II

replacement

parts

are

needed

plea

se

order

them

directly

lrom

Weasler

.

WEASLER

COUPLING

ASSEMBLY

202

A SAFETY RULES A

TRAINING

1. Regard your

snow

blower

as a piece

of

power

equipment

and teach

this

regard to all

who

operate

it

2.

Never

allow

children

or

young

teen-agers

to

operate

the

tractor

and

snow

blower.

3.

Be sure you

know

how

to stop

the

tractor

and

snow

blower

at a

moment's

notice.

4.

Instruct

children

to keep

away

from

the

area

of

operation

at all times.

PREPARATION

1.

Check

the

tractor

and

snow

blower

to make certC!in both

are in good operating condition.

2.

Fill gas

tank

out

of

doors and avoid

spilling

gasoline

over engine. Do

not

fill

tank

with

gasoline

while

smoking

or

while

engine

is

running.

3. Do

not

remove

any

guards

or

covers

while

operating

tractor

and

snow

blower.

OPERATION

1. Give complete and undivided

attention

to

the

job

at hand.

2. Keep

the

area clear

of

all persons,

particularly

small

children.

3.

Stop

engine

when

tractor

is unattended.

4. Disengage

snow

blower

clutch

when

someone

approaches.

5.

Do

not

allow

anyone

other

than

the

operator

to ride on

the

tractor

or

to be

towed

behind

.

6. Extreme caution should be exercised

under

slippery

conditions

. Reduce

forward

speed.

Install

tire

chains

to

traction

wheels

for

added safety.

7.

Do

not

attempt

to clear auger

or

discharge

elbow

while

engine

is running.

8.

When

changing position

of

the

deflector, disengage

the

auger clutch.

9.

Never

direct

snow

discharge

at people

or

buildings

.

6

10

. Disengage

snow

blower

clutch

when

transporting

.

11

.

If

snow

blower

becomes plugged

with

snow,

or

jammed

due

to

hitting

a foreign object, declutch

snow

blower

immediately

and stop

tractor

engine. Clear

snow

from

spout

if

plugged, before

resuming

operation.

-CAUTION-

NOTE: If auger is

jammed,

or

bent

from

hitting

foreign

ob-

ject, remove spark plug

wires

from

tractor

engine

spark

plugs and

then

remove foreign object

from

auger.

If

auger

damage is noted, repair

prior

to

continuing

operation

.

Then

replace spark plug

wire

and resume operation.

MAINTENANCE

AND

STORAGE

1.

Follow

implicitly

the

manufacturer's

recommendations

for

maintenance

.

2. Have a

competent

serviceman make

thorough

inspection

of

the

snow

blower

before

the

snow

season begins.

3. Store gasoline in a safe

container.

Store

container

in

a cool,

dry

place,

not

in

the

house

or

near

heating

appli-

ances.

4. Keep

the

snow

blower

tractor

and gas

container

in

locked

storage to

prevent

children

from

playing

and

tampering

with

them

.

5.

Maximum

snow

removal results and safety can be ex-

pected

only

if

the

snow

blower

is

maintained

and

operated

correctly.

6.

Gasoline

powered

equipment

or

fuel

containers

should

not

be

stored in

basement

or

in

any

closed area

where

heating appliances

or

open

pilot

lights

are present, unless

fuel is

completely

drained

from

power

equipment

or

fuel·

containers.

This manual suits for next models

3

Table of contents