EPS POWERBOOST PRO E Series User manual

POWERBOOST

Clean Water

Booster

Sets

Flow Range O&M Manual

2

POWER

BOOST

by EPS Group

Table of Contents

General 3

Installation Checklist 4

Location Consideration 5

Installation Information & Diagrams 5

Commissioning 6

Pressure Vessel 7

Pump Specifi cation 8

Controller Specifi c Instructions & Troubleshooting 9

Declaration of Conformity 11

3

POWER

BOOST

by EPS Group

General

Delivery and Handling

The weight and size of the POWERBOOST unit may require the aid of lifting equipment and

must be handled in a safe manner. The unit must be lifted only by the base and not the pipe

work, pumps or vessel.

Inspection

On delivery, the POWERBOOST unit should be inspected thoroughly and any damage reported

to the supplier as soon as possible. This should be conrmed in writing within 48 hours.

Applications

The POWERBOOST FLOW range of cold water booster units are designed for domestic and light

commercial pressure boosting.

The POWERBOOST unit should not be installed in areas that are classied as hazardous or

where there is a risk of an explosion or harm to people. The manufacturer does not accept

responsibility if the unit is used to pump liquids other than clean water unless suitability has

previously been agreed in writing.

Warranty

All mechanical components of the POWERBOOST unit are covered by a 12 month warranty

against manufacturing defects. In case of failure please contact the relevant technical

department on one of the following:

Site Storage

Should a POWERBOOST unit need to be stored before installation it should be in a safe place

away from moisture, dust and frost.

ROI 094 963 3500

NI 028 9181 8347

UK 01543 415200

4

POWER

BOOST

by EPS Group

Installation Checklist

1. Check the unit for any visual defects. Contact your supplier immediately if any are found.

2. Choose a suitable location for installation. Please ensure the unit is tted in accordance

with these instructions.

3. Connect the inlet and outlet pipe work as per the installation diagram.

• The POWERBOOST Unit is designed to be gravity fed from a cold water storage

tank.

• The inlet pipe work should be sized according to minimise friction & turbulence

maintaining a suction velocity of less than 2m/s and in any case should be at least

the size of the inlet manifold.

• Good quality full bore Isolation Valves should be tted before and after the unit to

allow for reliable service or repair.

4. Fit the supplied pressure vessel to the discharge manifold (See Page 7).

5. In accordance with the latest IEE regulation all electrical connections should be carried

out by a qualied electrician. The booster unit must be earthed. It is recommended that a

residual current device (RCD) is tted on the incoming electrical supply.

6. Once all mechanical and electrical connections have been made the following steps

should be followed before the unit is powered up:

• Fully close all isolation valves on the outlet side of the booster set;

• Ensure there is sucient water in the supply tank;

• Fully open all isolation valves on the inlet side of the booster set;

• Open bleed screw at the top of each pump in turn and fully de-aerate the pumps.

5

POWER

BOOST

by EPS Group

Location Consideration

The POWERBOOST unit should be installed in a dry, well- ventilated area where it is not exposed to

extreme temperature or frost.

Reasonable access to all parts of the set and adequate service work space must be provided.

Provision for lifting equipment is recommended for units incorporating large pumps. There should

ideally be adequate lighting in the location of the POWERBOOST unit for ease of maintenance.

All system pipe work should be aligned and self supporting preventing any strain or distortion

within the unit. All pipe work that may be exposed to freezing conditions should be fully protected.

Provision should be made for the disposal of water drained from the system.

Foundation & Mounting

The POWERBOOST unit must be mounted on a solid foundation to support the weight of the unit.

Surfaces must be rm and level in all directions, the recommended surface is a concrete plinth or

oor and points are provided for oor xing if desired. Isolation mounts are provided and should

be tted if required.

Outlet Manifold

NB: Pipe Work connections can be made to either end of the inlet & outlet Manifold to suit your

site layout. Blanking Caps are supplied loose to close any open ends.

Installation Information & Diagrams

3.

0

General Notes

ALL ITEMS TO BE TAGGED WITH EPS TAG STATING;

EPS, DRAWING No, PURCHASE ORDER No.

1st ANGLE

PROJECTION

FOR HANDRAIL DETAILS SEE EPS DRAWING;

EPS/A-L/HANDRAILING/RAILFAB.

REMOVE ALL SHARP EDGES AND BURRS

IF IN DOUBT ASK DO NOT SCALE OFF THIS DRAWING

Drawn By:

Cost Code:

Checked By: Date:

Revision Suffix:

Drawing No.:

Job No.:

Drawing Title:

Scale:

reproduced in any form without the prior written consent of E.P.S. Pumping & Treatment Systems.

This drawing is protected by copyright and must not be

contracts@epsireland.com

022-31250

022-31200

Quartertown Industrial

Co. Cork.

Job Title:

Email:

Phone:

Fax:

Mallow,

Estate,

COPYRIGHT

094-9630761

094-9630226

Mountrath, Co. Laois.

Ballyhaunis, Co. Mayo.

0502-32518

0502-32279

Fax:

Phone:

Phone:

Fax:

QtyItem No. Material Finish

NOTES

2.

4.

1.

BOOSTER SETS

POWERBOOST FLOW-V

CR RANGE

LC0000046

*PB0010*

*PB0010*

TOS

27/05/2016

LC0000046

Sheet 1 of 2

N.T.S.

123

FINISH:

MATERIAL :

ELEVATION

Inlet Manifold

6

POWER

BOOST

by EPS Group

Electrical Installation

The POWERBOOST unit is designed for professional installation and should be connected by a

suitably qualied electrician in accordance with the latest IEE regulations.

Ensure that the electrical supply is fully isolated before removing any electrical covers. The

POWERBOOST unit must be earthed and it is recommended that an RCD is tted on the incoming

electrical supply.

Single phase Powerboost units are suitable for voltage supply 230 +/- 10%.The supply cable should

be sized POWERBOOST to its required length allowing for voltage drop with all pumps running

simultaneously and protected by a suitable MCB or fuse.

Wiring Connections

The POWERBOOST unit has provision for an external level switch input and a volt free general

alarm output (BMS connection). Connections for these features are made within the main wiring

box as per the diagrams below.

FLOW-V

Connect incoming power to RCD

Terminals 1 & 2 -

Normally Closed alarm output

Terminals 3 & 4 -

Level switch input, to be looped out if not required

Commissioning

1. Make a visual check to ensure all pipe work and electrical connections are connected in a

safe manner.

2. Ensure the supply tank is suciently full and the pumps have been de-aerated.

3. Ensure that the closest outlet to the booster set is open to allow water to ow once the set

is turned on.

4. Check the main discharge valve after the outlet manifold is closed and all other valves are

fully open.

7

POWER

BOOST

by EPS Group

5. Turn on the power supply to the controllers and press the start button on the controllers.

6. Slowly open the discharge valve on the booster unit to gradually ll the delivery main.

7. Once water is owing from the nearest outlet, check the pipe work around the set for leaks.

8. Working away from the set, open each outlet in turn until water ows to purge air from the

system.

9. When all the air has been purged, close all outlets. The pump set will shut off within 10

seconds after building up pressure in the system.

10. The POWERBOOST unit is factory set as per the details on the pump specication page.

11 Please see controller specic instructions for guidance on how to chance the Pressure cut in

and cut out settings of your booster unit if required.

Pressure Vessel

The air pre-charge in the pressure vessel should be set 65% of the pre-set working pressure for maximum

effectiveness. It is recommended to check the tank air pressure every 4-6 months. The vessel can be

charged with an air source via an inlet valve. The pressure can be checked using a suitable pressure

gauge. Air can be added or released as required in order to adjust the percentage of pressure.

In order to check the air pressure in the vessel, it is necessary to release the pressure in the vessel

To do this:

1. The isolation valve below the vessel must rst be closed

2. The drain valve is opened to release water pressure

3. The air pressure is tested with a suitable gauge at the air valve

4. Add or release air depending on the pressure reading

5. When the pressure has been adjusted, close the drain valve and open the isolation valve to

return the set to service

ELEVATION

END VIEW

END VIEW

PLAN

ISOMETRIC

SHORT

MIDDLE

LONG

IF IN DOUBT ASK DO NOT SCALE OFF THIS DRAWING

Title:

Client:

FLOW THRU ISOLATION VALVE

CLEAN WATER BOOSTER SETS

COPYRIGHT

This drawing is protected by copyright and must not be

reproduced in any form without the prior written consent of US.

Isolation Valve

Drain Valve

8

POWER

BOOST

by EPS Group

Pump Specication

Pump

Power Amps Per Pump Factory Maximum

kW HP 230V 400V Cut In System

Pressure Flow Pressure

4CR80 0.55 0.75 3.4 2 2 3 80 5.2

5CR80 0.75 1 4.3 2.5 3 4 80 6.7

4CR100 0.75 1 4.5 2.6 2 3 100 5.0

5CR100 1.1 1.5 4.2 2.4 3 4 100 6.3

4CR200 1.5 2 7.3 4.2 3 4 200 5.8

5CR200 1.8 2.5 9.4 5.4 4 5 200 7.3

6CR200 2.2 3 10.2 5.9 5 6 200 8.7

Flow V Variable Speed

9

POWER

BOOST

by EPS Group

Starting up: Steadypres

Switch on power to controller

and wait the STARTING time

(approx. 10 sec.)

By pressing START STOP you

put the inverter IN SERVICE

or OUT OF SERVICE.

To increase 0.1 bar press

SIMULTANEOUSLY

To decrease 0.1 bar press

SIMULTANEOUSLY

ENTER

ENTER

P 3.2

P 3.3

P 3.1

Set pressure quick adjustment: Steadypres

Light Signals: Steadypres

Keyboard

ON OFF BLINKING

STATUS

POWER

STEADYPRES does not detect power supply. WARNING: cannot

guarantee the absence of power supply, the electronic board

may be faulty, but under tension

STATUS

POWER

STEADYPRES is live, but the pump is not running (STANDBY)

STATUS

POWER

STEADYPRES is live, and the pump is running

STATUS

POWER

STEADYPRES is live, but out of serivce; the re-arm is only manual

STATUS

POWER

is only manual STEADYPRES is in ALARM mode, re-arm

Controller Speci c Instructions & Troubleshooting

+

+

10

POWER

BOOST

by EPS Group

Controller Specic Instructions & Troubleshooting

Alarms: Steadypres

OVER

CURRENT %

The current exceeded the allowable tolerance on the current set. The inverter

stops the pump, the rearm is only manual.

CURRENT

LIMIT

Occurs if, in the absence of ow, the pump cannot reach the SET pressure, but can

reach at least a pre-determined percentage of the SET pressure, dened through the

parameter Pd. The inventer does not stop the pump.

I DRY

(Only with ow

sensor)

Occurs if, in the absence of ow, the pump cannot reach the SET pressure, but can

reach at least a pre-determined percentage of the SET pressure, dened through

the parameter Pd. The inventer does not stop the pump.

DRY

RUNNING

(applications WITH

ow Sensor)

Occurs if, in the absence of ow, the pump falls to reach the pressure of the set but

does not even reach a predeterminded percentage of the SET pressure, expressed

by the parameter Pd; the inverter stops the pump . The error is reset after the time TP

and the inventer re-starts in automatic mode.

DRY

RUNNING PF

(only T/T models)

Occurs if the electrical parameter COSFI (power factor) falls to value indicating the

unload operation of engine. the inverter stops the pump. the error is reset after the

time TP.

LOW PRESS Occurs if the pump is running at maximum frequency (50/60 Hz), in the presence

of ow, and the pressure doesn’t reach 0.3 bar; the inverter stops the pump. the

error is reset after the time TP and the inverter re-starts in automatic mode.

VOLTLAGE

ERROR L

A voltage drop has occurred beyond minimum operating threshold. The inverter

stops the pump. The error is reset after one minute, and the inverter re-starts in

automatic mode.

HIGH TEMP.

BOX

(Only T/T models)

The temperature inside the inverter has reached 65°C; is automatically limited

the maximum frequency of 5 Hz but the drive continues to run, the error is reset

below 60°C.

OVER TEMP.

BOX

(Only T/T models)

The temperature Inside the Inverter has reached 80°C, the inverter stops the

pump, the error is reset below 60°C and the drive will restart automatically.

HIGH TEMP.

MOD

The module temperature has reached the rst alarm threshold; the maximum

working frequency is automatically limited, but the drive continues to run, the

error is reset when the module temperature returns below 70°C.

OVER TEMP.

MOD

The module temperature has reached the second alarm threshold, the inverter

stops the pump, the error is reset when the module temperature returns below

70°C and the drive will restart automatically.

INPUT

ERROR

There has been a reversal of the power connections / output to the motor . the in-

verter is locked, the error is reset by connecting the cables correctly in the terminal.

COM ERROR Communication has been interrupted between the control board and the power

board; the cause could be integrity of the cable and the connection ports or an

electronic board fault.

PHASE

ERROR

(Only for models with three-phase output) lack of phase towards the motor during

operation. The inverter stops the pump; reset is manual only.

LOW LEVEL This occurs when the digital input EL is congured as“WATER LEVEL” (level signal)

and there is no signal. When the signal returns, the message disappereas and the

inverter operates normally again.

EXT OFF This occurs when the digital input EL is congured as “EXT ENABLE” (control

enabled from outside) and there is no signal. When the signal returns (external

enabling) the message disappears and the inverter operates normally again.

11

POWER

BOOST

by EPS Group

We, EPS Group

of Mallow Business and Technology Park

Quartertown

Mallow

Co Cork P51 AC94

Telephone: +353 (22) 31200

Email: info@epswater.ie

Hereby declare that:

Equipment: POWERBOOST PRO E, PRO S, & FLOW V Ranges

Model : All standard models

in accordance with the following Directives:

• Machinery Directive 2006/42/EU

• EMC Directive 2014/30/EU

is in conformity with the applicable requirements of the following documents:

• ISO 12100 (Safety of machinery — General principles for design — Risk assessment and risk reduction)

I hereby declare that the equipment above has been designed, assembled, and tested to comply

with the relevant section of the above referenced specications. The unit complies with all essential

requirements of the directives.

The Technical File is maintained at:

EPS Group

Mallow Business and Technology Park

Quartertown

Mallow

Co Cork P51 AC94

Telephone: +353 (22) 31200

Email: info@epswater.ie

DECLARATION OF CONFORMITY

PLEASE KEEP THIS DOCUMENT IN A SAFE PLACE

Signed:

Managing Director, EPS

Date:

02/01/2020

POWERBOOST

by EPS Group

IRL & NI

powerboost.ie

info@powerboost.ie

094 963 3500 (IRL)

028 9181 8347 (NI)

UK

power-boost.co.uk

01543 415200

This manual suits for next models

2

Table of contents

Popular Water System manuals by other brands

Hellenbrand

Hellenbrand Promate 6.0-DMT brochure

AdEdge

AdEdge Residential Drinking Water System Installation instructions operations manual

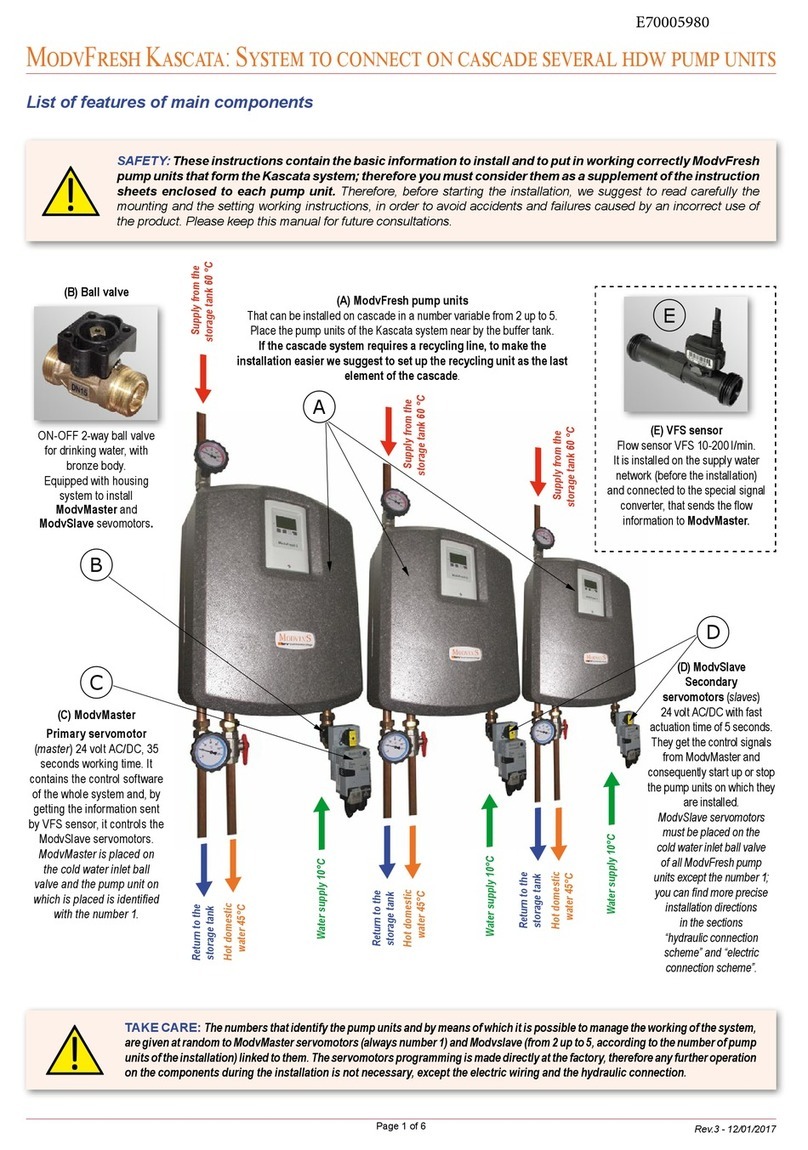

ModvlvS

ModvlvS Kascata manual

IXOM

IXOM SolarBee SB10000 owner's manual

ICA

ICA AQUA OCEAN AQ4000 instruction manual

Watts

Watts 909 Series INSTRUCTION, INSTALLATION, MAINTENANCE AND REPAIR MANUAL