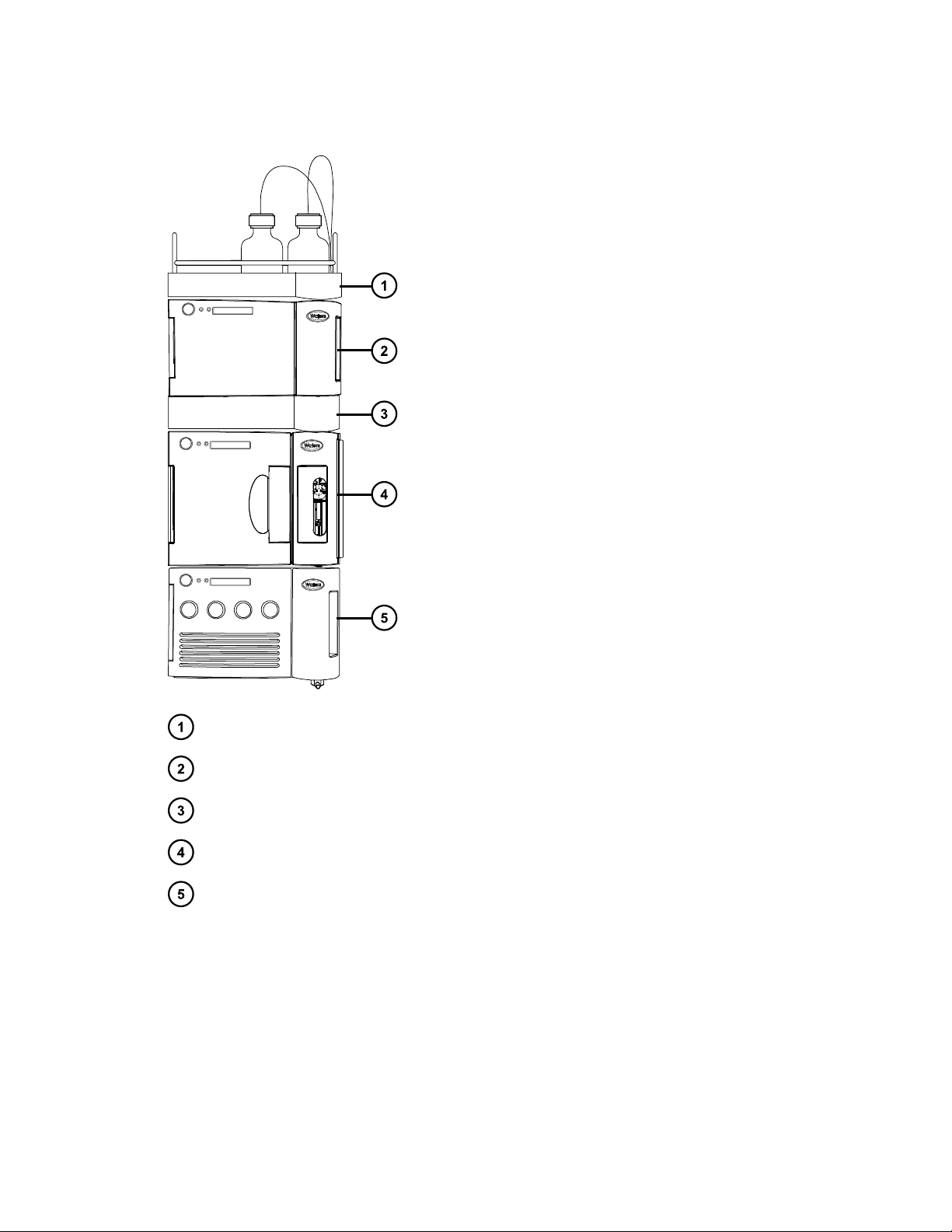

1.3.2 Sample manager-flow through needle.................................................................................20

1.3.3 Column heater .....................................................................................................................21

1.3.4 Column manager (optional) .................................................................................................21

1.3.5 Sample organizer (optional).................................................................................................22

1.3.6 Detection..............................................................................................................................22

1.3.7 Local Console Controller (optional) .....................................................................................23

1.3.8 FlexCart (optional) ...............................................................................................................23

1.3.9 Column technology..............................................................................................................23

1.4 For additional information..............................................................................................................24

2 Performance optimization........................................................................................26

2.1 General guidelines ........................................................................................................................26

2.1.1 Follow these general recommendations when performing a UPLC analysis.......................27

2.2 Dispersion .....................................................................................................................................28

2.3 Carryover ......................................................................................................................................28

2.4 Cycle time (between injections) ....................................................................................................29

2.5 Preventing leaks............................................................................................................................29

2.5.1 Installation recommendations for fittings .............................................................................30

2.6 Developing methods .....................................................................................................................41

2.7 Sample preparation.......................................................................................................................41

2.7.1 Particulates..........................................................................................................................41

2.7.2 Matching sample diluents ....................................................................................................42

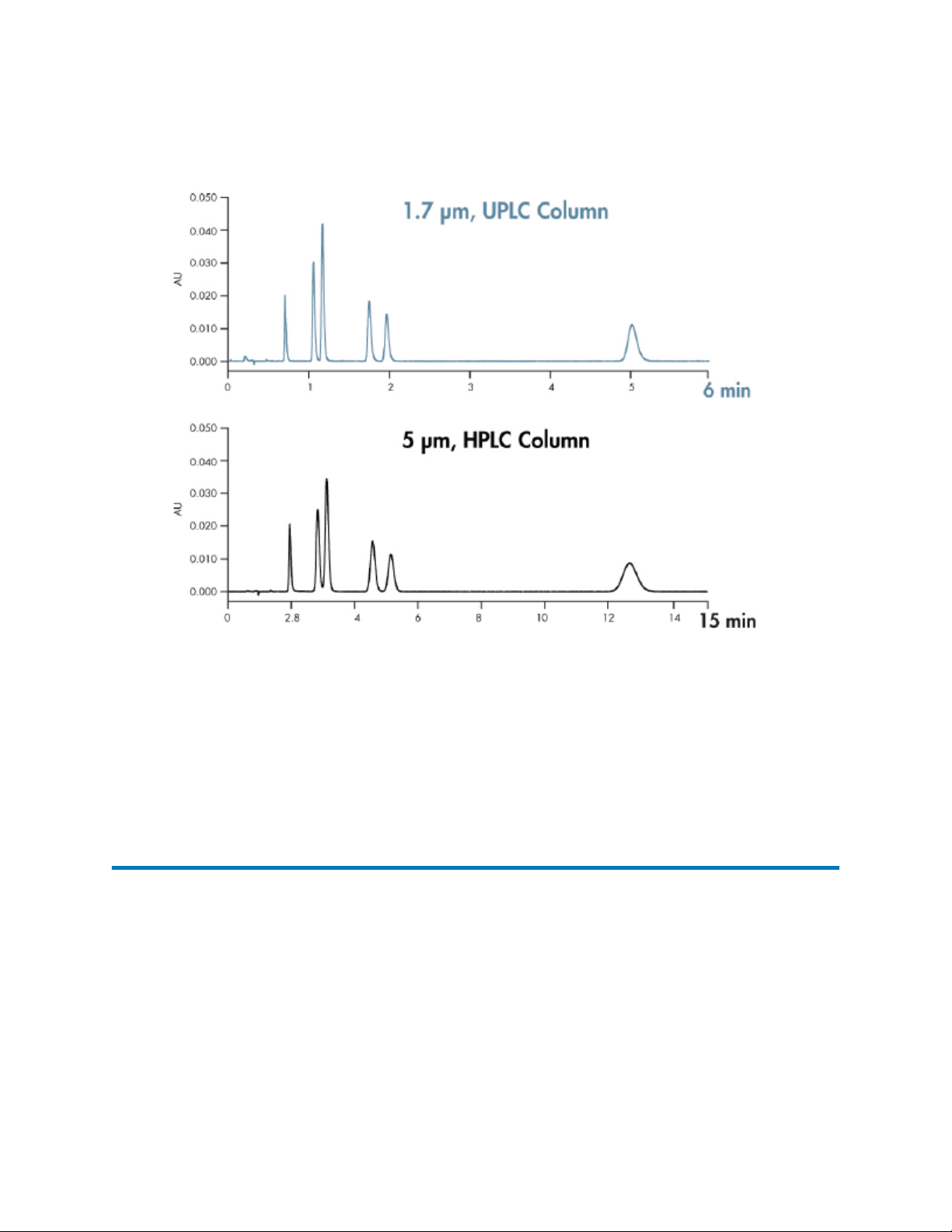

2.8 Transferring methods ....................................................................................................................42

2.8.1 Columns calculator .............................................................................................................44

2.8.2 Transferring from HPLC to UPLC........................................................................................44

2.8.3 Transferring from UPLC to HPLC........................................................................................44

3 System preparation ..................................................................................................46

3.1 Powering-on the system................................................................................................................46

3.2 Opening the console .....................................................................................................................47

3.2.1 To open the console from Empower software .....................................................................47

3.2.2 To open the console from MassLynx software ....................................................................47

3.2.3 To open the console from UNIFI software...........................................................................48

3.3 Priming the system........................................................................................................................48

August 8, 2016, 715005049 Rev. C

Page x