ERL Aquamist HFS3-v3.2 User manual

Page 1

Page 2

HFS3

-

v

3.2

F-IDC tracking PWM water injection system

User manual -v3.2

N:104004on

Whats new on Aquamist HF 3-v3.2 pwm system (August 2022)

The latest v3.2 systems are now shipped with the all new DD 4-v2 dash gauge. It com-

prises the following technical enhancements.

1. Captures and holds peak flow rate

2. hows clear failsafe window settings automatically

3. uper smooth gauge dimming adjustment

4. IDC pre-scaler extended to x6 for E85 integration

5. Accepts inline 5V adaptor for powering external MAP sensor *

6. Decoder for new tank fluid level and temperature with the new multi-level sensor **

* Inline Adaptor is sold separately (available 3rd qtr of 2022)

** Multi-level tank sensor sold separately (designed for 5/10L aquamist tanks, available

3rd qtr of 2022)

Aquamist has been pioneering the IDC (injector duty cycle) tracking water injection system

with constant pressure/PWM inline valve for the last 20 years with great effect. This offers

precise engine load mirroring, resulting in seamless integration with the factory fuel

delivery system. Little or no tuning is required. Very high quality components are part of

the package.

PWM

Page 4

Page 3

Contents:

ystem Check Page

4 Checking the contents of the box

5 Getting started on the installation

Installation

6 Installation for long-term reliability

7 Generic wiring diagram for HF -3

8-9 Choosing jet sizes

ystem testing

10 HF -3 function directory

11-12 Quick tart & manual testing

Gauge

13 Flow management and other trimmers

14 Preparation for test run of the system

Dash gauge

15-16 DD 4-V2 Dash Gauge functions

Fail-safe

17-19 etting up the fail-safe

Advanced

20-21

HF 3-v3.2 extended flow options

22 Trouble shooting guides

Appendix

23 Appendix, Guarantee and Warranty

Checking the contents of the box carefully

This is a “must do” immediately

after unpacking ....

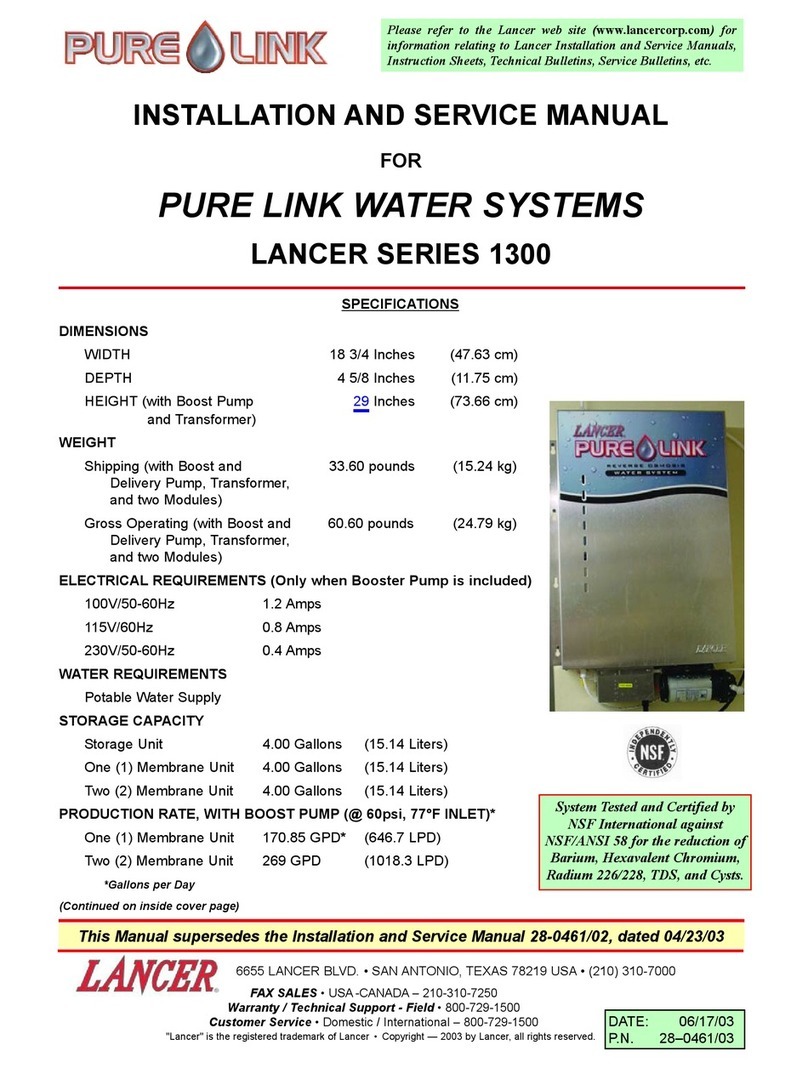

Water pump

Water pumpWater pump

Water pump

Unpack the corrugated sheet carefully. The pump

should be labelled with the original custom

Aquatec/Aquamist logo.

The white box

The white boxThe white box

The white box

♦ 6 of 6mm OD nylon hose (806-261)

♦ 2 of 4mm OD nylon hose (806-266)

♦ HFS-3 Flow Control odule

♦ 0.8 mm water jet (806-323) in plastic bag

♦ 0.9 mm water jet (806-324) in plastic bag

♦ 1.0 mm water jet (806-325) in plastic bag

♦ 1x 4mm Tee compression fitting (806-395) in

plastic bag (new for v3.1 on kit)

♦ 2x 8 x 1/8 NPT jet adapter with plug (806-

357N)l

♦ x water tank adapter 1/8 BSP (806-270), 6mm

compression fitting and in-tank filter (806-258)

♦ 4x 5x40mm bolt, washers and fasteners for pump

♦ 1x 6 grounding stud with washer and nuts and

6mm eyelet for pump ground.

♦ 2x 6mm to 1/8 BSP compression fitting for pump..

♦ 2x 3/8BSP- to 1/8BSP-F reducer for pump.

♦ 1x 4mm to 1/8 BSP compression fitting for FAV.

♦ 1x 6mm to 1/8 BSP compression fitting for FAV.

♦ Water pump harness. 6 of #12 AWG cable and

6 of multi-core cable with blue harness.

♦ 1x Fast acting valve with red harness

♦ 1x flow sensor with yellow harness (HFS-3 only)

♦ 1x water level switch with connector (806-281c)

♦ 1x DDS3v12 Gauge & 1.5 x 8-way cable (HFS-3

only)

♦ 1x Dash button with 6-way cable (HFS-2 only)

♦

1.5 of multi-core with grey capped RJ48 for

. ECU interface, fail-safe and map switching.

♦ olex type 4-way power in harness

♦ Green harness for Direct injection engines (v3).

♦ User manual (on request only for D-I engines)

Note: Please contact your supplier immediately should you discover any missing parts.

Page 5

Getting started on installation

Before installation guidelines

Before installation guidelinesBefore installation guidelines

Before installation guidelines

♦ The pump and water tank are designed to be

fitted in the trunk. Install the water pump below

the water tank if possible.

♦ Ensure all fittings are tightened and leak proof

before filling up with methanol, test it with water

test it with water test it with water

test it with water

first

firstfirst

first.

..

. If a high concentration of methanol mix is

used, please vent the tank’s breather hole exter-

nally. ethanol is poisonous when inhaled.

Assembling the pump in steps

Assembling the pump in steps Assembling the pump in steps

Assembling the pump in steps

♦ Gently assemble the two 3/8 BSP adapters into

the pump without crossing the threads. Ensure

the o-ring is properly seated between the fitting

and the I/O port. Do not over-tighten.

Water tank components

Water tank componentsWater tank components

Water tank components

♦ Ensure the outlet is facing the rear or the side of

the tank. Drill/bore a burr-free 23mm hole. Clear

up all the burred edges and wash the tank thor-

oughly. No debris or plastic shavings should re-

main in the delivery system. 1-2 inches from the

bottom of the tank is ideal.

♦ Screw fit the in-tank filter on the inlet side of the

tank adaptor, insert the assembly into the tank

and tighten the 16 plastic nut. Stop the assem-

bly from rotating with a 6mm allen key into the

centre of the assembly. Do not over tighten to

avoid splitting the rubber gasket seal.

♦

Drill the same hole size for the water level sensor.

IF using a washer tank for supply, do not locate

the Aquamist float sensor near the stock washer

pump. The float arm should swing upwards.

♦

A tall and slim water tank is ideal for this type of

application. This minimises delivery surge prob-

lems at low water level.

Page 6

Installation for long-term reliability

This is the most important section of the HFS-2/3

This is the most important section of the HFS-2/3 This is the most important section of the HFS-2/3

This is the most important section of the HFS-2/3

chapter. Please do not skip reading this part.

chapter. Please do not skip reading this part. chapter. Please do not skip reading this part.

chapter. Please do not skip reading this part.

52mm Dash Gauge (HFS-3 only):

52mm Dash Gauge (HFS-3 only): 52mm Dash Gauge (HFS-3 only):

52mm Dash Gauge (HFS-3 only):

Location is not too critical as long as it is in view of

the driver. There aren’t too many pitfalls on this.

HFS-3 controller box:

HFS-3 controller box:HFS-3 controller box:

HFS-3 controller box:

Please locate the box in a dry location in the passen-

ger compartment. The glove box is a good place.

Please allow plenty of slack to ease accessibility

during tuning and diagnostic work.

Fast acting valve and flow sensor assembly (FAV):

Fast acting valve and flow sensor assembly (FAV):Fast acting valve and flow sensor assembly (FAV):

Fast acting valve and flow sensor assembly (FAV):

The location of this module is most critical to overall

system reliability. It is designed to be installed in the

engine compartment.

This module must be installed in a cool, dry and well

ventilated area away from any heat source. The

bulkhead/fire wall is not always a good location as

most heat is flowing towards it during driving. Avoid

locations near any electromagnetic components

such as the ignition coil, solenoid valves and elec-

tronic motors. It is very important that the hose is

cut cleanly with a razor blade to retain the “round-

ness”. The use of side cutters produces a semi-

round hose end, resulting in a major leak sooner or

later. It is also vital that the hose must be cut

perpendicular/square relative to its length. This is

because the compression fitting has a short hose-

tail. An accurate cut will allow maximum grip on the

walls of the hose.

Ensure the thin rubber gasket is placed between the

FAV coil and electrical plug (red harness) before

tightening. Press the clip of the yellow harness into

the centre section of the flow sensor body, Orienta-

tion is not important. Ensure the electrical plug’s

cable outlet is facing downwards. All cables leading

away from the assembly must be looped downwards

to avoid condensed water trickling into the clip and

plug.

The tank level sensor:

The tank level sensor: The tank level sensor:

The tank level sensor:

Drill/bore the same hole size for the water level

sensor. A 23mm burr-free hole must be used to

ensure a good seal.

The float arm should swing

upwards.

Check that there is ample room for the

sensor arm to swing before drilling.

A tall and slim

water tank is ideal for this type of

application. This

minimises delivery surge problems at low water

levels.

If the stock washer tank is going to be used, do not

mount the float near the stock washer pump. The

motor magnet

will affect the sensor reading properly.

The sensor can be installed 3/4 way down the tank,

preferably at the rear facing w

all of the tank. Never

over tighten or the seal will split; just tighten enough

to prevent leakage, no more.

.

WATER TANK

IN TRUNK BATTERY+

30A

RELAY

DDP5800

160 PSI BYPASS PUMP

MADE IN USA

BY

AQUATEC

THIS PUMP IS FACTORY SET TO 160PS. DO NOT

ATTEMPT TO INCREASE THE BY-PASS VALVE

PRESSURE OR THE LIFE E PECTANCYWILLBE

GREATLY REDUCED. IT IS NOT RECOMMENDED

TO RUN BEYOND 50% METHANOL BECAUSE OF

FLAMMABILITY AND VAPOUR INHALATION CAN

BE HAZARDOUS TO YOUR HEALTH.

TO FAV ASSEMBLY

TO CONTROLLER

(BLUE HARNESS)

15A FUSE

Page 7

Generic wiring diagram for HF -2/3

Page 8

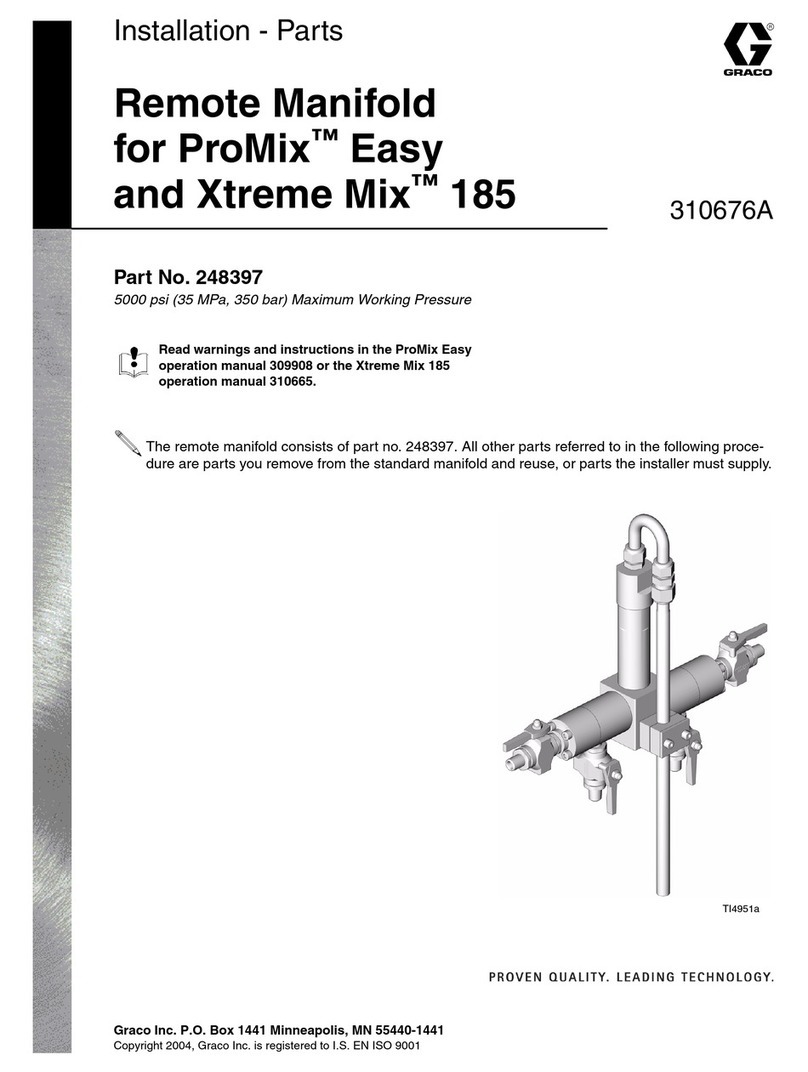

Choosing jet sizes

This is a general guide only:

- 100% water ................................1cc/hp.

- 50:50 methanol/water ............... 1.5cc/hp.

- 100% methanol ............................2cc/hp

Choosing the jet by calculation:

First determine the target HP and multiply the

result by the preferred ratio recommended above.

Pick the nearest jet/jets size to match the flow.

Don’t forget to subtract the boost pressure from

the line pressure of 160psi. For example, if you are

boosting 25psi, you should select the jet flow at

135 psi. Allow 10-15% drop due to system loss.

Alternatively, pump pressure can be increased to

offset the boost pressure with a 1/16“ allen key in

the front of the pump head. 1/2T = ~25psi

Pressure vs Flow

(compensated)

0

50

100

150

200

250

300

350

400

450

500

550

600

6

7

5

00

0

0

760 0 80 90 100 120 130 140 150 160 170 180 190 200

Flow (cc/min)

Pressure (psi)

1.2mm (M7.5)

1.0mm (M6.0)

0.9mm (M5.3)

0.8mm (M4.5)

0.7mm (M3.9)

0.6mm (M3.2)

0.5mm (M2.6)

0.4mm C (M1.9)

0.4mm (M1.5)

0.4mm A (M0.8)

11.4.15

WATER TANK

IN TRUNK

GND

FLOW

ml/m100 20 0 300 4 00

Aquamist

WL W HSC

WATER LEVEL

M

a

d

e

in

E

n

g

la

n

d

W. IN ECTIO N

12V

+

HEAD LAMP

SWITCH

PUMP RELAY & LEVEL SENSOR

FAV & FLOW SENSOR

(ENGINE BAY)

FUEL

INJECTOR(-)

FUEL INJECTOR(+) or

IGN. SW+ (pre-crank)

MAP SENSOR (optional)

DDP5800

160 PSI BYPASS PUMP

MADE IN USA

BY

AQUATEC

THIS PUMP IS FACTORY SET TO 160PS. DO NOT

ATTEMPT TO INCREASE THE BY-PASS VALVE

PRESSURE OR THE LIFE E PECTANCYWILLBE

GREATLY REDUCED. IT I S N OT RECOMMENDED

TO RUN BEYOND 50% METHANOL BECAUSE OF

FLAMMABILITY AND VAPOUR INHALATION CAN

BE HAZARDOUS TO YOUR HEALTH.

FLOW

806-239

FAST

ACTING

VALVE

FAST ACTING VALVE

AND TURBINE FLOW

SENSOR ASSEMBLY

+12V 15A

(fused and

switched)

30A

RELAY

15A FUSE

DASH GAUGE

(DDS4v2)

33OHM 7W

K1C12H

COIL 12VDC

3A 30VDC/125VAC

K1C12H

COIL 12VDC

3A 30VDC/125VAC

5A FUSE

POWER

FAV USER

v3.2

Page 9

Page 10

HF 3-v3.2

1. DASH GAUGE (P.15)

2. 12V, HEAD LIGHT SWITCH and GROUND (P.11)

3. FAST ACTING VALVE in ENGINE AY (P.6)

4. WATER FLOW SENSOR (FAV CLUSTER) (P.6)

5. ECU INTERFACE AND FAILSAFE (P.11/18)

6. WATER TANK and PUMP in TRUNK AREA (P.5)

7. DIRECT INJECTED ENGINES (instructions in bag)

8. SYSTEM CONFIGURATION Y USER (P.12)

9. FLOW & SYSTEM MANAGEMENT TRIMMERS (P.13)

10. IDC PRE-SCALER (P.20)

Since the introdution of the Aquatec 5800 se-

ries pump in 2011, we have received no re-

port on any related issues on running high

ratio of methanol.

Great care and attention must be taken to

ensure the fluid tank is capable of handling

methanol and is designed for this type of appli-

cation. These tanks are normally termed as a

Fuel Cell and are available from most reputable

racing parts suppliers. Follow the maker’s

guidelines carefully.

The breather hole on the tank must be vented

externally with a suitable hose. All fluid deliv-

ery hoses and fittings must be free of all leaks.

Ensure the area is well ventilated and isolated

from the driver’s compartment. Take whatever

measures to avoid any methanol fumes build-

ing up in trunk area.

Using a engineered tank cap with an inbuilt

checkvalve capsule will not alleviate the fume

from escaping out of the tank and into the

cabin area. This is because pure methanol has

a saturated vapour pressure of 2psi+ at 22C

(70F) and over 4psi @35C (95F). It is most likely the cabin

will reach those temperatures

on a hot day or parked on an

open air car park under the sun.

Higher crack pressure caps will

only allow several psi of pres-

sure trapped in the tank and

may causing leaks or cracking...

For this reasons, please vent

the tank to the outside of the

cabin. ethanol fume is odour-

less and extremely toxic when inhaled.

ethanol is highly flammabl

ethanol is highly flammablethanol is highly flammabl

ethanol is highly flammable

ee

e

. The main delivery hose to

the engine bay should be routed underneath the car. En-

sure it is securely clipped and fastened. Avoid kinks and

close proximity of moving parts and heat producing compo-

nents. Please treat this recommendation seriously. If in

doubt, ask advice from a professional person familiar with

this kind of application. DO NOT take any undue risks. It is

recommended that a suitable fire extinguisher is placed

within easy reach of the driver. All electrical connections

must be properly tightened to avoid spark production.

Managing Methanol usage on the system

33OHM 7W

K1C12H

COIL 12VDC

3A 30VDC/125VAC

K1C12H

COIL 12VDC

3A 30VDC/125VAC

5A FUSE

POWER

FAV

USER

2 3 4 5 6 7

v3.2

8

9

10

Quick tart

Page 11

Mechanical work (checklist :

Only after testing with distilled water should

methanol be used. BEFORE hooking up line to

the jet the system should be manually activated

to flush any possibly dirt/debris from the lines.

Wiring work (checklist :

The HFS-3 is pre-configured from the factory.

Plug in the following harness for testing the

power supply into the controller.

1. 4-way Power-in connector:

1. 4-way Power-in connector: 1. 4-way Power-in connector:

1. 4-way Power-in connector:

- Red ................ Switched 12V (IGN SW#2)

- Black ............... Chassis ground

- White .............. Chassis ground

- Purple .............. Head lamp switch (optional)

2. Signal to the grey RJ48 connector:

2. Signal to the grey RJ48 connector:2. Signal to the grey RJ48 connector:

2. Signal to the grey RJ48 connector:

- Red ................. Ignition switched 12V

- Green ............. Fuel injector (-) pin

- Blue .................. AP sensor (optional)

3. grey flat cable to the Dash Gauge

3. grey flat cable to the Dash Gauge 3. grey flat cable to the Dash Gauge

3. grey flat cable to the Dash Gauge

Power-up procedure:

Please follow this procedure “strictly” or per-

manent damage to the system may result. Do

not SKIP

SKIPSKIP

SKIP any steps please....

1. Ignition key on the “OFF” or “0” position:

1. Ignition key on the “OFF” or “0” position:1. Ignition key on the “OFF” or “0” position:

1. Ignition key on the “OFF” or “0” position:

- Dash Gauge button is depressed (system on)

- No leds should be lit anywhere.

2. Ignition key on the “ACC” or “#1” position:

2. Ignition key on the “ACC” or “#1” position:2. Ignition key on the “ACC” or “#1” position:

2. Ignition key on the “ACC” or “#1” position:

Absolutely no change, same as the above conditions.

3. Ignition key on the “pre-cranking” or “#2” position:

3. Ignition key on the “pre-cranking” or “#2” position:3. Ignition key on the “pre-cranking” or “#2” position:

3. Ignition key on the “pre-cranking” or “#2” position:

- Do not crank. Observe the gauge and controller leds

- Yellow led on the gauge will stay lit for 5-10s before

the rest of the gauge lights up.

4. Start the engine and let it idle for a minute or so:

4. Start the engine and let it idle for a minute or so: 4. Start the engine and let it idle for a minute or so:

4. Start the engine and let it idle for a minute or so:

- The green led on the controller should flicker

- The flicker should speed up with engine speed.

- If the system behaves as stated above, you have

successfully wired up the HFS-3!

Now plug in the rest of the harnesses:

Now plug in the rest of the harnesses:Now plug in the rest of the harnesses:

Now plug in the rest of the harnesses:

- The “S” led should confirm the presence of the flow

sensor.

- The yellow led will activate if the tank level is low.

This completes the basic system test. The next stage

will be testing the system manually by using the

jumper links on the controller board. You will need a

small 3/32“slotted screw driver. .

Page 12

Quick tart - ystem setting and manual testing.

Knowing the default controller functions:

(function explained from left to right)

(function explained from left to right) (function explained from left to right)

(function explained from left to right)

1.TRIG:

The system is set to be triggered by IDC (fuel injec-

tor duty cycle) % from factory. The alternative trigger

mode is PS ( anifold Pressure Sensor). Flow will

be progressive depends on “ ODE” setting.

2. MODE:

- PW mode (factory default):

PW mode (factory default): PW mode (factory default):

PW mode (factory default): Flow can be progres-

sive with IDC, Boost or Both (P20.4).

-

--

- SSG (single stage) mode:

SSG (single stage) mode:SSG (single stage) mode:

SSG (single stage) mode: “all on” or “all off”

3. ON: Enabled FAV (default) or disable FAV.

4. PRK: Parking for unused jumper link.

5. M. TEST:

- FDC:

- FDC:- FDC:

- FDC: Link to display F-IDC on gauge (testing only)

- BAR

- BAR- BAR

- BAR: Link to test bargraph with the “SC” trimmer.

- SYS:

- SYS:- SYS:

- SYS: This link can be used to activate the pump only

for the purpose of priming the system. Unlink the #3

(FAV) to disable FAV to avoid hydro-lock.

6. CEL:

Boost cut without CEL (check engine light) activa-

tion. This is only used in conjunction with internal

relay fail-safe output. DR1 = No CEL.

7. SET FAIL SAFE:

- CLP (factory default):

- CLP (factory default):- CLP (factory default):

- CLP (factory default):

Output voltage is clipped

from 8V to 5V.

- FS0 (factory default):

- FS0 (factory default):- FS0 (factory default):

- FS0 (factory default):

Fail-safe output to ground

upon activation.

- FS1

- FS1- FS1

- FS1

: Fail-safe output switches from 0 to 5V or 8V

upon activation.

(this fail-safe output option is on the orange wire of

the grey harness.

-

DHB (defaut=linked)

DHB (defaut=linked)DHB (defaut=linked)

DHB (defaut=linked)

:“Disable High Boost“. When

the gauge is switched off, all fail-safe outputs be-

come activated. This safe guards any engine dam-

age. If the DHB is ”unlinked“, the yellow LED

(water level) will be lit when the gauge is switched

off, giving the user a reminder that the engine is not

protected againist ”High Boost“.

- DFS (defaut=unlinked)

DFS (defaut=unlinked)DFS (defaut=unlinked)

DFS (defaut=unlinked)

:“Disable Fail-Safe“. Link to

stop all fail-safe activation during test or preliminary

test run prior to finalizing fail-safe window. .

8. DEFAULT:

Factory default setting (gold dots)

1 2 3 4 5 6 7

8

Page 13

Flow management and other trimmers

Setting the onboard trimmers:

(default=12 o’clock

The system

The system The system

The system requires no trimming from

the factory. If the user wants to alter the

flow and other parameters, just use a

small screw driver to complete the task.

Below are the working details of each

trimmer. (left to right).

1. LED panel:

Three leds monitor the real time opera-

tion of the system,

- Green (F-IDC):

- Green (F-IDC): - Green (F-IDC):

- Green (F-IDC): Blinks upon successful

detection of fuel injector duty cycle sig-

nal. The blink rate and brightness in-

crease with engine speed and duty

cycle respectively.

- Amber (THRES):

- Amber (THRES): - Amber (THRES):

- Amber (THRES): At 42% F-IDC (de-

fault), this led will activate, confirming

the system is triggered and delivery

commences.

- Red (95% DC):

- Red (95% DC):- Red (95% DC):

- Red (95% DC):

When the water/methanol duty cycle is

approaching 95%, The red led begins to turn on, indicating that

you have almost reached the maximum flow of your system.

ore flow requires additional jets.

2. Trimmers for fine tuning:

- THRES:

- THRES: - THRES:

- THRES: Factory set to 42%, User adjustment range is be-

tween 12-72%.

- GAIN:

- GAIN:- GAIN:

- GAIN: User can define the slope of water/

methanol relative to F-IDC from -25 to

300%. The factory slope is set to 1:1 ratio

of fuel duty cycle. Useful tool to compen-

sate low F-IDC when large fuel injector is

used. It can also be used to trim flow at

high F-IDC.

- FS-DL:

- FS-DL: - FS-DL:

- FS-DL:

Fail-safe delay

to undue fail-safe activation due to

spike and noise signal from the flow sensor. The factory

default setting (12-o’clock) is 400mS (milli-second). User ad-

justable between 200mS to 600mS.

- DI :

- DI :- DI :

- DI :

This trimmer works in conjunction with the head lamp

switch. When it sees a 12V signal, the trimmer becomes

active. This coincides with night drive conditions. The high-

intensity led used on the dash gauge is too bright for night

motoring. so wiring in the “purple wire” from the 4-way power

plug to the head lamp switch is essential. Do not wire it to the

car’s interior dimming circuit or unexpected results may occur.

Page 14

Preparation for a test run of the system

1. First step - system check list:

a.

a.a.

a. Tank and pump is fully secured and leak free.

b.

b.b.

b. The FAV assembly is securely located in a cool

and dry spot of the engine bay.

c.

c.c.

c. The controller is accessible and can be secured

down with minimum movement during motoring,

d.

d.d.

d. The jets are securely installed in the inlet tract.

e.

e.e.

e. Dash gauge installed.

2. Priming and purging of the system:

a.

a.a.

a. Fill up the tank with water half way.

b.

b.b.

b. Disconnect the 6mm hose from the FAV assem-

bly and put the hose into a container securely.

c.

c. c.

c. Ignition switch in pre-crank position and gauge is

switched on.

Uncover the controller and pull out the

“FAV” jumper (disabling the FAV) and put it to the

link marked “SYS”. The pump should power up and

water should come out of the 6mm hose within a

few seconds, Let it run for a 10-20 seconds so that

trapped air and debris are purged.

d.

d.d.

d. Listen to the pump during the priming period; it

should go very quiet after completion of purging

procedure. If not, repeat step “c”.

e.

e. e.

e. Upon successful completion of the above, rein-

state the 6mm hose into FAV assembly.

3. Testing the spray pattern of the jets:

a.

a.a.

a.

Secure an unused jet onto the windscreen and

connect it to the outlet port of the FAV assembly.

b.

b.b.

b.

Activate the system by linking up “ FAV” (default)

and “SYS” on the controller. You should see an instant

full-cone spray at the jet. Do it for a few seconds only.

You can repeat the test with the remaining jets. At the

same time the gauge should register a few bars.

Remove the “SYS” test link.

4. Activate the system by F-IDC:

a.

a.a.

a.

Set the far left trimmer to fully counter-clockwise.

Crank the engine and leave it to idle, you should see

the blinking green led on the controller board.

b.

b.b.

b.

Blip the accelerator paddle sharply to induce an

artificial load. The amber led should respond. A faint

but noticeable spray should develop at the jet.

5. Road test the system:

Still with jet on windscreen, make a short drive and

confirm the spray is progressive with load. After a

successful road test, reconnect the hose to the inter-

nal spray jets. This concludes the system test,

The system is ready for the next stage - fail-safe

setting. At anytime if there is a problem, please con-

tact us.

W AT E R F L O W

FUEL FLOW

+200%

-25%

IDC GAIN

trip point

95%

MAX

Dash Gauge Functions cont.

9. Under-range setting potentiometer (WL

This setting can indicate partial blockage and trapped

air inside a delivery hose. Again a 20-stepped poten-

tiometer is used. Each click represents a fixed por-

tion of the window width of 8-bars. Gauge will show

setting status in real time during adjustment.

10. Over-range setting potentiometer (WH

It is just as important to monitor over-range condi-

tions as well as under-range flow conditions. If a leak

develops close to the water jet and starves the

engine of the water, the user must know this condi-

tion. A 20-stepped potentiometer allows accurate

and repeatable adjustment range. Gauge will display

the setting status during adjustment.

WL covers the lower 4 bars of the display and the

WH covers the upper 4 bars. Figure on the right

illustrates the span of the coverage. Setting is very

simple once SC is calibrated.

NOTE:

NOTE:NOTE:

NOTE:

In order to make the

fail-safe adjustment

easier, it is recom-

mended to set the bar-

graph to display 5-6

bars at maximum

flow. This way, the

fail-safe window can

span from the centre

outwards.

If the WL and WH is set at 12 O’clock, the fail-safe

window width is approximately spanned between

3-7 bars. This is a good starting point.

inor trimming for the WL is necessary if the water

injection trigger point is set to commence earlier.

Recap:

1. “B” led

1. “B” led1. “B” led

1. “B” led

(right of the bargraph) will only stay

activated if the flow is inside the fail-safe window

during injection period, unless the DFS (Disable

Failsafe jumper is linked reminder)

2. The two “yellow” leds

2. The two “yellow” leds2. The two “yellow” leds

2. The two “yellow” leds

Both leds will activate

when fail-safe is triggered. Only the lower led illumi-

nates during low tank level.

As soon as the “fail-safe” is tripped, there will be a

3 second reset period before it reset while the

fail-safe drops boost.

When gauge is switched off, expect low boost and

safe map unless the DHB jumper is unlinked.

Please use the failsafe option offered as even your

application is not water/methanol critical.

WL WH

failsafe window width

coverage (20-clicks)

page16

Knowing DD 4-v2 Dash Gauge

1. 8-element Bargraph (0-100% Fullscale

Each segment is equivalent to a fixed percentage of

the total flow of the sensor scaled by the SC poten-

tiometer.

2. “S” indicates flow sensor connected.

The letter “S” (sensor) must be lit after power up

and stay on to show the flow sensor cable is con-

nected and on-standby.

3 Fail-safe activation LED (normally off

This LED turns on at approximately the same time

as the lower LED (water level) when failsafe is

triggered. Otherwise stays off at all time. This helps

to identify between low tank level and true failsafe

activation.

4. Water level LED (normally off

This LED will only activate when tank level is at its

lowest. Remains on until tank is refilled (even system

is turned off). It also prevents the system from turning

on If it stays on if tank level is high, it merely reminds

the users the DHB jumper is unlinked

5. SC (Sensor Calibration - default table

Scaling the flow sensor to display 5-6 bar during nor-

mal motoring. Treat this as an indictor similar to a n

engine temperature gauge. Hi-res output can be read

from yellow wire on the ‘USER’ port.

6. Backlit legend

Legend displays % of full scale of 8-bars

7. “B” High Boost Enabled LED

Stays on at when system is operating normally after

triggering. It also stays on if the DFS jumper is linked

at all time, reminding failsafe is disabled.

8. System on/off button (monentary

This multi-function button will access future upgrades

1.

1.1.

1.

Hold 3-4s to switch on the system, subsequent

short press will turn off the system immediately.

2.

2.2.

2.

Once system is turned on, this button can access

the multi-level tank sensor**. Press and hold to initi-

ate count down sequence from full 8 bars to 1.

a)

a)a)

a)

release at 7th bar displays fluid levels in the tank on

gauge (8-levels).

b)

b)b)

b) release at 6th bar displays water temperature be-

tween -30C to +40C on gauge “0”C on 4th bar.

** Sold separatelty.

1

2

3

4

5

6

7

8

9

10

Page 15

Page 17

etting up the fail-safe

etting up the alternative Fail-safe Channels

Page 18

1. The MAP Switching Channel:

The orange wire from the grey RJ48 connector is

a voltage based AP Switching for an ECU

equipped with this input. This wire is factory config-

ured to send out a voltage of 4.7V DC under a “no

fault ” condition, from idle to full boost. This volt-

age will switch to 0v upon a fail-safe activation or

the gauge is switched off.

Other voltages such as 0, 5V or 8V can be user

configured. This is by far the most effective

method to save your engine from lack of water

injection. A jumper link can invert the AP switch

output if necessary.

Although it is simple and convenient to use a

single wire to communicate a fail-safe activation, this can

only be achieved “as long as” the system is powered up

properly. The alternative way is to use the on-board relay

to convey a fail-safe activation since the relay will guaran-

tee a “make or break” circuit when system’s power is

lost or a blown system fuse.

2. Change-over relay: (HFS-3

The HFS-3 has an onboard relay to supply a set of

voltage-free, change-over contacts for the sole use of

fail-safe activation. It can be used to perform various

tasks to save your engine. Contact rated up to 1 amp.

Please

Please Please

Please refer to page 19 for full switching se-

quence under various conditions.

Example1: OE boost control valve (BCV):

Example1: OE boost control valve (BCV): Example1: OE boost control valve (BCV):

Example1: OE boost control valve (BCV):

Disabling the OE boost control valve.

“Cut and splice” the boost control cir-

cuit. White to “ECU side”. Brown to

“BCV side”. You will need to link the

“Anti-CEL” option on page 12.6 to avoid

the onset of CEL during fail-safe activa-

tion. Dummy resistor replaces the BCV.

Example 2: (third party boost controllers)

Example 2: (third party boost controllers) Example 2: (third party boost controllers)

Example 2: (third party boost controllers)

Disabling the third party electronic boost

control system. “Cut and splice” the

pulsed wire to the BCV. White to the

“Controller” and Brown to the “BCV”

side.

This option will not work with EBC (Elec-

tronic Boost controller) utilizing a stepper

motor to control boost. HKS-EVC is such an ex-

ample. Use the AC valve option on page 17.

Note: During the initial testing period soon after

Note: During the initial testing period soon after Note: During the initial testing period soon after

Note: During the initial testing period soon after

the installation, you can disable the fail-safe from

the installation, you can disable the fail-safe from the installation, you can disable the fail-safe from

the installation, you can disable the fail-safe from

activation by connecting the “DFS” (Disable Fail

activation by connecting the “DFS” (Disable Fail activation by connecting the “DFS” (Disable Fail

activation by connecting the “DFS” (Disable Fail

Safe) jumper link.

Safe) jumper link.Safe) jumper link.

Safe) jumper link.

orange

LACK

ROWN

WHITE

This final stage should be quick, simple and

effective. Please read it before proceeding.

It will save you time in the long run.

If fluid flow falls inside the fail-safe detection window

after triggering, no action will be taken. Setting up

the width of the window to accommodate the full

fluid flow is vital.

Setting up the fail-safe should only be done after the

Setting up the fail-safe should only be done after the Setting up the fail-safe should only be done after the

Setting up the fail-safe should only be done after the

car has been tuned or the jet/jets sizes are finalized

car has been tuned or the jet/jets sizes are finalizedcar has been tuned or the jet/jets sizes are finalized

car has been tuned or the jet/jets sizes are finalized.

Recommended steps to set up the fail-safe:

Recommended steps to set up the fail-safe:Recommended steps to set up the fail-safe:

Recommended steps to set up the fail-safe:

1. Adjust the “SC” to display 6 bars at manual test.

jJets are placed outside the engine to avoid hydrolock.

2. Rinstate jet/s into the engine. ental note the

number of bars displayed on the at spool up & WOT.

3. Set the WL to match the number of spool-up bars.

It is recommended to allow 2-3 clicks below that

point to avoid false triggering. Full span of WL is

20 clicks, covering from 0 bar to 4 bars.

4. Same procedure is used to set up the WH, allow-

ing 2-3 clicks above 6 bars. Full span of WH is 20

clicks covering 4-8 bars.

This completes the fail-safe set-up ...

Options after the fail-safe is triggered:

The most common way to minimize engine damage

in the absence of injection is to reduce the boost

pressure.

1.

For engines with an electronic boost control

For engines with an electronic boost control For engines with an electronic boost control

For engines with an electronic boost control

valve

valvevalve

valve:

The grey harness contains a set of relay

contacts that goes open circuit when the fail-safe is

triggered. See page 18 and 19 for more details.

2. For engines with BC (manual boost controller):

For engines with BC (manual boost controller):For engines with BC (manual boost controller):

For engines with BC (manual boost controller):

The onboard fail-safe relay can be used to control a

3-port solenoid valve to by-pass the BC or a step-

per motor type of boost controller. Essentially, this

directs full boost to the wastegate.

3.

3.3.

3.

For an engine with AP switching capabilities:

For an engine with AP switching capabilities:For an engine with AP switching capabilities:

For an engine with AP switching capabilities:

The orange wire on the grey connector has a dedi-

cated output to perform such a task. This pin can be

user configured to match the signal requirement of

the “third party” ECU to switch AP. See page

18-1 for more details. This pin is factory configured

to give a 5V for “OK” and “0v” is “flow fault”

aximum current of this output is 5mA.

Page 19

Page 20

Relay Fail-safe output switching tables

Fail-safe relay output truth table:

Fail-safe relay output truth table:Fail-safe relay output truth table:

Fail-safe relay output truth table:

The above table is created to simplify the fail-safe

relay switching status under all circumstances.

White, Brown and Black wires are located in the

grey harness. The relay contacts are capable of

switching 1A@30V continuous and 3A pulsed due

to the 24awg wires used.

Based on the table above, you can use these con-

tacts to either connect or disconnect electro-

mechanical components such as a wastegate con-

trol valve or third party fail-safe devices. The con-

tacts are gold flashed so it can be used for low

current signal switching.

GAUGE ON

IGNITION @ PRE-CRANK/RUN

GAUGE ON (NOT TRIGGERED)

IGNITION @ PRE-CRANK/RUN

GAUGE ON (TRIGGERED)

FLOW INSIDE FAILSAFE WINDOW

GAUGE ON (TRIGGERED)

FLOW OUTSIDE FAILSAFE WINDOW

GAUGE ON (FAILSAFE TRIGGERED)

RESET AFTER ~3 SECONDS

GAUGE OFF

IGN.SW @ PRE-CRANK/RUN

IGN.SW - ACCESSORY

IGNITION SW. KEY - OUT

NORMAL SYSTEM OPERATION

FAIL SAFE ACTIVATED

DH LINKED

(DEFAULT)

DH UNLINKED DFS LINKED

DFS UN-LINKED

(DEFAULT)

WHITE ROWN

LACK

WHITE ROWN

LACK

WHITE ROWN

LACK

WHITE ROWN

LACK WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE ROWN

LACK

WHITE ROWN

LACK

WHITE ROWN

LACK

WHITE ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

WHITE

ROWN

LACK

1

2

3

4

5

6

7

8

LACK

ROWN

WHITE

Advanced system configurations (optional)

1. System configuration (factory use

1. System configuration (factory use1. System configuration (factory use

1. System configuration (factory use

Reserved

ReservedReserved

Reserved

2. Rescale flow signal output:

Solder link this a reduce the flow signal by 50%

Solder link this a reduce the flow signal by 50%Solder link this a reduce the flow signal by 50%

Solder link this a reduce the flow signal by 50%

3. IDC signal detection polarity:

3. IDC signal detection polarity:3. IDC signal detection polarity:

3. IDC signal detection polarity:

Solder link to change edge detection to positive.

Solder link to change edge detection to positive. Solder link to change edge detection to positive.

Solder link to change edge detection to positive.

4. Configuring 70% IDC & 30% MPS:

(a) 100% IDC:

(a) 100% IDC:(a) 100% IDC:

(a) 100% IDC: system default from factory

(b) 70% IDC / 30% PS:

(b) 70% IDC / 30% PS:(b) 70% IDC / 30% PS:

(b) 70% IDC / 30% PS: If AP sensor signal is

available. Solder link PS.

(c) 100% PS:

(c) 100% PS:(c) 100% PS:

(c) 100% PS: Cut IDC link and solder link PS link.

5.

IDC pre-scaler (topside :

The option allows the

system to match the

incoming IDC signal.

Can be used for oversized

injectors with low duty

cycle. Select x2.5 for all

direct injection engines.

6. Select MAP sensor range:

(a) Absolute:

(a) Absolute: (a) Absolute:

(a) Absolute: This can be used for any

sensors with 0-5V output, such as throttle posi-

tion, mass air flow sensors etc.

(b) 2.5 bar AP sensor:

(b) 2.5 bar AP sensor: (b) 2.5 bar AP sensor:

(b) 2.5 bar AP sensor: Select this link to con-

vert a 2.5 bar AP sensor to read from atmos-

pheric to 22psi full scale 0-5V output.

(c) 3 - 3.5 bar AP sensor (default):

(c) 3 - 3.5 bar AP sensor (default): (c) 3 - 3.5 bar AP sensor (default):

(c) 3 - 3.5 bar AP sensor (default):

Select this link to convert a 3.5 bar AP sensor

to read from atmospheric to 36psi full scale 0-5V

output.

7 Flow map table:

(a)

(a)(a)

(a) Unlinked: two large jets (default).

(b)

(b)(b)

(b). Solder link 1&2 for single jet.

(c)

(c)(c)

(c) Solder link 2&3 for three very large jets .

IN

1 2 3 4 765

x1.00

x4.00

x1.75

x4.75

x2.50

x5.50

x3.25

x6.25

Page 21

Page 22

Trouble shooting

New installation power up issues

(failsafe disabled)

(failsafe disabled)(failsafe disabled)

(failsafe disabled)

1. System does not power up at “pre-crank”:

1. System does not power up at “pre-crank”:1. System does not power up at “pre-crank”:

1. System does not power up at “pre-crank”:

- Check gauge button is depressed

- Check the red wire of the grey harness is con-

nected to a 12V source.

.2. System does not power up at “pre-crank” but

.2. System does not power up at “pre-crank” but .2. System does not power up at “pre-crank” but

.2. System does not power up at “pre-crank” but

water led is lit:

water led is lit:water led is lit:

water led is lit:

- Check water tank level.

- Check level sensor is installed the right way up.

3. System powers up but green led does not blink

3. System powers up but green led does not blink 3. System powers up but green led does not blink

3. System powers up but green led does not blink

with RP :

with RP : with RP :

with RP :

- Check the green wire of the grey harness is spliced

Into the fuel injector’s “pulsed” wire (PI)

- Check the green and red wire of the green harness

is spliced Into the fuel injector’s wires (DI).

.4. THRES led lit on throttle blip but no spray:

.4. THRES led lit on throttle blip but no spray: .4. THRES led lit on throttle blip but no spray:

.4. THRES led lit on throttle blip but no spray:

- “THRES” should be set to fully counterclockwise.

- IDC pre-scaler is set to match PI’s IDC max.

- IDC prescaler is set to x2.5 for DI engines.

.5. Failsafe triggers during acceleration:

.5. Failsafe triggers during acceleration: .5. Failsafe triggers during acceleration:

.5. Failsafe triggers during acceleration:

- Disable failsafe by moving “PRK” jumper to “DFS”

Failsafe should only be set after system is setup and

tuned,

System running issues

(failsafe activated)

(failsafe activated)(failsafe activated)

(failsafe activated)

6. Flow bar display surges and drops:

6. Flow bar display surges and drops:6. Flow bar display surges and drops:

6. Flow bar display surges and drops:

- Reduce hose length to the jet/jets.

7. Failsafe trips at the WOT:

7. Failsafe trips at the WOT:7. Failsafe trips at the WOT:

7. Failsafe trips at the WOT:

- Set gauge’s S/C to only display 5-6 bars at WOT.

- If still trips, set WH clockwise until it settles.

Advance two more clicks.

8. Failsafe trips at the start of acceleration:

8. Failsafe trips at the start of acceleration:8. Failsafe trips at the start of acceleration:

8. Failsafe trips at the start of acceleration:

- IDC prescaler is not set correctly. See #4

You can check the incoming IDC% on the gauge by

linking “FDC” (fuel duty cycle) %

- If it still trips, set gauge’s WL counter-clocwise

until it settles. Advance two more clicks.

- If it still clicks, “THRES” on the controller is set too

low, set it to 10am. Then recal “WL” on the gauge

9. System blanks out during activation:

9. System blanks out during activation: 9. System blanks out during activation:

9. System blanks out during activation:

- Water tank level is dropped below permitted level

for ~20 seconds. System will trigger failsafe. The

system will not reset until the tank is refilled.

The water level led should flash long before this.

HF 3-v3.2 extended flow options

The HFS flow options:

Extensive developments have been made over the last few

years to extend the flow range HFS systems.

We are offering the following options:

We are offering the following options:We are offering the following options:

We are offering the following options:

1. For flowrates up to 1300cc/min there is no need to up-

grade the standard system. It is possible to increase the

160psi pump pressure to 200+ psi by clockwising the set

screw with 1/16“ allen key located at the front of the pump

head. When an audible click is heard, the maximum is

reached. This can be around 220psi depending on flow. It will

increase the standard flow rate to approximately 1500cc/min

2. Beyond 1500cc/min a 1600cc Tee (806-557D) is available.

But must accompany with Hi-flow sensor tube (806-555D.

As above, you can squeeze a bit more, some 50-100cc from

the standard pump. (free at initial purchase)

3. 1 & 2 can further upgraded by acquiring the 3000cc pump

(806-582D). Can maintain 200psi of line pressure, allowing

1800-1900cc of flow. (options with initial system purchase)

4. For those engines run high concentration of methanol and

requires flow rate beyond 1800cc to 3000cc, A large pump

accompanies the twin-FAV module (806-

401) is essential.

This drastically changes the charge-pipe

set up to a multi-port delivery where

charge pipe with large jets can no longer

guarantee even distribution of fluid into

the cylinders evenly.

However you can retain no more than two

small jets at the charge pipe for post-

intercooler charge cooling purposes. Size

of the charge pipe jet should can be the

same as the direct port jet.

Conclusions:

The standard system will support engine

power up to 800hp running 50/W50,

(based on 1.5cc/hp).

Power beyond 800 running 100% metha-

nol (2cc/min) should consider #1-#4 option.

But when making a new order, please

specify your target power goal, we will

supply you with a 1600cc FAV and a Hi-

Flow sensor at no extra cost.

Page 23

GUARANTEE

ERL guarantees, at our option, to replace faulty goods sup-

plied or repair the same, subject to the claim made in writing

to us within 12 months after the sale by us, or for such other

period as may be indicated by us for specific products in lieu

of any warranty or condition implied by law as to the quality

or fitness for any particular purpose of the goods.

Any claim against us must be made to us in writing within

the period of 12 months after the sale by us , or our agents,

or our distributors of goods in question (or such other period

as may be indicated by us) and any goods to which the claim

relates must be returned to us within that period suitably

packaged and cleaned and, with any particular instructions

which we may have notified to you at the time of supply.

Original invoice, the nature of any claimed defect must ac-

company the goods in question prior to despatch to us.

If these requirements are not complied with our Guarantee

shall not apply and we shall be discharged from all liability

arising from the supply of defective goods.

LIABILITY

We shall not be under any liability whether in contract, or

tort or otherwise and whether or not resulting from our neg-

ligence or that of our employees, in respect of defects in

goods supplied or for any damage or loss resulting from

such defects.

We shall not be under any liability for damage, loss of ex-

pense resulting from failures to give advice or information

or giving the incorrect advice or information whether or not

due to our negligence or that of our employees.

In no event shall any breach of contract on our part or tort

(including negligence) or failure of any time on our part that

of our employee give rise to liability for loss of revenue or

consequential loss or damages arising from any cause what-

soever.

Note: ERL reserves the right to make changes to our prod-

ucts without notice in order to improve design performance

and reliability.

ERL ltd Iroko House Bolney Ave Peacehaven East ussex BN10 8HF England

Useful Aquamist technical links

Aquamist owners have been pretty good in supporting each other. ost experienced users will

help new users with questions, not necessary to email or make long distance phone calls and

wait on hold to get help. Here are a list of forum links where users can seek help and advice from

others:

- http://www.waterinjection.info (general)

Page 24

END

ENDEND

END

Appendix

Pin Colour Size Description Electrical parameter

Molex Microfit power harness (1.5 M): Main Power supply and Dimmer control

1 red 20awg +12V Power supply (switched) 250mA max@12v

2 purple 20awg Gauge dimming input to head lamp switch+ 0-5 VDC @10mA

3 white 20awg 0V Ground (signal ground) 250mA max@12v

4 black 20awg 0V Ground (Power ground) -1A @12V max.

Red Harness to Engine bay (2.5M): To Flow Control assembly

1 red 24awg +12V PSU to Fast acting valve 1A max @12v

2 yellow 24awg +12V PSU to Fast acting valve 1A max @12v

3 blue 24awg PWM ground switch to Fast acting valve 1A max @0v

4 black 24awg PWM ground switch to Fast acting valve 1A max @0v

Yellow Harness to Engine bay (2.5M): To Flow Control assembly

1 red 24awg +5V Power supply to Turbine flow sensor 5mA max @5v

2 yellow 24awg Turbine fow sensor signal output 1mA max @5v

3 blue 24awg Feedback signal (return ground) 1mA max @0v

4 black 24awg 0V/ground power supply 1mA max @0v

Grey Harness to EMS (2.5M): IDC/ oost detection and Fail-Safe / Map-Switching interface

1 === 24awg Future extension I/O channel1 ----------------

2 red 24awg Ignition Switching detection 30mA max@12v

3 green 24awg Fuel injection IDC detection 10mA max@12v

4 pink 24awg Map switching interfacing 0, 5V, 7.5V @1mA

5 white 24awg Failsafe Relay contact (COM, Wiper) 1A @24V max.

6 yellow 24awg Reserved for internal communication Signal level

7 blue 24awg Map Sensor Signal input 0-5 VDC @1mA

8 black 24awg Failsafe Relay contact (N/C contact) or DR 1A @24V max.

9 brown 24awg Failsafe Relay contact (N/O contact) 1A @24V max.

10 === 24awg Future extension I/O channel 2 ----------------

lue Harness to Trunk Area (6M):

1 red 24awg +12V Power supply to 40A relay 0.5A max @12v

2 yellow 24awg Water level sensor signal signal ground 0.5A

3 blue 24awg Pump relay activation (ground switch) ----------

4 black 24awg Water level sensor ground ----------

--------------------------------

9 Red 12awg 12V Power cable to water pump relay 38A @12V max.

10 lack 12awg 0v ground for water pump 38A @12V max

Green Harness to EMS (2M): Direct, P&H Injection systems, Common Rail Diesel Interface

1 red 24awg Fuel injector (+) signal detection 600V 8mS dc<50%

2 green 24awg Fuel injector (-) signal detection 600V 8mS dc<50%

3 blue 24awg Spare port for custom interface ------------

4 yellow 24awg Flow sensor signal (analogue 0-5V) 0.5 - 4.5V @1mA

5 white 24awg Water/Methanol IDC monitor (analogue) output 0 - 5V @1ma.

6 black 24awg Signal ground 0.2A max.

Other ERL Water System manuals

Popular Water System manuals by other brands

Everpure

Everpure CG5-20S Replacement Cartridge DEV9108-27 Specification sheet

Everpure

Everpure Quad-MC EV9628-28 Specification sheet

Xylem

Xylem CentriPro Aquavar SOLO 2 Frequently asked questions

HeatLink

HeatLink PEX-a installation guide

Culligan

Culligan MEDALLIST SERIES Service manual

Intex

Intex Krystal Clear Saltwater System owner's manual

Geekpure

Geekpure RO4 Installation and maintenance manual

Elkay

Elkay HATENBOER WATER VRCGNDWS C Series Installation and use manual

Everpure

Everpure QL2-OCS2 Specification sheet

Istore

Istore 180L installation manual

EINHELL

EINHELL 41.731.90 Original operating instructions

Marco

Marco FRIIA HC instruction manual