Equalizer International HT125KM Assembly instructions

HT125KM, FA3TM,

FA6TE

FLANGE ALIGNMENT

TOOLS

Operator Instruction Manual

www.equalizerinternational.com

INNOVATION IN ITS MOST FUNCTIONAL FORM

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 1

SECTION CONTENTS PAGE NO.

1 INTRODUCTION 2

2 SAFETY INFORMATION 3-4

3 TECHNICAL DATA 5

4 FLANGE MISALIGNMENT DETERMINATION PROCEDURE 6

4.1 LATERAL MISALIGNMENT 6

4.2 ROTATIONAL (TWIST) MISALIGNMENT 7

5HT125KM HAND ALIGNMENT TOOL 8-13

5.1 KIT COMPONENTS 8

5.2 HOW THE HT125KM WORKS 8

5.3 INSTALLATION AND OPERATION 9-10

5.4 EXAMINATION, MAINTENANCE AND STORAGE 11

5.5 PARTS LIST 12

5.6 WEIGHTS AND DIMENSIONS 12

5.7 RANGE OF APPLICATION 13

6FA3TM MECHANICAL FIXED FLANGE AND ROTATIONAL ALIGNMENT TOOL 14-21

6.1 KIT COMPONENTS 14

6.2 HOW THE FA3TM WORKS 14

6.3 INSTALLATION AND OPERATION 15-17

6.4 EXAMINATION, MAINTENANCE AND STORAGE 18

6.5 PARTS LIST 19

6.6 WEIGHTS AND DIMENSIONS 20

6.7 TROUBLESHOOTING 21

6.8 RANGE OF APPLICATION 22

7FA6TE HYDRAULIC FIXED FLANGE AND ROTATIONAL ALIGNMENT TOOL 23-31

7.1 KIT COMPONENTS 23

7.2 HOW THE FA6TE WORKS 23

7.3 INSTALLATION AND OPERATION 24-25

7.4 EXAMINATION, MAINTENANCE AND STORAGE 26

7.5 PARTS LISTS 27-28

7.6 WEIGHTS AND DIMENSIONS 29

7.7 TROUBLESHOOTING 30-31

7.8 RANGE OF APPLICATION 32

INDEX

FAT IM REV 02

28.02.08

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 2

The Equalizer HT125KM, FA3TM and FA6TE are aids for use in normal maintenance and

installation procedures, and enable the realignment of misaligned flanges within their

respective working capacities. For example, all of the tools can be used to assist in the

replacement of ring and other types of flange joint. The use of these instructions will

promote safe use, and maximize the service life of the tools. It is recommended that the

operator read the relevant sections of this instruction manual for the particular flange

alignment tool to be used.

1. INTRODUCTION

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 3

2. SAFETY INFORMATION

The operator MUST read this manual prior to using the tools.

Failure to comply with the following cautions and warnings could cause equipment

damage and personal injury; read the manual fully!

Read all the following instructions, warnings and cautions carefully. Follow all safety

precautions to avoid personal injury or property damage during system operation.

Equalizer International Ltd cannot be responsible for damage or injury resulting from unsafe

product use, lack of maintenance or incorrect product and/or system operation. Contact

Equalizer International Ltd when in doubt as to the safety precautions and applications. To

protect your warranty, use only good quality hydraulic oil of the grade 32cSt.

Only people competent in the use of mechanical and hydraulic equipment should use these

tools.

In all installations the site safety requirements must be adhered to. ALSO the safety of the

operator, and when present, any assisting personnel, is of paramount importance along with

the safety of others including, when present, the general public.

These instructions are only to cover the safe operation of THE EQUALIZER HT125KM, FA3TM

AND FA6TE FLANGE ALIGNMENT TOOLS, during normal maintenance/installation operations.

All other safety aspects must be controlled by the operation supervisor.

CAUTION:

1. The tools must not be attached to a pressure vessel nozzle

2. The tools must not be attached to a flange joint prior to

misalignment

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 4

A CAUTION is used to indicate correct operating or maintenance procedures and practices to

prevent damage to, or destruction of equipment or other property.

A WARNING indicates a potential danger that requires correct procedures or practices to avoid

personal injury.

A DANGER is only used when your action or lack of action may cause serious injury or even

death.

IMPORTANT: Operator must be competent in

the use of hydraulic equipment. The operator

must have read and understood all instructions,

safety issues, cautions and warnings before

starting to operate the Equalizer equipment.

WARNING: To avoid personal injury and

possible equipment damage, make sure all

hydraulic components are rated to a safe

working pressure of 700 bar (10,000 psi)

WARNING: Do not overload equipment. Over-

loading causes equipment failure and possible

personal injury.

The risk of overloading can be avoided by using

the Equalizer Hand Pump, which has its safety

valve set to 700 bar by the factory. If alternative

pumps are used, ensure they are rated at a safe

working pressure of 700 bar (10,000 psi).

CAUTION: Make sure that all system compo-

nents are protected from external sources of

damage, such as excessive heat, fl ame, mov-

ing machine parts, sharp edges and corrosive

chemicals.

CAUTION: Avoid sharp bends and kinks that

will cause severe back-up pressure in hoses.

Bends and kinks lead to premature hose failure.

Do not drop heavy objects onto hoses. A sharp

impact may cause internal damage to hose wire

strands; applying pressure to a damaged hose

may cause it to rupture. Do not place heavy

weights on the hoses, or allow vehicles to roll

over the hoses; crush damage will lead to pre-

mature hose failure.

WARNING: Immediately replace worn

or damaged parts with genuine Equalizer

parts. Equalizer parts are designed to fi t

properly and withstand rated loads. For

repair or maintenance service contact your

Equalizer distributor or service centre.

DANGER: To avoid personal injury keep

hands and feet away from the tool and

workpiece during operation.

WARNING: Always wear suitable clothing

and Personal Protective Equipment (PPE).

DANGER: Do not handle pressurised hos-

es. Escaping oil under pressure can pen-

etrate the skin, causing serious injury. If

oil is injected under the skin, seek medical

attention immediately.

WARNING: Never pressurize unconnected

couplers. Only use hydraulic equipment in

a connected system.

IMPORTANT: Do not lift hydraulic equip-

ment by the hoses or couplers. Use the car-

rying handle or other means of safe trans-

port.

CAUTION: Do not operate the equipment

without lubricating all moving parts as in

section 5.4, 6.4 & 7.4. Use only high pres-

sure molybdenum disulphide grease.

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 5

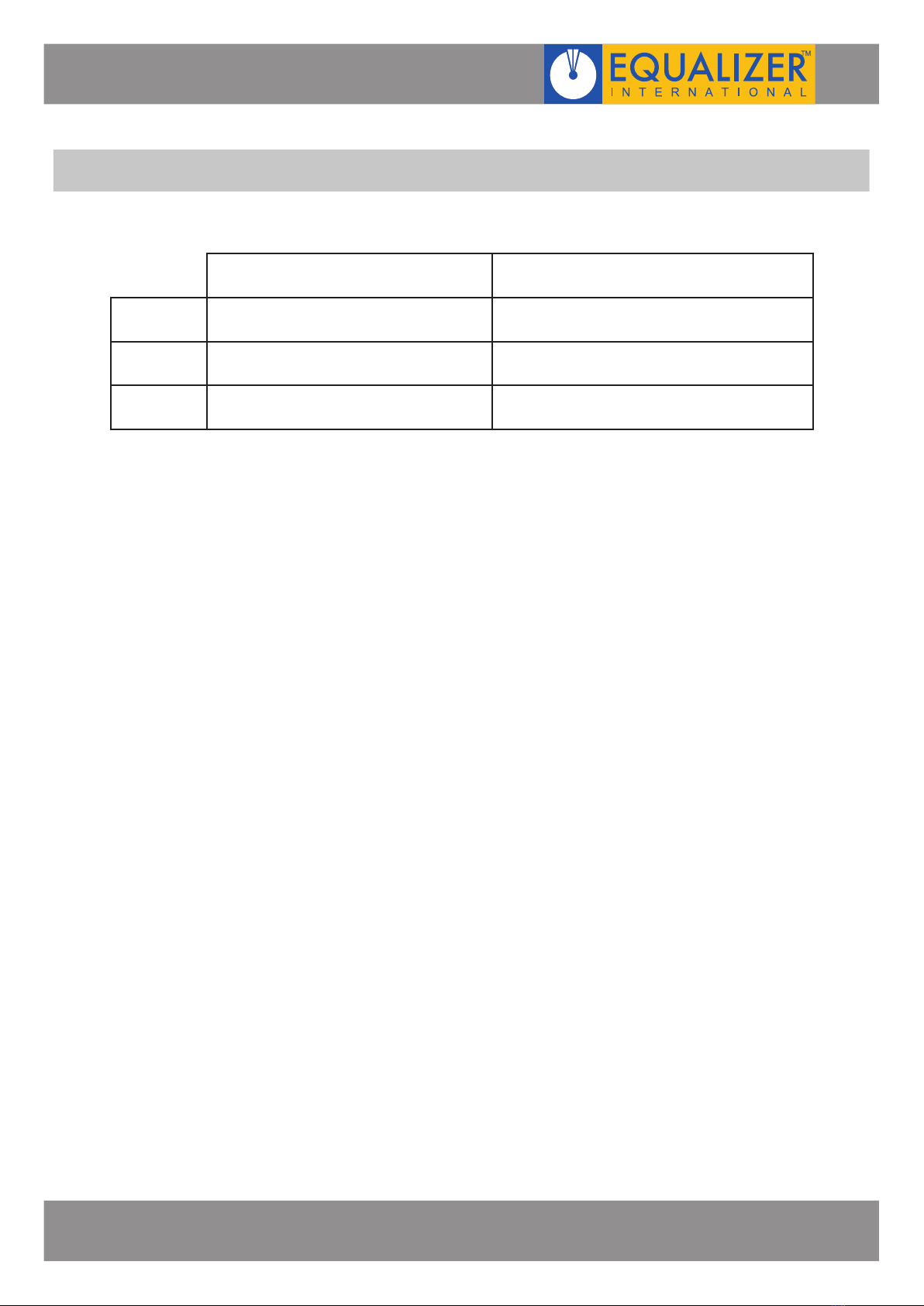

3. TECHNICAL DATA

Tool Description Aligning Force

HT125KM Hand

Alignment Tool

125 kg (275 lbs)

Mechanical Advantage 5 to 1

FA3TM Mechanical

Fixed Flange and Rotational Alignment Tool

3.3 T (33kN)

from 50 ft/lbs (67.8 Nm) of torque

FA6TE Hydraulic

Fixed Flange and Rotational Alignment Tool

6 T (60 kN)

from 10,000 psi (700 bar) of hydraulic pressure

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 6

4. FLANGE MISALIGNMENT DETERMINATION PROCEDURE

The tool being used must not be attached to a flanged joint prior to the misalignment

procedure being carried out.

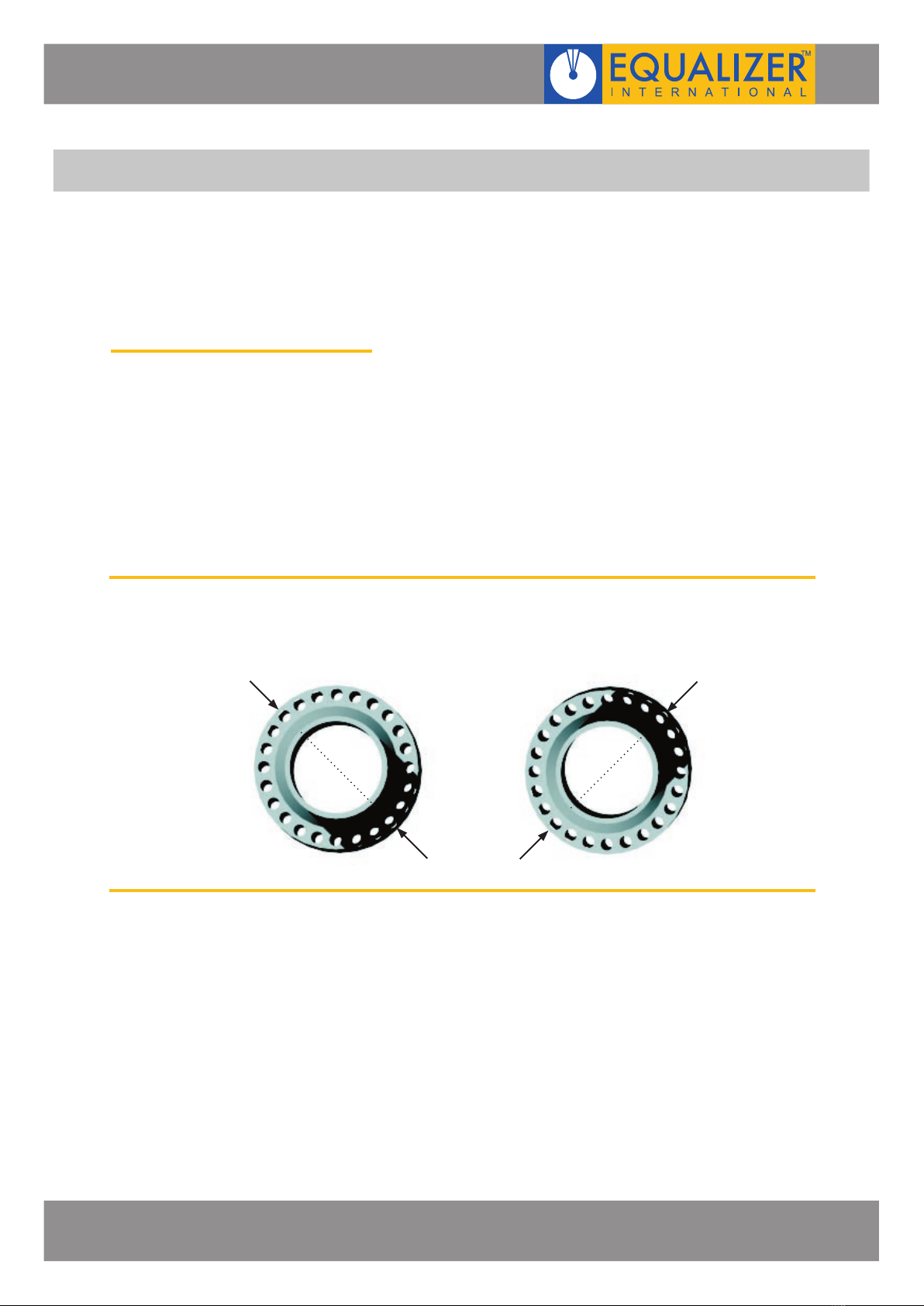

4.1 LATERAL MISALIGNMENT

1. Slacken and remove every second bolt around the flange , continue with this until

misalignment occurs.

A flanged joint, once broken down, may spring out of alignment at any point, or in

any direction around its circumference. Misalignment may not occur until only a few

bolts remain.

2. At this point the direction of any misalignment should become obvious. The

alignment tool being used should be attached at the maximum point of misalignment

(point A or B in the examples shown below) as shown in sections 5.3, 6.3 & 7.3.

POINT A

POINT B POINT A

POINT B

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 7

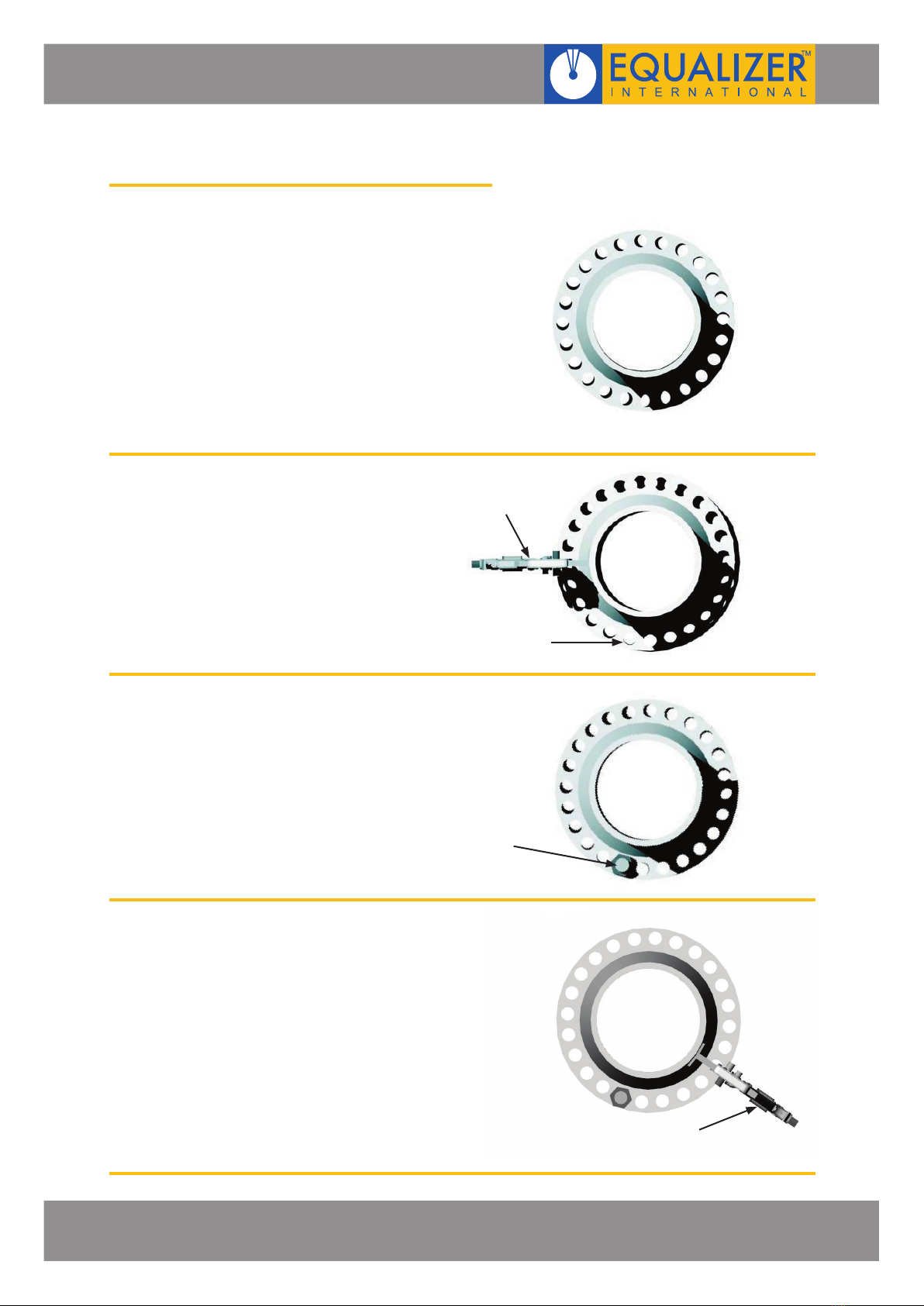

4.2 ROTATIONAL (TWIST) MISALIGNMENT

If the outer circumference of the flanges

are in alignment but the operator is unable

to fit the bolt into any two corresponding

bolt-holes then rotational misalignment may

have occured.

In this case the alignment tool can be

attached to the most accessible point as

misalignment occurs at all bolt-holes to the

same degree.

1. Attach the alignment tool at the

most accessible/convenient point

(as shown in sections 5.3, 6.3 &

7.3) and use it to push the flanges

out of alignment until one pair

of bolt-holes becomes parallel.

2. Insert the bolt into the aligned bolt-

hole and release the alignment tool.

The load will transfer onto the bolt.

3. Repeat steps 1 and 2 at other points

around the flange until all of the

remaining bolt-holes are parallel and

the rest of the bolts can be inserted.

PARALLEL

BOLT-HOLES

BOLT

ALIGNMENT

TOOL

ALIGNMENT

TOOL

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 8

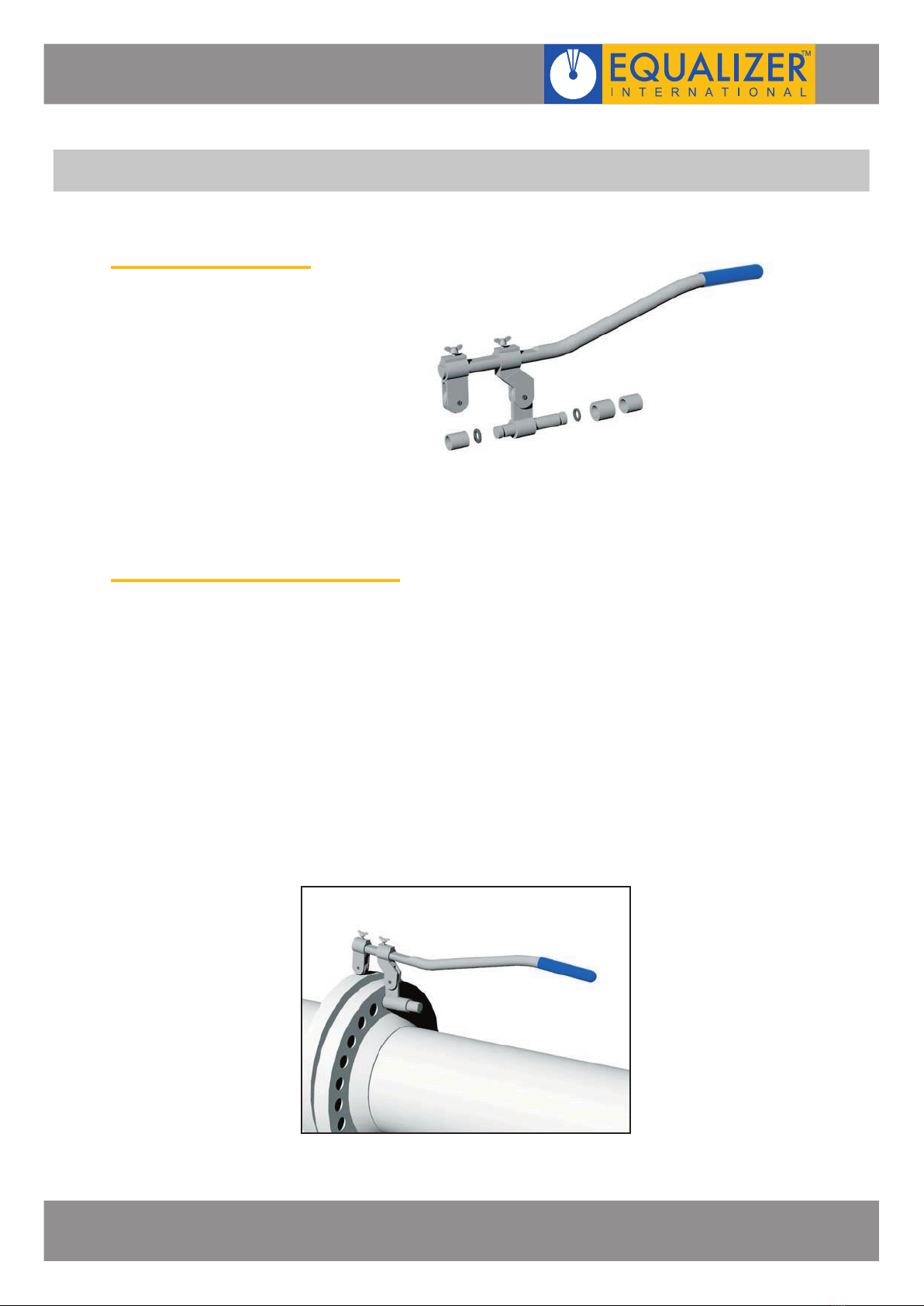

5. HT125KM HAND ALIGNMENT TOOL

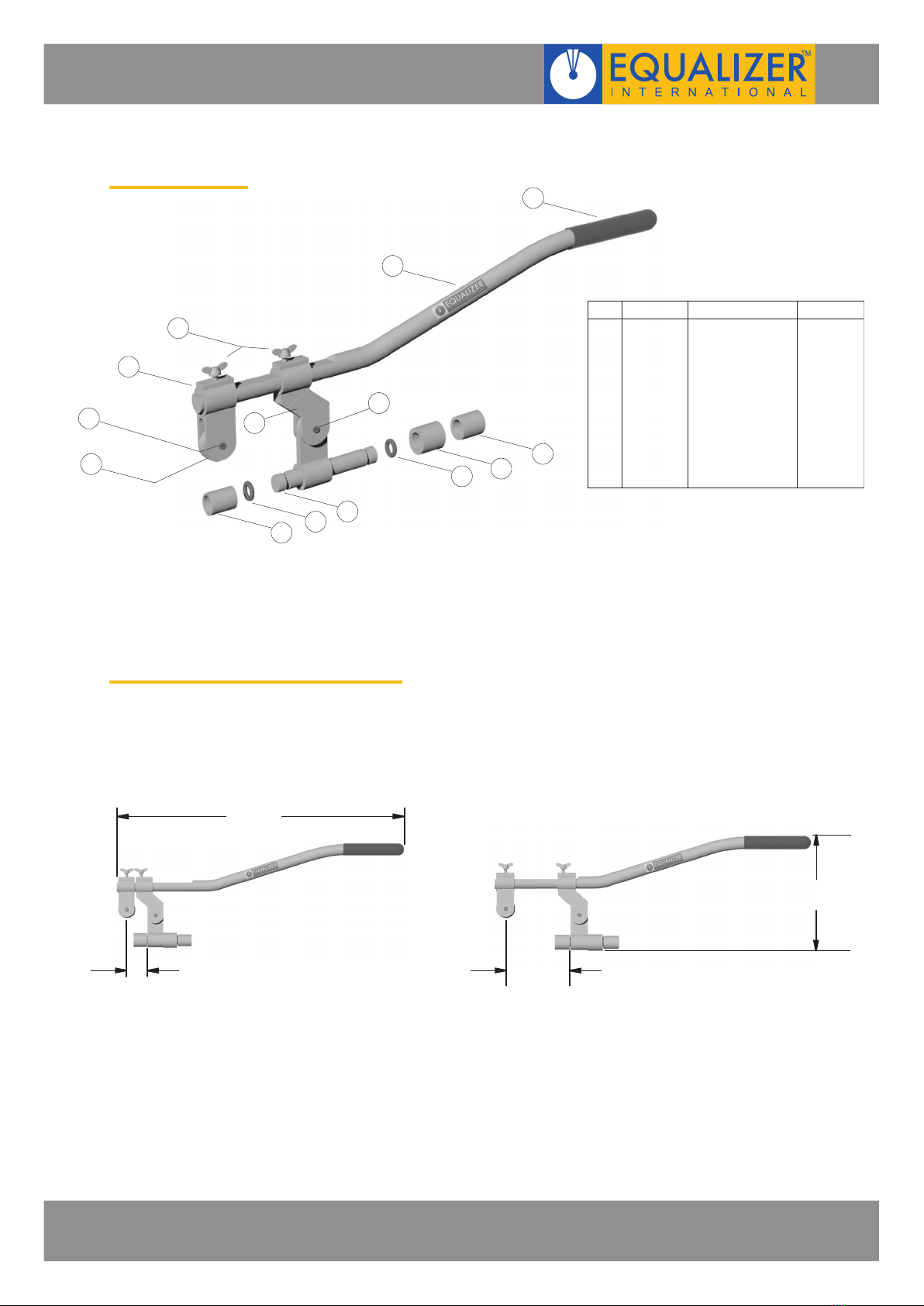

5.1 KIT COMPONENTS

1 x HT125KM Tool

3 x Adaptor Bushes

1 x Instruction Manual

Product Code: HT125KGSTD

5.2 HOW THE HT125KM WORKS

1. The HT125KM is secured to the lower of the two flanges by fully inserting the lift pin

into the bolt-hole which is parallel with the bolt-hole on the opposite flange. This is

where the misalignment is at its greatest point.

2. The counter-balance is adjusted to the desired distance and the butterfly nut is

tightened at the top.

3. The flange can now be levered up into alignment and the bolts inserted.

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 9

5.3 INSTALLATION AND OPERATION

LIFT MODE:

1. Carry out the Flange Misalignment

Determination Procedure (see

section 4) to determine the points

of maximum misalignment.

In this example the points of

maximum misalignment are at the

top and bottom of the joint.

2. From the three bushes, select the

one which best fits the bolt-hole of

the flange requiring alignment.

3. Attach the selected bush onto the

lift pin.

4. Insert the bush/lift pin into the bolt-

hole on the lower flange.

Adjust the lifting assembly or the

counter-balance and tighten the

butterfly nuts.

POINT OF MAX.

MISALIGNMENT

POINT OF MAX.

MISALIGNMENT

BUSH

LIFT

PIN

COUNTER-

BALANCE

LIFTING

ASSEMBLY

BUTTERFLY

NUT

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 10

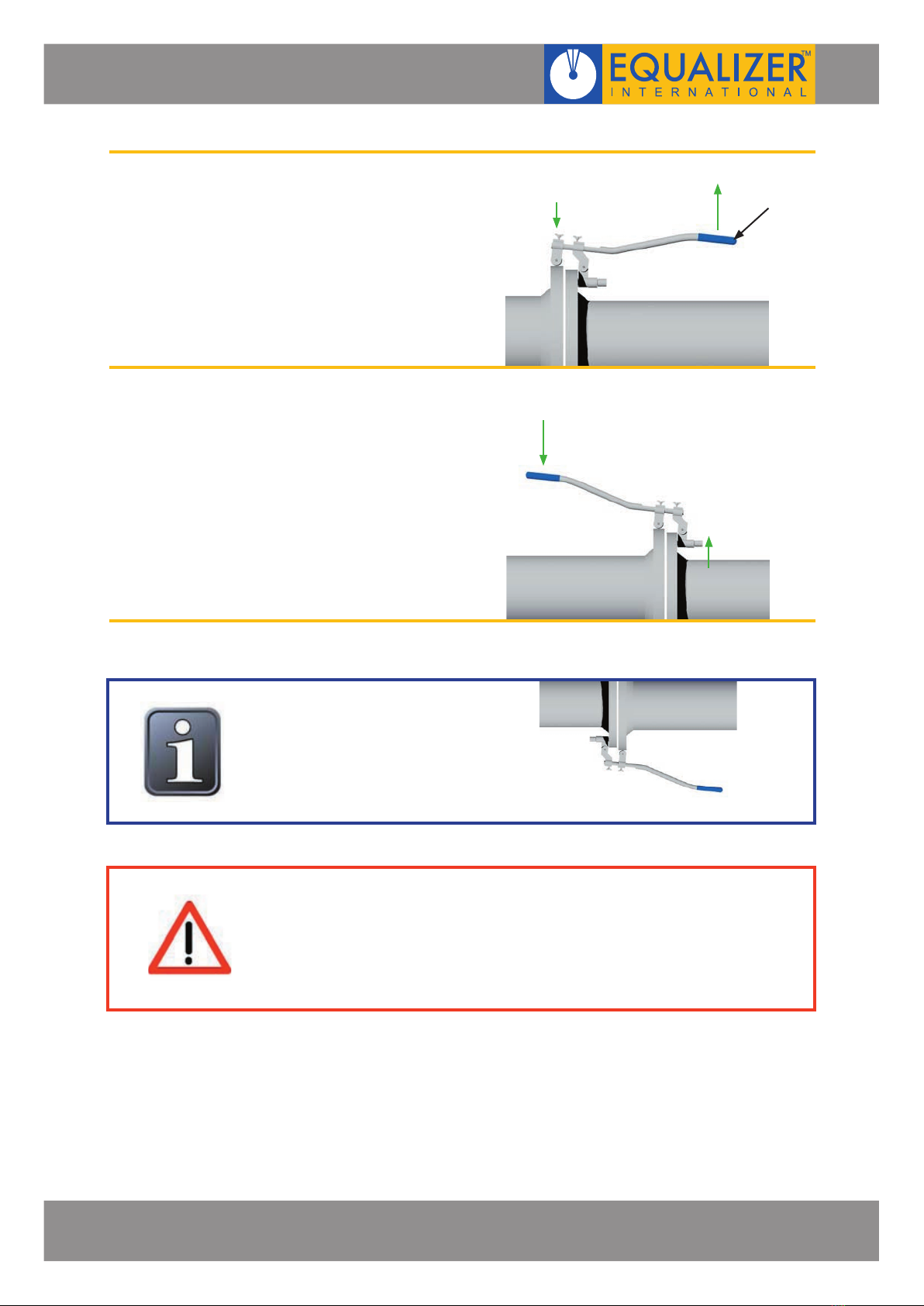

5. Lift up on the handle and the

counter-balance will push down on

the higher flange bringing the joint

into alignment.

PUSH MODE:

By removing the handle from the

lifting assembly and

counter-balance, the handle can be

re-inserted from the opposite side.

Align the joint by pushing down on

the handle.

Care should be taken not to drop any of the component parts when

removing them from the flange joint. This action will prevent injuries to

either the operator’s lower limbs, or to passers-by.

HANDLE

In this example the joint was

being aligned from the top.

However if access were limited

at the top the alignment could

be rectified from the bottom of

the joint

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 11

• On return from each job and before allocation against subsequent work the

completeness of the Equalizer HT125KM kit must be established and items examined

to ensure that they are serviceable

• Any missing or damaged items are to be replaced as soon as possible and prior to the

tool being used again

• Store the HT125KM in a cool dry place and ensure all machined surfaces are greased

• Grease all moving parts regularly

• Ensure the roller remains grit free

5.4 EXAMINATION, MAINTENANCE AND STORAGE

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 12

5.5 PARTS LIST

5.6 WEIGHTS AND DIMENSIONS

01

02

04

05

06

07

08

09

10

10 11

12

13

*

*

*

*

*03 01 each

01 each

01 set of 2

01 each

01 each

01 each

01 each

01 each

01 each

01 set of 2

01 each

01 each

01 each

201201-01

200102-01

200901-02

200202-01

200302-01

201102-01

200502-01

200601-01

200402-01

201001-02

200801-01

200701-01

201401-01

HANDLE SLEEVE-BLUE

MAIN BAR

BUTTERFLY NUT

LIFTING ASSEMBLY

COUNTER-BALANCE

ROLL PIN 3/4”

ROLLER

BUSH A

BOLT-HOLE LEVER

“O” RING

BUSH C

BUSH B

ROLL PIN 1/2”

01

02

03*

04

05

06*

07

08

09

10*

11

12

13*

ITEM PART No. DESCRIPTION QUANTITY

*Repair Kit Part No: 201301-01 with Items 03, 06, 10 & 13

33.0 mm

(1.30")

465 mm

(18.25")

88 mm

(3.46")

230 mm

(9.00")

MINIMUM EXTENSION MAXIMUM EXTENSION

TOOL WEIGHT = 2.0 kg (4.4 lbs)

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 13

5.7 RANGE OF APPLICATION

DN

PN

6

10

16

25

40

64

100

160

pressure

(psi)

150

300

400

600

900

1500

2500

Pin Only = Ø 17.0 mm (.669”)

Bush A = Ø 21.3 mm (.836”)

Bush B = Ø 24.4 mm (.957”)

Bush C = Ø 27.4 mm (1.07”)

Pin Only = Ø 17.0 mm (.669”)

Bush A = Ø 21.3 mm (.836”)

Bush B = Ø 24.4 mm (.957”)

Bush C = Ø 27.4 mm (1.07”)

TABLE A: RANGE OF APPLICATION on ANSI, BS & API FLANGES

TABLE B: RANGE OF APPLICATION on DIN FLANGES

+

+

1/2

3/4

+

+

+

1

+

+

+

1 1/4

+

+

+

1 1/2

+

2

+

+

+

+

2 1/2

+

3

+

3 1/2

+

4

+

5

6

8

10

12

14

16

25

+

+

+

32

+

+

+

+

40

+

+

+

+

50

+

+

+

+

65

+

+

+

+

80

+

+

+

+

+

100

+

+

+

+

+

125

+

+

+

+

+

150

+

200

+

250

+

300

350

400

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 14

6. FA3TM MECHANICAL FIXED FLANGE AND ROTATIONAL ALIGNMENT TOOL

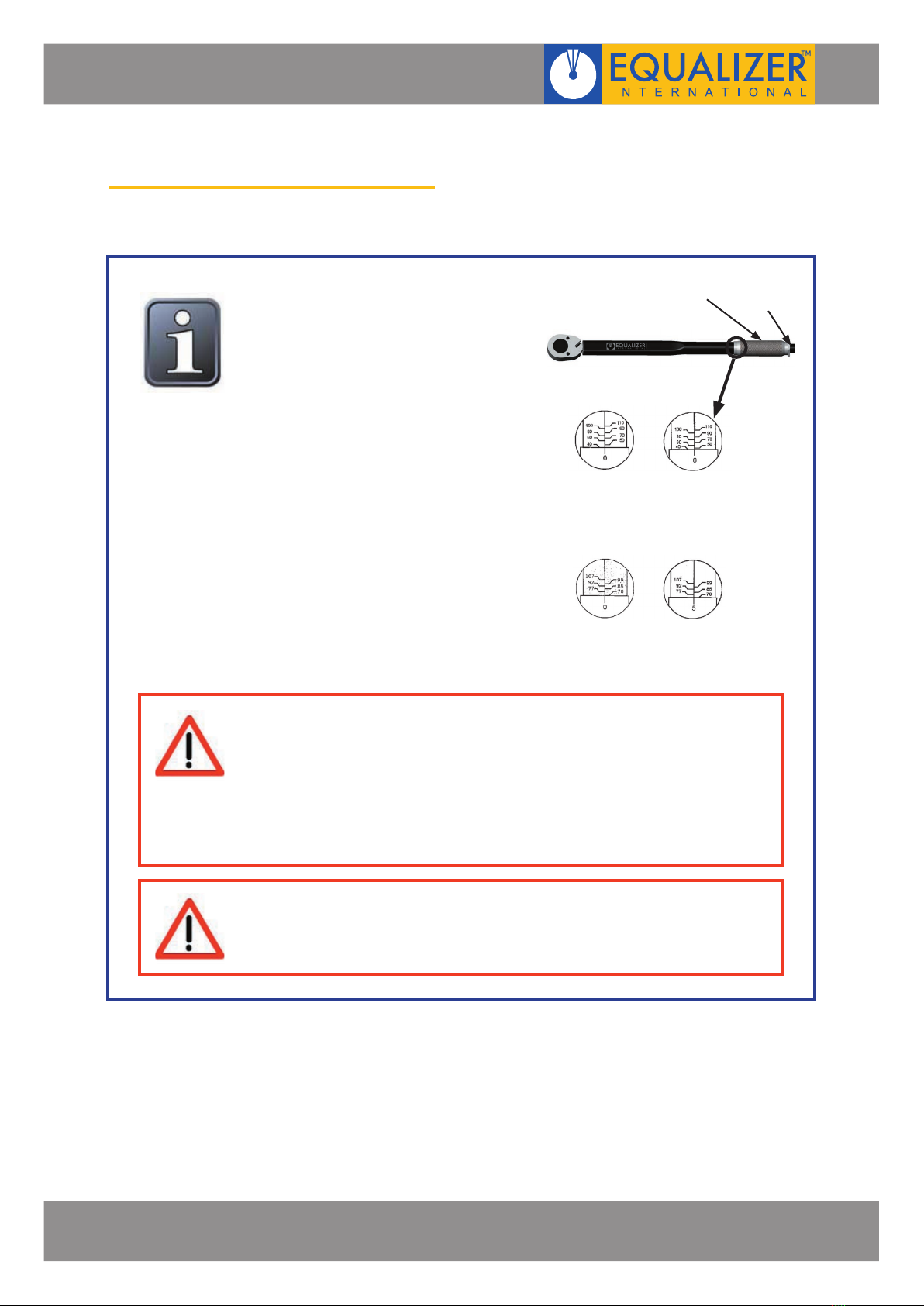

6.1 KIT COMPONENTS

1 x FA3TM Tool

1 x 50 ft/lbs (67.8 Nm) Torque Wrench

with 22 mm Socket

1 x Instruction Manual

1 x Carry-Case with Protective Foam

Inserts

Product Code: FA3TMSTD

6.2 HOW THE FA3TM WORKS

1. The FA3TM is secured to the lower of the two flanges by fully inserting the lift hook

into the bolt-hole which is parallel with the bolt-hole on the opposite flange. This is

where the misalignment is at its greatest point.

2. The drop leg is released onto the pipe while the tool is held up level in the bolt-hole.

3. The wing retaining clip is pulled out to allow the wing to be extended to the required

distance.

4. The screw bolt is turned clockwise until the friction pad comes into contact with the

circumference of the opposite flange.

5. The torque wrench is set to 50 ft/lbs (max), attached to the screw bolt and turned to

screw down on the flange, bringing the joint into alignment.

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 15

6.3 INSTALLATION AND OPERATION

Do not pull after the wrench clicks. Use special care at low torque settings.

If the wrench has not been used for some time: operate it several times

at low torque to allow internal lubricant to recoat. When not in use set to

lowest torque setting. Don’t turn handle below lowest torque setting. Your

torque wrench is a precision measuring instrument and should be treated

as such. Clean only by wiping, do not use any type of cleaner which may

affect the special internal lubricant with which this wrench is packed at the

factory.

How to use the torque wrench

Balance the wrench in your left hand

and unlock the knurled handle by

turning the locking knob anti-clockwise.

Set the torque amount by turning the

knurled handle - see example 40-46

N/m

1. Turn the handle till 0 on fine scale

reach 40 N/m on base scale

2. To set 46 turn handle till fine scale

reach 6

3. Lock handle by turning the locking

knob clockwise

Install the proper socket and attach to

the tool. Pull handle till you feel and/or

hear the wrench click. Setting of ft/lb

scale is done in the same way as above.

KNURLED

HANDLE LOCKING

KNOB

1. Do not attempt to turn the grip while it is locked

2. Do not turn the grip more than one turn below the lowest scale reading

or above the highest scale reading

Newton Scale (N/m)

40 N/m 46 N/m

(1 on fine scale

= 1 N/m)

Foot Pound (Ft.lb)

70 ft/lb 75 ft/lb

(1 on fine scale

= 0.74 ft/lb)

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 16

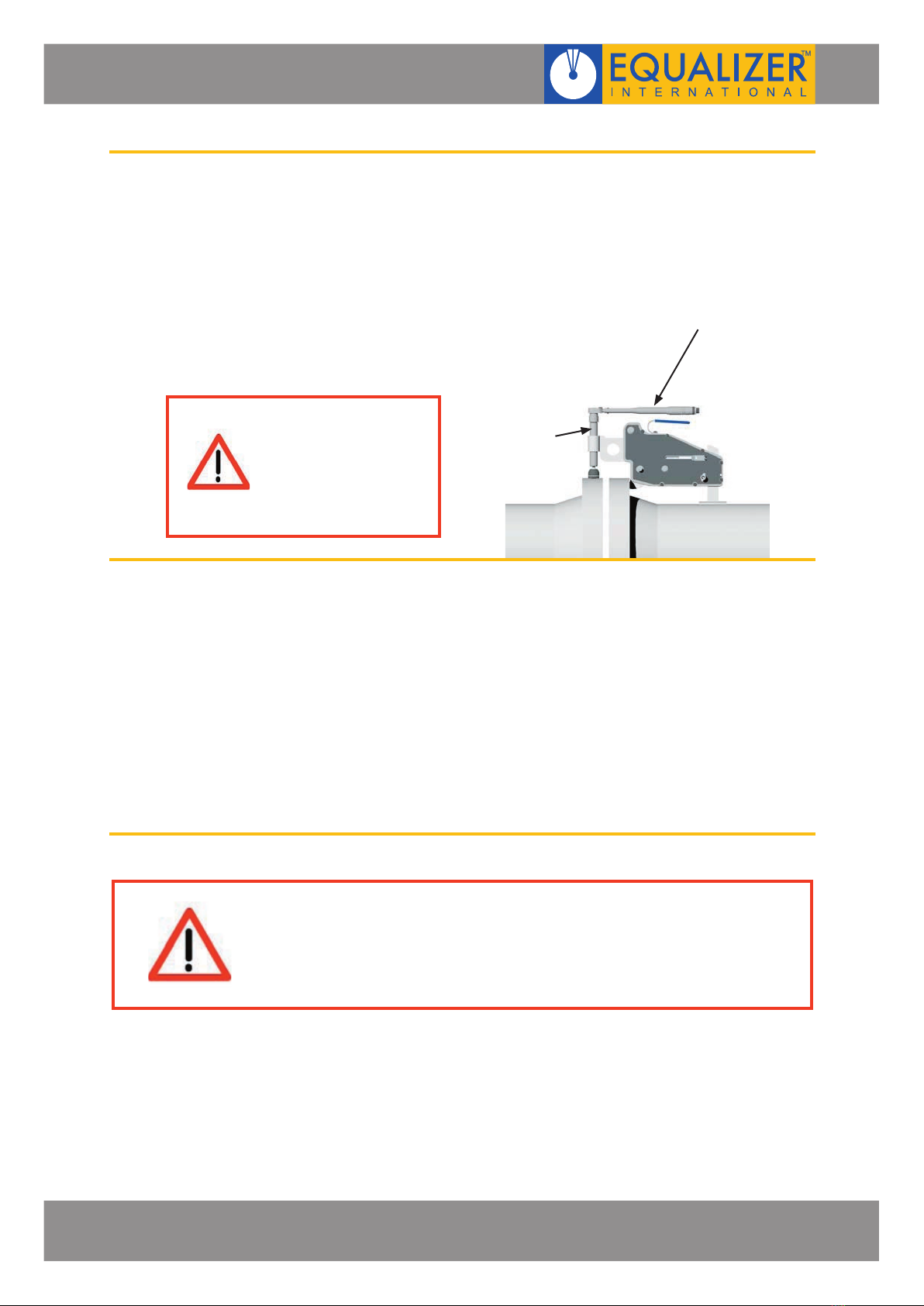

1. Carry out the Flange Misalignment

Determination Procedure (see

section 4) to determine the points

of maximum misalignment.

In this example the points of

maximum misalignment are at the

top and bottom of the joint.

2. Guide the lift hook into the bolt-hole

at the maximum point of

misalignment.

Release the drop leg onto the pipe

(using the release knob) while

holding the lift hook up level with

the bolt-hole.

3. Pull the wing retaining clip out and

extend the wing to the required

distance.

Rotate the screw bolt onto the

surface of the opposite flange.

Ensure that the tool is sitting

level and that the friction pad on

the base of the swivel is in full and

even contact with the surface of the

opposite flange.

POINT OF MAX.

MISALIGNMENT

POINT OF MAX.

MISALIGNMENT

LIFT

HOOK

RELEASE

KNOB

WING RETAINING

CLIP

WING

SCREW

BOLT

SWIVEL

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 17

4. Attach the torque wrench to the

screw bolt and tighten in a

clockwise direction until the joint

comes into alignment.

The torque wrench should be set

at staged increases, e.g. 10 ft/lbs,

20ft/lbs until the maximum

setting of 50ft/lbs (67.8 N/m) is

reached.

5. Once in alignment the bolts may

be inserted and tightened.

After replacing all of the bolts (apart

from the bolt which will go into the

bolt-hole in which the FA3TM is

located), remove the tool by

reversing steps 2 - 4.

Insert the last bolt and tighten.

The torque wrench

will click when the full

50 ft/lbs (67.8 N/m) is

achieved - exceeding

50 ft/lbs will result in

damage to the tool

Care should be taken not to drop any of the component parts when

removing them from the flange joint. This action will prevent injuries to

either the operator’s lower limbs, or to passers-by.

TORQUE

WRENCH

SCREW

BOLT

FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL PAGE 18

• On return from each job and before allocation against subsequent work the

completeness of the Equalizer FA3TM kit must be established and items examined

to ensure that they are serviceable

• Any missing or damaged items are to be replaced as soon as possible and prior to the

tool being used again

• Store the FA3TM in a cool dry place and ensure all machined surfaces are greased

• Return all items to carry case when not in use

• Ensure rollers, pins and wing remain grit free and that the rollers rotate freely

• Grease all moving parts regularly:

6.4 EXAMINATION, MAINTENANCE AND STORAGE

1. Place the tool on a flat bench.

2. Using a small flat screw driver, lever

out the end of the spiral clips and

then rotate anti-clockwise and

remove.

3. Remove the pull pin and lift hook,

unscrew the seven side plate

screws, and lift off the side plate.

4. Inspect the roller pin and needle

bearings within the rollers for dirt or

grit. Clean and then smear a small

amount of grease onto the roller pin

and into the needle bearing.

Recommended grease -

Rocol or Sapphire Hi-Load

5. Re-assemble by reversing steps 2-3.

SPIRAL

CLIP

PULL

PIN

LIFT

HOOK

SIDE PLATE

SCREW

SIDE

PLATE

ROLLER

PIN

NEEDLE

BEARING

This manual suits for next models

2

Table of contents

Other Equalizer International Power Tools manuals