Equalizer HP350S Assembly instructions

HP350S, HP350D,

HP550S, HP550D

HP1000S, HP1000D

HYDRAULIC SEALED

HAND PUMPS

Operator Instruction Manual

www.equalizerinternational.com

INNOVATION IN ITS MOST FUNCTIONAL FORM

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 1

SECTION CONTENTS PAGE NO.

1 INTRODUCTION 1

2 SAFETY INFORMATION 2-3

3 KIT COMPONENTS 4

4 TECHNICAL DATA 5

5 HOW THE HAND PUMPS WORK 6

6 INSTALLATION AND OPERATION 7-12

6.1 HP350S, HP550S & HP1000S 7-8

6.2 HP350D, HP550D & HP1000D 9-12

7 EXAMINATION, MAINTENANCE AND STORAGE 13

8 PARTS LISTS 14-16

9 WEIGHTS AND DIMENSIONS 17

10 TROUBLESHOOTING 18-19

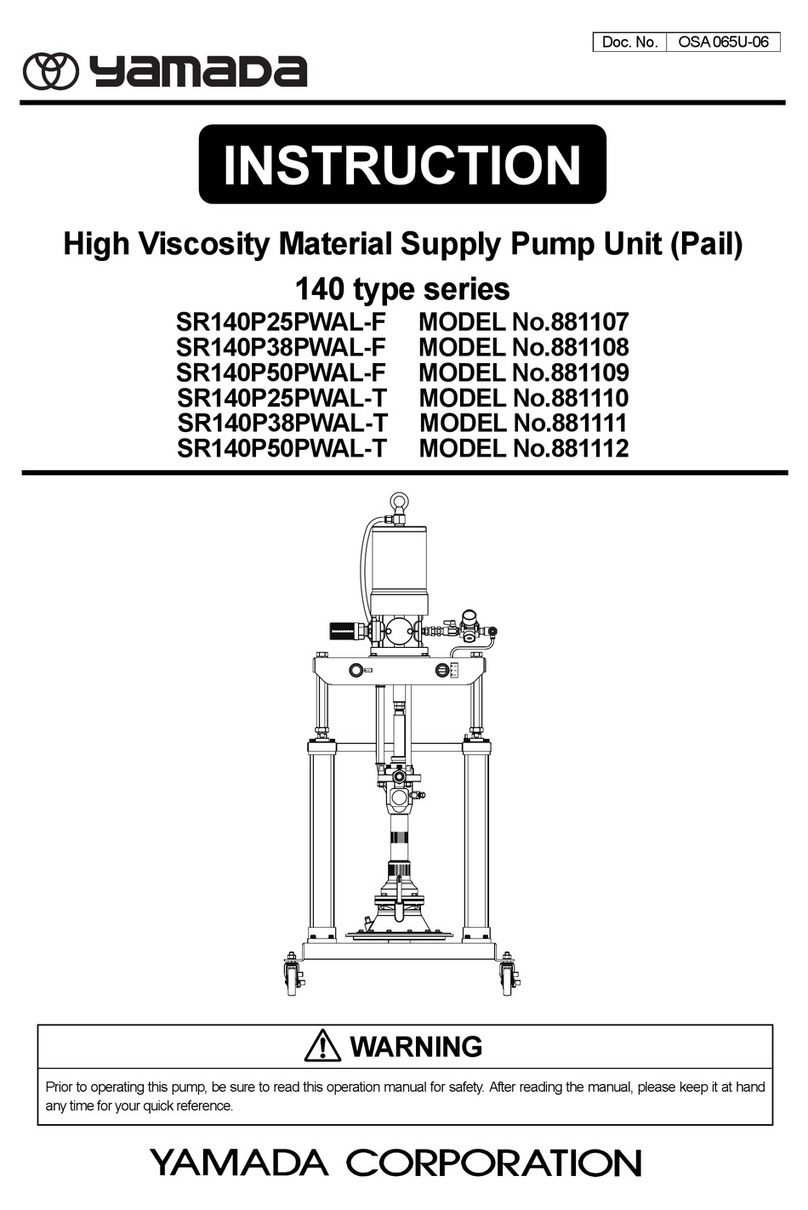

The Equalizer HP-S hydraulic single-port sealed hand pump and HP-D hydraulic twin-port

sealed hand pump replace the Equalizer P142 hydraulic hand pump.

The HP350S, HP550S, HP1000S, HP350D and HP550D and HP1000D are tailored for use

with Equalizer International Ltd hydraulic equipment. Their output is regulated to 700bar

(10,000psi) and is delivered from an output port threaded ⅜” NPT. The HP350S and HP350D

can be used with any 700 bar (10,000 psi) rated hydraulic equipment with an oil capac-

ity of 350cc (21.35 in3) or less. The HP550S and HP550D can be used with any 700bar

(10,000psi) rated hydraulic equipment with an oil capacity of 550cc (30.51 in3) or less. The

HP1000S and HP1000D can be used with any 700bar (10,000psi) rated hydraulic equipment

with an oil capacity of 1000cc (61.0 in3) or less.

The diaphragm oil reservoir means that, unlike conventional hand pump units, the HP-S and

HP-D pump ranges are operable at all angles and are highly resistant to accidental spillage of

hydraulic uid.

Pressure rating:

●1st stage: 13.8 bar (197 psi)

●2nd stage: 700 bar (10,000 psi)

INDEX

1. INTRODUCTION

HP IM REV 07

06/06/2014

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 2

2. SAFETY INFORMATION

The operator MUST read this manual prior to using the tools.

Failure to comply with the following cautions and warnings could cause equipment

damage and personal injury; read the manual fully!

Read all the following instructions, warnings and cautions carefully. Follow all safety

precautions to avoid personal injury or property damage during system operation.

Equalizer International Ltd cannot be responsible for damage or injury resulting from unsafe

product use, lack of maintenance or incorrect product and/or system operation. Contact

Equalizer International Ltd when in doubt as to the safety precautions and applications. To

protect your warranty, use only good quality hydraulic oil of the grade 15cSt.

Only people competent in the use of hydraulic equipment should use these tools.

In all installations the site safety requirements must be adhered to. ALSO the safety of the

operator, and when present, any assisting personnel, is of paramount importance along with

the safety of others including, when present, the general public.

These instructions are only to cover the safe operation of THE EQUALIZER HP350S, HP550S,

HP1000S, HP350D, HP550D and HP1000D HYDRAULIC SEALED HAND PUMPS during normal

maintenance/installation operations. All other safety aspects must be controlled by the

operation supervisor.

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 3

A CAUTION is used to indicate correct operating or maintenance procedures and practices to

prevent damage to, or destruction of equipment or other property.

A WARNING indicates a potential danger that requires correct procedures or practices to avoid

personal injury.

A DANGER is only used when your action or lack of action may cause serious injury or even

death.

IMPORTANT: Operator must be competent in

the use of hydraulic equipment. The operator

must have read and understood all instructions,

safety issues, cautions and warnings before

starting to operate the Equalizer equipment.

WARNING: To avoid personal injury and

possible equipment damage, make sure all

hydraulic components are rated to a safe

working pressure of 700 bar (10,000 psi)

WARNING: Do not overload equipment. Over-

loading causes equipment failure and possible

personal injury.

CAUTION: Make sure that all system compo-

nents are protected from external sources of

damage, such as excessive heat, ame, mov-

ing machine parts, sharp edges and corrosive

chemicals.

CAUTION: Avoid sharp bends and kinks that

will cause severe back-up pressure in hoses.

Bends and kinks lead to premature hose failure.

Do not drop heavy objects onto hoses. A sharp

impact may cause internal damage to hose wire

strands; applying pressure to a damaged hose

may cause it to rupture. Do not place heavy

weights on the hoses, or allow vehicles to roll

over the hoses; crush damage will lead to pre-

mature hose failure.

WARNING: Immediately replace worn

or damaged parts with genuine Equalizer

parts. Equalizer parts are designed to t

properly and withstand rated loads. For

repair or maintenance service contact your

Equalizer distributor or service centre.

DANGER: To avoid personal injury keep

hands and feet away from the tool and

workpiece during operation.

WARNING: Always wear suitable clothing

and Personal Protective Equipment (PPE).

DANGER: Do not handle pressurised hos-

es. Escaping oil under pressure can pen-

etrate the skin, causing serious injury. If

oil is injected under the skin, seek medical

attention immediately.

WARNING: Never pressurize unconnected

couplers. Only use hydraulic equipment in

a connected system.

IMPORTANT: Do not lift hydraulic equip-

ment by the hoses or couplers. Use the car-

rying handle or other means of safe trans-

port.

CAUTION: Do not operate the equipment

without lubricating all moving parts. Use

only high pressure molybdenum disulphide

grease.

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 4

3. KIT COMPONENTS

HP350S KIT COMPONENTS

1 x HP350S Pump Unit

1 x Pressure Gauge

1 x ⅜” Port Gauge Adaptor

1 x Instruction Manual

1 x Cardboard Packaging

Product Code: HP350SMIN

HP550S KIT COMPONENTS

1 x HP550S Pump Unit

1 x Pressure Gauge

1 x ⅜” Port Gauge Adaptor

1 x Instruction Manual

1 x Cardboard Packaging

Product Code: HP550SMIN

HP1000S KIT COMPONENTS

1 x HP1000S Pump Unit

1 x Pressure Gauge

1 x ⅜” Port Gauge Adaptor

1 x Instruction Manual

1 x Cardboard Packaging

Product Code: HP1000SMIN

HP350D KIT COMPONENTS

1 x HP350D Pump Unit

2 x Pressure Gauge

2 x ⅜” Port Gauge Adaptor

1 x Instruction Manual

1 x Cardboard Packaging

Product Code: HP350DMIN

HP550D KIT COMPONENTS

1 x HP550D Pump Unit

2 x Pressure Gauge

2 x ⅜” Port Gauge Adaptor

1 x Instruction Manual

1 x Cardboard Packaging

Product Code: HP550DMIN

HP1000D KIT COMPONENTS

1 x HP1000D Pump Unit

2 x Pressure Gauge

2 x ⅜” Port Gauge Adaptor

1 x Instruction Manual

1 x Cardboard Packaging

Product Code: HP1000DMIN

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 5

4. TECHNICAL DATA

STAGE HP350S HP550S HP1000S

PUMP TYPE TWO SPEED TWO SPEED TWO SPEED

PRESSURE RATING 1st 13.8bar (197psi) 13.8bar (197psi) 13.8bar (197psi)

2nd 700bar (10,000psi) 700bar (10,000psi) 700bar (10,000psi)

NOMINAL OIL CAPACITY 350cc (21.4in3) 550cc (33.6in3) 1000cc (61.0in3)

USABLE OIL CAPACITY 300.0cc (18.3in3) 580.0cc (35.4in3) 1110.0cc (67.7in3)

OIL VOLUME PER

STROKE

1st 3.62cc (0.221in3) 3.62cc (0.221in3) 3.62cc (0.221in3)

2nd 0.77cc (0.046in3) 0.77cc (0.046in3) 0.77cc (0.046in3)

MAX HANDLE EFFORT 33kgf (72.75lbf) 25kgf (55.12lbf) 21kgf (46.30lbf)

PISTON STROKE 18.0mm (0.71”) 18.0mm (0.71”) 18.0mm (0.71”)

HYDRAULIC OIL Grade 15 cSt Grade 15 cSt Grade 15 cSt

STAGE HP350D HP550D HP1000D

PUMP TYPE TWO SPEED TWO SPEED TWO SPEED

PRESSURE RATING 1st 13.8bar (197psi) 13.8bar (197psi) 13.8bar (197psi)

2nd 700bar (10,000psi) 700bar (10,000psi) 700bar (10,000psi)

NOMINAL OIL CAPACITY 350cc (21.4in3) 550cc (33.6in3) 1000cc (61.0in3)

USABLE OIL CAPACITY 300.0cc (18.3in3) 580.0cc (35.4in3) 1110.0cc (67.7in3)

OIL VOLUME PER

STROKE

1st 3.62cc (0.221in3) 3.62cc (0.221in3) 3.62cc (0.221in3)

2nd 0.77cc (0.046in3) 0.77cc (0.046in3) 0.77cc (0.046in3)

MAX HANDLE EFFORT 33kgf (72.75lbf) 25kgf (55.12lbf) 21kgf (46.30lbf)

PISTON STROKE 18.0mm (0.71”) 18.0mm (0.71”) 18.0mm (0.71”)

HYDRAULIC OIL Grade 15 cSt Grade 15 cSt Grade 15 cSt

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 6

5. HOW THE HAND PUMPS WORK

1. The release valve is closed fully by

rotating clockwise until hand tight

2. The pump handle is raised, which

creates a vacuum in the piston

chamber which sucks oil from the

reservoir into the chamber

3. The pump handle is depressed,

which pumps the oil from the

chamber through the outlet port

and into the system to which the

pump is connected

4. Steps 2 & 3 are repeated, which will

pump oil into the system until the

maximum pressure of

10,000 psi (700 bar) is achieved, at

which point the safety release valve

will open and the oil will cycle back

to the reservoir

CLOSE RELEASE

VALVE

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 7

6. INSTALLATION AND OPERATION

WARNING:

Never attempt to pressurise the pump when the pressure gauge is not

connected or the pump is not connected to a system!

DANGER:

Always check the hydraulic system in which the pump is to be used is rated

for 10,000 psi (700 bar). Over pressurising a hydraulic system will result in

component failure and personal injury!

2. Ensure the hydraulic system you

wish to pressurise has been bled

and is free from air and leaks.

Connect the pump into the system

using the screw connector supplied

with the pump, push the male and

female connectors together fully and

rotate the locking ring clockwise

until fully tight.

WARNING:

Never disconnect the pump

or other components when

the system is pressurised

6.1 HP350S, HP550S & HP1000S

MALE AND FEMALE

CONNECTORS

LOCKING

RING

LOCKING

RING

1. Prior to using the pump the hydraulic

gauge must be tted.

push the male connector on the gauge

and female connector on the gauge

adaptor together fully and rotate the

locking ring counterclockwise until fully

tight.

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 8

3. Close the release valve fully by

rotating clockwise until hand tight

4. Pressurise the system by raising and

depressing the pump handle until

the desired pressure is indicated

on the pressure gauge

N.B. max. pressure 10,000 psi (700

bar)

5. To depressurise the system, gently

open the release valve by rotating

the release knob anti-clockwise

6. Once the system has been fully

depressurised, the pump can be

disconnected by unscrewing the

connectors.

OPEN RELEASE

VALVE

CLOSE RELEASE

VALVE

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 9

6.2 HP350D, HP550D & HP1000D

The HP350D, HP550D and HP1000D pumps have been designed for use with Equalizer maxi kit

systems, however the HP350D can be used in any situation where 2 separate hydraulic systems

require to be pressurised and controlled independently by the same operator.

WARNING:

Never attempt to pressurise the pump when the gauge is not connected or

the pump is not connected to a system!

DANGER:

Always check the hydraulic system in which the pump is to be used is rated

for 10,000 psi (700 bar). Over pressurising a hydraulic system will result in

component failure and personal injury!

2. Ensure the hydraulic systems you

wish to pressurise have been bled

and are free from air and leaks.

Connect the pump into the systems

using the screw connectors supplied

with the pump, push the male and

female connectors together fully and

rotate the locking rings clockwise

until fully tight.

WARNING:

Never disconnect the pump

or other components when

the system is pressurised

MALE AND FEMALE

CONNECTORS

LOCKING

RING

1. Prior to using the pump the hydraulic

gauges must be tted.

push the male connector on the gauges

and female connector on the gauge

adaptors together fully and rotate the

locking ring counterclockwise until fully

tight.

LOCKING

RING

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 10

3. The HP-S pumps are tted with two

control valves and a release valve.

This enables the operator to adjust

the pressure on both hydraulic

systems independently or

simultaneously.

a.

If control valves 1 and 2 are set to

the fully open position and the

release valve is screwed fully home,

when the pump handle is raised and

lowered both hydraulic systems will

be pressurised to an equal pressure

(max. pressure 10,000 psi (700

bar))

CONTROL VALVE 1

CONTROL VALVE 2

RELEASE VALVE

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 11

b.

If control valve 1 is open and

control valve 2 is closed with the

release valve screwed fully home,

when the pump handle is raised and

lowered only the system connected

to control valve 1 will be pressurised

(max. pressure 10,000 psi (700

bar))

c.

If control valve 2 is open and

control valve 1 is closed with the

release valve screwed fully home,

when the pump handle is raised and

lowered only the system connected

to control valve 2 will be pressurised

(max. pressure 10,000 psi (700

bar))

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 12

d.

If after pressurising one system the

control valve for the unpressurised

system is opened then the pressure

in both systems will adjust until they

are equal

4.

a.

To depressurise both systems

simultaneously open both control

valves and gently open the release

valve by rotating the release knob

anti-clockwise

b.

To depressurise only one system

open only the control valve for that

system and gently open the release

valve by rotating the release knob

anti-clockwise

5. At any time during pressurisation

of the systems the appropriate

control can be closed to hold one

system at a xed pressure while the

pressure in the other system can be

increased by raising and lowering

the pump handle or decreased by

opening the release valve

6. Once both systems have been fully

depressurised the pump can be

disconnected by unscrewing the

couplers

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 13

7. EXAMINATION, MAINTENANCE AND STORAGE

• On return from each job and before allocation against subsequent work the

hand pumps should be examined to ensure that they are serviceable.

• Any missing or damaged items are to be replaced as soon as possible and prior to the

pump being used again.

• Store the pump in a cool dry place and ensure all machined surfaces are greased.

• Grease all moving parts each and every time the pump is used.

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 14

n

www.equalizerinternational.com

DESCRIPTION

PUMP HOUSING

SERVICE KIT A:

- OIL FILTER

- O-RING

- RESERVOIR BLADDER

- REFILLING PLUG

RESERVOIR

SERVICE KIT B:

- TAIL BASE

- SCREW

- SPRING WASHER

SERVICE KIT C:

- O-RING

- BACK-UP RING

- PUMP PISTON

- SNAP RING

- O-RING

- BACK-UP RING

- PUMP PISTON

SERVICE KIT D:

- HANDLE

- YOKE

- PISTON PIN

- YOKE PIN

- RETAINING RING

SERVICE KIT E:

- YOKE BASE

- SPRING PIN

SERVICE KIT F:

- RELEASE VALVE

SCREW

- WASHER

- SEAL

- SCREW

- RELEASE KNOB

- COUPLERS

- CHECK BALL

SERVICE KIT G:

- SPRING

- STEEL BALL

- OUTLET BALL SPRING

- COPPER WASHER

- VALVE COVER SCREW

- STEEL BALL

PART No.

710101-01

715100-01

710601-01

725200-01

715300-01

715400-01

715500-01

715600-01

715700-01

KIT

QUANTITY

01

01

01

01

01

04

04

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

02

02

02

02

02

02

ITEM

01

02

03

04

05

06

07

08

09

11

12

13

14

15

16

17

18

19

20

21

22

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

DESCRIPTION

SERVICE KIT H:

- STEEL BALL

- SPRING END CAP

- L.P. SPRING

- O-RING

- OVERLOAD COVER

SCREW

- CAP

- OVERLOAD COVER

SCREW

SERVICE KIT I:

- BASE PLATE

- SCREW

PART No.

715800-01

715900-01

KIT

QUANTITY

01

01

01

02

01

02

01

01

02

ITEM

40

41

42

43

44

45

46

50

51

HP350S HYDRAULIC SINGLE-PORT SEALED HAND PUMP

8. PARTS LISTS

- NUT 0410

- HANDLE GRIP 0123

- SCREW 0124

- CONE SEAT0 147

- CONE 0148

- LONG SEPARATOR

SPRING

0149

SERVICE KIT K:

- SCREW

- SCREW

716100-01

04

01

52

53

SERVICE KIT L:

- GAUGE COUPLER

MALE

- GAUGE

716200-01

01

01

54

55

SERVICE KIT M:

- GAUGE COUPLER

FEMALE

- COUPLER

716300-01

01

01

56

57

- GAUGE PORT

ADAPTOR

01

58

PUMP

QUANTITY

01

01

01

02

01

02

01

01

02

01

01

01

03

01

01

01

01

01

01

PUMP

QUANTITY

01

01

01

01

01

01

01

04

04

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

02

02

02

02

02

02

04

01

01

- SCREW

- CHECK BALL

01

04

24

33

01

03

89

10

8910

8

8910

9

10

76

54

2

3

50 51 51

133

33

52

52

29

28 32

33 27

31

30

39

39

34

34

35

35

36

37

38

36

37

38

23 18

19 22 21

20

17

24

16

15

14

13

12

11

25 26

55

54

57

58

56

53 24

52

33

40

41

42

43

44

45

43

46

45

49

48

47

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 15

HP550S HYDRAULIC SINGLE-PORT SEALED HAND PUMP

DESCRIPTION

PUMP HOUSING

SERVICE KIT C:

- O-RING

- BACK-UP RING

- H.P. PISTON

- SNAP RING

RESERVOIR

SERVICE KIT E:

- YOKE BASE

- SPRING PIN

SERVICE KIT F:

- SEAL

- WASHER

- RELEASE VALVE

SCREW

- SCREW

- RELEASE KNOB

- COUPLERS

SERVICE KIT G:

- SPRING

- STEEL BALL

- OUTLET BALL SPRING

- COPPER WASHER

- VALVE COVER SCREW

SERVICE KIT H:

- STEEL BALL

- SPRING END CAP

- L.P. SPRING

- O-RING

SERVICE KIT I:

- BASE PLATE

- SCREW

PART No.

710101-01

715300-01

730601-01

715500-01

715600-01

715700-01

715800-01

715900-01

KIT

QUANTITY

01

01

01

01

01

01

01

01

01

01

01

01

02

02

02

02

02

01

01

01

02

01

02

ITEM

01

03

04

05

06

02

10

11

12

13

14

15

16

17

18

19

20

21

22

24

25

26

27

34

35

DESCRIPTION

SERVICE KIT M:

- GAUGE COUPLER

FEMALE

- COUPLER

- PORT GAUGE

ADAPTOR

SERVICE KIT N:

- RESERVOIR BLADDER

- OIL FILTER

PART No.

716300-01

735100-01

KIT

QUANTITY

01

01

01

01

01

ITEM

4

41

42

43

44

45

- O-RING

- BACK-UP RING

- L.P. PISTON

01

01

01

07

08

09

- STEEL BALL 02

23

- OVERLOAD COVER

SCREW

- CAP

- CONE SEAT

- CONE

01

02

01

01

28

29

30

31

- LONG SEPARATOR

SPRING

- OVERLOAD COVER

SCREW

01

01

32

33

SERVICE KIT K:

- SCREW

- CHECK BALL

716100-01

04

04

36

37

- CHECK BALL 01

37

- SCREW 01

38

SERVICE KIT L:

- GAUGE COUPLER

MALE

- GAUGE

716200-01

01

01

39

40

- O-RING

- REFILLING PLUG

01

01

46

47

SERVICE KIT O:

- HANDLE

- YOKE

735300-01

01

01

48

49

- PISTON PIN

- YOKE PIN

01

01

50

51

- RETAINING RING

- HANDLE GRIP

01

01

52

53

- SCREW 0154

- SCREW 01

54

SERVICE KIT P:

- SCREW

- TAIL BASE

735200-01

04

01

55

56

- SPRING WASHER

- NUT

04

04

57

58

PUMP

QUANTITY

01

01

01

01

01

01

01

01

01

01

01

01

01

01

02

02

02

02

02

01

01

01

02

01

02

01

01

01

02

01

02

01

01

01

01

03

03

01

01

01

01

01

PUMP

QUANTITY

01

01

01

01

01

01

01

01

01

01

01

01

01

01

04

01

04

04

58

57

55

58 57 55 56

57

58 55

55

57

58

2

47

44

45

46

1

343535

37

36

37

36

12

13

17

37

14

15 16

24

2526

3227

27

36

38

54

43

41

42

28

33

29

29

39

40

11

10

3

4

5

6

7

89

54

50

51

4952

48

2222

21

21

20

20

19

19

18

18

23

23

37

30

31

53

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 16

HP1000S HYDRAULIC SINGLE-PORT SEALED HAND PUMP

ITEM NO.

PART NO

KIT

DESCRIPTION

QTY.

1 710101-01

-

PUMP HOUSING

1

2 710201-01

A/N

OIL FILTER

1

3 707003-01

A/N

O-RING

1

4 520001-01

T

RESERVOIR BLADDER 1000 1

5 710501-01

A/N

REFILLING PLUG

1

6 520002-01

-

RESERVOIR 1000 1

7 710701-01

B/P

TAIL BASE

1

8 520003-01

U

SCREW

4

9 707009-01

B/P

SPRING WASHER4

10 710901-01

B/P NUT

4

11 712801-01

F/K/R

CHECK BALL

4

12 713201-03

K

SCREW

3

13 707013-01

D/K/O

SCREW

2

14 711001-01

C

O-RING

1

15 711101-01

C

BACK-UP RING

1

16 711201-01

C

H.P. PISTON

1

17 711301-01

C

SNAP RING1

18 711401-01

C

O-RING

1

19 711501-01

C

BACK-UP RING

1

20 711601-01

C

L.P. PISTON

1

21 712201-01 E

YOKE BASE

1

22 712301-01 E

SPRING PIN

1

23 712001-01

D/O

YOKE

1

24 711701-01

D/O

PISTON PIN1

25 711801-01

D/O

YOKE PIN

1

26 711901-01

D/O

RETAINING RING

1

27 708004-01

O HANDLE

1

28 201202-01

D/O

HANDLE GRIP 1

29 707029-01 G/Q

STEEL BALL

2

30 713501-02 G

SPRING

2

31 713601-02 G

STEEL BALL

2

32 713701-02 G

OUTLET BALL SPRING

2

33 713801-02 G

COPPER WASHER

2

34 713901-02 GV ALVLE COVER SCREW 2

35 714001-02

H

STEEL BALL

1

36 714101-02

H

SPRING END CAP

1

37 714201-01

H

L.P. SPRING

1

38 714401-02

H

O-RING

2

39 714501-02

H

OVERLOAD COVER SCREW

1

40 714601-02

H

CAP

2

41 377201-01

H

CONE SEAT1

42 377301-01

H

CONE

1

43 377401-01

H

LONG SEPARATOR SPRING1

44 707044-01

H

OVERLOAD COVER SCREW

1

45 707067-01

Q

SCREW

1

46 707072-01

M

GAUGE COUPLER FEMALE

1

47 714901-01

I

BASE PLATE

1

48 715001-01

I

SCREW

2

49 771110-01

M

3/8" NPT COUPLER 10kPSI

1

50 707072-01

L

GAUGE COUPLER MALE

1

51 302501-01

L

GAUGE

1

52 070054-01

-

QC SEALED TOP PLATE STICKER

1

53 300401-01

F/J

M5 SCKT SET SCREW

1

ITEM NO.

PART NO

KIT

DESCRIPTION

QTY.

54 713001-01

F/J RELEASE KNOB

1

55 712901-01

F

RELEASE VALVE SCREW1

56 712701-01

F/J

COUPLERS

1

57 712601-01

F

WASHER 1

58 712501-01

F

SEAL

1

59 302502-01

M

PORT GAUGE ADAPTOR

1

62 070263-01

-

HP1000S STICKER

1

8

9

10

6

5

4

23 1

474848

11

12 58

57 56

11 55

53 54

35

36

43

38

12

45

13

59

46 49

44

40

50

22

21

14

15

16

20

24

2326

27

34

33

32

31

30

29

11

41

42

28

51

25

17

18

19

13

7

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 17

HP350D HYDRAULIC TWIN PORT SEALED HAND PUMP

DESCRIPTION

PUMP HOUSING

SERVICE KIT A:

- RESERVOIR BLADDER

- OIL FILTER

- O-RING

- REFILLING PLUG

RESERVOIR

SERVICE KIT B:

- SCREW

- TAIL BASE

- SPRING WASHER

- NUT

SERVICE KIT C:

- O-RING

- BACK-UP RING

- H.P. PISTON

- SNAP RING

- O-RING

- BACK-UP RING

- L.P. PISTON

SERVICE KIT D:

- HANDLE

- YOKE

- PISTON PIN

- YOKE PIN

- RETAINING RING

SERVICE KIT E:

- YOKE BASE

- SPRING PIN

- RELEASE VALVE

SCREW

- WASHER

- SEAL

SERVICE KIT F:

- SPRING

- STEEL BALL

- OUTLET BALL

SPRING

- COPPER WASHER

- VALVE COVER SCREW

- STEEL BALL

SERVICE KIT G:

PART No.

720101-01

715100-01

710601-01

725200-01

715300-01

715400-01

715500-01

715600-01

715700-01

KIT

QUANTITY

01

01

01

01

04

01

04

04

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

02

02

02

02

02

02

ITEM

01

03

04

05

06

02

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

25

26

27

28

29

34

35

36

37

38

39

DESCRIPTION

SERVICE KIT H:

- STEEL BALL

- SPRING END CAP

- L.P. SPRING

- O-RING

- OVERLOAD COVER

SCREW

- CAP

- OVERLOAD COVER

SCREW

SERVICE KIT I:

- BASE PLATE

- SCREW

SERVICE KIT J:

- VALVE SCREW

- BACK-UP RING

- O-RING

PART No.

715800-01

715900-01

726000-01

KIT

QUANTITY

01

01

01

02

01

02

01

01

02

01

01

01

ITEM

40

41

42

43

44

45

46

50

51

52

53

54

- HANDLE GRIP 01

23

- SCREW 01

24

- RELEASE KNOB

- SCREW

01

01

30

31

- COUPLERS

- CHECK BALL

01

01

32

33

- CONE SEAT

- CONE

- LONG SEPARATOR

SPRING

01

01

01

47

48

49

- SCREW 01

31

- COUPLERS 01

32

SERVICE KIT K:

- SCREW

- CHECK BALL

716100-01

04

04

55

56

33

SERVICE KIT L:

- GAUGE COUPLER

MALE

- GAUGE

716200-01

01

01

57

58

SERVICE KIT M:

- GAUGE COUPLER

FEMALE

- COUPLER

- PORT GAUGE

ADAPTOR

716300-01

01

01

01

59

60

PUMP

QUANTITY

01

01

01

01

01

01

04

01

04

04

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

02

02

02

02

02

02

01

01

01

02

01

02

01

01

01

01

01

01

01

01

01

01

PUMP

QUANTITY

01

02

02

02

02

02

02

04

04

02

02

02

02

02

- RELEASE KNOB 01

30 02

HYDRAULIC SEALED HAND PUMPS

OPERATOR INSTRUCTION MANUAL PAGE 18

HP550D HYDRAULIC TWIN-PORT SEALED HAND PUMP

61 60 58 61 60 58 5860

61586061

59

2

50

47

36 36 35

51

56

43

42

55

54

43

42

57

9

16

15

37

46 44

45

10

11

57

8

7

6

5

43

17

39

38

23

23

22

22

21

21

20

20

19

24

19

24

49

18

48

40

1

41

40

18

17 39

38 37

16

15

4645 44

18

18

40

40

14

13

17

18 12

15

30

30

29 34

28

28

27

26 25

53

16

33

32

31

52

ITEM

NO.

SUP PART

NO

KIT PART NO

DESCRIPTION

QTY.

1

F0366

-

707001-01

PUMP HOUSING

1

2

D0853

-

708002-01 RESERVOIR1

3

GA050

C

711001-01

O-RING

1

4

G0108

C

711101-01

BACK-UP RING

1

5

E0164

C

711201-01

H.P. PISTON

1

6 I0035

C

711301-01

SNAP RING

1

7

GA127

C

711401-01

O-RING

1

8

G0126

C

711501-01

BACK-UP RING

1

9

E0165

C

711601-01

L.P. PISTON

1

10

C0617Z

E

712201-01

YOKE BASE

1

11

B1177

E

712301-01

SPRING PIN

1

12

H0053Z

F

712901-01

RELEASE VALVE SCREW

1

13

J0156

F

712601-01

WASHER

1

14

G0105

F

712501-01

SEAL

1

15

E1604

F/J

713001-01

RELEASE KNOB

3

16 H0050

F/J

300401-01

M5 SCKT SET SCREW

3

17

H0052Z

F/J

712701-01

COUPLERS

3

18

K0001 F/K/R

712801-01

CHECK BALL

5

19

J0045

G

713501-02

SPRING

2

20

K0003

G

713601-02

STEEL BALL

2

21

J0001

G

713701-02

OUTLET BALL SPRING

2

22

J0002

G

713801-02

COPPER WASHER

2

23

H0006Z

G

713901-02

VALVLE COVER SCREW

2

24

K0002 G/Q

707029-01

STEEL BALL

2

25

K0011

H

714001-02

STEEL BALL

1

26

E0006

H

714101-02

SPRING END CAP

1

27

J0140

H

714201-01

L.P. SPRING

1

28

G0009

H

714401-02

O-RING

2

29

H0007Z

H

714501-02

OVERLOAD COVER SCREW

1

30

G0010

H

714601-02

CAP

2

31

E1749

H

377201-01

CONE SEAT

1

32

E1748

H

377301-01

CONE

1

33

J0389

H

377401-01

LONG SEPARATOR SPRING

1

34

H0340Z

H

707044-01

OVERLOAD COVER SCREW

1

35

C0687A

I

714901-01

BASE PLATE

1

36 H0189

I

715001-01

SCREW

2

37

E1721Z

J

720401-01

VALVE SCREW

2

38

G0270

J

720501-01

BACK-UP RING

2

39

G0086

J

720601-01

O-RING

2

40

H0003Z

K

713201-03

SCREW

4

41

H0215Z

Q

707067-01

SCREW

1

42

CP212

L

707072-01

GAUGE COUPLER MALE

2

43

M0031-

EG

L

302501-01

GAUGE

2

44 E174S

M

302502-01

PORT GAUGE ADAPTOR

2

45

CP211

M

707072-01

GAUGE COUPLER FEMALE

2

46

CP331

M

771110-01

3/8" NPT COUPLER 10kPSI

2

47

G0564

N

708001-01

RESERVOIR BLADDER

1

48

M0018

A/N

710201-01

OIL FILTER

1

49

G0102

A/N

707003-01

O-RING

1

50

E0772

A/N

710501-01

REFILLING PLUG

1

51

D0854

O

708004-01

HANDLE

1

52

G0664

D/O

201202-01

HANDLE GRIP

1

53

C0686

D/O

712001-01

YOKE

1

54

E0389Z

D/O

711701-01

PISTON PIN

1

55

E0005Z

D/O

711801-01

YOKE PIN

1

56 I0001Z

D/O

711901-01

RETAINING RING

1

57

H0048Z

D/K/O

707013-01

SCREW

2

58

H0338Z

P

708003-01

SCREW

4

59

F0335

B/P

710701-01

TAIL BASE

1

60

J0036

B/P

707009-01

SPRING WASHER

4

61 H0325

B/P

710901-01

NUT

4

Other manuals for HP350S

1

This manual suits for next models

5

Table of contents

Other Equalizer Water Pump manuals

Popular Water Pump manuals by other brands

Grundfos

Grundfos SP Safety instructions and other important information

Kärcher

Kärcher BTA 5421700 user manual

Messner

Messner eco-X2 4500 operating instructions

evosanitary

evosanitary QGD1.8-50-0.5 user manual

Becker

Becker VariAir VASF 2.50/1-0.AC115 operating instructions

FILL-RITE

FILL-RITE FR100 Series Installation and operation manual