Instalarea pompei trebuie efectuata de catre personal calificat.

Pentru fixarea pompei cu un cablu sau sfoara in pozitia de lucru utilizati manerele cu care este

prevazuta.

Domeniu de utilizare.

Aceasta electropompa este destinata transportului apei din fantani, puturi si a micilor

lucrari de irigatii agricole sau gradini. Nu utilizati produsul pentru extragerea

hidrocarburilor (carburanti, uleiuri, solventi...)

Constructia speciala a rotorului faciliteaza racirea pompei in timpul functionarii.

NU ESTE PROIECTATA PENTRU UZ INDUSTRIAL.

ATENTIE ! Pompa este proiectata si construita pentru extragerea lichidelor fara

continut de substante explozive si a lichidelor non-agresive chimic si cu

densitatea maxima a particulelor de 15g/m³.

Pregatirea pentru punerea in functiune

ATENTIE! IN CAZUL IN CARE APAR ZGOMOTE ANORMALE IN FUNCTIONARE

OPRITI IMEDIAT POMPA SI ADRESATI-VA UNUI SERVICE AUTORIZAT PENTRU

CONSTATARI SI REPARATII.

ATENTIE ! Deconectati alimentarea cu energie electrica inaintea inceperii oricarei

operatiuni de reglare sau intretinere

Reglare intrerupator cu flotor (accesoriu optional)

Prin modificarea lungimii portiunii de cablu dintre flotor si punctul de fixare se stabileste punctul in

care pompa intra in functiune / se opreste. Asigurati-va ca intrerupatorul cu flotor se poate misca

liber in timpul functionarii.

Asigurati-va ca reglati pozitia oprit a intrerupatorului cu flotor astfel incat corpul pompei sa

nu ramana deasupra nivelului apei.

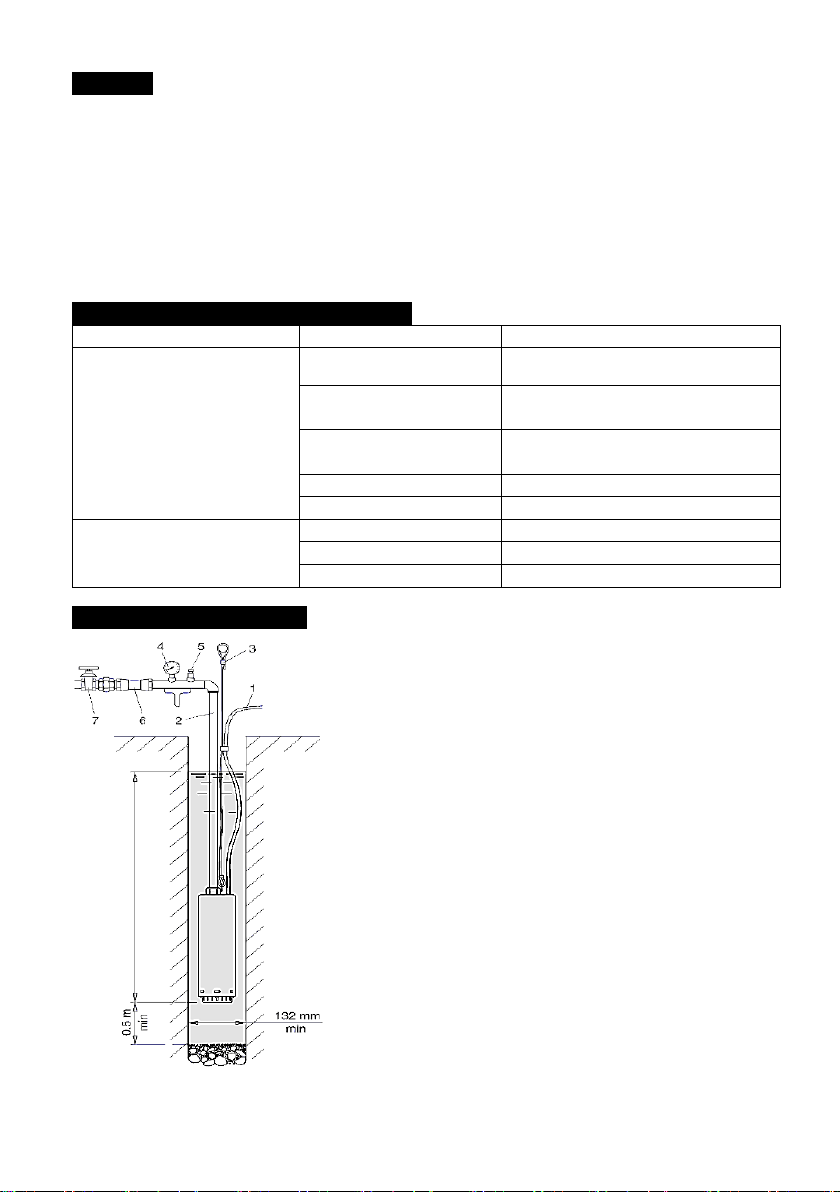

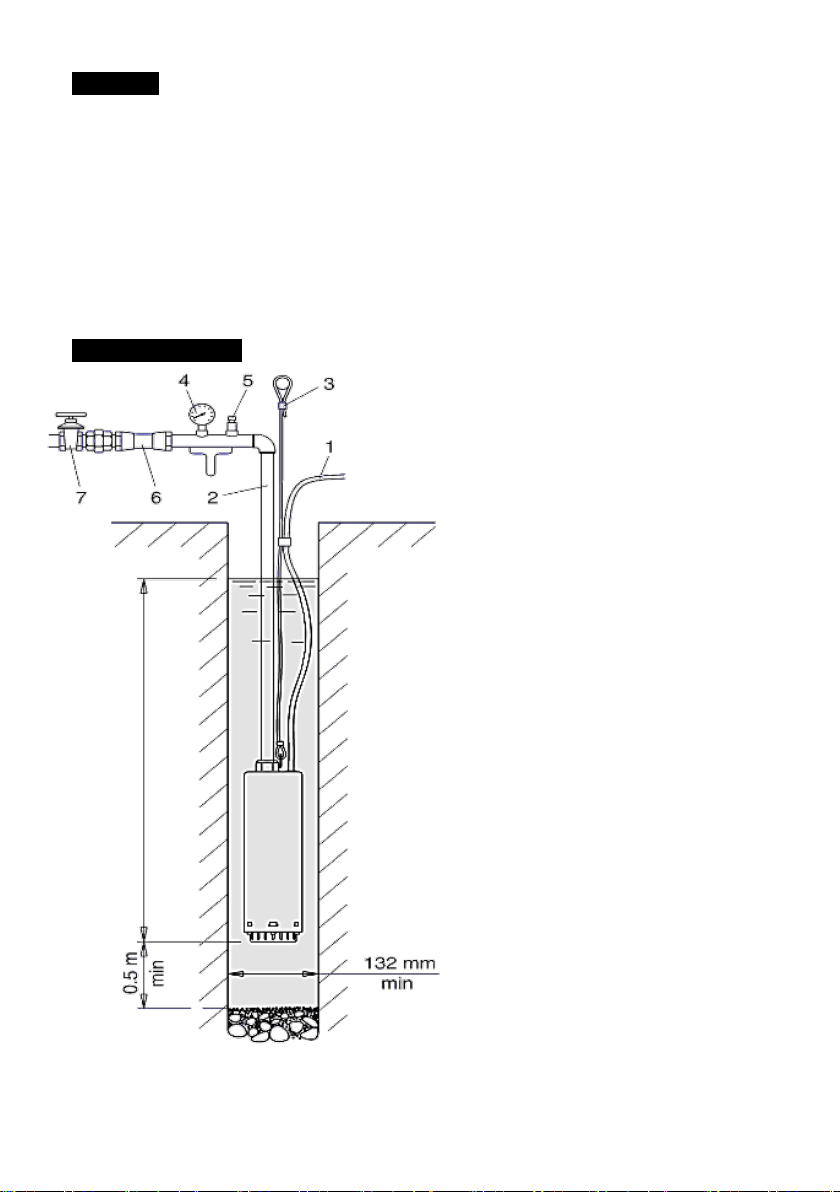

Zona de lucru:

Inainte de imersarea electropompei in pozitia de lucru asigurati-va ca nu exista nisip sau

sedimente solide.In cazul existentei acestora curatati foarte bine amplasamentul pompei.

Pompa functioneaza in pozitie verticala.

Pozitionati pompa la cel putin 0.5 m desupra bazei amplasamentului astfel incat

depunerile ulterioare de sedimente sa nu afecteze buna functionare a pompei.

Este foarte important ca nivelul apei sa nu coboare niciodata sub corpul pompei.

PERICOL DE INGHET! In situatia in care pompa ramane inactiva la temperaturi sub

0ºC,asigurati-va ca nu exista apa reziduala care poate ingheta si prin urmare poate

distruge componentele pompei.

Conexiune hidraulica

Se face utilizand tubulatura rigida sau flexibila din metal sau plastic.

Este recomandata utilizarea unei tubulaturi cu un diametru interior cel putin egal cu cel al

pompei, pentru evitarea scaderii performantelor pompei si aparitiei colmatarii.

Dimensiunile amplasamentului pompei trebuie calculate in stransa legatura cu volumul

estimat de apa si cu debitul pompei, pentru evitarea unei frecvente prea mari de porniri

ale pompei.Pompa nu trebuie supusa la mai mult de 30 cicluri de pornire pe ora pentru

evitarea supraincalzirii motorului.

Conexiune electrica

Este recomandata conectarea pompei la un circuit electric dedicat, cu impamantare.

Aceste pompe cu motoare monofazate sunt dotate cu protecte termica si pot fi conectate

direct la retea.