Equipment Technologies APACHE AS1010 User manual

FORM # 580000049

COPYRIGHT 2008

EQUIPMENT TECHNOLOGIES

APACHE

A S 1010 & A S 1210

2008 Owner’s Manual

DO NOT OPERATE THIS EQUIPMENT UNTIL THIS MANUAL HAS BEEN READ AND UNDER-

STOOD. ONLY PROPERLY TRAINED PERSONS SHOULD OPERATE THIS MACHINE.

TM

INTRODUCTION

Dear Valued Customer,

Congratulations on the purchase of your new Apache Sprayer and welcome to

the Apache family of owners. We hope that your new sprayer exceeds your

expectations and gives you years of satisfaction. We invite you to visit us at

www.apachesprayer.com or in person at our plant in Mooresville, Indiana if

you are in the area.

On behalf of all of our employees we thank you for your business.

Yours Faithfully,

Matthew F. Hays

Chief Executive Officer

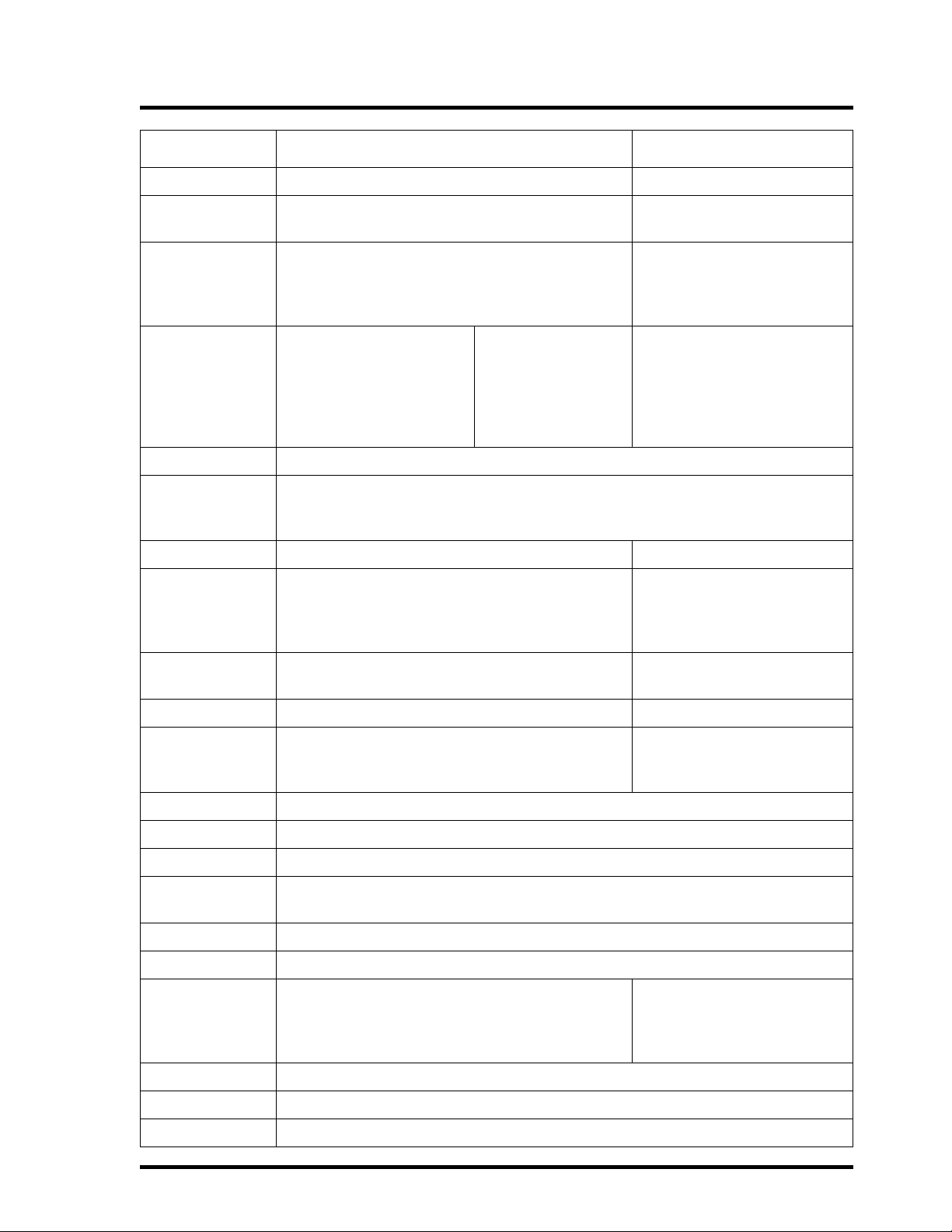

SPECIFICATIONS

AS1010 AS1210

Tank Capacity 850 gallons (1000 gallons optional) 1200 gallons

Engine 215 Cummins Tier III

655 ft-lb@1500 rpm

275 Cummins Tier III

655 ft-lb@1500 rpm

Transmission Standard: ITL Powershift 6-speed

torque converted

Optional: Funk Powershift 6-speed

torque converted

Funk Powershift

6-speed, torque converted

Speeds ITL 6-Speed

1st 0-5 mph

2nd 0-8 mph

3rd 0-11 mph

4th 0-18 mph

5th 0-29 mph

6th 0-36 mph

Funk Transmission

1st 0-5 mph

2nd 0-8 mph

3rd 0-11 mph

4th 0-18 mph

5th 0-29 mph

6th 0-36 mph

1st 0-5 mph

2nd 0-8 mph

3rd 0-11 mph

4th 0-18 mph

5th 0-29 mph

6th 0-36 mph

Brakes Internal, wet disc self-adjusting

Suspension Front Axle: Center oscillation with independent hydraulic accumulation.

Rear Axle: Patented hydraulic load suspension with compensating anti-sway con-

trol, self-adjusting for diminishing/increasing load.

Crop Clearance 36”, 42”, 48” 48”

Axles Narrow fixed: 88” to 90”, 100” to 101”, 102” -

104”, 105” to 114”. 48” crop clearance only.

Wide adjustable: 120” to 144” (Optional hydraulic

adjust)

Wide adjustable: 120” to

144”. (Optional hydraulic

adjust)

Final Drive Standard: Fairfield all gear drop box

Optional: ITL/JCB planetary gear set Fairfield all gear drop box

Cab ET custom ET custom

Weight 17,329 lbs. (approximate)

Dry weight with poly tank.

20,170 lbs. (approximate)

Dry weight with stainless

steel tank.

Width 144” (12’)

Height 144” (42” crop clearance)

Length 27’

Booms 60’, 75’, 80’, 90’, 100’

60/80, 60/90

Boom Height 14” to 74” (42” crop clearance); 20” to 80” (48” crop clearance)

Wheel Base 173” (14’5”)

Tires Standard Front: 12.4 x 28

Standard Rear: 380/90R46

Optional Front: 380/80R38

Optional Rear: 320/90R46

Standard Front: 380/80R38

Standard Rear: 380/90R46

Turning Radius 17’

Fuel Capacity 100 gallons

Product Pump Hypro 9306S HM1C, hydraulically driven centrifugal pump

OPTIONAL EQUIPMENT

AS1010 Optional Equipment

Please contact your Apache dealer or

www.apachesprayer.com

for more information on optional equipment.

• Narrow axle (48”CC) fixed 88” or 90”, 100-

101”, 102-104”, or 105-114

• 120”-144” manual adjust axles with 36” crop

clearance

• Heavy-duty front axle with 380/80R38 tries,

h.d. spindles, and hubs for all axle spacing

• Hydraulic on the go wheel adjust (not avail-

able on any narrow axle)

• Funk 6-speed power shift transmission

• 1000 gallon poly tank (must get heavy duty

front axle with this tank)

• 850 gallon stainless steel tank

• 1000 gallon stainless steel tank (must get

heavy duty front axle with this tank)

• Raven 4400 Rate controller, radar speed

pickup or drive shaft sensor

• Raven Envisio Pro Controller (must choose

GPS receiver)

• Raven Envizio Plus

• Raven SmarTrax Autosteer

• Raven GPS receivers 200 and 300

• Raven Autoboom PowerGlide Plus (wheel

gauged)

• Raven Autoboom UltraGlide (optical eye)

• Raven Viper Pro Controller

• Raven AccuBoom (automatic boom shut

off)**

• Smucker Injection Foam Marker

• Additional 50 gallon poly rinse tank (rear

mounted)

• Rotoflush, pump pressured (poly tank only)

• Fence row nozzles one side or both

• Hypro chemical eductor

• 5-way nozzle bodies

• Front fenders (not available on 36” CC)

• Rear fenders (not available on 36” CC)

• Auxiliary field light kit (mounts to cab roof)

• Narrow front ties 320/85R38 (for heavy duty

front axle only)

• Narrow rear tires 320/90R50

• Dual rear tires and spacers either 380/90R46

or 320/90R50 (48” CC only)

• Product tank fill 3” (see wet system for more

options on product side)

• Wide tires front, either 480/70R34 or

23.1”x26” R-3 TORC TRAC TL*

• Wide tires rear, either 520/85R46 or 30.5”x32”

R-3 TORC TRAC TL*

* Only for use on 48” crop clearance models.

** Must also choose controller and GPS options

Note: The AS1010 can be ordered with a Funk 6-

speed power shift transmission option. This option

allows for a second hydraulic pump to be

mounted to the transmission for operating an air

boom.

OPTIONAL EQUIPMENT

AS1210 Optional Equipment

Please contact your Apache dealer or www.apachesprayer.com for more information on optional equp-

ment.

• Hydraulic on the go wheel adjust

• Raven 4400 Rate controller, radar speed pickup or drive shaft sensor

• Raven Envizio Pro Controller (must choose GPS receiver)

• Raven Envizio Plus

• Raven SmarTrax Autosteer

• Raven GPS receivers 200 or 300

• Raven Autoboom PowerGlide Plus (wheel gauged)

• Raven Autoboom UltraGlide (optical eye)

• Raven Viper Pro Controller

• Raven AccuBoom (automatic boom shut off)*

• Smucker Injection Foam Marker

• Additional 50 gallon poly rinse tank (rear mounted)

• Rotoflush, pump pressured (poly tank only)

• Fence row nozzles one side or both

• Hypro chemical eductor

• 5-way nozzle bodies

• Front fenders

• Rear fenders

• Auxiliary field light kit (mounts to cab roof)

• Dual rear tires 380/90R46

• Wide tires front, either 480/70R34 or 23.1”x26” R-3 TORC TRAC TL

• Wide tires rear, either 520/85R46 or 30.5”x32” R-3 TORC TRAC TL

• Product tank fill 3” (see wet system for more options on product side)

• New Leader L3020G4 stainless steel spinner box with (Apache dealer must purchase from Highway

Equipment Company directly and mount the box to Apache)

* Must also choose a controller and GPS option

General Information

The graphics and text in this manual generally describe the AS1010 and AS1210 Apache Sprayers.

Apache Sprayers differ by model and by optionally installed equipment. Your Apache Sprayer may not

exactly match the graphics and/or text descriptions in this manual. Please contact your dealer or Equip-

ment Technologies with any questions regarding this manual or the instructions within.

CONTENTS

Chapter 1: Safety Rules

Safety Signals . . . . . . . . . . . . . . . . . . . . .1-1

Safety Rules . . . . . . . . . . . . . . . . . . . . . . .1-1

Training . . . . . . . . . . . . . . . . . . . . . . . .1-1

Preparation . . . . . . . . . . . . . . . . . . . . .1-1

Starting . . . . . . . . . . . . . . . . . . . . . . . .1-1

Seat Belt . . . . . . . . . . . . . . . . . . . . . . .1-1

Operation . . . . . . . . . . . . . . . . . . . . . .1-2

Entanglement . . . . . . . . . . . . . . . . . . . 1-2

Protective Equipment . . . . . . . . . . . . .1-2

Chapter 2: Safety Decals

Left-Side Decals . . . . . . . . . . . . . . . . . . . .2-1

Cab-Mounted Decals . . . . . . . . . . . . . . . .2-2

Engine-Mounted Decals. . . . . . . . . . . . . .2-3

Chassis-Mounted Decals . . . . . . . . . . . . .2-3

Tank-Mounted Decals . . . . . . . . . . . . . . .2-4

Chapter 3: Vehicle Operation

General Guidelines. . . . . . . . . . . . . . . . . .3-1

Pre-operation Check List . . . . . . . . . . . . .3-1

Cab Overview. . . . . . . . . . . . . . . . . . . . . .3-2

Cab Access Ladder . . . . . . . . . . . . . . . . .3-2

Steering Column. . . . . . . . . . . . . . . . . . . .3-3

Fault Code Indicator:. . . . . . . . . . . . . .3-3

Apache Sprayer Console . . . . . . . . . . . . .3-4

Raven 4400 Controller and T-Handle . . .3-6

Fuse Block . . . . . . . . . . . . . . . . . . . . . . . .3-7

Climate Control and Light

Switches . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Vehicle Lighting . . . . . . . . . . . . . . . . . . . .3-8

AM/FM Radio with

Weather Band and CD Player . . . . . . . . .3-8

CB Radio Knockout . . . . . . . . . . . . . . . . . 3-9

Seat Adjustment . . . . . . . . . . . . . . . . . . . .3-9

Starting and Stopping the Engine . . . . .3-10

Starting . . . . . . . . . . . . . . . . . . . . . . .3-10

Warm-up . . . . . . . . . . . . . . . . . . . . . .3-11

Stopping . . . . . . . . . . . . . . . . . . . . . .3-11

Vehicle Direction and Speed . . . . . . . . .3-12

Neutral. . . . . . . . . . . . . . . . . . . . . . . .3-12

Forward . . . . . . . . . . . . . . . . . . . . . . .3-12

Shifting Gears . . . . . . . . . . . . . . . . . .3-13

Reverse. . . . . . . . . . . . . . . . . . . . . . .3-14

Cruise Control . . . . . . . . . . . . . . . . . .3-14

Towing. . . . . . . . . . . . . . . . . . . . . . . .3-15

Hood Release. . . . . . . . . . . . . . . . . . . . .3-15

Battery . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Antenna Mounting Plate . . . . . . . . . . . . .3-16

Raven Drive Shaft Speed

Sensor (Optional) . . . . . . . . . . . . . . . . . .3-16

Raven Radar Gun (Optional) . . . . . . . . . 3-16

Axle Adjustment (Manual) . . . . . . . . . . . 3-17

Front . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Rear . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Axle Adjustment (Optional)

(Adjust On The Go) . . . . . . . . . . . . . . . . 3-18

Front . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Rear . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Optional Equipment . . . . . . . . . . . . . . . . 3-19

Chapter 4: Wet System Operation

Wet System Overview . . . . . . . . . . . . . . . 4-1

Fill Station . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Product Pump and Valves . . . . . . . . . . . . 4-2

Sump Valve . . . . . . . . . . . . . . . . . . . . . . . 4-2

Rinse and Foam Tank . . . . . . . . . . . . . . . 4-2

Second Rinse Tank (Optional) . . . . . . . . . 4-3

Flow Control . . . . . . . . . . . . . . . . . . . . . . . 4-3

Standard Flow. . . . . . . . . . . . . . . . . . . 4-3

Electronic Boom Valves . . . . . . . . . . . 4-3

Raven 4400 Monitor. . . . . . . . . . . . . . . . . 4-4

Apache Precision Fuse Box . . . . . . . . 4-5

Side Console . . . . . . . . . . . . . . . . . . . . . . 4-6

T-Handle . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Filling Product Tank . . . . . . . . . . . . . . . . 4-11

Filling Rinse Tank. . . . . . . . . . . . . . . . . . 4-11

Operating Booms . . . . . . . . . . . . . . . . . . 4-13

Tilt to Remove Boom from Cradle. . . 4-13

Unfold Booms . . . . . . . . . . . . . . . . . . 4-13

Unfold Boom Tips . . . . . . . . . . . . . . . 4-14

Height Adjustment. . . . . . . . . . . . . . . 4-14

Tilt to Level Boom . . . . . . . . . . . . . . . 4-15

Fold Boom Tips. . . . . . . . . . . . . . . . . 4-15

Fold Booms. . . . . . . . . . . . . . . . . . . .4-16

Tilt to Return Boom to Cradle . . . . . .4-16

Adjust Poly Tank Straps (if equipped)4-16

Spraying . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Operating Foam Marker . . . . . . . . . . . . . 4-20

Auto Foam . . . . . . . . . . . . . . . . . . . . 4-20

LandMark Injection Foam Marker . . . 4-21

Flushing Product Tank . . . . . . . . . . . . . . 4-24

Flushing Booms . . . . . . . . . . . . . . . . . . . 4-25

Flushing Wet System . . . . . . . . . . . . . . . 4-26

Cleanload Chemical Eductor . . . . . . . . . 4-28

Startup . . . . . . . . . . . . . . . . . . . . . . . 4-28

Loading Liquid or Powdered Chemical into

Hopper . . . . . . . . . . . . . . . . . . . . . . . 4-28

Loading Liquid and/or Powdered Chemical

with Suction Lance . . . . . . . . . . . . . . 4-29

Shutdown . . . . . . . . . . . . . . . . . . . . . 4-29

Chapter 5: Lubrication and Maintenance

General Information . . . . . . . . . . . . . . . . 5-1

Apache Sprayer Service Interval Chart . 5-2

Before Initial Use . . . . . . . . . . . . . . . . . . 5-3

After First 10 Hours. . . . . . . . . . . . . . . . . 5-3

Adjust Boom . . . . . . . . . . . . . . . . . . . 5-3

As Required . . . . . . . . . . . . . . . . . . . . . . 5-5

Inspect Front Accumulator. . . . . . . . . 5-5

Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Grease Boom. . . . . . . . . . . . . . . . . . . 5-6

Flush Wet System . . . . . . . . . . . . . . . 5-8

Check Tire Pressure . . . . . . . . . . . . . 5-8

Check Engine Oil Level . . . . . . . . . . . 5-8

Check Cooling System . . . . . . . . . . . 5-9

Check Brake Fluid Level . . . . . . . . . . 5-9

Check Transmission Fluid Level . . . 5-10

Check Hydraulic Fluid Level . . . . . . 5-11

Check A/C Compressor Belt . . . . . . 5-11

Every 40 Hours . . . . . . . . . . . . . . . . . . . 5-12

Torque Lug Nuts . . . . . . . . . . . . . . . 5-12

Grease Steering Components . . . . . 5-12

Grease Axle Components . . . . . . . . 5-13

Torque Boom Lead Bolts. . . . . . . . . 5-13

Check Differential Fluid Level . . . . . 5-14

Check Rear Differential for Leaks . . 5-14

Re-Phase Steering Cylinders . . . . . 5-14

After First 100 Hours. . . . . . . . . . . . . . . 5-15

Every 100 Hours . . . . . . . . . . . . . . . . . . 5-15

Grease Driveline Components . . . . 5-15

Check Axle Extension Bolt Torque . 5-16

Adjust Poly Tank Straps

(if equipped). . . . . . . . . . . . . . . . . . . 5-17

Replace Fuel Filter . . . . . . . . . . . . . 5-17

Replace Fuel Separator Filter . . . . . 5-17

Every 250 Hours . . . . . . . . . . . . . . . . . . 5-18

Clean or Replace Engine Primary

Air Filter . . . . . . . . . . . . . . . . . . . . . . 5-18

Replace Differential Fluid . . . . . . . . 5-19

Replace Hydraulic Fluid Filter . . . . . 5-19

Clean Hydraulic Fluid Strainers . . . . 5-20

Every 500 Hours or Yearly . . . . . . . . . . 5-21

Check Accumulator Fluid Level . . . . 5-21

Replace Fuel Filter. . . . . . . . . . . . . . 5-21

Replace Fuel Separator Filter . . . . . 5-22

Replace Planetary Fluid

(AS 1010 Only) . . . . . . . . . . . . . . . . 5-22

Replace Steering Pressure Filter. . . 5-23

Replace Engine Oil and Filter . . . . . 5-23

Replace Transmission Fluid

and Filter . . . . . . . . . . . . . . . . . . . . . 5-24

Recalibrate Raven Radar Gun. . . . . 5-26

Inspect and Repack Wheel

and Inter-Flex Bearings . . . . . . . . . . 5-26

Every Year . . . . . . . . . . . . . . . . . . . . . . 5-27

Adjust Toe-In . . . . . . . . . . . . . . . . . . 5-27

Replace Engine Safety Air Filter . . . 5-28

Winterize Wet System . . . . . . . . . . . 5-28

Replace Cab Recirculating

Air Filter . . . . . . . . . . . . . . . . . . . . . . 5-31

Replace Cab Charcoal

Air Filter . . . . . . . . . . . . . . . . . . . . . . 5-31

Replace Drop Box Fluid. . . . . . . . . . 5-32

Check Front Suspension

Accumulator Charge . . . . . . . . . . . . 5-32

Every 1000 Hours or Yearly . . . . . . . . . 5-33

Clean Transmission Fluid Strainer. . 5-33

Replace Hydraulic Fluid. . . . . . . . . . 5-33

Chapter 6: Cummins Engine Fault Codes

Chapter 7: Torque Value Charts

Fittings. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Chapter 8: Troubleshooting

Apache Sprayer Troubleshooting Symptoms

and Solutions . . . . . . . . . . . . . . . . . . . . . 8-1

Chapter 9: System Schematics

Hydraulic System . . . . . . . . . . . . . . . . . . 9-1

Electrical System (Sheet 1 of 5) . . . . . . . 9-2

Electrical System (Sheet 2 of 5) . . . . . . . 9-3

Electrical System (Sheet 3 of 5) . . . . . . . 9-4

Electrical System (Sheet 4 of 5) . . . . . . . 9-5

Electrical System (Sheet 5 of 5) . . . . . . . 9-6

Chapter 10: Warranty

Equipment Technologies Warranty Policy10-1

1-1

SAFETY RULES

Safety Signals

Safety is a primary concern in the design and

manufacturing of our products. Throughout this

manual and on the machine potential hazards are

identified by the “Safety Alert Symbol” followed by

a “Signal Word” which indicates the degree of

hazard. The three degrees of hazard are “Dan-

ger”,” Warning”, and “Caution”

“Danger” indicates an imminently hazardous situ-

ation that, if not avoided, will result in death or

serious injury.

“Warning” indicates a potentially hazardous situa-

tion that, if not avoided, could result in death or

serious injury, and includes hazards that are

exposed when guards are removed.

“Caution” indicates a potentially hazardous situa-

tion that, if not avoided, may result in minor or

moderate injury.

Safety Rules

Training

Carefully read and understand this manual and all

safety decals. If the manual or safety decals

become damaged or misplaced, replacements

may be obtained from your dealer or by calling

(317) 834-4500.

Carefully read and understand all non-Apache

Sprayer manufacturer instructions and manuals

supplied with the Apache Sprayer. These include,

but are not limited to the Engine Owner’s Manual,

Sprayer Monitor System Manual, Radio Manual,

Chemical Eductor Manual, Product Pump Instruc-

tions, and other optional equipment.

Do not allow anyone to operate this equipment

without proper instruction.

If you do not understand any part of this manual

and need assistance, see your dealer.

Preparation

Check all hardware, tighten to torque chart speci-

fications shown in the “Lubrication and Mainte-

nance” section of this manual. See “Lubrication

and Maintenance” on page 5-1.

Check all hydraulic hoses and fittings for leaks

and make sure they are in good working condition

prior to starting the machine. Replace any worn or

damaged fittings or hoses. Check hose routing to

prevent damage during machine operation.

Check tires for proper inflation pressure according

to tire manufacturers recommendations.

Starting

Start engine only from operator’s seat, with trans-

mission in neutral and the parking brake set.

Never start engine by shorting across starter ter-

minals.

Seat Belt

Periodically inspect seat belt and seat belt mount-

ing for damage. Inspect belt for cuts, frays, wear,

discoloration, or abrasion. Replace any damaged

parts (see your dealer).

Never operate equipment without seat belt prop-

erly installed.

SAFETY RULES

1-2

Operation

Reduce the chance of machine roll-over:

• Do not operate on steep slopes.

• Do not drive across a slope. Drive up and

down slopes.

• Do not turn down a slope.

• Slow down when turning.

• Keep booms as close to the ground as possi-

ble.

• Drive slowly across rough ground.

• Do not operate on public roads or highways

with product in the product tank.

Always come to a complete stop before reversing

directions.

Do not fold or unfold booms near power lines.

Do not fold or unfold booms while the vehicle is

moving over 5 mph.

Secure any loose items in cab. Items that are

unsecured may cause injury in case of a vehicle

roll-over.

Do not allow riders in the cab or on the Apache

Sprayer.

Entanglement

Keep hands, feet, hair, and clothing away from all

moving parts. Wear relatively tight and belted

clothing while operating or repairing machine.

Protective Equipment

Always wear clothing appropriate to the job.

When handling chemicals wear long sleeves and

pants, goggles, and gloves. If necessary wear a

respirator when handling chemicals. Remove or

clean contaminated clothing before entering the

cab.

Always wear safety glasses when repairing

machine.

2-1

SAFETY DECALS

Left-Side Decals

NOTE

For 12.4X28” tires:

Torque wheel bolts to

180 foot pounds.

NOTE

For 38” tires:

Torque wheel bolts to

315 foot pounds.

SAFETY DECALS

2-2

Cab-Mounted Decals

SAFETY DECALS

2-3

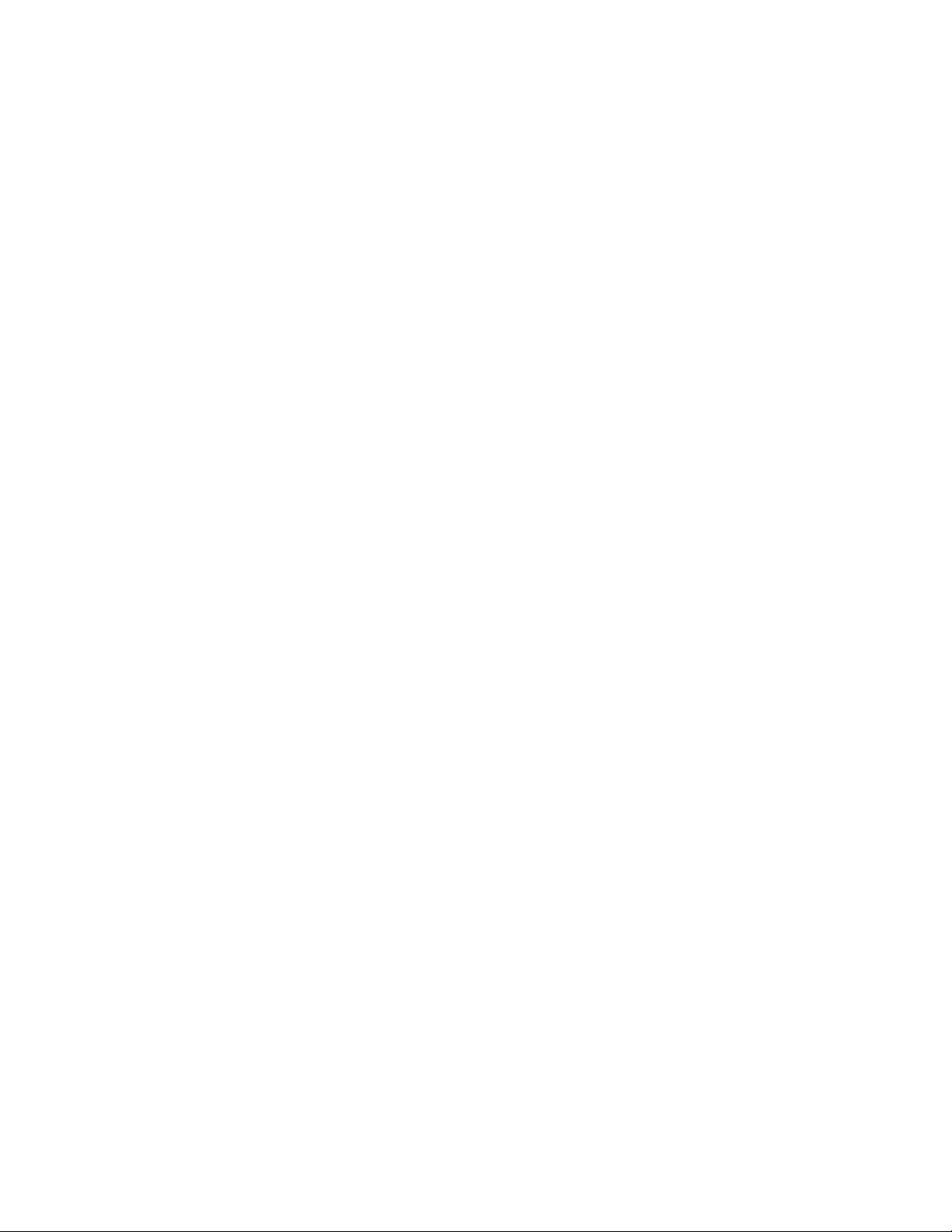

Engine-Mounted Decals

Chassis-Mounted Decals

SAFETY DECALS

2-4

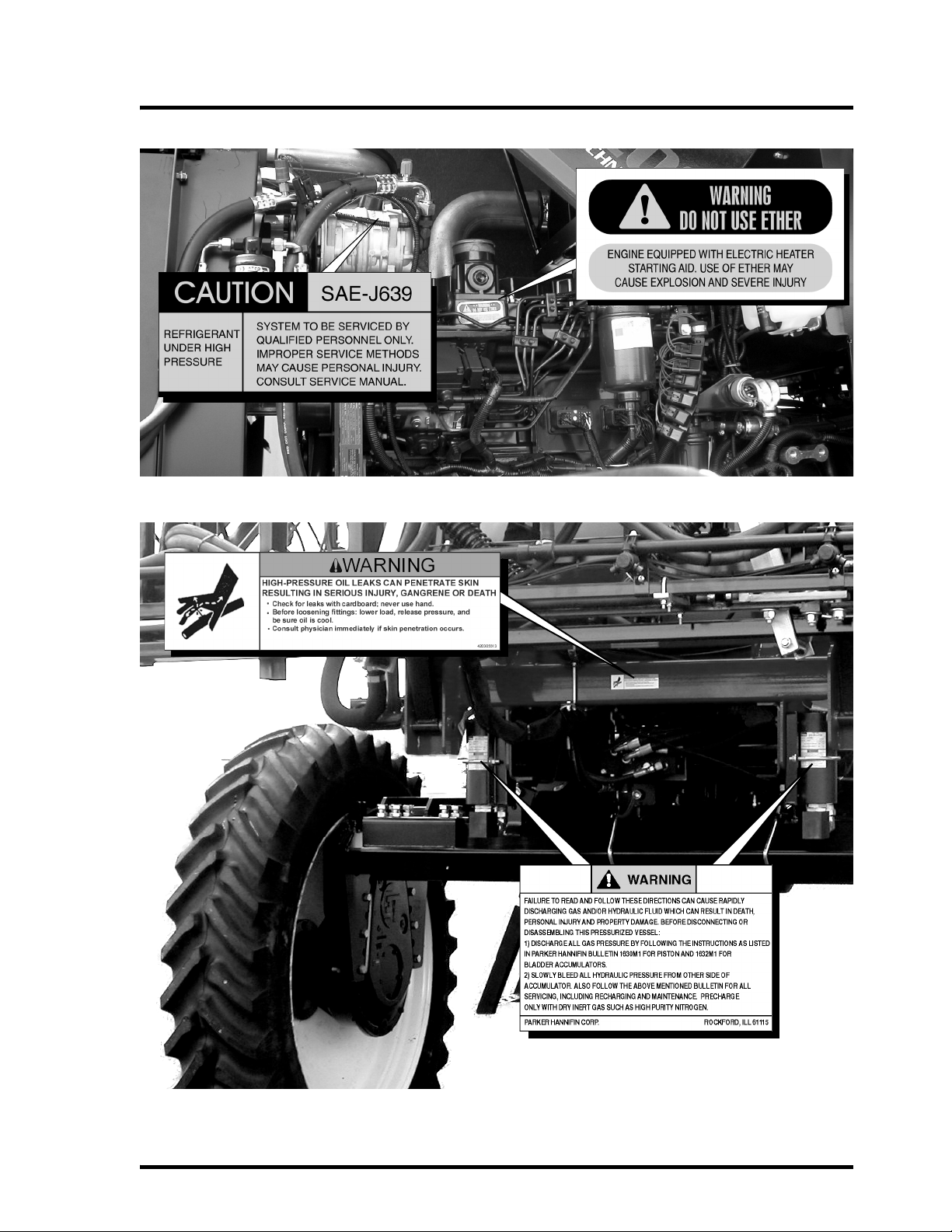

Tank-Mounted Decals

3-1

VEHICLE OPERATION

General Guidelines

Carefully read and understand this manual and all

safety decals. If the manual or safety decals

become damaged or misplaced, replacements

may be obtained from your dealer or by calling

(317) 834-4500.

Do not allow anyone to operate this equipment

without proper instruction.

If you do not understand any part of this manual

and need assistance, see your dealer.

Pre-operation Check List

• Read and understand the owner’s manual

before operating the Apache Sprayer.

• Review and follow all safety rules and safety

decal instruction. See “Safety Rules” on

page 1-1. See “Safety Decals” on page 2-1.

• Check that all safety decals are installed and

in good condition. Replace if damaged.

• Check that all shields and guards are properly

installed and in good working condition.

Replace if damaged.

• Check that all hardware is properly installed

and secured.

• Check area for bystanders and obstruction

before operating.

• Check that all hydraulic hoses and fittings are

in good condition and not leaking before start-

ing tractor.

• Check that hoses are not twisted, sharply

bent, kinked, frayed, or pulled tight and are

not rubbing. Replace any damaged hoses

immediately.

• Make sure seat belt is in good condition.

• Check tires for proper inflation pressure

according to specifications on the back cover

of this manual. See “Check Tire Pressure” on

page 5-8.

• Check oil level in engine prior to starting. Add

oil as needed according to specifications on

the back cover of this manual. See “Check

Engine Oil Level” on page 5-8.

• Check fluid level in transmission. Add fluid as

needed according to specifications on the

back cover of this manual. See “Check Trans-

mission Fluid Level” on page 5-10.

• Check fluid level in differential, gearboxes,

and/or planetaries prior to starting. Add fluid

as needed according to specifications on

back cover of this manual. See “Check Differ-

ential Fluid Level” on page 5-14.

• Check coolant level. Add coolant as needed

according to specifications on back cover of

this manual. See the engine manufacturer’s

manual for details.

• Check hydraulic fluid level in reservoir. See

“Check Hydraulic Fluid Level” on page 5-11.

• Check tank straps on poly product tank to

make sure they are tight.

VEHICLE OPERATION

3-2

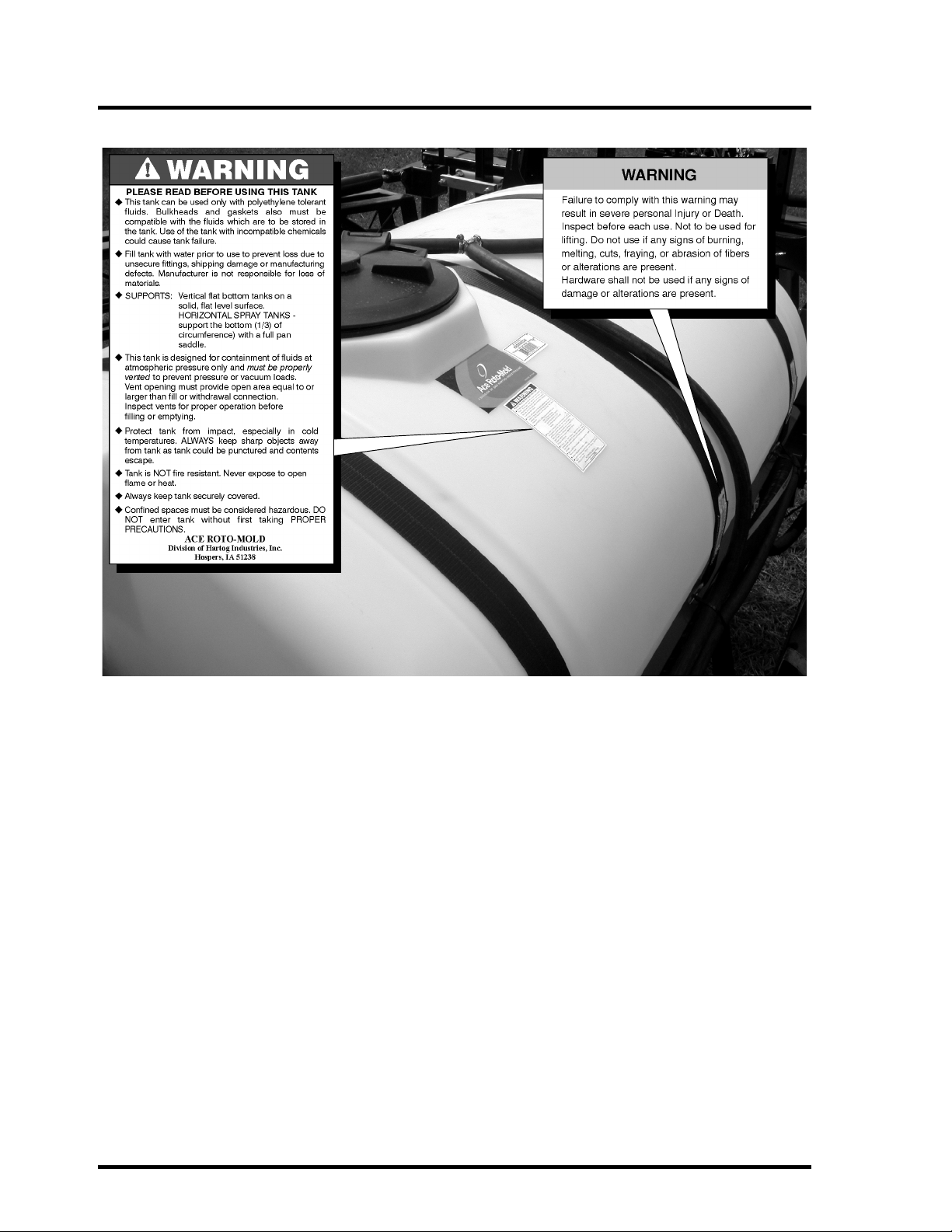

Cab Overview

1. Air vents

2. Steering Column

3. Steering Wheel

4. T-Handle

5. Side Console

6. Air Seat

7. Vehicle Brakes

8. Padded Storage Unit

9. Cup Holder

10. Fire Extinguisher

Cab Access Ladder

1. Access Ladder

The cab access ladder is

automatically actuated by the

parking brake switch. When

the parking brake is applied,

the ladder folds down. When

the parking brake is released,

the ladder folds up.

VEHICLE OPERATION

3-3

Steering Column

1. Adjustment Lever

Turn the lever counter-clockwise to

release the column. Set the tilt and tele-

scope to the desired position. Turn the

lever clockwise to lock the column.

2. Hazard Flasher Button

3. Steering Wheel

4. Key Switch

Shown in “OFF” position. See Starting

and Stopping the Engine for more details.

5. Turn Signal Lever

Push lever up for right turn signal, push

down for left turn signal.

6. Windshield Wiper Switch

Turn lever to the “I” position for low speed

wiper. Turn lever to the “II” position for

high-speed wiper.

7. Windshield Washer

Push ring to operate washer.

8. Horn Button

Push to sound horn.

Fault Code Indicator:

1. Fault Code Indicator on Console

When a fault code is logged, the ET logo

will disappear on the right side of the con-

sole display and one or more of the fol-

lowing fault codes will appear:

• Stop Engine

• Check Engine

• Water In Fuel

• Wait To Start

• Water Temperature

• Failed Fuse F11

• Low Oil Pressure

• Change Air Filter

• High Hyd Temp

• High Trans Temp

• Low Coolant

•ECUFailure

• SPN 00000 FMI 00

Refer to Fault Codes in the Maintenance Section; See “Cummins Engine Fault Codes” on page 6-1.

VEHICLE OPERATION

3-4

Apache Sprayer Console

1. MPH Readout

2. Engine RPM

3. Engine Oil Pressure

4. Engine Water Temperature

5. Voltage Level

6. Fuel Level

7. Direction & Gear Indicator

8. Park Brake Switch

9. Cruise Control Master Switch

10. Axle Hydraulic Adjust Switches In & Out

(Optional)

11. Left Boom Fold In & Fold Out

12. Right Boom Fold In & Fold Out

13. Left Boom Tip In & Fold Out

14. Right Boom Tip In & Fold Out

15. Product Pump On/Off Switch

16. Agitation Pressure Increase & Decrease

17. Foam Master On/Off Switch

18. Foam Auto On/Off

19. Turn Foam Drop On for Right Side

& Left Side

20. Cigarette Lighter

21. Auxiliary Power Outlet

This manual suits for next models

1

Table of contents

Popular Paint Sprayer manuals by other brands

Clarke

Clarke AP8GFM Operation & maintenance instructions

Smith Performance Sprayers

Smith Performance Sprayers S103E use and care manual

Sagola

Sagola Junior 140 instruction manual

ASM

ASM Zip-Spray 2300 Plus Hi-Boy Operation

Smithco

Smithco Spray Star 3182 Operator's manual

Graco

Graco RentalPro 230PC HDR Operation, parts