TOPMAQ SX-ST60A User manual

Trolley Electric Sprayer

Model: SX-ST60A

SX-ST80A SX-ST100A

SX-ST80B SX-ST100B

User’s Manual

This manual is a part of the Sprayer, please keep it properly! In order

to better use and maintain this product, please read this manual carefully

before use. If you have any questions, please contact the dealer.

The Sprayer can only be operated, maintained and repaired by

personnel who are familiar with the characteristics of the Sprayer and

have relevant safety operation knowledge.

The manufacturer shall not be held liable for the reduction of

reliability, damage of sprayer or personal injury caused by unauthorized

restructuring of the Sprayer.

Due to product updating, the contents of this manual are subject to

change without prior notice.

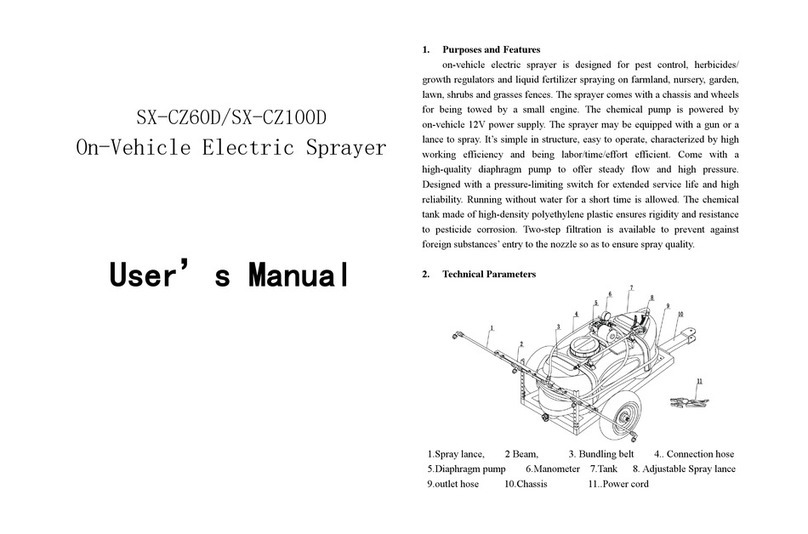

I. Product Overview

1. Comes with a 12V, 100W high power DC electric diaphragm pump,

with maximum working pressure of 10bar, plus overload protection

function, contributing to high pressure, large flow, strong power and

stable performance.

Please read the manual carefully prior to

operation and keep it for future reference!

2. Long boom high-pressure adjustable spray gun, with high strength

engineering plastic body allowing for high pressure spraying and

comfortable grip; with a rotary nozzle offering optional mist/columnar jet

spraying of good atomization performance and far range up to 7m. The

90° spraying angle copper nozzle is wear resistant to ensure extended

service life.

3. The 30m reinforced high-pressure hose allows for long-distance

operation, coupled with a hand-operated hose reel to ensure tidy and

convenient collection.

4. 38Ah high capacity lead-acid power battery allows for continuous

operation up to 4 hours.

5. Designed with a hydraulic adjustment device, with pressure display, to

increase/decrease the working pressure to meet the operation demands.

6. Comes with a trolley frame of double beam and big wheel hub, 4-layer

rubber inflatable engineering tire, to ensure wear-resistance, anti-skid,

shock absorption, easy obstacle crossing, labor-saving push-pull and

flexible steering.

7. The spray tank is made of premium high-density polyethylene under

multi-point wall thickness process control to ensure uniform wall

thickness, good strength, corrosion/aging resistance. The large-size inlet

and drain outlet allow for easy refilling and cleaning.

8.Designed with an external filter of corrosion-resistant PVC to ensure

easy disassembly and cleaning . Its transparent housing makes dirt

visible.

9. Transparent liquid-level display with the help of a floating ball.

10. The spray parts are modularized. You can either chose a high

pressure spray gun with strong targeting performance, and far distance,

or a folding spray wand with large spraying range.

II. Technical parameters

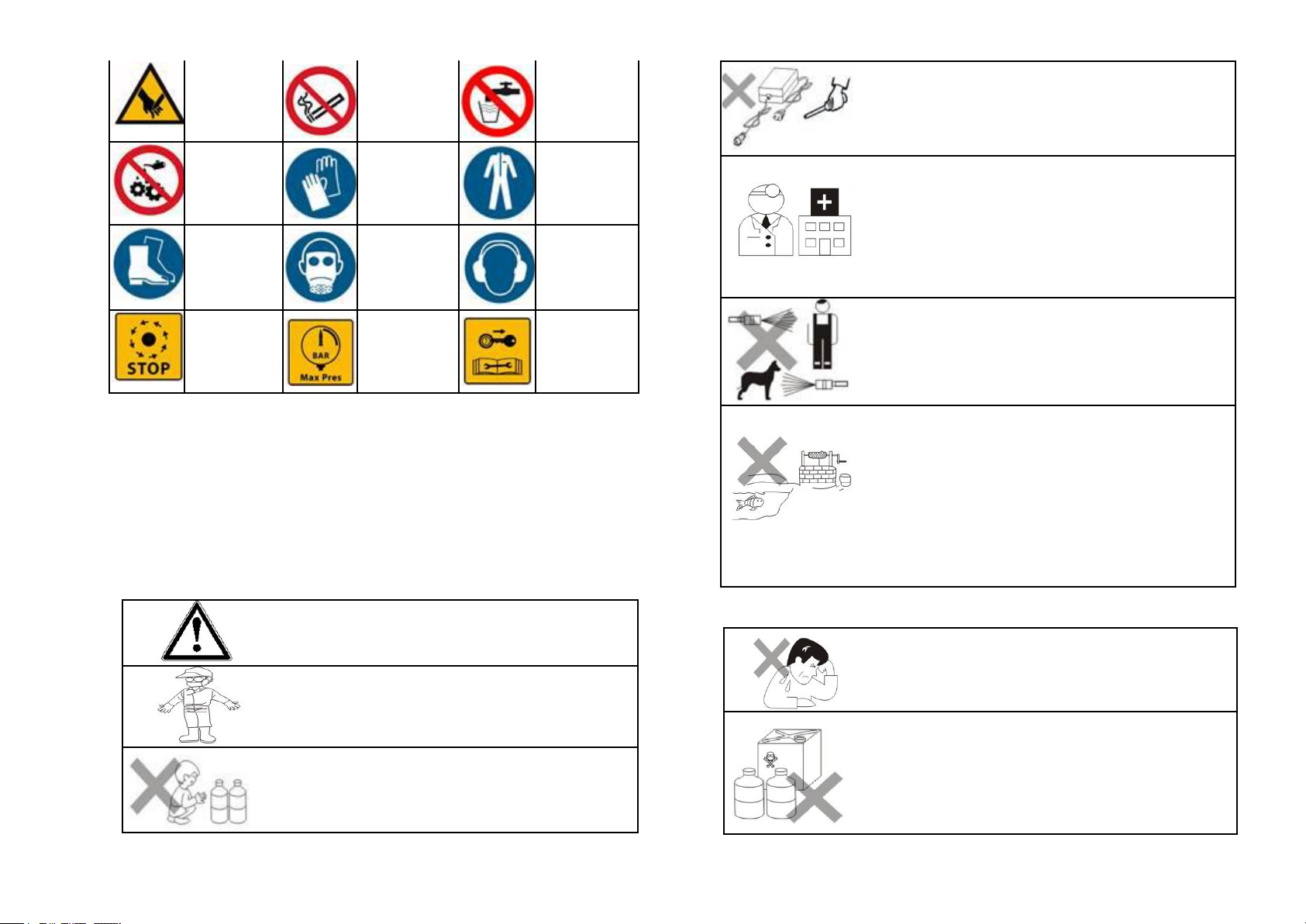

III. Description of safety signs

Caution!

Mind width limit

Crush

hazards.Mind

your hands

Model

SX-

ST60A

SX-

ST80A

SX

-

ST100A

SX-

ST80B

SX

-

ST100B

Capacity of spray tank

60L

80L

100L

80L

100L

External dimension

1440×710

×830

1520×740

×865

1520×740

×865

1520×710

×865

1520×710

×865

Sprayer weight

54.4

56.5

58.5

55.8

57.5

Battery

12V38Ah

Working voltage

12V

Working current

8A

Hose

Specifications

Ø8.5×Ø16

Length

30m

Pump

Type

Diaphragm pump

electric

motor

Power

100w

RPM

2900rpm

Rated pressure

10bar

Pressure limiting

pressure

13bar

Inhalation

volume

7L/min

Charger

input

AC100-240V 2A

output

DC14V 5.0A

Misting

Spray angle

90 Degrees

flow

1.45L/min

Jetting

range

7M

flow

3.3L/min(5bar)

Injury hazards.

Mind your

hands

No Smoking

No drinking

No refuel

during

operation

Wear

protective

gloves

Wear protective

clothing against

pesticide

penetration

Wear

waterproof

rubber shoes

Wear goggles

and masks

Wear ear

protection

STOP alert

Maximum

working

pressure

Refer to the

manual for

operation &

maintenance

IV. Precautions

●while strictly observing the safety operation rules in the Manual,

you are required :

1.Do not use special working fluid;

2.When handling pesticides, follow the safety instructions provided

by the pesticide manufacturer.

DANGER

Please read the manual carefully before operating

the Sprayer and follow the instructions and safety

rules during operation.

In operation, you must wear a mask, a work cap, a

protective clothing, waterproof gloves, rubber

boots and other suitable clothing for operation.

Warehousing and storage of pesticides. Keep out

of reach of children. The safety instructions

provided by pesticide manufacturers should be

strictly followed in the treatment of pesticides.

It is forbidden to repair the charger by non

professionals. If there is any fault, please contact

the dealer.

In case of inhaling the poison, leave the poisoning

environment as soon as possible, move to a

well-ventilated place and lie down for a rest; If your

skin is contaminated, rinse with clean water

immediately; in case of ingesting by mistake, use

clean water or warm salt water to induce vomiting,

before going to the hospital as soon as possible.

During operation, it is never allowed to spray at

people or animals, or operate against the wind.

The unused residual chemicals shall not be

poured into the field, ground or river. It shall be

stored in a special chemical bottle and brought

back safely. Empty chemical bottles and bags

shall either be collected and handed over to the

original manufacturer for centralized disposal, or

buried in a remote area with very deep

underground water , very small rainfall , and far

away from the living area and water resources.

Warning

Persons affected by fatigue, poor health, injury,

pesticide allergy or during pregnancy shall never

engage in pesticide spraying. Alcohol drinking

immediately after the spraying is prohibited.

Never use strong acid, strong alkaline, and other

inflammable solutions. Never use highly-toxic and

highly-persistent pesticide for pest control of

vegetables, melon crops, fruit trees, tee, herbal

medicines etc. And the harvesting time after

pesticide application shall be long enough.

Never put the waste batteries into the fire or

disassemble them without authorization. They

should be collected and handed over to the

manufacturer or environmental protection

authority for recycling.

Don’t keep it at a public place unattended which

may endanger public security.

Notes

The operating temperature of the Sprayer should

not exceed 45°C. Don’t operate when the ambient

temperature is higher than 45°C or lower than -

10°C.

Trial spraying with clean water, a check of various

joints for possible leakage and a check for

atomization condition are required prior to initial

operation. Make sure everything is ok before

preparing the chemical solution.

The preparation of chemical shall follow the

instructions and formula furnished by the pesticide

manufacturer. Unauthorized altering of the dilution

rate of chemical is prohibited, which may either

endanger the human being and animal, or result in

the failure of pest control.

Upon the finish of operation, you shall change

clothes and wash those exposed part of body such

as hands and face. In case of highly toxic pesticide

and germicide, a shower after operation is required

to ensure safety

After use, clean with water and spray the water out

of the spray gun.

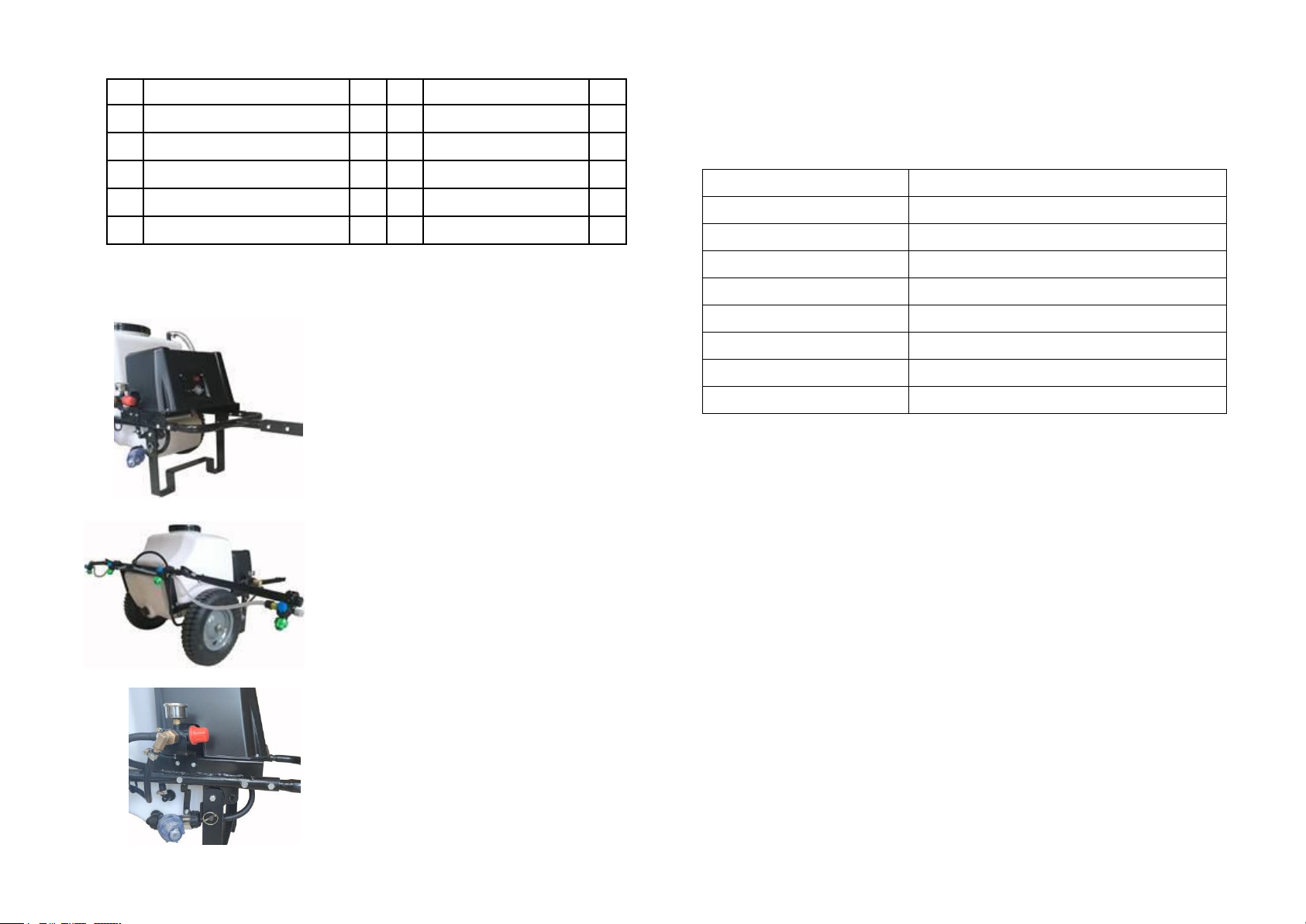

V. Installation of the sprayer

1. Installation of Wheel

Insert the axle into the axle tube of the frame,

before mounting the wheel onto the axle, followed

by putting on flat washer 16, spring washer 16,

M16 nut, and M16 cap nut ,and tightening finally.

2.Installation of hose reel

a.Attach the Reel support to the mounting stand w

ith two M8×20 hexagon bolts before fastening wit

h M8 nuts.

b.The three-way sleeves on both sides of the hos

e reel are respectively mounted on the Reel supp

ort, Use two axis pin 6×35 to pass through the thr

ough-holes on the three-way sleeves and the Ree

l support respectively, and then install the Flat wa

sher 6. Use R-pin 1.8×32 bolt shaft hole to lock.

3. Installation of high pressure connecting hose

Pass the high-pressure connecting hose through t

he lifting ring under the frame and connect it to th

e pump head union(in the accessory package),Pu

t washerØ10×Ø19.3×2 in the pump head union, t

hen install it to the outlet of the pressure regulator,

lock pump head union.

4. Installation of Handlebar

Insert the two Handlebars into the corresponding

frame tube (under the electric control box), and fix

them by inserting four M8 ×40 bolts into the

designated holes, followed by fastening with M8

nuts.

5. Fuse tube installation

Take out fuse tube and fuse cap from the instructio

n bag,Insert the fuse tube into the fuse holder,Then

tighten the fuse cap clockwise.

(After installing the fuse tube, the voltmeter pointer

should rotate to the green area of the dial)

VI. Operation of the Sprayer

Charging Before charging, please confirm whether

the charger input parameters are consistent with the

mains supply. If not, please contact the dealer.

The battery of the sprayer has been charged upon

delivery. Due to self-discharge in the process of

transportation and storage, you are suggested to

check the voltmeter before operating. If the indicator

is in yellow or red area, a re-charging is suggested.

When the charge indicator moves to green area, it

indicates the battery has been fully charged.

Note: please use the charger provided by the

manufacturer to charge The Sprayer

Voltmeter The Sprayer is equipped with a

high-precision voltmeter with the voltage indication

range between DC11V~15V. The green area of the

dial indicates that the battery has been fully charged for

normal operation; the yellow area indicates that the

voltage is insufficient but still capable of further

operation; the red area on the left side indicates that

the voltage is seriously insufficient and needs to be

charged immediately. The scale and value above the

color scale indicates the percentage of the battery's

current capacity to that of full charge. If the sprayer has

been used for a short time, it’s not necessary to charge

after every use. If it is put idle for a long time, a regular

(every one or two months) full discharging followed by

full charging is suggested.

Refilling of chemical Prior to each spraying

operation, remove the spray tank cap and fill the tank

with prepared chemical solution through the filter,

followed by replacing and tightening the tank cap

Notes:1. Trial spraying with clean water and checking

various joints for possible leakage are required prior

to initial operation. Make sure everything is ok before

starting spray operation.

2. The sprayer should not be submerged

directly into the water to fetch water or clean.

Power switch Press the red button next to the

charging port and voltmeter to power on/off the

pump.

Note: 1.The sprayer is designed with overload

protection function. While the power switch is

activated, the pump will stop working by itself once

the spray gun shut-off is at OFF position or the

nozzle is blocked. While the spray gun shut-off is

switched to ON position , the pump will start

operation by itself.(The automatic start/stop system

is only applicable when the battery power exceeds

50%)

2. If the Sprayer is put idle for a long time,

the power switch should be turned off in time.

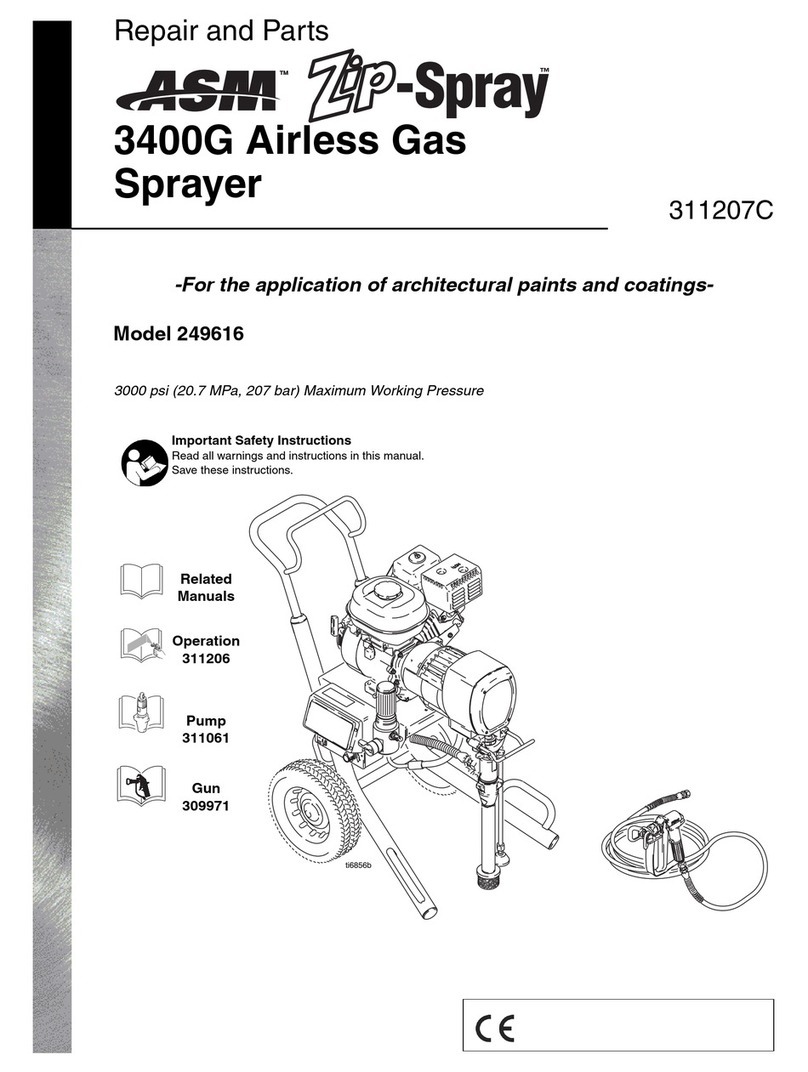

Pressure regulator The working pressure of the

pump may be varied depending on the nozzle and

the object of application, so as to improve the size

of spraying droplets.

The pump pressure may be varied between 0 to

10 bars. Rotate the pressure regulating knob

clockwise to increase; and anticlockwise to

decrease the pressure.

Pressure gauge Display the working pressure of

the pump.

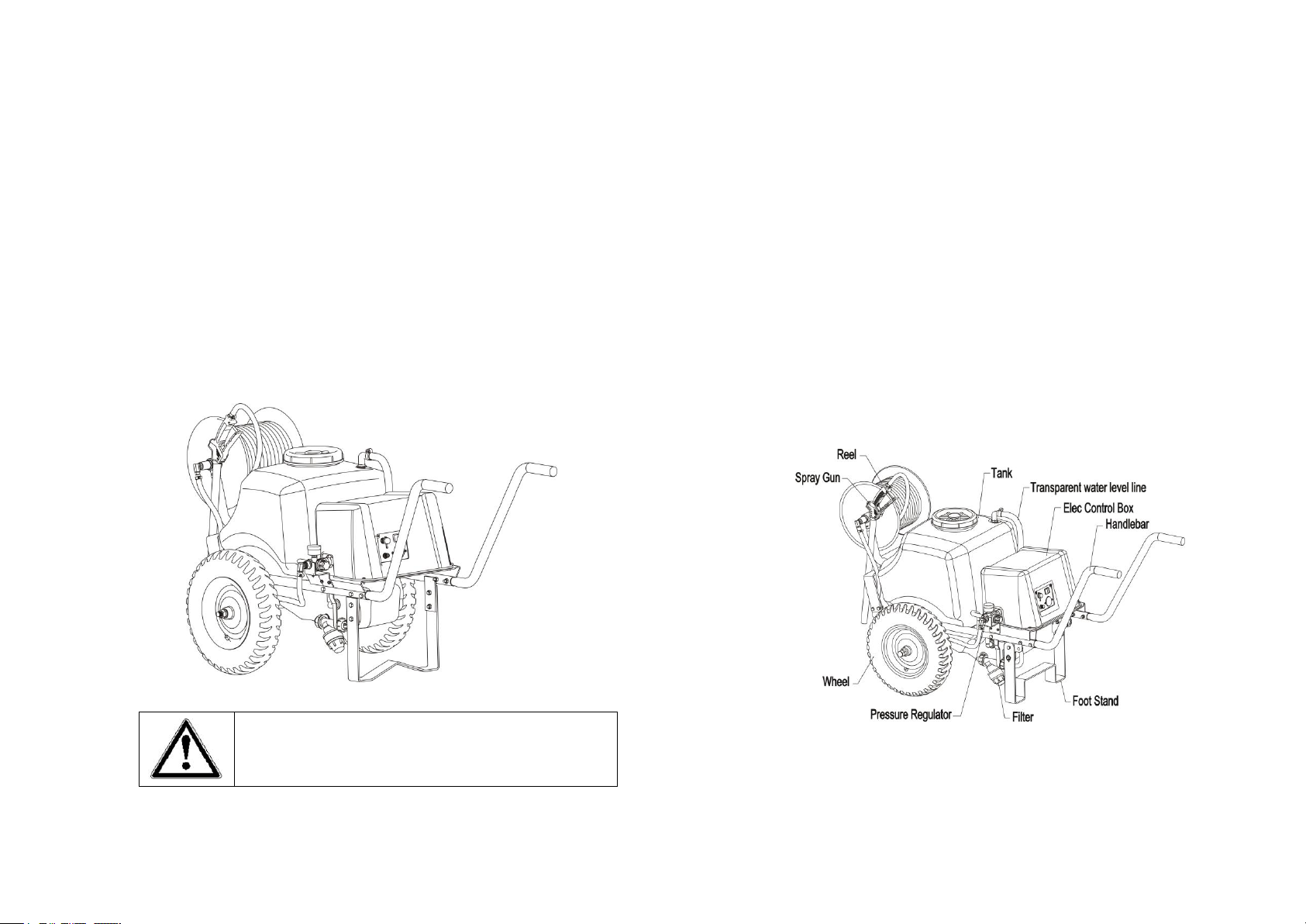

Liquid level line Through the transparent tube

between the electric control box and the spray tank,

the volume of the chemical liquid in the spray tank

can be viewed, and the red floating ball indicates

the liquid level height.

Spray gun shut-off assembly

The handle is equipped with a hook to lock the trigger for continuous

spraying, contributing to convenient operation for the operators.

1. Shut 2. Continuous

Adjustment of nozzle The fogging angle may be varied by rotating the

nozzle. Tightening the nozzle to provide higher

fogging angle, finer fog droplets, and wider

spraying width; loosening to nozzle to obtain

smaller fogging angle, larger flow rate, and

longer spraying distance.

VII. Cleaning and maintenance

After each application, the sprayer should be cleaned to prevent the

corrosion or blocking of the sprayer by pesticides, meanwhile avoid

mixing of chemicals of different varieties between the residual liquid of

this and next applications, which may adversely affect the application

performance or cause harm to crops.

Clean the external surface of the sprayer with a wet cloth. Fill the

tank with clean water and start the pump to spray

until the sprayed water becomes clean. The

remaining water in the spray tank can be

discharged through the water outlet.

Outlet Rotating the drain nut to discharge the

residual liquid or cleaning water. After cleaning,

re-tighten the drain nut.

Cleaning of Filter Rotate anticlockwise to

remove the transparent housing before pulling out

the strainer for a rinsing with water.

Note: When there is chemical in the spray tank,

the chemical may flow out in the process of

removing filter housing.

VIII. Storage

The Sprayer should be stored indoors at a dry place out of reaches of

children. In case of storage for a long time, a regular (every one or two

months) full discharging/charging is required.

When the pest-control season is over and the sprayer is to be stored

for a long time, the sprayer shall be thoroughly cleaned and the residual

water in the pump and pipeline shall be thoroughly removed to prevent

against freezing in winter.

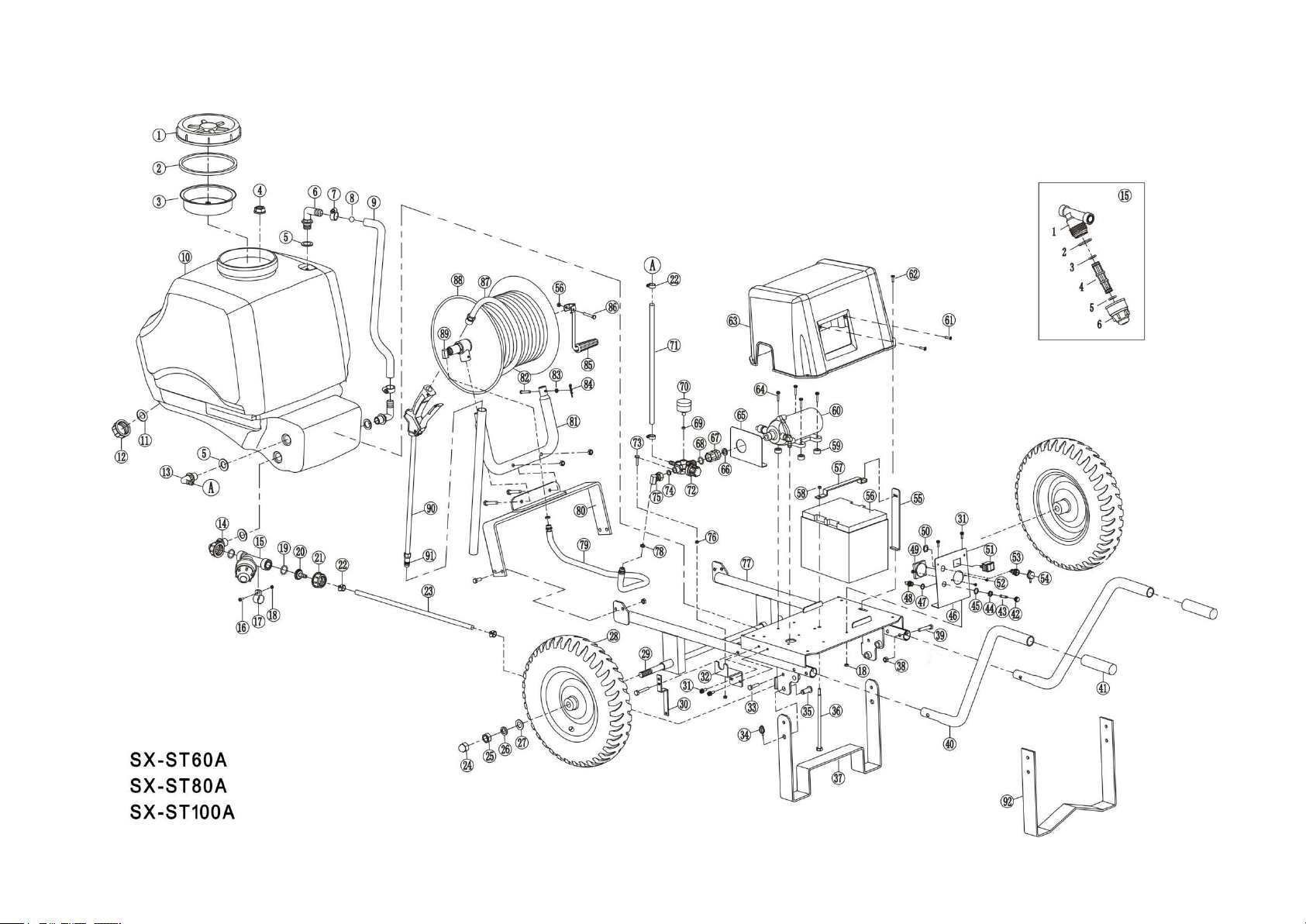

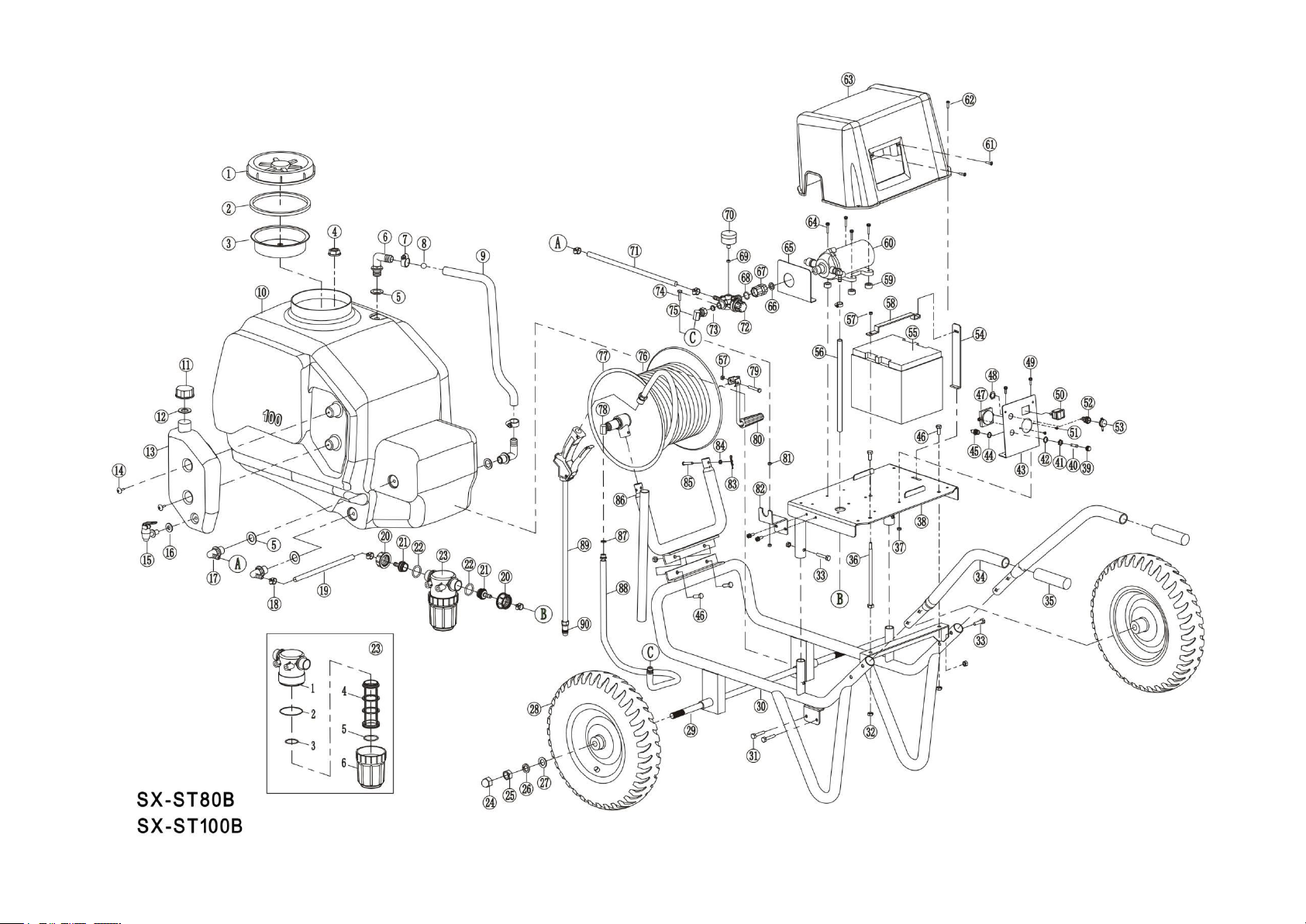

IX. Structural drawings and schedules

Schedules of SX-ST60A/SX-ST80A/SX-ST100A

Schedules of SX-ST80B / SX-ST100B

SN

Part Description

Qty.

SN

Part Description

Qty.

1

Tank Lid

1

30

Filter rack

1

2

Washer for spray tank port

1

31

Cross groove screw M5 × 16

6

3

strainer

1

32

pressure regulator bracket

1

4

Elbow nut

4

33

Hexagonal Bolt M8×20

6

5

Seal Washer Ø20.3×Ø30×3

4

34

Ring lock pin 4 × 25

2

6

Right angle elbow

2

35

Pin with hole 12 × 40

(for SX-ST80A / 100A)

2

7

Pipe-clip 14-27

2

36

Hexagonal Bolt M6×180

1

8

Floating ball

1

37

foot stand(for SX-ST80A/100A)

1

9

Trans. steel wire hose

1

38

Hexagon lock nut M8

12

10

spray tank

1

39

Hexagonal Bolt M8×40

6

11

Washer for drain cap

1

40

Handlebar

2

12

Drain cap

1

41

Handle cover

2

13

Water-return joint

1

42

Fuse cap

1

14

Water inlet Union

1

43

Fuse tube 15A

1

15

filter

1

44

Fuse holder nut

1

15-1

Filter body

1

45

Flat washer

1

15-2

O Ring Ø41×3.5

1

46

panel

1

15-3

O Ring Ø24.5×3.5

1

47

Plastic gasket

1

15-4

strainer

1

48

Fuse holder

1

15-5

O Ring Ø25.5×3.5

1

49

voltmeter

1

15-6

Transparent housing

1

50

Charging seat nut

1

16

cross head screw M5×12

1

51

power switch 30A

1

17

Stainless steel clamp Ø25

1

52

Self tapping screw w/pad ST2.9×8

2

18

Hexagon lock nut M5

13

53

charging seat

1

19

O Ring Ø27×3

2

54

dust cover

1

20

Filter connector

1

55

Battery holder

1

21

Filter lock cap

1

56

battery

1

22

Pipe-clip 13-19

4

57

retainer plate

1

23

Inlet Pipe

1

58

Hexagon lock nut M6

2

24

Cap nut M16

2

59

Damping pad

4

25

hex nut M16

2

60

Water pump

1

26

Spring washer 16

2

61

Cross groove screw M4 × 12

2

27

Flat washer 16

2

62

Cross groove screw M5 × 20

4

28

wheel

2

63

Electric control box cover

1

29

wheel shaft

1

64

Cross groove screw M5 × 25

4

SN

Part Description

Qty.

SN

Part Description

Qty.

1

Tank Lid

1

17

Water-return joint

2

2

Washer for spray tank port

1

18

Pipe-clip 13-19

6

3

strainer

1

19

Water inlet connection hose

1

4

Elbow nut

4

20

Filter lock cap

2

5

Seal Washer

Ø20.3×Ø30×3

4

21

Filter connector

2

6

Right angle elbow

2

22

O Ring Ø23×2.4

2

7

Pipe-clip 14-27

2

23

filter

1

8

Floating ball

1

23-1

Filter body

1

9

Transparent steel wire hose

1

23-2

O Ring Ø66×2.6

1

10

spray tank

1

23-3

O Ring Ø36×2.3

1

11

Water tank cover

2

23-4

strainer

1

12

Washer for drain cap

2

23-5

O Ring Ø41.5×2.65

1

13

water tank

1

23-6

Transparent housing

1

14

Cross groove screw M5 × 12

2

24

Cap nut M16

2

15

water sprout

1

25

hex nut M16

2

16

sprout gasket

1

26

Spring washer 16

2

SN

Part Description

Qty.

SN

Part Description

Qty.

65

baffle

1

79

High pressure connecting

hose

1

66

Seal ring of pump port

1

80

Fixing bracket

1

67

Outlet connection

1

81

Reel support

1

68

O Ring Ø22×2.65

1

82

axis pin 6×35

2

69

Seal Washer

Ø3.5×Ø8.2×2.5

1

83

Flat washer 6

2

70

pressure gauge

1

84

R-pin 1.8×32

2

71

Return Pipe

1

85

rockarm

1

72

pressure regulator

1

86

Cross groove screw M6 × 40

1

73

Bolt for T-groove M5 × 30

1

87

Hose assembly

1

74

washer Ø10×Ø19.3×2

1

88

Reel

1

75

Pump head union

1

89

Reel union

1

76

hex nut M5

1

90

spray gun

1

77

Frame

1

91

Copper nozzle

1

78

O Ring Ø14.5×2.4

2

92

foot stand (for SX-ST60A)

1

List a

X.Troubleshooting

Problems

Analysis

Solutions

Pump doesn't

work after power

on

·The fuse is blown

·The battery is dead

·The power switch is damaged

·Power wires come off

·Motor damaged

·Replace

·Charging

·Replace the switch

·Remove the cover of the

electric control box and

secure the connection of

the wires.

·Replace the motor

Abnormal noise

heard while the

pump rotates

·The fastening screws of pump

is loose

·Tighten the screws

Pump powers

on-off

intermittently

·The work pressure is too high

·Turn the pressure knob

counterclockwise to lower

the pump pressure or

adjust the copper nozzle

to increase the spray

volume.

water leakages

·Damage or looseness occurs to

pipe joints

·The pump head is loose or the

diaphragm is damaged

·Tighten the locking nuts

Tighten the hose clamp

Replace the gasket and

repair it

·Tighten the screw and

replace the water pump

Poor spray

·Pump pressure is set too low

·Low battery power

·The hose is twisted or folded

·Filter or spray gun clogged

·Nozzle wears

·Pump ages

·Turn the pressure regulator

knob clockwise to

increase the pump

pressure

·Charging

·Repair

·Remove impurities

·Replace the nozzle

·Replace

The pump works

but the spray gun

doesn’t spray

water

·The inlet is completely blocked

·The pressure regulator has

been set to the lowest point

and the liquid returns to the

tank

·Valve conglutinates (usually

occurring upon initial use or

after long-term storage)

·Clean up

·Turn the pressure regulator

knob clockwise to

increase the pump

pressure

·Add a small amount of

clean water into the spray

tank, rotate the pressure

regulator anticlockwise to

the dead point, turn on the

power switch until the

liquid pump sprays water

SN

Part Description

Qty.

SN

Part Description

Qty.

27

Flat washer 16

2

59

Damping pad

4

28

wheel

2

60

Water pump

1

29

wheel shaft

1

61

Cross groove screw M4 × 12

2

30

Frame

1

62

Cross groove screw M5 × 20

4

31

Hexagonal Bolt M8×12

2

63

Electric control box cover

1

32

Hexagon lock nut M8

10

64

Cross groove screw M5 × 25

4

33

Hexagonal Bolt M8×40

8

65

baffle

1

34

Handlebar

2

66

Seal ring of pump port

1

35

Handle cover

2

67

Outlet connection

1

36

Hexagonal Bolt M6×180

1

68

O Ring Ø22×2.65

1

37

Hexagon lock nut M5

14

69

Seal Washer Ø3.5×Ø8.2×2.5

1

38

Pallet assembly

1

70

pressure gauge

1

39

Fuse cap

1

71

Return Pipe

1

40

Fuse tube 15A

1

72

pressure regulator

1

41

Fuse holder nut

1

73

washer Ø10×Ø19.3×2

1

42

Flat washer

1

74

Bolt for T-groove M5 × 30

1

43

panel

1

75

Pump head union

1

44

Plastic gasket

1

76

Hose assembly

1

45

Fuse holder

1

77

Reel

1

46

Hexagonal Bolt M8×20

4

78

Reel union

1

47

voltmeter

1

79

Cross groove screw M6 × 40

1

48

Charging seat nut

1

80

rockarm

1

49

Cross groove screw

M5 × 16

6

81

hex nut M5

1

50

power switch 30A

1

82

pressure regulator bracket

1

51

Self tapping screw with pad

ST2.9 × 8

2

83

R-pin 1.8×32

2

52

charging seat

1

84

Flat washer 6

2

53

dust cover

1

85

axis pin 6×35

2

54

Battery holder

1

86

Reel support

1

55

battery

1

87

O Ring Ø14.5×2.4

2

56

Water inlet hose

1

88

High pressure connecting hose

1

57

Hexagon lock nut M6

2

89

spray gun

1

58

retainer plate

1

90

Copper nozzle

1

and returns to the spray

tank, or spray or blow the

water pump from the

water inlet pipe with

high-pressure water or

small air inflator until the

water pump works

normally

The battery fails

to be re-charged

·Poor contact of charging plug

·Internal wires in the Sprayer

breaks

·The input/output lines of charger

are damaged or broken

·The charger is damaged

·The battery is damaged

·Repair or replace the

charging socket

·Remove the cover of the

electric control box and

connect the wires firmly

·Call a professional

technician to repair

·Replace

·Replace

The green light

keeps on during

charging

·Has fully charged

·Poor contact between socket

and charging plug

·The charger malfunctions

·Open circuit

·Faulty soldering or

disconnection of charging

circuit

·OK

·Repair or replace the socket

·Replace

·Repair

·Repair

The red light

keeps on during

charging

·Under charging

·The charger malfunctions

·Battery ages

·The power switch has not been

turned off

·OK

·Replace·Replace

·Replace·Replace

·Turned off

The indicator

does not light up

when charging

·There is no electricity in the

mains socket

·The charger malfunctions

·Repair

·Replace

XI. Packing list

XII. SX-ST80A /SX-ST100A accessories (purchased separately)

S/N

Descriptions

Unit

Qty.

Remarks

1

Sprayer body

unit

1

2

Handlebar

piece

2

3

wheel axle

piece

1

4

wheel

piece

2

5

Reel and spray gun assembly

set

1

S/N

Descriptions

Unit

Qty.

Remarks

6

Reel support

piece

1

7

Charger

unit

1

8

Fuse tube 15A

piece

2

9

Fuse cap

piece

1

10

Instruction Manual

piece

1

11

Accessory

Package

Hexagonal Bolt M8×40

piece

4

Hexagonal Bolt M8×20

piece

2

Hexagon lock nut M8

piece

6

axis pin 6×35

piece

2

Flat washer 6

piece

2

R-pin 1.8×32

piece

2

Pump head union

piece

1

washer Ø10×Ø19.3×2

piece

1

hex nut M16

piece

2

Spring washer 16

piece

2

Flat washer 16

piece

2

Cap nut M16

piece

2

Pipe-clip 13-19

piece

2

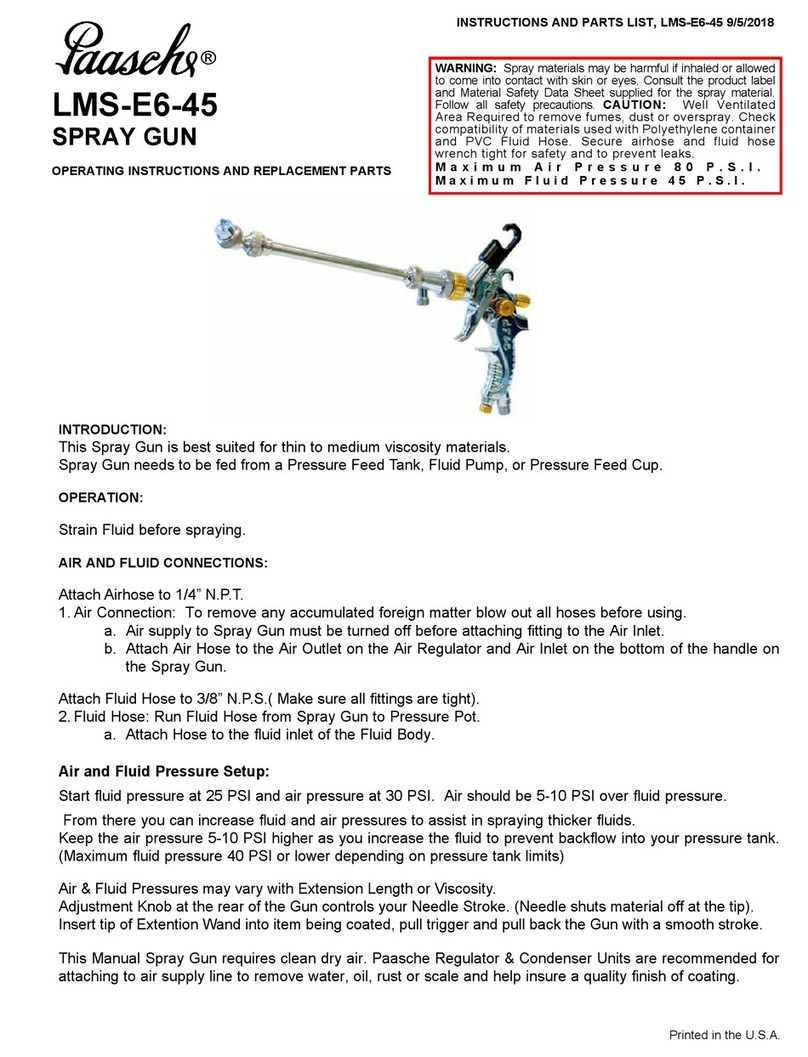

(I)Installation of accessories

1.Installation of traction bracket and

traction rod

Insert the double-rod end of the traction

bracket into the frame tube (under the

electric control box), before leading four

M8 × 40 bolts into the designated holes

and fastening with the M8 nut; followed by

inserting the single-rod into the traction

rod, and fastening with two M8 × 50 bolts

and M8 nuts.

2.Installation of spray boom

Put the folding boom horizontally on the

bracket, and lead two M8 * 40 hex bolts

into the two fixing holes in the bracket and

the spray boom, followed by fastening

with two M8 nuts (the folding direction of

the boom should be towards the rear of

the sprayer).

3.Installation of connecting hose

Lead the connecting hose through the

lifting ring under the frame and connect it

with the pump head. Connect the nut at the

other end of the connecting hose to the tee joint

of the folding boom.

(II) Tech Parameters

Nozzle Model

110-01.5

Nozzle Type

Drip-proof fan nozzle

Nozzle spraying angle

110°

Spraying width

2.5m

Nozzle quantity

6 pcs

Nozzle spacing

500mm

Max. Pressure

7bar

Suggested Pressure

3bar

Single nozzle volume

0.7L/min(3bar)

(III) Adjustment of sprayer and operation

1. Upon the finish of installation of the Sprayer, check nozzles and various

connections to make sure they are sound. Extend the spray boom and

make sure the inclination angle between the nozzle slit and the spray

boom to be 5 ~ 10 degrees, and the spacing between nozzles on the spray

boom to be 0.5m.

2. Prior to operation, a trial spraying with clean water for possible leakage

at various connection points is required. Rotate the pressure regulator to

3bar (Extra-high working pressure may lead to spray drifting and

extra-wearing of nozzle). Turn off the power switch after confirming that the

sprayer is in good condition.

3. The traction rod of the sprayer shall be connected to the tractor with a 12

× 65 pin with split hole, followed by securing with a 4 × 25 cotter ring.

4. Remove the 4 × 25 cotter ring on both sides of stand and pull out 12 × 40

pin with split hole, followed by rotating the stand to the horizontal position,

S/N

Descriptions

Qty.

S/N

Descriptions

Qty.

1

Folding boom assembly

1

6

Ring lock pin 4 × 25

1

2

Traction rod

1

7

Hexagonal Bolt M8×50

2

3

Traction bracket

1

8

Hexagonal Bolt M8×40

4

4

Connecting tube

1

9

Hexagonal Bolt M8×20

2

5

Pin with split pin hole 12 × 65

1

10

Hexagon lock nut M8

8

before inserting the 12 × 40 pin with split hole into the fixing hole which

is secured with the 4 × 25 cotter ring.

5. Fill the sprayer with clean water, and the pesticide of a certain

proportion, followed by stirring and mixing evenly. Turn on the power

switch to start operation .

6. In the process of operation, the speed and direction of spraying shall

be kept constant, free of fluctuation of speed or deviation of route. In

case any blockage, leakage or other fault occurs to the nozzle , power

off the sprayer in time for troubleshooting.

7. Before being moved to another site or put aside for storage, the

spray boom shall be folded and secured. If the nozzle angle affects the

folding of the spray boom, loosen the nozzle locking screw to adjust the

nozzle angle before folding. After arriving at the operation site, the

nozzle shall be reset.

8. A filter screen is available in the nozzle. In case the nozzle is blocked,

the filter screen and nozzle can be washed with clean water after

removing the nozzle cap. Never unblock the nozzle by hard objects or

mouth blowing.

This manual suits for next models

4

Table of contents

Other TOPMAQ Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

Nordson

Nordson Encore LT quick start guide

paasche

paasche LMS-E6-45 Operating instructions and replacement parts list

Graco

Graco ASM Zip Spray 3400G Repair and parts

Graco

Graco LT Series Instructions - parts

Graco

Graco RTX 1500 Repair and parts

Harbor Freight Tools

Harbor Freight Tools 47274 Assembly and operation instructions