erc 450VS+ User manual

450VS+ PAPER CUTTER

User Manual

Before Installation

Please Read This Instruction Manual.

Thank you for your choice of our Precise Paper Cutting Machine series. We

will provide you with good quality and reliable post-sale service. On the

basis of original products, our research and develop engineers combined

advantages of products at home and abroad, and finally developed new

model of Precise Paper Cutting Machine. It owes hlgh technology, preclse

constructlon deslgnation, and elegant appearance, with the securitycon-

trol part and cutting precision improved.It can be broadly used in printing

centers and offices. It is the most ideal cutting machine which well com-

plies with office automation system.

Warning:This kind machine is allowed to cut printed paper or books or soft

leathers only. It is forbidden to cut any metal sheets or other hard objects

do harm to the machine quality with kind machine.

Children must not operate this machine.

Do not reach beneath the blade

Do not extract or transport the blade without

protection

Do not cut hard material or material which

may splinter

Must use socket with ground wire connected

Note:

In order to have more usage information of Numerical-controlled Paper

Cutting Machine, you have to read this specification carefully first.This will help

you improve your working efficiency, realize the machine's property, have the

best cutting effects. This will also be good for the maintenance of the machine,

and can prolong service life of the machine.

FOREWORD

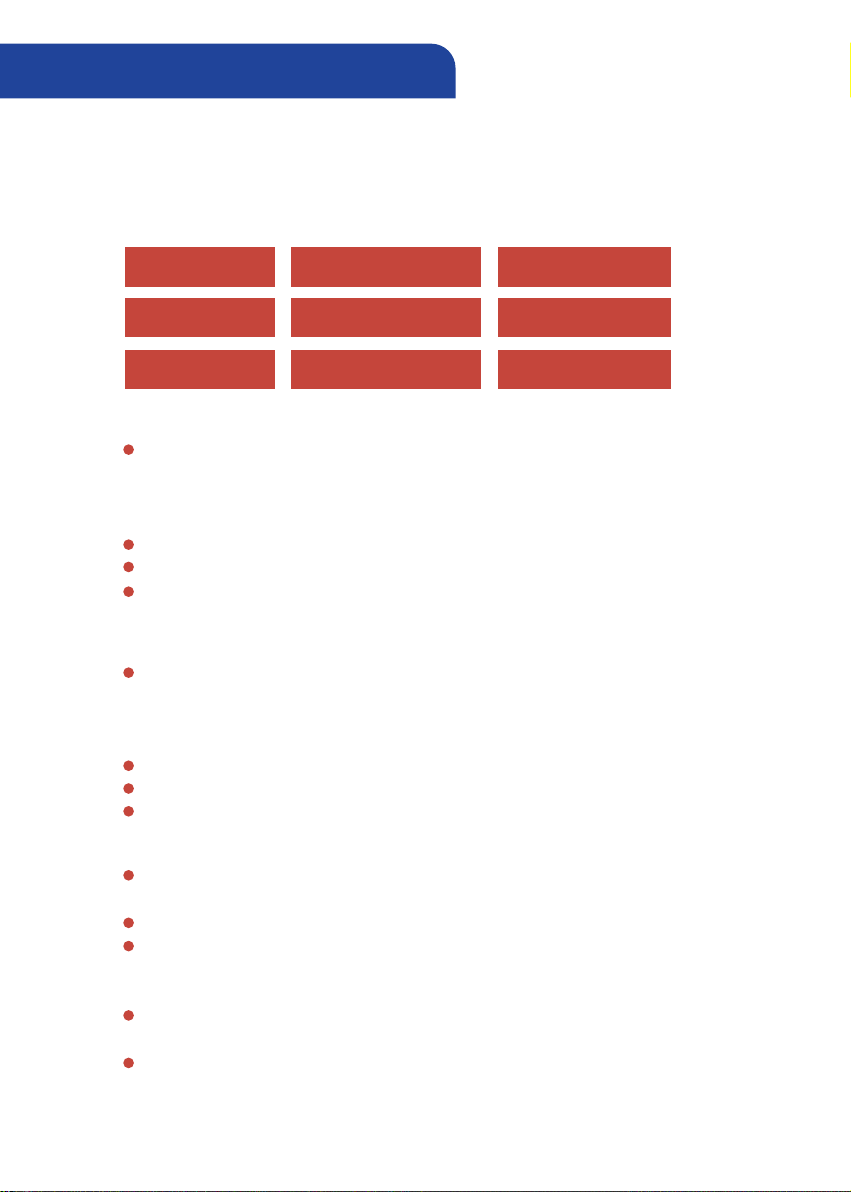

SAFETY

CAUTIONS

According to relevant standards, to avoid accident and

accidental injury, only professional operators are allowed

to use this machine (children or non-professional opera-

tors are forbidden to operate). When you use or maintain

these machines, please pay high attention to safety

cautions below:

SETTLEMENT POSITION

The welght of this kind machine is is heavy ,Please put it

balanced and in a clean place.

POWER

Please connect with the power source correctly in accordance

with the speclficatlon, And the machine will run irregularly if the

voltage is too high or too low. We suggest you use alternating

current (AC) power source with steady voltage to improve your

working efficiency.

GROUND CONNECTION

For safety you should use electric supply socket with ground wire

connected.

SUPERCHARGE

Please don't connect many electrical products on ane electric

supply socket, because supercharge may cause a fire or an

CLEANNESS

Before you clean or maintain the machines, you must cut off the

electric source and pull out the electric supply socket.

Ⅰ.SETTLEMENT POSITION 1

2

4

8

9

1.Open the machine and check

2.Settlement of the machine

3.Operating environment

4.Special suggestions

Ⅱ.BRIEFINTRODUCTION OF THE PAPER-CUTTING MACHINE

1. Parts description of the paper-cutting machine

2. Operating panel.

3. Principal technical parameter

4. Performance features

III.BASIC OPERATION AND BASIC ADJUSTMENT

1.Basic operation

2.Basic adjustment

2-1 Dimension check and adjustment

2-2 Cutting power adjustment

2-3 Knife blade change

2-4 Cutting stick adjustment

1-1 Start the machine

1-2 Push paper

1-3 Cut paper

IV.LUBRICATION AND MAINTENANCE

1. Lubrication

2. Maintenance

3. Attached figure

V. COMMON ERROR AND ELIMINATION

CONTENTS

1.Open the machine and check

1

2.Settlement of the machine

SAFETY CAUTIONS

BEFORE INSTALLATION

I

When you open the package of the machine, firstly you should check

the machine and relevant accessorles. Please contact the seller or our

company if there is any damage or shortage.

Open the wooden crate, take out the machine casing, and discharge

four M8 screws on the base plate of the main machine;

The machine casing needs to assembly, and the screws should be

fixed firmly;

The main unit should be put on the machine casing correctly;

Check all parts of the machine, and clean them;

Turn on the power to electrify to test running.

3.Operating environment

The machine should be placed in clean working environment, keep

away from direct sunlight and wind;

Temperature of the operating environment: 10-30°C, cannot higher

than 32°C;

Humidity level of the operating environment: 50-80%:

Working power source of the machine: 110V±10%; 60HZ; 0.8KW;

Connect the ground wire correctly.

4.Special suggestions

Remember, only one professional operator is allowed to work on the

machine;

When you cut, you should operate buttons by both of your hands;

Please dan't disassemble the safety covering;When you put your

hands or other things into the cutting area,you must cut the power

first;

When you change knife blades, you should firmly comply with the

blade changing instruction;

You are not allowed to re-equlp the Inner constructlon and circult of

the machine by yourself.

Main unit

one set

Machine chassis

one set Specification

one piece

Tooling

one set

Rubber under chassis

four pleces Certificate

one piece

Stick

one piece

Screw stem

two pleces Specification

one piece

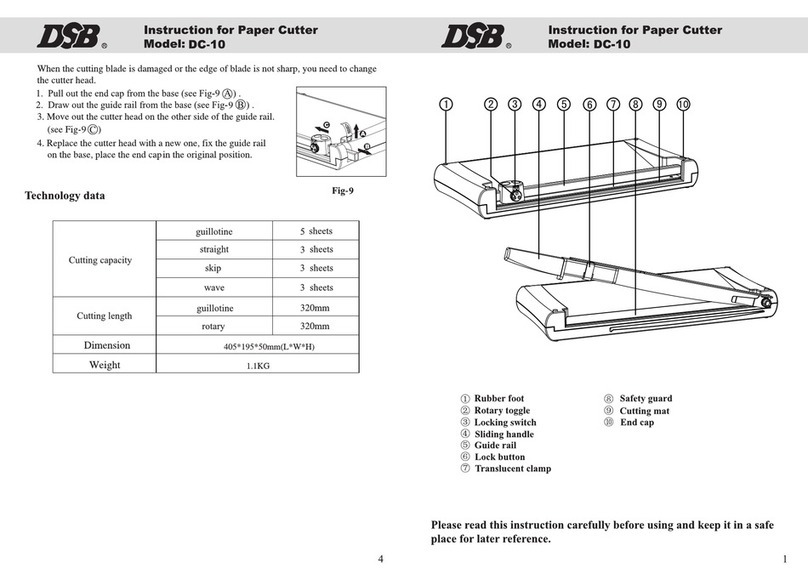

1.Parts description

Safety lock

Reset

Door

Rubber under chassis

Power

Chassis

Front protective cover

BRIEF INTRODUCTION OF

THE PAPER-CUTTING MACHINE

Ⅱ

/OPERATING PANEL/

2

Cut Keys

Power

Forward

RESET There is a mistake operation when cutting with pressing two CUT

buttons. Please release and keep the blade stopping there. Then press

RESET. The blade and paper pushing to make it reset.

PRESS Single clamp

Clamp before cuttingPRESS

1

111

2

4Return

6

Delete

7

Number key

8

Confirm

9Reset

10

Proofread

5

2 43 5 6 7 8 9 10 11

3

2.Parts description

2.Parts description

Model

Cutting Width(Mm)

Cutting Thickness

Paper Pressing Structure

Paper Pushing Mode

Safety Protection

Power Supply

Machine Size(H*D*W)

Net Weight

450

40

Automation

Automation

Have

800W

1020X760X670mm

105kg

450VS+

● CNC circuit design, double guide rail pushing

paper device

● Inclined knife paper cutting technology device;

●The whole frame casting processing, quality assurance;

● Automatic paper pressing, pressing before

cutting device

● Front guard and safety protection

switch device

● Cutting light line;

BASIC OPERATION

AND ADJUSTMENT

Ⅲ

4

1.Basic operation

1-1 Start the machine

1-2 Paper Pushing

1-2 Cutting Paper

Before operating, please review contents

described before carefully. Then you can do

operations below.

Insert the power

Turn the protective switch to 'On'

position. Turn on the power supply, the

liquid crystal display and indicative

wiring of knife position is lighting, that

means electricity connection is normal.

Open the front protective cover;

Push paper or book to the left side aligned

with the measuring scale.

If the cutting size does not comply with

measuring scale marks, please adjust

according to the method in diameter

check and adjustment

When the cutting dimension is adjusted,

please put down the front protective cover;

Press the Reset key, then the indication red

light and knife position indicating line on;

Press the Cut buttons by two hands.

You can start operation first to make.

sure that paper has been pressed

firmly by the paper press jack. If you

need to have the paper press jack turn

back, you can press the Cut button by

left hand and press Reset button by

rlght hand, then the paper press Jack

wlll turn back automate.

If you need to cut, press the Cut button

bytwohands, and then cutting proce-

dure finish; ※ Note: If the front guard is not tightly

covered, the cutting button will not be

able to operate.

If you find the last piece of paper can't be cut completely.please adjust

according to Knife shim adjustment method.

Check whether there is any foreign matter on the guiding rod;

Pull out the front covering strip, and check stepping motor, to see

whether the synchranous pulley and synchronous belt are fixed

normal;

Adjust the support chip on the screw, and you can move it back

and forth until digital display dimension matches measuring scale

dimensian, then lock the retaining screw firmly.

Cut the electricity power;

Cut the electricity power;

Disassemble retaining screws on both sides of the upper cover, and

then take the upper cover away;

Loose seven M6 fasten screws on the blade which is on blade carrie,

and adjust screws of adjusting blade depth on blade carrier,until the

blade cuts into cutting stick about 0.3-0.5 mm;

Tighten up fasten screws on blade carrier, put on the upper cover,then

fix up;

Choose one piece of paper to have a trial cut. If it cannot be cut

completely, you can readjust according to the processes above.

Open the upper cover;

Loose the notched fasten screw on the blade carrier, revolve the two

screw stems clockwise, and then fix up and lock firmly;

Take away other fasten screws on the blade carrier;

Revolve the two screw stems anticlockwise 180°, then take out the

blade. Please wear gloves or use cotton cloth to wrap the blade to

avoid scratch;

※ Note:

Dull blade can't cut paper correctly.

Also, blade will become dull if it always cuts thick paper or pasteboard.

If cutting quality and accuracy can't meet required standard, the blade

needs to be changed. Your work will go smoothly if you always have

one replacement on hand.

When you need to change blade, you must operate according to the

steps of blade change instruction.

2.Basic adjustment

2-1 Cut the electricity power;

2-2 Cutting power adjustment

2-3 Knife blade change

5

When you install the blade, you should loose the screw of adjusting

blade depth on the blade carrier ,then screw up the screw stems, and

fix up the blade to blade carrier. After that ,make screw strip be

fasten and fix up one by one, then adjust according to cutting depth

adjustment method;

One cutting stick can be used for 8 times;

When slash on the shim is too deep, you should adjust or change

knife strip;

Cutting stick can be took out by screw, and should be assembled onto

the cutting desk flatly when it needs to be set back;

Cutting stivk should lean to the left side, then re-push the front brace

plate;

Blade sharpening needs to be done in a professional factory, so that

to ensure the quality.

※ Note:To avoid any injury, you must be the most careful when you

change the blade.

※ Note:When cutting stlek is being changed, the blade itself also needs to

be adjusted. If the blade cuts too deep, the cutting stick will be damaged

easily, and also the blade will abrade rapidly.

2-1 Cutting stick adjustment;

7

8

LUBRICATION AND

MAINTENANCE

IV

1. Lubrication

2.Maintenance

3.Attached figure

450 Paper cutting machine circuit line chart

The power on off power

220V

Main motor

DC AC

CUT POWER

OPERATE MAINBOARD

Every three month, you should open the brace plate of the machine, check

and clean, tighten parts, and use lubricating oil to rolling parts. When you do

lubrication, be careful to avoid lubricating oil dripping on the wires or

electrical parts. The speed reduction box needs to be cleaned and lubricated

once a year.

1)When the machine is running, foreign objects are forbidden to put on the

machine, because if hard objects come under the blade, the blade will be

damaged. There should be no staple pin in the book, which is coming to the

cutting area, to avoid damaging the blade.

2) After everyday work, you should wipe the machine, remove junk, wax the

blade to protect it, and cut the power.

COMMON ERRORAND

ELIMINATION

V

9

Error

No power

source display

Indicating light is off 1.Check the power source plug

2.Check main switch

3.The power Source wire is bad

1.The blade abrades badly

2. The knife position is too high.

Revolve the screw of adjusting

blade depth on the blade carrler

downward to have the knife

position lower.

The knife position is too low.

Revolve the screw of adjusting

blade depth on the blade upward

to have the knife position higher.

1. Sharpen the blade: Use

whetstone to sharpen or aşk

professional factory to do

sharpening;

2. Change a new blade

Change Capacitor

Loose tighten screw, and use a

ruler to adjust the angle between

measuring scale and paper

pushing plate

1.The sensor is displaced or

damaged.

2.Circuit main panel is damaged

Incomplete

cutting

Paper can't be cut

completely

Slash on the knife strlp

it too deep

Paper can't be cut

completely or cutting

becomes difficult

The knife work up and

down slowly

or powerlessly

The cut paper has one

side wide and the other

side nanow, or has big

deviation on dimenslons

The button is invalid.

The blade works up and

down without stopping

Too deep cutting

Dull blade

Capacitor of

electrical motor

damaged

Imegular

papercutting or

too big difference

The knife can't

reset or works

up and down

continuously

Phenomena Elimination method

Before Installation

Please Read This Instruction Manual.

Table of contents