PS-2063 Page 4 of 4

DESCO INDUSTRIES INC.

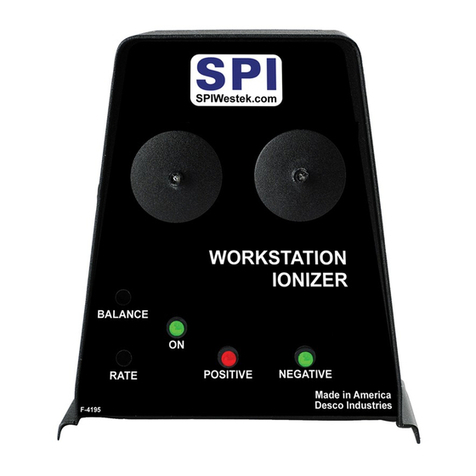

of emitters are located internally on

the unit, mounted above each of the

fan assemblies. Each set of emitters is

mounted over a fan which provides air

current to assist the mixing and speed

of the neutralization. The fan guards

also function as the sensor plate

monitoring the voltage balance of

each fan output. The balance signal is

sent to the control circuit which

modifies the pulse length of the

positive or negative output to maintain

a balanced output.

An automatic shutdown circuit is

included as a safeguard against the

failure of either the positive or

negative power supply or

contaminated or damaged emitter

needles. These conditions could lead

to an imbalanced output of ions which

could potentially damage sensitive

components. If an out of balance

condition is detected and persists for a

period of 20 seconds or more, the

automatic circuit will shut down the

unit, sound a 10 second alarm (if the

audio/alarm switch is activated), and

light the red alarm LED. When

automatic shutdown occurs, turn the

unit off and wait a few seconds before

trying to turn it on again. This is to

allow the timer circuitry to reset.

The Audio/Alarm indicator will be lit

by a green LED whenever the unit is

powered and the audio alarm is

activated. A flashing red LED will

turn on when the auto-shutdown

circuit has detected an unbalanced

condition and has shut down the

ionizer. When the red LED is on you

should turn off the power, clean the

emitters and then restart the unit. See

the section on maintenance for the

proper cleaning procedures.

Testing and Calibration

Ionizers are tested and calibrated

using a charged plate analyzer. For

proper testing we recommend a

charged plate analyzer and the

procedure outlined in ESD

Association Standard 3.1. This

standard may be obtained from the

19 BRIGHAM STREET, UNIT #9

MARLBORO, MA 01752-3004

http://www.esdsystems.com/

PHONE (508) 485-7390

FAX (508) 480-0257

The comparative efficiency of bench

ionizers is determined by a standard

test published by the ESD Association

Standard 3.1. The typical decay rates

measured using this standard for the

ionizer are shown in the following

diagram. The performance of the

ionizer was measured with a charged

plate analyzer positioned at varying

distances with the ionizer fan speed on

high.

Specifications

Input:

120/220 VAC 50-60 Hz-

400/200 mA

Fuse:

5x20mm - 1 Amp - 250V - Fast

Acting

Output:

6-8 KV - 5 microamps

Ozone:

Less than 0.05ppm

Air Flow:

50-150 CFM - adjustable

Size:

40" L x 4 1/2" W x 2 1/2" H

Weight:

10 pounds

Cord:

7' 6" cord set with IEC connector

Mounting:

Five each 1/4"-20 threaded holes

on each end.

Theory of Operation

Figure 13. Location of emitters and

sensors.

The system employs pulse-width-

modulated bipolar D.C. ionization,

with closed-loop monitoring on each

fan output, maintaining proper balance

under varying conditions. Three sets

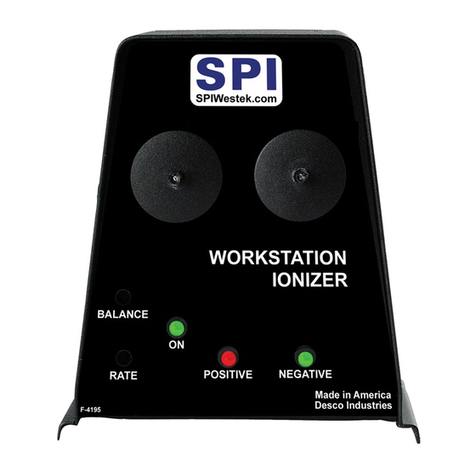

CONTROL/STATUS

PANEL

SENSOR/FAN GRILL

2 SETS OF INTERNAL EMITTERS PER FAN

ESD Association, Norstar Building,

200 Liberty Plaza, Rome NY 13440,

(315) 339-6937. ESD Systems will be

happy to send you information on our

model 42630 charged plate analyzer.

ESD Systems ionizers can be

calibrated to NIST traceable standards.

Contact our customer service

department for details.

Adjustments

There are no user adjustable or

serviceable parts inside the ionizer.

Adjusting or dismantling your ionizer

may create dangerous conditions, and

unauthorized modifications will void

the product warranty. Servicing

should be performed only at the

factory, or by a technician trained in

high voltage circuits. See warranty

section for repair charges.

Limited Warranty

ESD Systems expressly warrants that for a period of one

(1) year from the date of purchase, ESD Systems

Overhead Ionizers will be free of defects in material

(parts) and workmanship (labor). Within the warranty

period, a unit will be tested, repaired or replaced at ESD

Systems’option, free of charge. Call Customer Service at

508-485-7390 for proper shipping instructions and

address. You should include a copy of your original

packing slip, invoice, or other proof of purchase date.

Warranty repairs will take approximately two weeks. Any

unit under warranty should be shipped prepaid to the ESD

Systems factory.

If your unit is out of warranty, ESD Systems will quote

repair charges necessary to bring your unit to factory

standards. Call Customer Service at 508-485-7390 for

proper shipping instructions and address. Units should be

shipped freight prepaid

Warranty Exclusions

THE FOREGOING EXPRESS WARRANTY IS MADE

IN LIEU OF ALL OTHER PRODUCT WARRANTIES,

EXPRESSED AND IMPLIED, INCLUDING

MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE WHICH ARE

SPECIFICALLY DISCLAIMED. The express warranty

will not apply to defects or damage due to accidents,

neglect, misuse, alterations, operator error, or failure to

properly maintain, clean or repair products.

Limit of Liability

Electronic ionizers use high voltage corona discharge and

should not be used in or near flammable or explosive

environments. In no event will ESD Systems or any seller

be responsible or liable for any injury, loss or damage,

direct or consequential, arising out of the use of or the

inability to use the product.

Before using, users shall

determine the suitability

of the product for their intended

use, and users assume all risk and liability whatsoever in

connection therewith.