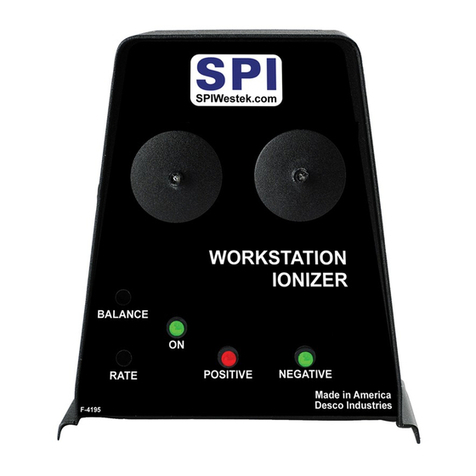

2. With the Counter SPI and the Charged Plate

Analyzer on, adjust the balance trimpot, located

on the lower left side of the ionizer. Balance the

ionizer to 0 volts on the Charged Plate Anaylzer.

NOTE: There are 3 LEDs located on the front

panel. The one on the left is the on light, the other

two LEDs are the indicators of the positive and

negative. Note the rate in which the lights switch.

Your unit should be set at a slow rate. Also note

when balancing, the indicator lights, as you offset

the positive and the negative (balance), the on and

off times changes on the lights.

3. Charge the Charged Plate Analyzer to 1KV of

either polarity (±) and push the decay button. The

timer will automatically time the decay rate. The

typical decay is 1,000 to 100 volts in under 60

seconds of both polarities.

There are two adjustments that can be made on the

Counter Workstation Ionizer: the BALANCE and the

RATE. The BALANCE of positive and negative ion

output can be adjusted to increase polarity bias by

inserting a small screwdriver through the BALANCE

port and slowly turning the trimpot clockwise to

increase positive and decrease negative ON time

pulses. Turn the trimpot counter-clockwise to increase

negative output and decrease positive ON time pulses.

The RATE or pulse frequency can be adjusted down

to one pulse per second or up to 5 pulses per second

by inserting a small screwdriver through the RATE port

and slowly turning the trimpot clockwise to increase

the frequency and counter-clockwise to decrease the

frequency.

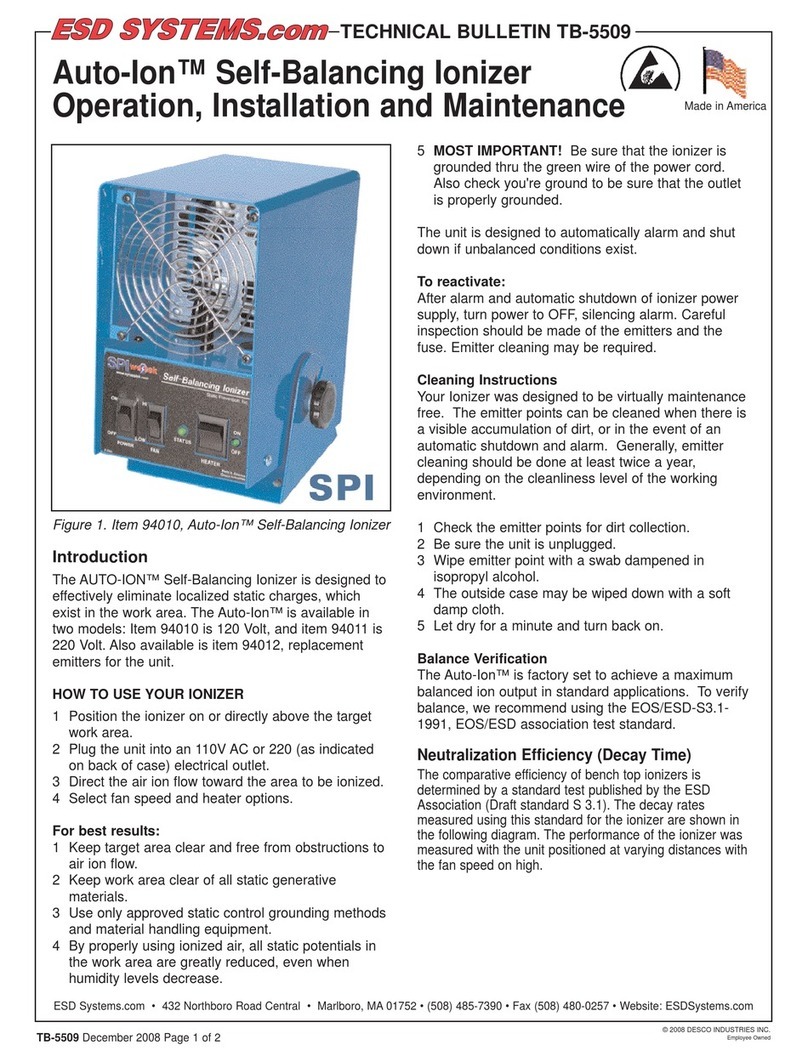

Specifications

Dimensions

5.0" W x 2.5" L x 5.5" H

(127 mm W x 63.5 mm L x 140 mm H)

Balance (offset voltage) at 12" in front of Ionizer*

±25 Volts Maximum

Neutralization (Discharge) Times at 12" in front of

Ionizer*

<15 seconds (positive and negative voltage)

Power Consumption

94000 - 120 VAC, .04 A, 4.8 W

94001 - 220 VAC, .14 A, 30 W

*Factory default settings

REMEMBER

It is important to verify calibration after any adjustments

and before using the Counter Workstation Ionizer

around sensitive electronics. Merely repeat above

Balance Verification steps after all adjustments.

TB-5508 Page 2 of 2 © 2016 DESCO INDUSTRIES INC.

Employee Owned

WEST COAST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178

EAST COAST - One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Website: ESDSystems.com

Field repairs are not normally encouraged during

the warranty period. Repair attempts by unqualified

personnel may invalidate the warranty.

IMPORTANT

The Counter Workstation Ionizer has been designed

to minimize effects of localized charges. If your

processing involves generation of considerable static

charges you may need more aggressive equipment.

ESD Systems offers a complete line of Ionizing

Blowers, Air Guns, Bars and Overhead Room systems

to meet all ionizing requirements.

Limited Warranty, Warranty Exclusions, Limit of

Liability and RMA Request Instructions

See the ESD Systems Warranty -

http://esdsystems.descoindustries.com/Limited-Warranty.aspx