Figure 2. Decay time in seconds from 1000 volts to

100 volts on a 6” x 6” charged plater per ANSI

EOS/ESD S3.1.

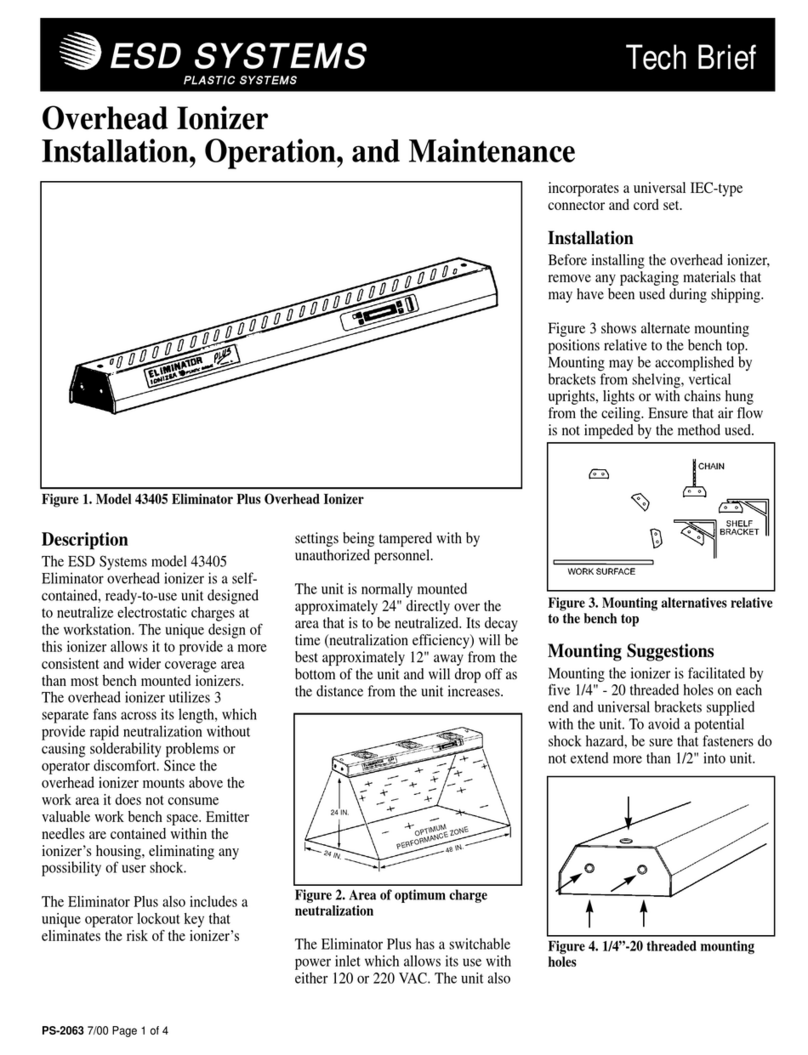

Objective: To observe, test and record performance

levels of ionization units, utilizing readily available

equipment, thereby verifying or certifying calibration.

Equipment Used:

Charged Plate Analyzer (Item 94052)

Procedure:

Following the procedures as outlined in the EOS/ESD

association standard, # EOS/ESD-S3.1-1991, TITLED

IONIZATION on page 12.

The balance of the unit can further be verified by

assuring that there is no residual surface charging on

the ground plain plate of either positive or negative

polarity immediately after the ionizer is shut-off.

The BALANCE of positive and negative ion output can

be adjusted to increase polarity bias by carefully and in

small increments, relocating the position of the vertical

sensor antenna directly behind the faceplate screen.

All other ionizer adjustments are done automatically for

you by the ionizer control system.

Remember:

It is important to verify calibration after any adjustments

and before using your ionizer around sensitive

electronics. Merely repeat above Balance Verification

steps after all adjustments.

TB-5509 Page 2 of 2

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

© 2008 DESCO INDUSTRIES INC.

Employee Owned

Limited Warranty

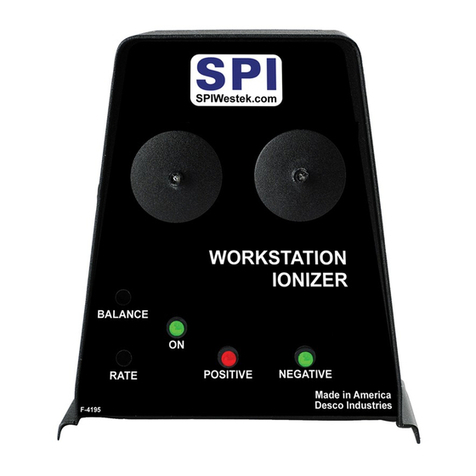

SPI Westek expressly warrants that for a period of one (1) year

from the date of purchase, SPI Westek Auto-Ion™ Self-Balancing

Ionizers will be free of defects in material (parts) and workmanship

(labor). Within the warranty period, the product will be tested,

repaired, or replaced at our option, free of charge. Call our

Customer Service Department at 909-664-9986 for a Return

Material Authorization (RMA) and proper shipping instructions and

address. Include a copy of your original packing slip, invoice, or

other proof of purchase date. Any unit under warranty should be

shipped prepaid to the SPI Westek factory. Warranty repairs will

take approximately two weeks.

If your unit is out of warranty, call Customer Service at 909-664-

9986 for a Return Material Authorization (RMA) and proper

shipping instructions and address. SPI Westek will quote repair

charges necessary to bring your unit up to factory standards.

Warranty Exclusions

THE FOREGOING EXPRESS WARRANTY IS MADE IN LIEU OF

ALL OTHER PRODUCT WARRANTIES, EXPRESSED AND

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE WHICH ARE SPECIFICALLY

DISCLAIMED. The express warranty will not apply to defects or

damage due to accidents, neglect, misuse, alterations, operator

error, or failure to properly maintain, clean or repair products.

Limit of Liability

In no event will SPI Westek or any seller be responsible or liable

for any injury, loss or damage, direct or consequential, arising out

of the use of or the inability to use the product. Before using,

users shall determine the suitability of the product for their

intended use, and users assume all risk and liability whatsoever in

connection therewith.

CHARGE DECAY TIME CONSTANTS

Notes: 1) Decay times are from +1000 volts to <100 volts in

accordance with ANSI EOS/ESD S3.1

2) Data taken using full fan speed

ESD TEST SET UP Static Dissipative Workbench Surface

Charged Plate

1 ft.

IMPORTANT:

Your IONIZER has been designed to minimize effects

of localized static charges. If your processing involves

generation of considerable static charges you may

need more aggressive equipment. SPI has available a

complete line of Ionizing Blowers, Air Guns, Bars and

Overhead Room Systems to meet all ionizing

requirements.