Eskridge 50 Series User manual

SERVICE MANUAL

50 SERIES DIGGER MODELS

THIS SERVICE MANUAL IS EFFECTIVE:

S/N: 58670 TO CURRENT

DATE: 9-2003 TO CURRENT

VERSION:SMD50L-AC

NOTE: Individual customer specifications (spindle

mounting, sprocket pilot, brake assembly, etc.) may

vary from exploded drawing and standard part num-

bers shown. If applicable, refer to customer drawing

for details.

54

Motor

Number

50

Model

2

Shaft

1

Bail Boss

F

Motor

Supplier

Example Part Number

05

Ratio

Model D50 service manual, SMD50L-AC Page 2

Eskridge, Inc. Olathe, KS. 913-782-1238 www.eskridgeinc.com

Single Stage Exploded View Drawing

ITEM QTY DESCRIPTION PART NO.

1 1 BASE - INTEGRAL BAIL 50-004-3303

2 1 OUTPUT SHAFT - 2" HEX .516 HOLE 50-004-4082L

BAIL ASSEMBLY 1-1/4" BAIL BOSSES 50-005-2132

BAIL ASSEMBLY 1" BAIL BOSSES 50-005-2142

4 1 INPUT GEAR 85-004-1262

7 1 CARRIER ASSEMBLY- SECONDARY 50-005-2031

8 1 RING GEAR 50-004-1033

9

9A 1 THRUST WASHER - INPUT 50-004-1091

9B 1 THRUST WASHER - SEC. CUP 50-004-1011

10

10A 2 O-RING 01-402-0560

10B 1 OUTPUT SHAFT SEAL 01-405-0530

11

11A 1 OUTER CONE 01-102-0140

11B 1 OUTER CUP 01-103-0140

11C 1 INNER CONE 01-102-0150

11D 1 INNER CUP 01-103-0130

12

12A 12 SHCS (7/16-20 X 3.0) GR8 01-150-1830

12B 12 LOCKWASHER (7/16) 01-166-0340

12C 2 12 PT CBORE CS (1/2-13 X 1.25 GR8) 01-150-1460

13 2 PIPE PLUG (3/8 NPT MAGNETIC 01-207-0070

14

14A * SHIM 50-004-1521

14B 1 LOCK RING 50-004-1462

14C 1 SPLIT RING MODEL 50 50-004-1452

14D 1 GASKET 90-004-1081

15 1 MOTOR 01-304-0550

MODEL D50 DIGGER WIT H INTEGRAL BAIL

THRUST W ASHERS & BEARINGS

MISCELLANEOUS

SEALS & O-RINGS

OUTPUT SHAFT BEARINGS

HARDW ARE

13

Eskridge

NOTES:

*

BEARING PRELOAD DETERMINES QUANTITY OF SHIMS.

SEAL KIT (PN 85-016-0601) INCLUDES (2 EA.) ORINGS AND (1 EA.) SEAL

X5005-21F55aa ECN ----- DATE: 04-20-10 HWP

EFFECTIVE

FROM: S/N 83000 (DATE) 04-26-10

TO: (CURRENT)

15

1

2

3

9A

10A

10B

11A

11B

11C

11D

14A

14B

14C

14D

13

12C

13

12B

7

12A

4

9B

8

5005-21F55

Model D50 service manual, SMD50L-AC Page 3

Eskridge, Inc. Olathe, KS. 913-782-1238 www.eskridgeinc.com

Double Stage Exploded View Drawing

ITEM QTY DESCRIPTION PART NO.

1 1 BASE - INTEGRAL BAIL 50-004-3303

2 1 OUTPUT SHAFT - 2" HEX .516 HOLE 50-004-4082L

BAIL ASSEMBLY 1-1/4" BAIL BOSSES 50-005-2132

BAIL ASSEMBLY 1" BAIL BOSSES 50-005-2142

4 1 INPUT GEAR 85-004-1122

5 1 CARRIER ASSEMBLY- PRIMARY 50-005-2011

6 1 SUN GEAR 85-004-1412

7 1 CARRIER ASSEMBLY- SECONDARY 50-005-2041

8 1 RING GEAR 50-004-1023

9

9A 1 THRUST WASHER - INPUT 50-004-1091

9B 1 THRUST WASHER - SEC. CUP 50-004-1011

10

10A 2 O-RING 01-402-0560

10B 1 OUTPUT SHAFT SEAL 01-405-0530

11

11A 1 OUTER CONE 01-102-0140

11B 1 OUTER CUP 01-103-0140

11C 1 INNER CONE 01-102-0150

11D 1 INNER CUP 01-103-0130

12

12A 12 SHCS (7/16-20 X 4-1/2 GR8 01-150-1820

12B 12 LOCKWASHER (7/16) 01-166-0340

12C 2 12 PT CBORE CS (1/2-13 X 1.25 GR8) 01-150-1460

13 2 PIPE PLUG (3/8 NPT MAGNETIC 01-207-0070

14

14A * SHIM 50-004-1521

14B 1 LOCK RING 50-004-1462

14C 1 SPLIT RING MODEL 50 50-004-1452

14D 1 GASKET 90-004-1081

15 1 MOTOR 01-304-0540

MODEL D50 DIGGER WITH INTEGRAL BAIL

THRUST WASHERS & BEARINGS

MISCELLANEOUS

SEALS & O-RINGS

OUTPUT SHAFT BEARINGS

HARDWARE

13

Eskridge

NOTES:

*

BEARING PRELOAD DETERMINES QUANTITY OF SHIMS.

SEAL KIT (PN 85-016-0601) INCLUDES (2 EA.) ORINGS AND (1 EA.) SEAL

X5016-21F54ab ECN 3393 DATE: 11-15-11 HWP

EFFECTIVE

FROM: S/N 83000 (DATE) 04-26-10

TO: (CURRENT)

15

1

2

3

8

9A

10A

10A

10B

11A

11B

11C

11D

14A

14B

14C

14D

13

12C

13

12A

12B

9B

7

4

6

5016-21F54

!

WARNING: While working on this equipment, use safe lifting procedures,

wear adequate clothing and wear hearing, eye and respiratory protection.

Model D50 service manual, SMD50L-AC Page 4

Eskridge, Inc. Olathe, KS. 913-782-1238 www.eskridgeinc.com

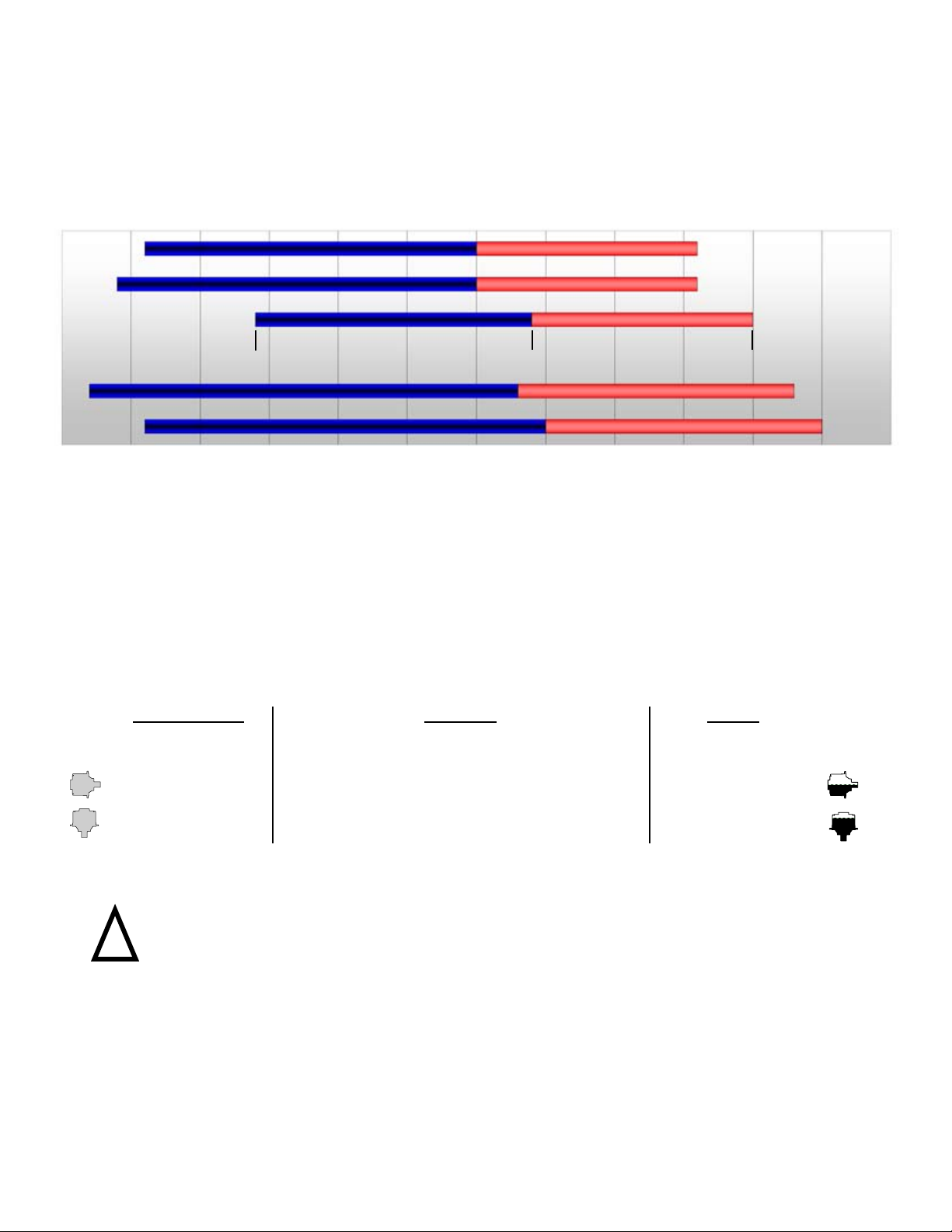

LUBRICATION & MAINTENANCE

Operating Position

Single stage

Oil Capacity

Double stage Triple stage

Oil Level

Horizontal Shaft - - To horizontal centerline of

auger drive

Vertical Shaft (Pinion Down) 2 pints / 0.95 liters 2.5 pints / 1.18 liters To midway on upper/

primary gear set

Using the chart below, determine an appropriate lubricant viscosity. Use only EP (extreme pressure) or API GL-5 designated lubricants.

Change the lubricant after the first 50 hours of operation and at 500 hour intervals thereafter. The auger drive should be partially disas-

sembled to inspect gears and bearings at 1000 hour intervals.

80W90 conventional

75W90 conventional

85W140 conventional

75W90 synthetic

80W140 synthetic

Note: Ambient temperature is the air temperature measured in the immediate vicintiy of the gearbox. A gearbox exposed to the direct rays of

the sun or other radiant heat sources will operate at higher temperatures and therefore must be given special consideration. The max operating

temp must not be exceeded under any circumstances, regardless of ambient temperature.

If your unit was specified “shaft up” or with a “-Z” option, a grease zerk was provided in the base housing. For shaft-up operation, the

output bearing will not run in oil and must be grease lubricated. Use a lithium based or general purpose bearing grease sparingly every

50 operating hours or at regular maintenance intervals. Over-greasing the output bearing should be avoided as it tends to fill the housing

with grease and thicken the oil

Recommended ambient and operating temperatures for conventional and synthetic gear lubricants

-50 -25 0 25 50 75 100 125 150 175 200 225 250 F

-45 -32 -18 -4 10 24 38 52 66 79 93 107 121 C

Min Ambient/operating temp Max Operating temp

Max Ambient temp

ESKRIDGE MODEL D50 OIL CAPACITIES

ESKRIDGE PART NUMBER INTERPRETATION

Note: All non custom Eskridge Geardrives are issued a descriptive part number which includes information regard-

ing the Model, means of shaft retention, base style, shaft style, input mounting, input shaft size, overall ratio and

various available options. For a detailed breakdown of this information, please refer to Eskridge product specifica-

tion sheets found at: http://www.eskridgeinc.com/diggers/diggerprodspecs.html

Model D50 service manual, SMD50L-AC Page 5

Eskridge, Inc. Olathe, KS. 913-782-1238 www.eskridgeinc.com

Unit Disassembly Procedure

There are two types of model D50 units: single planetaries with-

out a primary carrier and double planetaries with a primary planet

carrier. The differences in disassembling single stage and double

stage gearboxs are clearly defined throughout this manual.

All parts should be inspected as they are removed from unit.

1) Scribe across base (1), ring gear (8) and cover/ bail assembly

(3) joints on outside of gearbox to assure proper orientation

of oil fill and drain plugs, motor mounting, etc., as the unit is

reassembled.

2) Remove hydraulic motor (15) from auger drive. Drain oil.

3) Remove the twelve 7/16 x 4-1/2” socket head cap screws

(12A) and 7/16 lockwashers (12B), which retain cover/bail

assembly (3) and ring gear (8) to base (1).

4) Lift cover / bail assembly (3) off of unit.

Single stage: Remove input gear (4), input thrust washer

(7A, 7B) carrier assembly (7) and ring gear

(8).

Double Stage:Remove input gear (4), input thrust washer

(9A) primary carrier assembly (5). Remove

secondary sun (6) thrust washer (9B) and

secondary carrier (7).

5) The gearing is now disassembled and area(s) requiring re-

pair or service should be identified by thorough inspection

of the parts after they have been washed in solvent. Rotate

planet gears to check for any abnormal noises or roughness

in the primary planet bearings. At the same time, inspect

planet gears for any damage or worn teeth. Replace carrier

assembly if any problems are found in the carrier assembly.

Base Subassembly

Disassembly

1) Place unit on a press table with the output shaft (2) protruding

downward through a hole in the table; unit should be support-

ed only by the base (1). The only thing retaining output shaft

(2) is the locking ring (14B) and split ring segments (14C).

Remove the locking ring (14B) by prying upward, split ring

segments (14C) and shims (14A).

CAUTION: The Load-n-lock assembly is no longer retaining

output shaft. Take precautions if the unit is moved as the shaft

may fall out.

2) With output shaft down through centerhole in press table and

unit supported by base, press shaft out by applying press

load to top end of shaft (internal end) until it passes through

inner shaft bearing (11C). Outer shaft bearing (11A) and seal

(10B) will come out of unit attached to shaft.

3) Inspect inner and outer bearing cups (11B & 11D). If cups are

damaged remove and replace both bearing cups and cones.

CAUTION: Care should be taken not to injure feet or damage

output shaft during this procedure.

4) If outer bearing cone (11A) needs to be replaced, it will need

to be pressed off of output shaft. Also inspect inner bearing

cone (11C). If any one bearing component needs replaced

replace the both the cup and cone as a set.

NOTE: When installing or removing bearings, press only on

inner race of bearing cone. DO NOT press on outer roller cage

of bearing or it will damage bearing.

5) Clean all foreign material from magnetic oil plug (13) located

on bottom of base (1). Add a small amount of pipe thread

compound to pipe plug before installing it back into base.

Unit Reassembly

1) Start with base (1). Turn base upside down and position

on press table. Base should be pointing upward with outer

bearing cup (11B) exposed. Apply a layer of lithium bearing

grease to bearing cup surface.

2) Invert output shaft (2, load-n-lock retainer groove end

down) and carefully lower into base (1) until the shaft’s out-

er bearing cone (11A) is seated against outer bearing cup

(11B).

3) Press shaft seal (10B) into base until it is flush with bottom of

pilot diameter. Use a press fixture, if possible, to avoid distort-

ing seal. If press fixture is not available, a hammer and flat-

ended drift may be used by tapping outer edge of seal lightly

and alternating sides.

4) Stand base assembly upright on output shaft.

CAUTION: The only thing holding output shaft and base to-

gether at this point is the tightness in fit of the shaft seal. Se-

curely and cautiously turn unit upright, not allowing base and

shaft to separate.

5) While holding output shaft (2) with one hand, rotate base (1)

to be certain it turns freely and smoothly. The slight resistance

felt, if any, is due to shaft seal load (drag) on output shaft.

6) Apply a layer of lithium bearing grease to inner bearing cup

(11D) surface.

7) Install inner bearing cone (11C, small end down) over inter-

1

2

10B

11A

11B

11C

11D

14A

14B

14C

13

Model D50 service manual, SMD50L-AC Page 6

Eskridge, Inc. Olathe, KS. 913-782-1238 www.eskridgeinc.com

16) Install motor (15) with gasket (14D), using hex head cap

screws (12C) and torque bolts to 55 ft-lbs.

THE AUGER DRIVE IS NOW READY FOR USE.*

nal end of output shaft. Press bearing on slowly until it is just

seated against bearing cup (11D). With a slight press load still

applied, rotate base (1) by hand to ensure roller bearings are

rotating evenly and smoothly. Inner bearing cone (11C) may

require additional press load to reach proper bearing preload.

If roller bearings are seated properly, continue on to set and

check bearing preload.

SHAFT BEARING PRELOAD: Proper shaft bearing preload is

achieved when torque required to rotate base is 50 to 80 in-

lbs. This rolling torque is equal to a force of approximately 11

to 18 lbs if pulling on base flange to rotate base (1). This may

be determined by feel or by using a fish scale or similar mea-

suring device to check rolling torque.

8) Install shims (14A) over internal end of output shaft (2). Shims

should slide all the way down to outer bearing cone (11C),

where they will rest. The same number (quantity) of shims

removed from unit during disassembly should be returned.

Follow shims with split ring segments (14C). Segments will

sit directly on top of bearing shims.

NOTE: Quantity of shims (14A) may vary from unit to unit.

Bearing preload, set at the factory, determines quantity of

shims.

9) Install the locking ring (14B) onto output shaft.

10) Lightly grease a new o-ring (10A) and install it into o-ring

groove in base (1). Assemble ring gear (8) to base (1). Re-

fer back to scribe marks made across external joints of gear

drive prior to Disassembly Procedure. Line up scribe marks

between ring gear and base to give correct hole alignment.

NOTE: Be certain that o-ring (10A) stays seated in groove

during Step 10.

11) Install secondary carrier assembly into unit. Carrier assembly

should be installed with hub side down (24 tooth spline).

Rotate carrier assembly back and forth to mesh secondary

planet gear teeth (7) with ring gear (8) teeth. Once teeth

mesh, let secondary carrier slide down until it contacts with

output shaft spline. The carrier splined hub should spline onto

output shaft. Carrier hub will rest on top of locking ring (14B)

when splines are fully engaged.

12) Install the carrier cup washer (9B).

Single stage: Install input gear (4), input thrust washer

(9A).

Double Stage: Install secondary sun gear (6) primary car-

rier assembly (5) input gear (4), and input

thrust washer (9A).

13) Grease a new o-ring (10A) and install it into bottom of cover/

bail assembly (3). Refer back to scribe marks made across

external joints prior to Disassembly Procedure. Line up scribe

marks between cover/bail assembly and ring gear (8) so that

orientation of motor mount holes and oil plug are back to their

original positions.

NOTE: Be certain o-ring (10A) stays seated in cover/bail

assembly during Step 13.

14) Install all twelve of the 7/16 lockwashers (12B) and the 7/16

hex capscrews (12A) and torque to 70 ft-lbs.

15) Fill unit with oil per the capacity and lubricant recommenda-

tions posted on page 4.

Table of contents

Popular Tools manuals by other brands

Bosch

Bosch Professional GCG 18V-310 Original instructions

RIDGID

RIDGID RP 350 manual

Harbor Freight Tools

Harbor Freight Tools NITROUS 98475 instructions

Staubli

Staubli MA289 operating instructions

US Conec

US Conec Loose Fiber Ribbonizing Tool Applications Engineering Notes

Cornwell Tools

Cornwell Tools CTG-SSAGG operating instructions

Costway

Costway TL35302 user manual

Power works

Power works DDM402 Operator's manual

Delfast

Delfast RX40A owner's manual

Hitachi

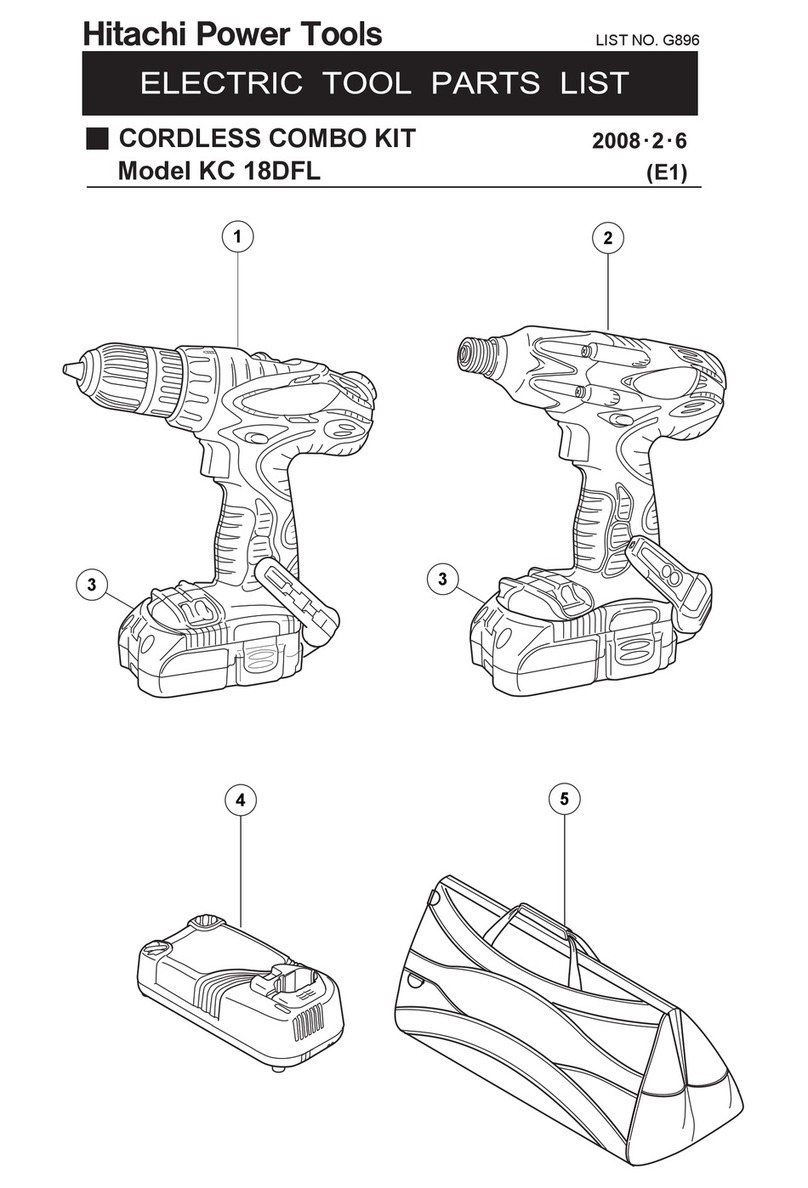

Hitachi KC18DFL - 18V Cordless Lithium Ion Two Piece... parts list

Axminster Trade

Axminster Trade AT25BM Original instructions

Retra

Retra REALEZY 320 Series Owner's operation and maintenance manual