Delfast RX40A User manual

RX40A REBAR TIER

OWNER’S MANUAL

| delfast.com

@DelfastNZ #Delfast

Improper and unsafe use of this tool will result in death or serious injury. It is very

important that the intended operator of this tool reads and understands this manual

before operating this tool. Keep this manual available for others before they use the tool.

TABLE OF

CONTENTS

Table of Contents

Parts Breakdown 1

Safety 2

Safety Lock 3

Product Specification and Technical Parameters 3

Battery and Charger Usage 5

Machine Operation and Methods Employed 6

Common Faults and Removal Methods 7

Care and Maintenance 7

Freephone. 0508 782 753

|

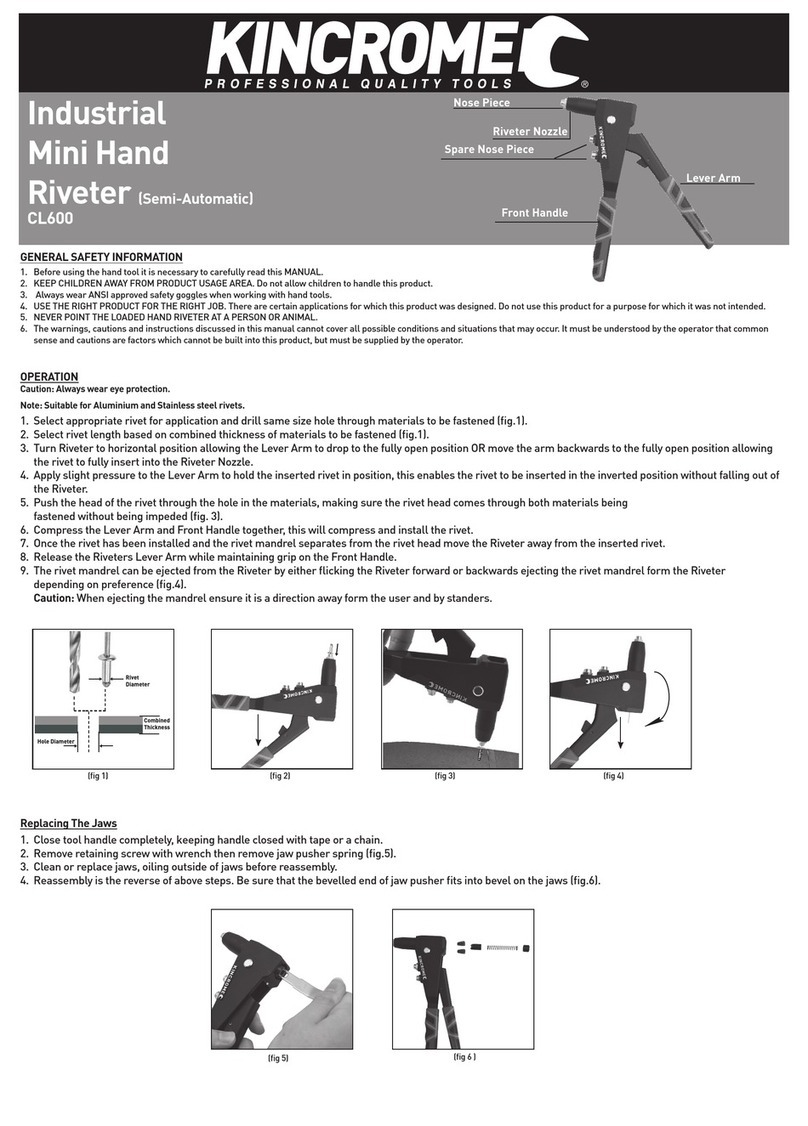

PARTS

BREAKDOWN

1

delfast.com

Parts Breakdown

Front

Battery Charger

Back

SAFETY

2Freephone. 0508 782 753

|

The RX40A is a high-performance battery-operated tool. Failure to follow the warnings and

instructions may result in electrical shock, fire or serious injury.

1. Always operate the tool with personal protective equipment (safety helmet and eye protection).

Using the appropriate safety equipment at all times will avoid body injury.

2. Keep children away while operating the tool. Distraction may cause injury.

3. Do not aim the tools at bystanders or co-workers. Serious injury may happen due to mishandling of

the tool.

4. Do not place hand near the tools mouth or position the tools mouth near the body. This will cause

serious injury.

5. Do not attempt to dismantle, modify or perform any maintenance on this tool. Any modification may

result in deterioration of the tool’s performance and may cause serious body injury.

6. When the machine is not being used or when abnormalities occur, please turn the switch off. When

changing or adjusting the battery, make sure to turn off the main switch and lock the trigger.

7. Do not place fingers, hands or position your body at the wire coil area. This may result in distortion

of the coil and may cause body injury.

8. Do not operate the tool under rain. This may result in electrical shock and accident.

9. Stay alert while working in a loft area. Do not operate the tool under the influence of drug, alcohol

and medication. A moment of inattention may result in serious injury.

10. Do not operate the tool in hazardous areas, where flammable liquid, gas and powder are present

and may ignite and cause fire.

11. The charger is designed to use AC power (100-240V, 50/60HZ). Do not recharge the battery using

power supply by generator, as this will cause the charger to malfunction.

12. When charging, the ambient temperature shall be in range of 0^0 – 45^0. Do not charge under

extremely cold or hot environments.

13. Continuous use of the charger is not allowed as this will shorten the lifespan of the battery and the

performance of the charger. When not in charging mode, the power supply must be switched off.

14. Please do not carry the charger by its power cord. Do not pull out the power cord from the power

socket with force, this will damage the cord and break the wires or cause a short circuit. A damaged

cord must be repaired or replaced.

15. Use only the supplied charger. Using unauthorised chargers may result in damage to the battery and

explosion.

16. Avoid contacting the battery with other metals. Trying to recharge with external wires may result in

short circuit of the battery.

17. Use the protective cap to cover the terminal when not in use.

Safety

SAFETY LOCK /

PRODUCT SPECS

3

delfast.com

WARNING! Make sure the safety features are operational before using

the tools. Do not operate the tool if the safety lock is not functional.

To ensure safe operation, the machine is equipped with the safety devices as follows:

1. Main Switch

Turn the switch on for power supply when in operation.

2. Trigger Lock

Always turn the trigger lock to the OFF position when not in use or when changing the coil.

Safety Lock

BATTERY AND

CHARGER USAGE

4Freephone. 0508 782 753

|

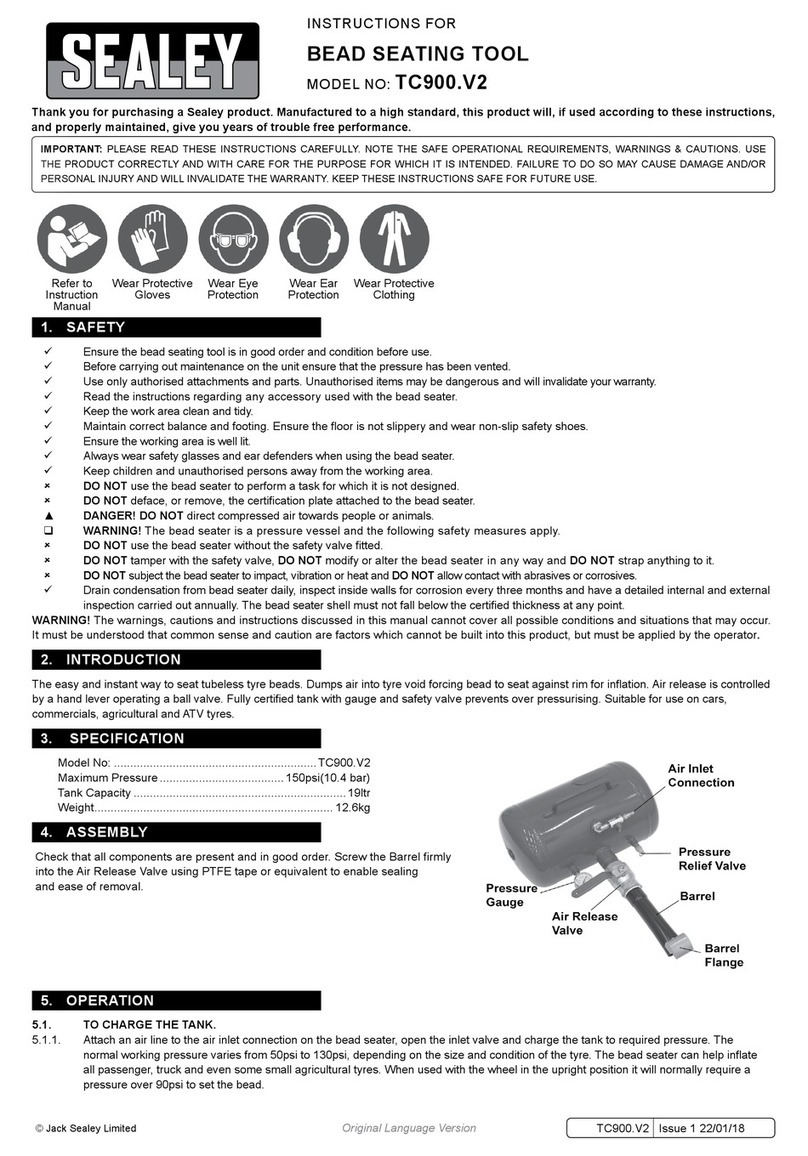

3. Corresponding rebar size for RX40A model

Longitudinal steel dia.

6 8 10 12 14 16 18 20 22 25 28 32

Traverse steel

dia

6X X 0000000000

8X00000000000

10 00000000000X

12 00000000000X

14 0 0 0 0 0 0 0 0 0 0 X X

16 000000000X X X

18 000000000X X X

20 0 0 0 0 0 0 0 0 X X X X

22 0000000XXXXX

25 0 0 0 0 0 XXXXXXX

28 0 0 0 0 XXXXXXXX

32 0 0 XXXXXXXXXX

Product Specification &

Technical Parameters

Model RX40A

Dimension (mm) 297x109x300

Total weight (kg) 2.6 (includes battery)

Voltage (V) 18

Max. tying dia. (mm) 40

1. Main technical parameters

Item Code FW-C10, FW-C30

Diameter (mm) 0.8

Material Q195

Length (m) 100 (approx.)

2. Main technical parameters for tying wire

BATTERY AND

CHARGER USAGE

5

delfast.com

WARNING! Before attaching or removing the battery, set the main

switch to the OFF position.

1. To avoid short circuiting the battery, always cover the battery terminal with the terminal cap when not in

use.

2. When placing the battery into the tool, press the battery lock before placing the battery into the slot. When

needing to remove the battery, press the battery lock button before removing the battery from the slot.

3. Use 100-240V AC, 50/60HZ power supply for the charger. Fully insert the battery into the charger slot and

it will begin to charge automatically. This is indicated by the charging light. It will take about 90 minutes to

fully charge a battery.

4. It is recommended to charge the battery at 0deg – 45deg. Do not charge under extremely cold or hot

environments.

Battery and Charger Usage

MACHINE

OPERATION

6Freephone. 0508 782 753

|

WARNING! Before attaching or removing the wire coil, set the main switch to the OFF position,

lock the trigger and remove the battery.

1. Installation of wire coils.

a. Only use Delfast wire coils in your RX40A rebar tool. Using nonstandard wire

coils will cause the tool to malfunction.

b. Remove the adhesive tape (if applied) and cut off about 2cm of the head of wire.

c. Push the reel stopper to release the reel and open it at the same time.

d. Install the wire coil with the left side facing the tool. Lock the opening by

closing the reel holder.

e. Insert the wire into the wire guide C. The wire must not be bent or curved.

f. The wire must pass through the wire guide C, in between the two feeding

gears till it reaches the end gap.

g. Keep inserting the wire into the pipe until it reaches the arm A unit.

h. Release the release stopper and confirm the release lever has returned to its

original position. The wire coil must be clamped to the gap

of the feeding gears.

i. Install the battery into the machine, when you hear the sound “ka” the battery

has been installed. Make sure the main switch is off, the trigger is locked

before installing the battery.

j. To turn on the main switch, keep the trigger on the ON position, the machine

is ready.

2. How to remove the wire coils.

a. Press the release lever and confirm the release lever is caught in the release

stopper.

b. Remove the wire coil.

c. Push the reel stopper to open the reel stay, take out the plastic spool.

3. Tying Procedure

a. Unlock the trigger lock, keep the mechanical arm on the rebars with a

45°angle at a vertical position to the rebars. Press the trigger and the tool will

tie automatically.

b. Remove the tool when the tying is complete.

c. Do not press the trigger when the mechanical arm is not on the rebar surface.

Should this happen, close all the switches, position the trigger lock to OFF

position and remove the trapped wire with a plier inside the mechanical

mouth.

4. How to adjust the number of turns per tie.

There are 2 options: 2 turns or 3 turns.

a. 3 turns: Default setting of the RX40A is 3 turns per tie.

b. 2 turns: Turn off the machine at the main switch. Press and hold trigger.

Machine Operation

COMMON FAULTS

& REMOVAL

METHODS

7

delfast.com

WARNING! Of any of the following conditions occur, set the main switch to the OFF position

and restart it after the problem has been solved.

This tool alerts you to the following conditions by means of a warning sound and warning lamp. If

the problem is not solved, please contact Delfast for support.

TABLE OVER LEAF

Common Faults and Removal

Methods

1. Carry out a daily inspection before sending or getting back the machine; the user must

carry out a daily inspection before using.

2. Please maintain your RX40A carefully, check if there is an incorrect adjustment,

moveable parts locked, damage to the switch as well as other possible conditions. If so,

stop using the machine and repair.

3. Please use the charger and batteries supplied with your tool. Using other chargers or

batteries may cause fire.

4. Improper use of the battery can cause liquid flow. If this happens please send your

battery for repair. Do not touch the liquid. If you do touch it, wash it off with clean water.

It it comes in contact with your eyes, go to the hospital for treatment immediately.

Additionally, the effusive liquid may stimulate your skin or cause burning.

5. Keep your tool case in good condition by wiping it with a soft cloth with soap suds.

Petrol, alcohol, amyl acetate etc. are forbidden, to avoid any damage to the plastic items.

6. Store the tool in its case, in a clean and dry environment when out of use.

7. In the event the tool malfunctions, send the tool to Delfast for repair.

Care and Maintenance

TROUBLE

SHOOTING

8Freephone. 0508 782 753

|

Normal Operation Cause Warning Sound Cause What to Check Solution

Power on – The tip

axis is initialised,

and the wire

cutter operates

automatically.

No operation takes

place.

No sound emitted Battery completely

empty

Confirm the battery

is charged

Perform normal

charge

Electrode plate has

been oxidized.

Take out the battery

and see if the

electrode is brown.

Polish terminal part

of battery pack with

cloth

Continuous short

beeps (pi, pi, pi)

Battery is empty Confirm the battery

is charged

Perform normal

charge

One short beep (pi) Bad connection

of twisting motor

connecting wire or

twisting motor is

broken.

Check twisting

motor connecting

wire or twisting

motor.

Reconnect the

connecting wire

or replace a new

twisting motor.

Twister cannot go

back to the initial

state.

Seven short

beeps repeated

(pipipipipipipi,

pipipipipipipi)

There is a foreign

substance between

magnetic plate (Pos.

328) and route PWB

unit (pos 325). Or

bad connection of

connecting wire K.

Check if there is

foreign substance

between magnetic

plate (Pos. 328) and

route PWB unit (pos

325). Or check the

wire K connection

Remove the foreign

substance between

magnetic plate

(Pos. 328) and route

PWB unit (pos 325).

Or replace a new

connecting wire K.

Trigger ON – Wire is

sent out.

No wire is sent out. Two short beeps

(pipi, pipi)

Curl guide is open. Open / close the curl

guide.

Fully close curl

guide.

Three short beeps

repeated (pipipi,

pipipi)

Tie wire has been

run out.

Check if the tie wire

has been run out.

Set the new tie wire

Wire caught inside

reel.

Check if the tie wire

inside the reel has

been loosened and

caught.

Remove fray on

wheel

Feeding channel is

blocked with foreign

substance.

Check the feeding

channel.

Wipe or blow with an

air gun to clean the

feeding channel

A small bump on the

tie wire.

Check tie wire. Cut off the small

bump on the tie

wire.

Bad connection

of feeding motor

connecting wire,

or feeding motor is

broken.

Check feeding motor

connecting wire or

feeding motor.

Reconnect the

connecting wire or

replace the feeding

motor.

Binding wire draws

a circle

Curl is disordered

and steps out of curl

guide.

No sound emitted. Wire, by hitting

reinforcing bars was

repelled

Check if wire hits

reinforcing bars at

binding.

Pay attention so that

wire does not hit

reinforcing bars at

binding.

Wire is subject to

cutting

No wire cutting

takes place.

No sound emitted. Cutter section is

blocked with foreign

substance.

Confirm function of

cutter section.

Either wipe cutter

section with cloth or

blow dry with air.

No sound emitted. Cutter or the cutting

mechanism is

broken or worn out

Check the cutter

and each part in the

cutting mechanism.

Replace a new part.

Wire twisting takes

place

Wire gets entangled No sound emitted. Wire, by hitting

reinforcing bars was

repelled

Check if wire hits

reinforcing bars at

binding.

Pay attention so that

wire does not hit

reinforcing bars at

binding.

Seven short

beeps repeated

(pipipipipipipi,

pipipipipipipi)

There is a foreign

substance between

magnetic plate (Pos.

328) and route PWB

unit (pos 325). Or

bad connection of

connecting wire K.

Check if there is

foreign substance

between magnetic

plate (Pos. 328) and

route PWB unit (pos

325). Or check the

wire K connection

Remove the foreign

substance between

magnetic plate

(Pos. 328) and route

PWB unit (pos 325).

Or replace a new

connecting wire K.

9

delfast.com

TROUBLE

SHOOTING

Normal Operation Cause Warning Sound Cause What to Check Solution

Wire twisting takes

place

Wire gets entangled Seven short

beeps repeated

(pipipipipipipi,

pipipipipipipi)

The wire is

entangled on the

twister.

Check the twister

if there is wire

entangled.

Clean entangled

wire on the twister.

Four short beeps

repeated (pipipipi,

pipipipi)

Bad connection

of twisting motor

connecting wire or

twisting motor is

broken.

Check twisting

motor connecting

wire or twisting

wire.

Reconnect the

connecting wire

or replace twisting

motor.

Binding power is

weak.

No sound emitted. Reinforcing bars are

not of designated

size

Confirm size of

reinforcing bars to

be bound.

Use appropriate

diameter scope.

Torque setting is not

at the right level.

Check the torque

setting level.

Adjust the torque to

a higher lever.

Erroneous handling

such as improper

application of

machine.

Confirm how to

apply machine to

reinforcing bars.

Adjust the torque to

a higher lever and

insert in vertical

direction, use as

tilting at 45°

Wire twisting takes

place

Twisting-off takes

place.

No sound emitted. Reinforcing bars are

not of designated

size

Confirm size of

reinforcing bars to

be bound.

Use appropriate

diameter scope.

Torque setting is not

at the right level.

Check the torque

setting level.

Adjust the torque to

a lower lever.

Erroneous handling

such as improper

application of

machine.

Confirm how to

apply machine to

reinforcing bars.

Adjust the torque to

a lower lever and

insert in vertical

direction, use as

tilting at 45°

Works properly. Continuous short

beeps (pi, pi, pi)

Low power remains

in the battery pack.

Confirm the battery

is fully charged

Perform normal

charge.

Six short beeps

repeated

(pipipipipipi,

pipipipipipi)

The tool is used at

high temperature.

Check the

temperature at the

job site.

Leave the tool and

the battery pack at

normal temperature

in the room for

some time and

then continue the

operation.

RX40A REBAR TIER

OWNER’S MANUAL

Improper and unsafe use of this tool will result in death or serious injury. It is very

important that the intended operator of this tool reads and understands this manual

before operating this tool. Keep this manual available for others before they use the tool.

| delfast.com

@DelfastNZ #Delfast

Table of contents

Other Delfast Tools manuals