Operating and Maintenance Instructions

enviro et series

ET30, ET40, ET60, ET80, ET100 & ET120

These pumps are precision instruments which will give many years of service provided that the

instructions on installation and operation are followed. Whilst the Company may offer advice as

to the model they recommend, it is the sole responsibility of the user to ensure that the pump is

suited to the application for which it is to be used and that the materials offered for the pump and

motor components are suitable for the performance, environmental limitations and chemical

resistance requirements of their application.

Product Features

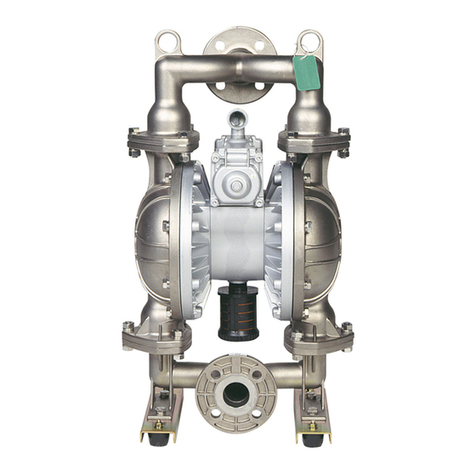

Two synthetic rubber diaphragms providing continuous air flow at consistent pressure.

Extremely low noise. Low energy consumption and long service life, easy to maintain.

Light-alloy casing, with excellent heat dissipation.

Installation

On receiving the pump, check that it is the model ordered and has not been damaged in transit.

Remove the protective covers from the inlet and outlet pipes where fitted. Ensure that the voltage at

which the pump operates is the same as the rating label.

The pump must is horizontal. Use only to pump air.

One or more aerators can be connected to the pump with piping and T pieces. Choose fittings

and pipe sizes that suit your installation requirements, ensure all pipes are secured with clips. Using

larger bore pipe, and avoiding sharp bends will improve performance.

Use new and sufficiently large aerators with enough discharge capacity, and place them no more

than 3 metres under water. Bends in the air pipe, aerators placed too deep, or old or dirty ones will

all reduce capacity and make the pump work harder and less efficiently. Ensure the pump can

discharge sufficient air at all times, never close off the pump outlet, otherwise the pump will heat

up and may be damaged.

To avoid any backflow of water into the pump, install the pump above water level. If this is not

possible, a non-return, or check valve must be used in the outlet pipe.

To guarantee a long service life, install the pump in dry conditions, free of condensation and dust.

Dust and moisture can seriously shorten the service life of the pump.

Please note that ambient temperatures above 40°C can cause the diaphragms to dry and crack.

Safety Instructions

Never immerse the pump in water.

The electricity supply must be grounded to protect the operator from electric shock.

If the pump falls into the water, unplug from the electricity supply before attempting to retrieve it.

Let qualified technicians check the pump before reconnecting it.

Before installation, and periodically, examine the power cord. If it is damaged it must be replaced

by the supplier or service agent or similarly qualified person in order to avoid a hazard. Never carry

the pump by the power cord. Switch off or disconnect the plug from the power when not in use, and

before installing or removing parts for cleaning.

Periodic maintenance is necessary, as described in these instructions.

Do not place the pump where it might come into contact with liquids, or near flammable or other

dangerous materials or objects.

If the normal pump sound is interrupted, or indicators no longer illuminate or anything abnormal

occurs, immediately disconnect the power and contact the pump supplier.

How it works

When the electromagnetic coils are energized by AC power (AC 100-120 & 200-240V) a magnetic

force is generated. This force then acts to induce poles between the permanent magnets fixed to the

diaphragm rods and the electromagnets. This causes alternate magnetic actions of repulsion and

attraction which move the rod in time with the AC power supply frequency. As the diaphragms move,

air is pumped by the change in volume of the space enclosed by the head and diaphragms and by

the repeated cycles of air intake and compression through the intake and exhaust valves.

Inlet Filter Sponge and Cleaning and Replacement

Any dust or foreign matter entering the air inlet may cause abnormal noise or result in failure of the

pump. Clean or replace the inlet filter sponge regularly, the frequency will depend on the environment.

Disconnect from the power supply before cleaning or replacement work.

With a screwdriver, lever the plastic filter cover off. Remove the filter sponge, clean the air inlet, filter

cover and sponge mounting surface. If the sponge is heavily soiled a new sponge will be needed or

the sponge can be washed in neutral detergent.

Rinse thoroughly, especially if using to aerate fish tanks as fish are extremely sensitive to detergent.

Dry thoroughly out of direct sunlight. Refit sponge and replace cover.

Diaphragm Replacement

Loosen the head screws. Remove the air chamber cover. Loosen the nut. Remove one by one the

diaphragm depressor, electrostatic membrane and diaphragm. Reassemble in reverse order. When

fitting the new diaphragm, ensure that the pip on the diaphragm fits into the notch in the bottom of

the air chamber. If necessary, repeat the repair for the other side of the pump.

www.kompressoren-drucklufttrockner-filtern.at