www.esavep.com PASRW060-D-BP

The Varimax 20 unit is MCS Certified and, if you wish to take advantage of

certain funding that may be available, your unit MUST BE INSTALLED BY AN

MCS ACCREDITED INSTALLER –please consult your supplier or ESP should

you require further clarification.

4.3 Emitter system.

The Heat pump must be matched to a suitable emitter system. The

Microgeneration Certification Scheme website offers guidance on pipe

spacing for UFH systems together with sizing consideration for fan coil units

such as the ESP Thermovec and traditional wet radiators can be found.

Please note that, in the case of an UFH system, the floor coverings must be

chosen very carefully to ensure that the heat is not ‘trapped’ in the floor by

laying the wrong floor covering for the individual room heat load. Again,

guidance is available from the MCS website.

5.0 Installation

5.1 Where to use and Where to Site the unit

The Varimax 20 can be used for domestic or commercial premises and

consideration should be given to the following when choosing an installation

site:

The unit must be installed in an outdoor location on a solid base

that can carry the weight of the unit. This can be on the ground, a

roof or balcony. If it is to be installed on a roof or balcony, a steel

frame must be used. Please contact ESP for further details.

The site must be well ventilated but NOT windy.

The site should be away from sources of high heat.

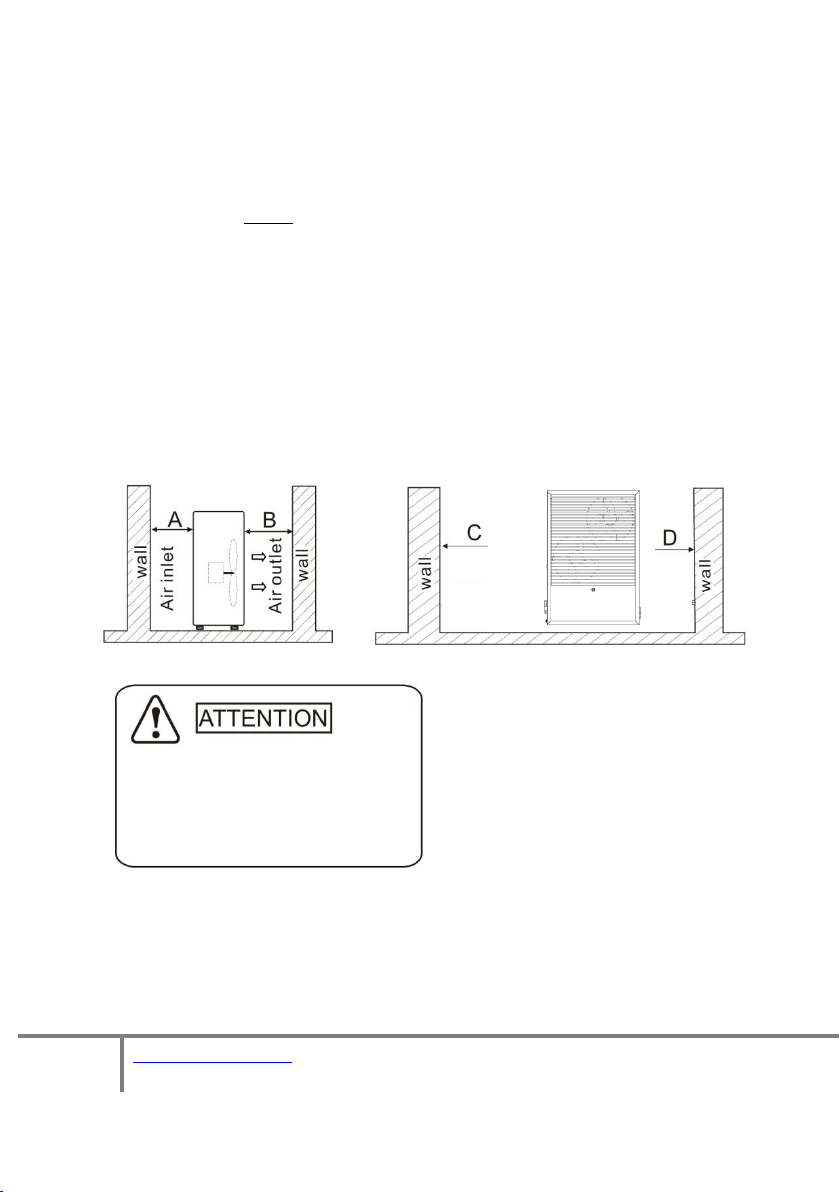

The unit must be sited away from any obstacles to the rear and

sides. There must be enough space around the unit for plumbing and

maintenance works as detailed in the diagram below. Care should

also be given to ensure that any overhead obstacles cannot create a

re-circulating air flow (where air exhausted from the ASHP is sucked

back in).

Further information is included in the section below entitled