D/B/A Essex PB&R Corporation

User Reference and Procedures Manual for the Essex Crewmember PBE

Document No: PRM-01, Revision: 21 Dated: 08/28/2015

For open-ended stowage brackets (MR-10042N) the tamper-evident seals are the

green plastic padlocks (Type B) and for (MR-10042NWA) the tamper-evident seals

are the green-knotted cable ties (Type D). (Ref. Figure 2)

For bracket-mounted, flange-mounted, or internal-mounted stowage cases ((MR-

10022N, 22NC, 22NEMB, 34N, 36N, 36NC, 37N, 39N, 49N, 49NA, and 50N), the

tamper-evident seals are the tamper-evident labels (Type C) and for (MR-10022NAA)

the tamper-evident seals are the green-pull grip seals (Type E). (Ref. Figure 2)

There are no seals for units stowed in Flame-Resistant fabric containers (MR-10035N,

MR-10051N, and MR-10052N).

(2) Pouch Access

The sealed barrier pouch containing the Essex Crewmember PBE is easily accessed

and removed from its stowage container (Ref. para. 1.C. (2)). A force of

approximately 18-28 pounds will be required to remove the pouch, or to lift the lid &

break the tamper-evident seals.

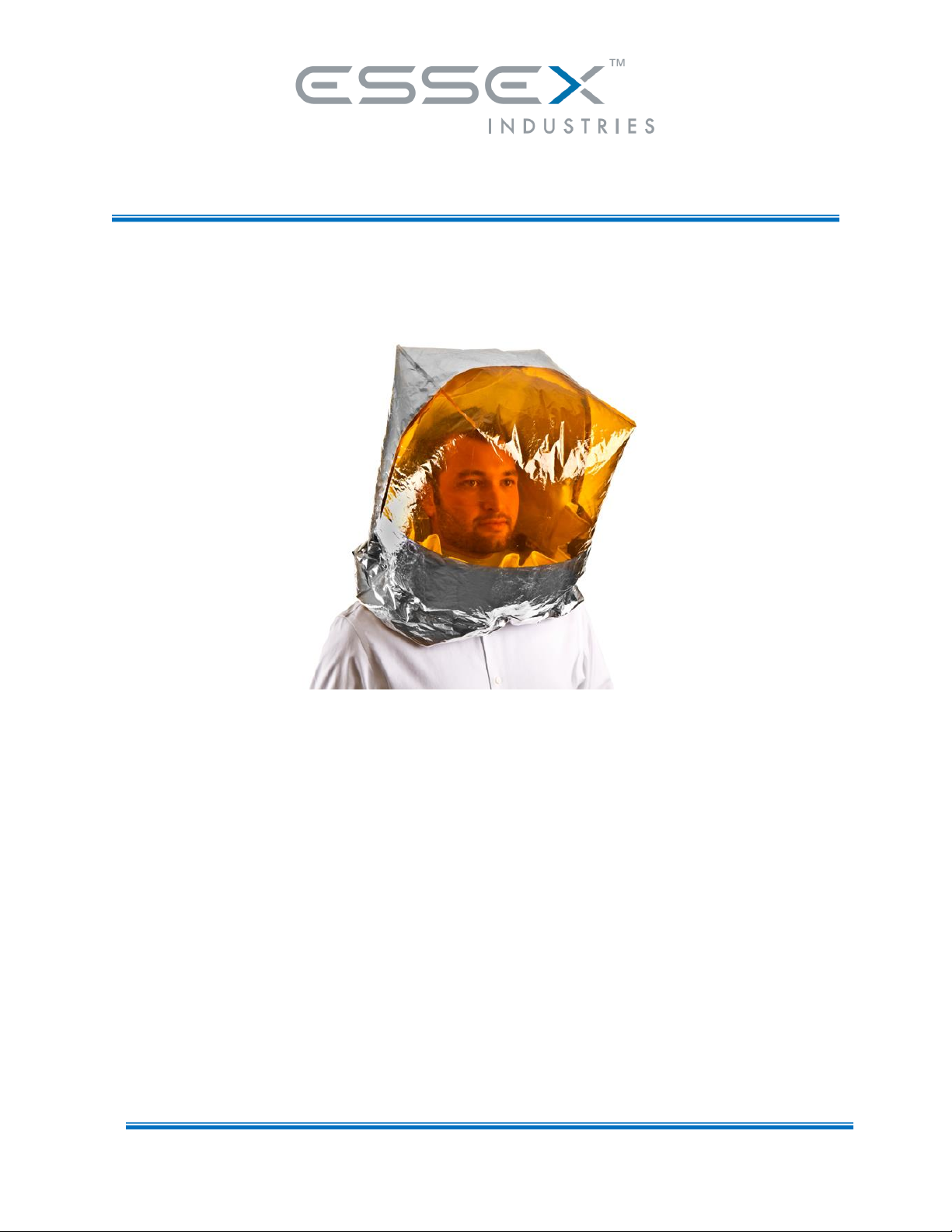

(3) Breathing System

Once the pouch is removed from its container and opened, oxygen flow is initiated by

snapping the two cylinders apart, which in turn activates the flashing green light on the

Service/End-of-Service Indicator. For the MR-10022NAA Unit, oxygen flow is

initiated by grasping one cylinder and sharply pulling the red ball. One bottle releases

oxygen rapidly, whereas the second bottle discharges oxygen slowly. An audible

hissing sound and inflation of the unit within (2) minutes indicates the PBE is

operating properly.

Once donned, the Essex Crewmember PBE will protect the wearer for up to 15

minutes. Although both bottles will completely discharge in 8 to 10 minutes, enough

oxygen will remain for the full, specified 15 minutes of respiratory protection. When

the unit deflates to the point where it touches the wearer’s head and face, or when the

red light on the Service/End-of-Service Indicator flashes, the unit’s useful life has

ended and must be removed.

The Essex Crewmember PBE operates at a positive pressure. The neck seal acts as a

relief valve to prevent excessive pressure from building up inside the hood.

(4) Time Required to Put On and Take Off Hood

A trained user can access and don the hood in approximately 15 seconds. It can be

removed in less than 5 seconds.