eta plus ELC N12 Guide

UV-

TECHNOLOGY

Technical Documentation

ELC

®

N12 - ELC

®

N32 /

ELC

®

NE12 - ELC

®

NE32 /

ELC

®

NE12D - ELC

®

NE32D

GB

eta plus electronic gmbh

Lauterstraße 29, D-72622 Nürtingen, Telefon +49 (0) 70 22 - 60 02-80, Fax +49 (0) 70 22 – 6 58 54

Postfach 1411, D-72604 Nürtingen, e-mail: info@eta-uv.de

––––––––––––––––––––––––––––

Eingetragen unter HRB 724321 AG Stuttgart, USt.-Id.-Nr. DE 146267800

Geschäftsführer: Dr. Peter Schwarz-Kiene

our name is our principle

eta plus electronic gmbh

Lauterstraße 29, 72622 Nürtingen, Telefon +49 7022 6002-80, Fax +49 7022 65854, E-mail: info@eta-uv.de, www.eta-uv.de

Eingetragen unter HRB 724321 AG Stuttgart, USt.-Id.-Nr. DE 146267800, Geschäftsleitung: Uwe Uhlemann, Dr. Markus Roth

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

ELC®(„Electronic Lamp Control“) is a registered trademark of

IST Metz GmbH.

Safety page 1

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

Contents

1 Safety................................................................................................ 3

1.1 Definition of Symbols.................................................................................3

1.2 Safety Advice ..............................................................................................3

1.3 Correct operation........................................................................................4

1.4 Extended use ..............................................................................................4

2 Description of functions.................................................................. 5

3 Installation........................................................................................ 6

3.1 Mounting of casing.....................................................................................6

3.1.1 Installation position N12, N16, NE12, NE16, NE12D, NE16D........................7

3.1.2 Installation position N22, N32, NE22, NE32, NE22D, NE32D........................9

3.2 Connection ................................................................................................11

3.3 Control current connections....................................................................16

3.3.1 Series N12 – N32 and NE12 – NE32...........................................................16

3.3.2 Series NE12D – NE32D ..............................................................................16

3.4 Explanations of the control functions for ELC.......................................18

3.4.1 Release relay ..............................................................................................18

3.4.2 Control input START ...................................................................................18

3.4.3 Setting lamp power......................................................................................18

3.4.4 Table: lamp power.......................................................................................19

3.4.5 Earth fault control ........................................................................................20

4 Operation of ELC ........................................................................... 22

4.1 Initial operation .........................................................................................22

4.2 Switching on the ELC...............................................................................22

4.3 Switching on the lamp..............................................................................22

4.4 Dimming Operation ..................................................................................23

4.5 Standby Operation....................................................................................23

4.6 Switching off the Lamp ............................................................................23

5 Troubleshooting ............................................................................ 24

5.1 Repair of ELC ............................................................................................24

Safety page 2

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

6 Technical Data ............................................................................... 25

6.1 General data ELC......................................................................................25

6.2 Type specific data NE12D/NE16D/NE22D/NE32D (nominal

values) .......................................................................................................26

6.3 Type specific data NE12/NE16/NE22/NE32 (nominal values)................28

6.4 Type specific data N12/N16/N22/N32 (nominal values) .........................30

Safety page 3

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

1 Safety

1.1 Definition of Symbols

Stop (Stop Danger). This symbol warns of serious danger of severe injury to

persons. It must be strictly observed.

Attention (Warning). This symbol indicates information the non-observance of

which can lead to extensive damage to property. The safety warning must be

strictly observed.

Information. This symbol indicates key information on use. Non-observance can

lead to failure.

1.2 Safety Advice

The ELC must be installed and connected in compliance with existing regulations

and practices. This is e.g. EN 60204-1 in Europe.

Repairs on the ELC may only be carried out by the manufacturer.

The installation and starting up may only be carried out by skilled electricians.

Do not open the ELC before it is disconnected from the mains. BEWARE OF

RESIDUAL VOLTAGE! The unit may still be live up to three minutes after it has

been switched off.

☞

Safety page 4

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

The ELC causes a leakage current greater than 3.5 mA!

Safeguarding by means of leakage current protection type A and type AC

according to IEC 60755 is not permitted!

The ELC operates in principle as a frequency converter and is equipped with a

mains filter whose leakage current could activate fuse protection.

Contact to the grounding connector must always be ensured.

Additional measures must be taken to ensure that

there is no danger when

touching the appliance. This could be by means of a universal leakage current

protection type B, taking into consideration the increased response threshold, or

by means of an independent equipotential connection

1.3 Correct operation

The ELC is an electrical unit intended to be installed in the switch cabinets of

industrial high-voltage power installations. It is conceived as an electronic ballast

for the operation of lamps intended for this purpose.

Any other use is deemed as misuse. The manufacturer will not assume liability for

damage resulting from misuse.

A pre-requisite for authorised operation of the ELC is the observance of both the

operating and maintenance instructions and the safety advice.

1.4 Extended use

Extended use beyond the operating specifications as stated is not permitted.

The manufacturer will not assume liability if the equipment is used in any other

way. The operator acts at his own risk.

Any operation beyond the scope of the authorised operation is considered to be

misuse.

Description of functions page 5

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

2 Description of functions

The ELC is an electronic power supply unit for the operation of gas discharge lamps with

electrical properties as described in chapter 6.

In contrast to conventional ballasts (inductive lamp ballast or transformer or transformer with

transductor), the lamp with an electronic ballast is operated with high frequency (approx.

100 kHz). The lamp does not flicker and dimming is infinitely adjustable to a range between

20 % and 100 % of the electric power or to between 15 % and 100 % of the UV radiation

respectively.

Dimming

The possibility of dimming the lamp has two advantages. Firstly the lamp can be switched to

minimum load (standby operation) during longer idle times and energy can thus be saved.

Secondly the optimum lamp power can be determined and adjusted as appropriate.

Power control

The ELC offers a high level of lamp power constancy due to its integrated power control.

Variations in operating voltage of ±10 % do not affect lamp power.

Ignition device

When the lamp is switched on the ELC initiates trigger pulses to fire the lamp; a separate

ignition device is not required.

Other performance characteristics

•High level of electrical efficiency.

•The potential-free control inputs allow various lamp conditions such as maximum lamp

power, dimming or standby to be set.

•The digital control inputs are designed for control voltages of between 10 and 30 V AC or

DC. Therefore ELC can be easily integrated into the installation’s electric system.

•Lamp current and lamp power are continuously recorded and output as analogous

0-10 V signals.

•The ELC monitors the lamp cables for earth fault.

•The lamp output potential is separated from that of the supply voltage.

•The ELC is both short-circuit proof and safe in open circuit operation at the lamp output.

Installation page 6

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

3 Installation

3.1 Mounting of casing

The ELC must be installed in a control cabinet with at least IP 54 protection (see

EN

60529). Operation without a control cabinet or in a control cabinet with a lower

degree of protection is not permitted.

It is only permitted to install the appliance in the positions described in 3.1.1 or

3.1.2. When installed vertically, as described in 3.1.1 or 3.1.2, the control

connections must be positioned at the bottom and supply connections at the top.

Installation must allow for the minimum spacing.

The ELC should not be mounted in the immediate proximity of sensitive electronic

equipment.

An appropriate distance must be maintained to scatter field

transformers or other inductors.

The flow of cool air for the ELC must be safeguarded. The ambient temperature

must not exceed the values prescribed in chapter 6.

Ventilation must be provided for the switch cabinet.

The amount of air necessary is determined by the size and positioning of the

switch cabinet, the total electrical losses and the external temperature. Please

consult your switch cabinet manufacturer. For the recommended throughput of air

please see the technical data in chapter 6.

Impure cooling air could affect the functionality of the ELC. This can be avoided

by installing a fine air filter.

Installation page 7

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

3.1.1 Installation position N12, N16, NE12, NE16, NE12D, NE16D

Vertical installation position

Fig. 1: Assembly of the ELC 12-16kW, vertical installation position (all dimensions in mm).

501 mm

min. 150

540 mm

31 mm 31 mm

650 mm

200 mm

Oben

top

min. 150

261 mm

263,5 mm

control connector

Lampenstecker

lampconnection

Netzanschluß

line input

Luftaustritt

air exhaust

Steckerleiste für Steuersignale

Lufteintritt

air entrance

Installation page 8

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

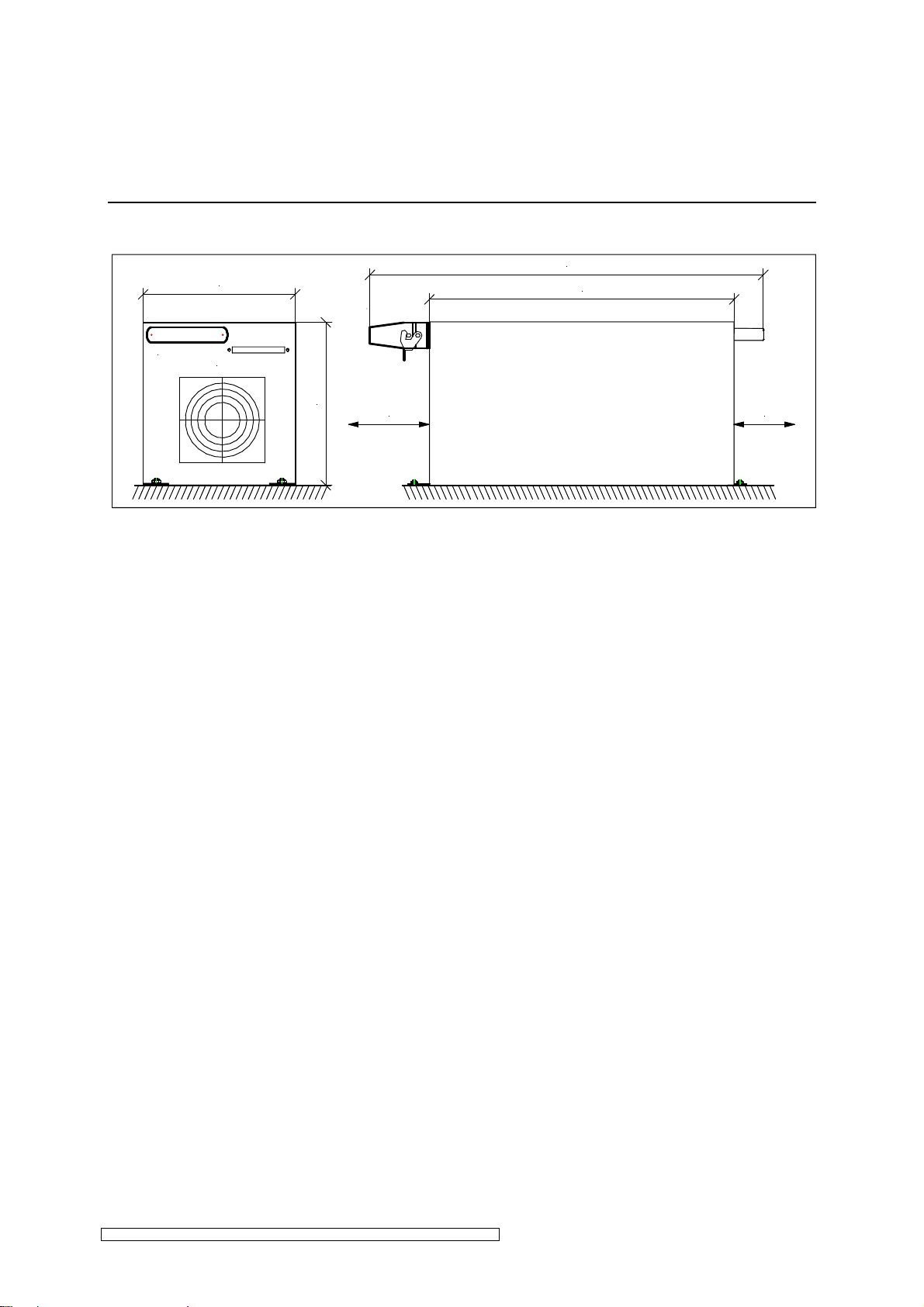

Horizontal installation position

Fig. 2: Assembly of the ELC 12-16kW, horizontal installation position (all dimensions in mm).

Steckerleiste für Steuersignale

501 mm

min. 150

650 mm

min. 150

263,5 mm

261 mm

control connector

Installation page 9

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

3.1.2 Installation position N22, N32, NE22, NE32, NE22D, NE32D

Vertical installation position

Fig. 3: Assembly of the ELC 22-32kW, vertical installation position (all dimensions in mm).

501 mm

min. 150

540 mm

31 mm 31 mm

650 mm

200 mm

Oben

top

min. 150

261 mm

control connector

Lampenstecker

lampconnection

Netzanschluß

line input

Luftaustritt

air exhaust

Steckerleiste für Steuersignale

Lufteintritt

air entrance

484 mm

Lufteintritt

air entrance

Luftaustritt

air exhaust

Installation page 10

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

Horizontal installation position

Fig. 4: Assembly of the ELC 22-32kW, horizontal installation position (all dimensions in mm).

501 mm

min. 150

650 mm

min. 150

261 mm

control connector

Steckerleiste für Steuersignale

Lufteintritt

air entrance

484 mm

Lufteintritt

air entrance

Installation page 11

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

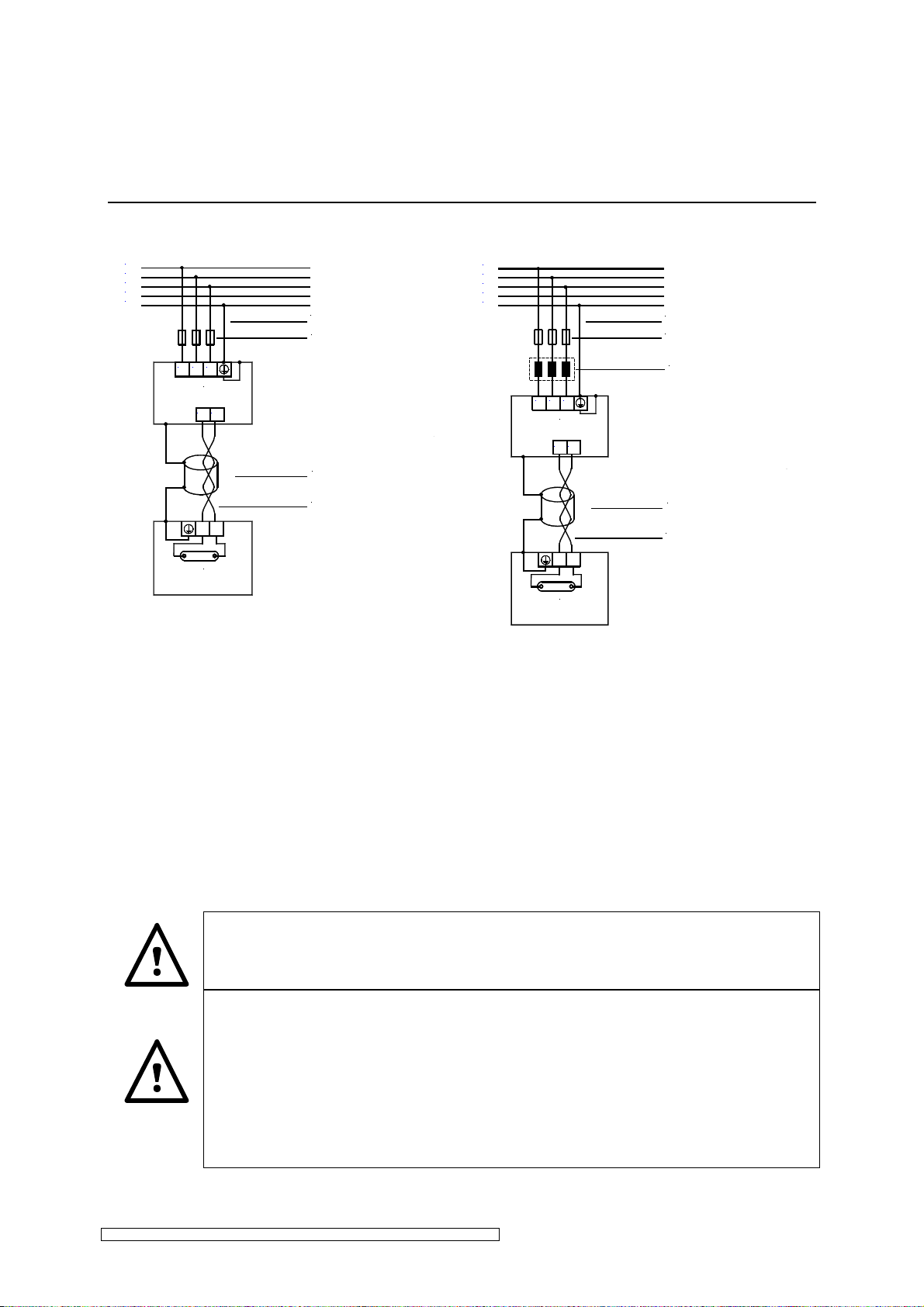

3.2 Connection

L3

out1

L1 L2

L1

L2

L3

N

PE

out2

earthed lead network side

automatic cutout

cable shield

lamp feeder cable

lamp assembly

ELC

Fig. 5: Power connection N12 - N32

L3

out1

L1 L2

L1

L2

L3

N

PE

out2

earthed lead network side

automatic cutout

cable shield

lamp feeder cable

lamp assembly

ELC

power choke

Fig. 6: Power connection NE12 – NE32

Power connection NE12D – NE32D

Fig. 5 and Fig. 6 show the respective electrical installation. Operation of appliances type

NE12-NE32 / NE12D-NE32D requires a power choke in series (see technical data chapter 6).

These appliances are implemented where the mains supply shows a low fault level or high

supply impedance.

The lamp feeder cable shielding must be connected to the ELC. To this end the connector

has an EMC screw connection (also see: connection lamp feeder cable).

If wished, the shielding can also be connected to the lamp unit.

The connection of mains supply cables and lamp feeder cables must be

separated from control cables.

For the mains power supply quality standards in accordance with EN 50160

(mains frequency, voltage drops, transients etc.) are pre-requisite.

ELCs of type “N” (N12/N16) are not designed for operation on high impedance

mains. Therefore the one-phase short-circuit power at the supply point must be

20 times higher than the nominal power of the UV installation or than the sum of

the nominal power of all electronic loads in the same arm.

Installation page 12

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

Mains connection

The cross section of the earthed wire must be at least 10 mm².

The three phases must be provided with an automatic cutout.

In order to avoid damaging the terminal pins, please do not exceed the

following torque:

N12 / N16, NE12 / NE16, NE12D /

NE16D, N22 / NE22 / NE22D:

•L1, L2, L3: 1.5 – 1.8Nm

•Grounding conductor: 3.0 – 4.0Nm

N32 / NE32 / NE32D:

•L1, L2, L3: 1.5 – 1.8Nm

•Grounding conductor:1.5 – 1.8Nm

☞

Installation page 13

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

Connecting the lamp feeder cable

The lamp feeder cable must correspond with the cable parameters described in

chapter 6.

Components of the connector:

connector module

hood

crimp contacts

EMC cable gland with

plastic insert

Preparing the lamp feeder cable:

•Remove sheath

•Free metal braid and put over cable

sheath

•Dismantle conductor

(measurements in mm)

A suitable contact crimping tool is required of

the type:

Amphenol group C146

Part No.: VN01 025 0029 1C

Closed crimp barrels (individual contacts)

2.5 mm

☞

7,5

100

12

Installation page 14

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

Top: Correct crimp connection

Middle: Stripped part of the wire too long, gap

between insulation and crimp barrel too large

Bottom: Stripped part of the wire too short

because conductor is not visible through

inspection hole.

•Insert cable into the cable gland and bush

casing

•Insert crimp contacts into the connector

module until they lock into place

•Ensure that the shield evenly covers the

plastic inset of the cable gland (360°

contact)

•Tighten EMC cable gland

Installation page 15

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

•Screw the module into the hood casing.

The picture on the left shows the

recommended orientation.

The lamp feeder cable between the switch cabinet and lamp assembly must be laid protected.

For the correct installation of the lamp assembly and lamp please observe the corresponding

manufacturer’s instructions.

Installation page 16

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

3.3 Control current connections

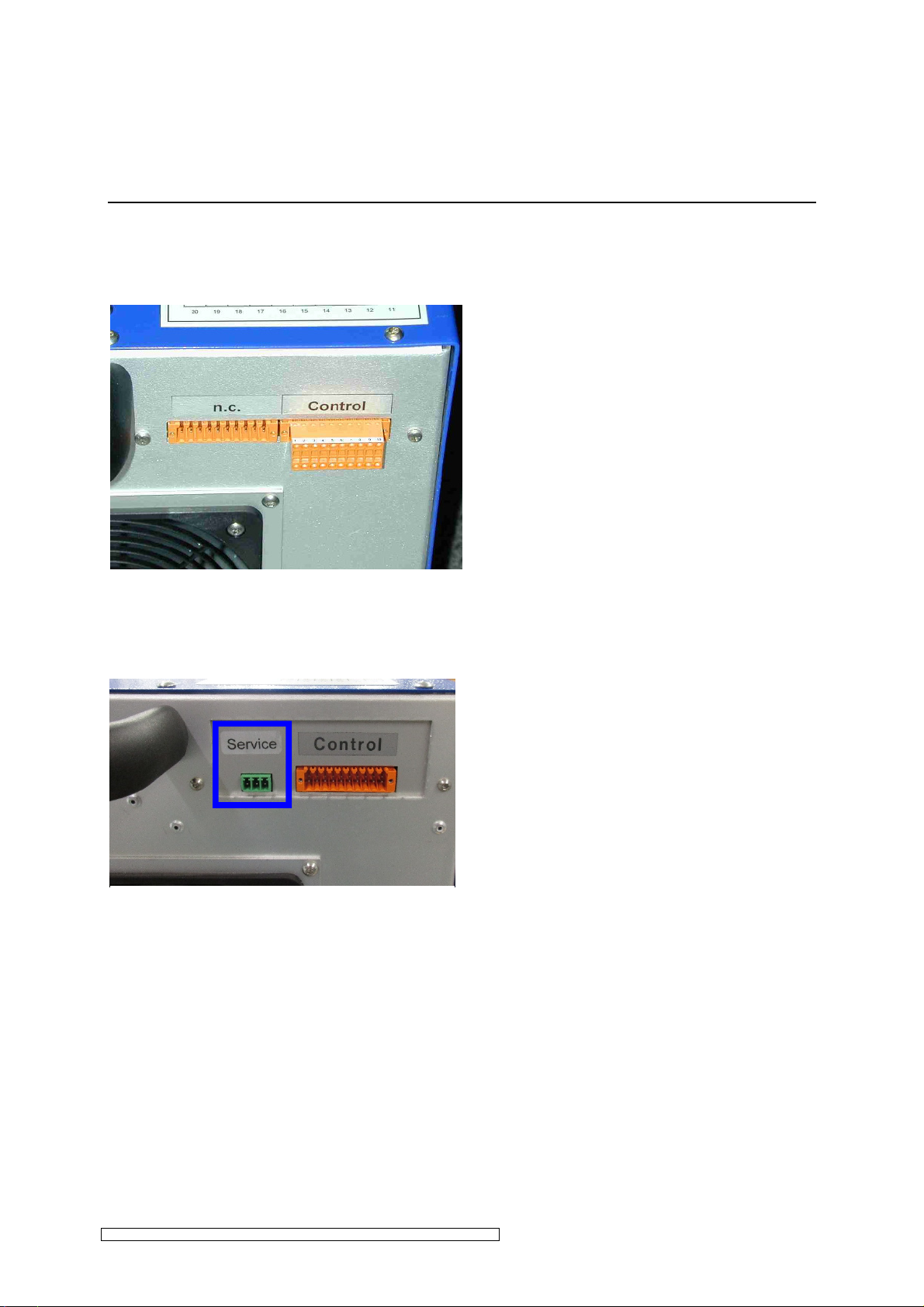

3.3.1 Series N12 – N32 and NE12 – NE32

The connector for the control connection is

to be plugged into the plug strip marked

Control. (Fig. 7)

The plug strip marked "n.c.” serves no

function.

The pin assignment is shown in Fig. 9 and

Table 1.

All control circuits must be earthed upon

installation.

3.3.2 Series NE12D – NE32D

The connector for the control connection is to

be plugged into the plug strip marked Control.

(Fig. 8)

The plug strip marked with “Service” is for

internal purposes.

The pin assignment is shown in Fig. 9 and

Table 1.

All control circuits must be earthed upon

installation.

Fig. 7 Control current connections N, NE-Series

Fig. 8 Control current connections NExxD Series

Fig. 7: Control current connections N, NE-Series

Fig. 8: Control current connections NExxD-

Series

Installation page 17

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

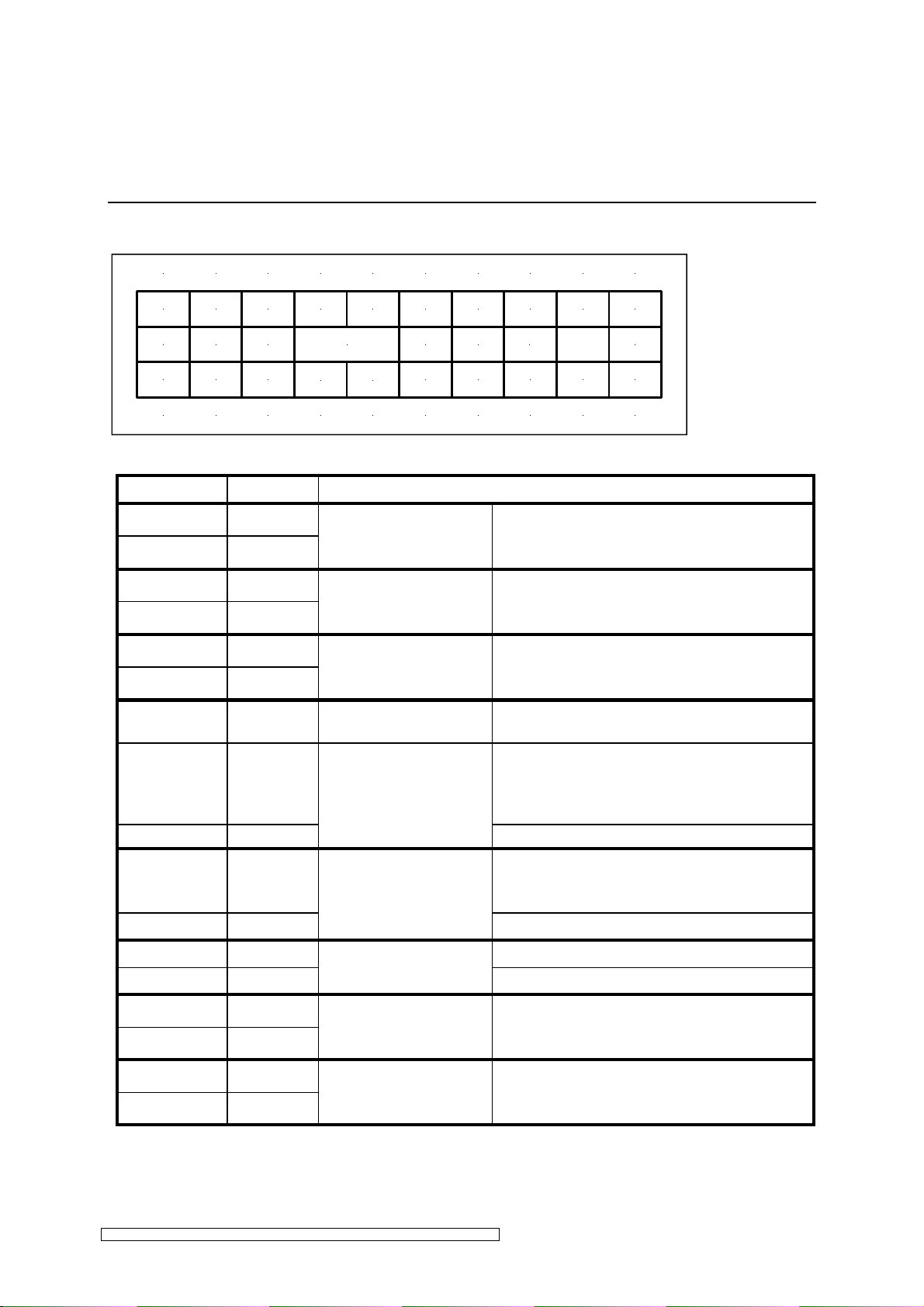

Pin assignment

Fig. 9: Pin plug for control of ELC

Designation Pin No. Description

Start1 1 digital control input

START

15 - 30 V DC, between Pin 1 and Pin 20 input

impedance = 1 kΩ

potential-free, active high

Start2 20

Max1 2 digital control input

MAX

15 - 30 V AC / DC, between Pin 2 and Pin 19

input impedance = 1 kΩ

potential-free, active high

Max2 19

Min1 3 digital control input

MIN

15 - 30 V AC / DC, between Pin 3 and Pin 18

input impedance = 1 kΩ

potential-free, active high

Min2 18

+ 10 V DC 4 control voltage for set value potentiometer 5 kΩto 10 kΩ

max. 10 mA

0-10V 5 analogous control input

SET VALUE *

set voltage between Pin 5 (0 –10 V) and

Pin 16,17 (GND),

input impedance > 200 kΩ(N12-N32, NE12-NE32)

input impedance > 13 kΩ(NE12D-NE32D)

GND 16, 17 control GND**

P-Lamp 6

analogous output

0-10 V DC / 1 mA, Reference: GND

1 V ≅1 kW appliance series up to 10 kW

1 V ≅4 kW appliance series above 12 kW

GND 15 PL (lamp output) control GND**

I-Lamp 7 analogous output 0-10 V DC / 1 mA, (1 V ≅2 A), Reference: GND

GND 14 IL (lamp current) control GND**

ES1 8 Relay earth contact ES

contact, potential-free

up to 30 V AC / DC, max. 0,5 A

Contact between Pin 8 and 13, closed in

operation, opens in the case of fault

ES2 13

OK1 10 RELEASE relay

contact, potential-free

up to 30 V AC / DC, max. 0,5 A

Contact between Pin 10 and 11, closed in

operation, opens in the case of fault

OK2 11

Table 1: Control current connection of ELC

* PWM coupling upon request

** control GND: all pins designated control GND are internally connected and potential-free.

Start1

Start2

Max1 Min1 + 10 V DC 0-10V P-lamp I-lamp ES1 n.c.

Max2 Min2 GND GND GND GND ES2 OK2

START SET VALUEMAX MIN

n.c.

OK1

PL IL RELEASE

12345678910

20 19 18 17 16 15 14 13 12 11

E S

Installation page 18

ELC N12-N32_NE12-NE32_NE12D-NE32D-V1.0-03.17-GB Subject to technical alterations

3.4 Explanations of the control functions for ELC

3.4.1 Release relay

The release relay indicates the trouble-free operation of the unit.

This means that the relay closes when the ELC (see chapter 4.2) is switched on and remains

closed during operation providing there is no defect.

A typical defect would be that the lamp does not fire.

3.4.2 Control input START

High: lamp is on

Low: lamp is off

By applying the High signal the lamp is fired and warms up at maximum current until the desired

power is achieved (see below).

We recommend warm-up at maximum power. After a short time (approx. 2 mins) the full output

has been reached and the lamp power can be varied as desired.

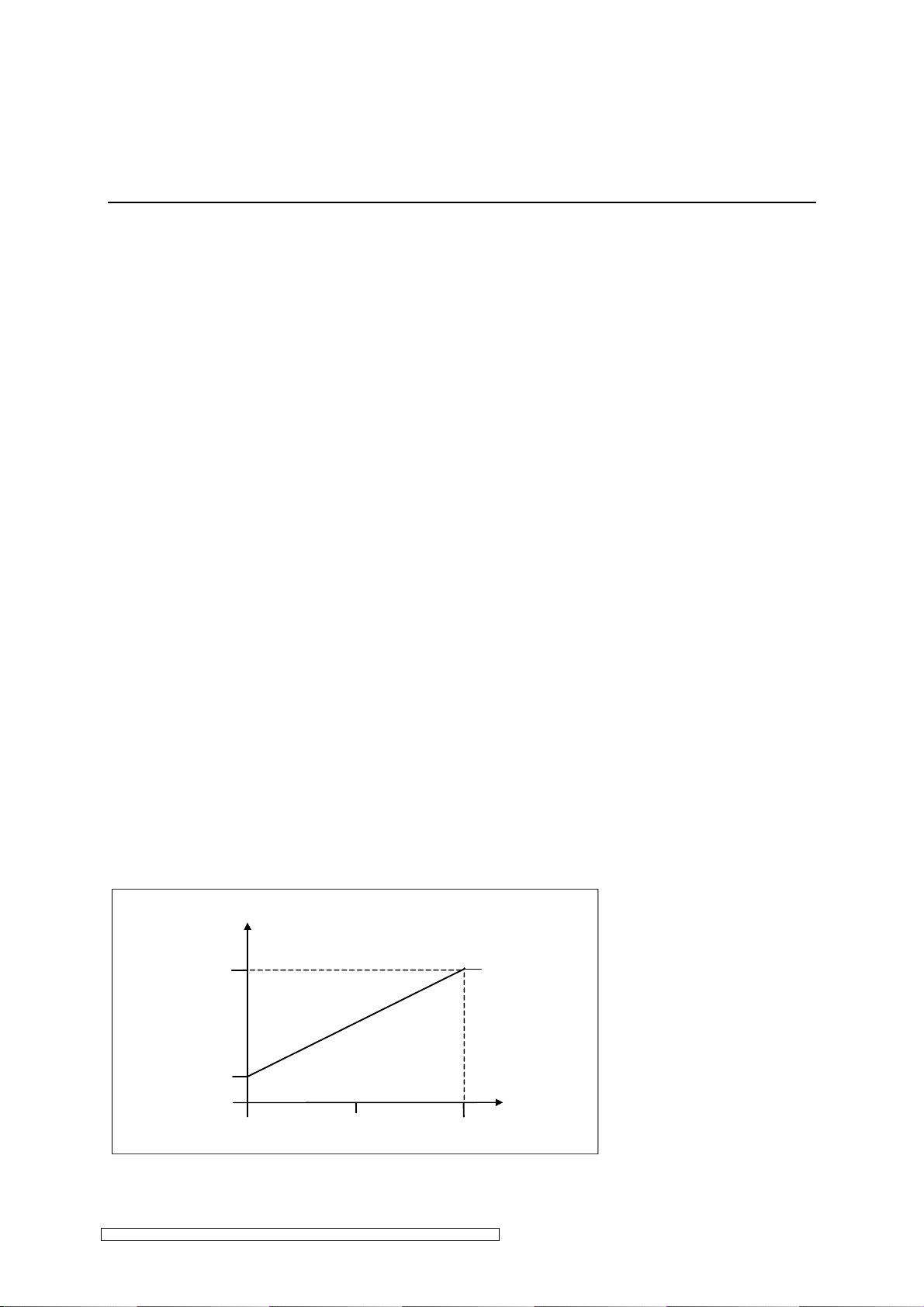

3.4.3 Setting lamp power

Stepless (infinitely variable)

The lamp can be dimmed steplessly from between approx. 20 % to 100 % of the nominal

power. The lamp power is set by applying an analog voltage of between 0 V and 10 V to control

input SET VALUE.

•0 V corresponds to min. power Pmin (20 % of nominal value)

•10 V corresponds to max. power Pmax (100 % of nominal value)

SET VALUE can be controlled manually by means of an external potentiometre.

Fig. 10: Control characteristic

20 %

Lampenleistung

Lamp power

Set value

100%

0 V 10 V

This manual suits for next models

5

Table of contents