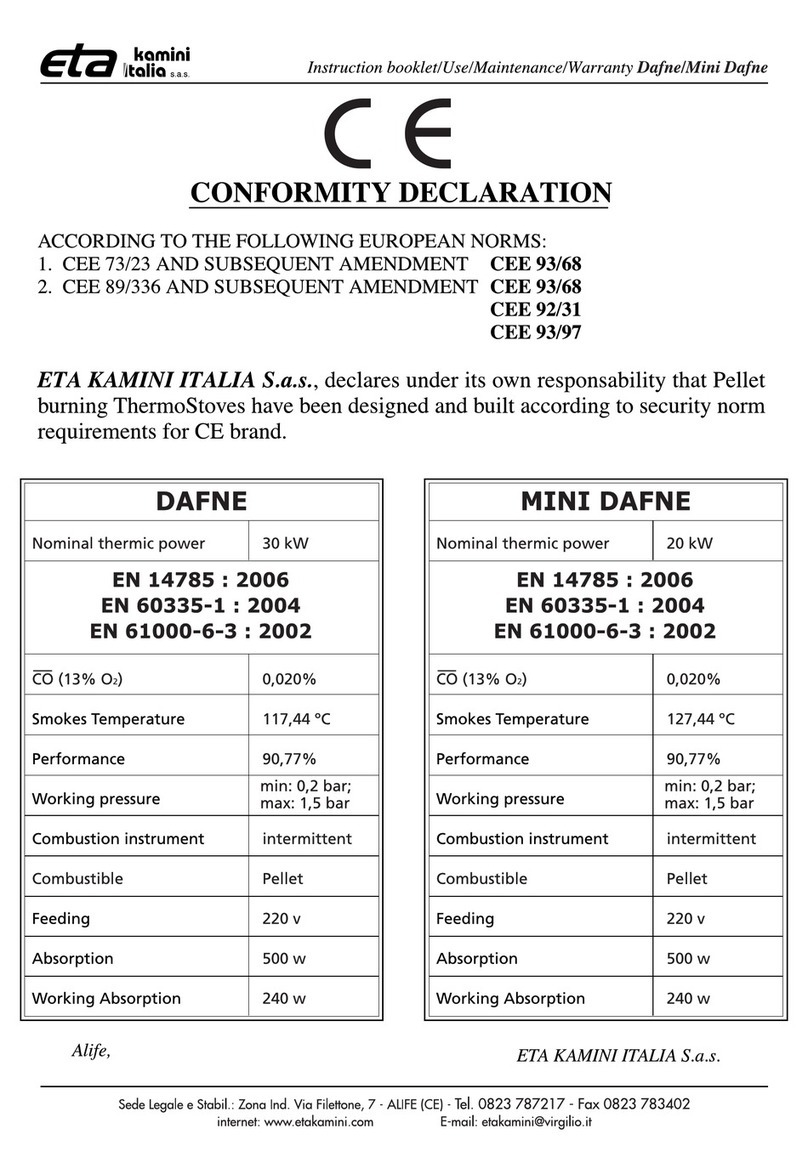

Cleaning and maintenance Maintenance notes

2 Cleaning and maintenance

2.1 Maintenance notes

Performing regular cleaning and maintenance

To ensure satisfactory functionality, cleaning and

maintenance must be performed at regular intervals.

You will receive a timely reminder about this from the

ETAtouch control system.

Cleaning of the boiler must be carried out at least

once a year, or when requested by the control

system. Maintenance is necessary at least every

3 years, or when requested by the control system. We

recommend that you perform maintenance annually.

You can also enter into a service agreement for your

heating system. Find out more from your heating

contractor or customer service.

All tasks where the maintenance table reads

"Customer" or "Customer or expert" in the column

"To be carried out by" can be carried out by any trained

adult. Instruction may be provided by the heating

technician or our customer service.

Steps that are marked with "Expert" only can only be

carried out by the heating technician or our customer

service.

Operation only by trained personnel

The product may be operated by trained adults only.

Training may be provided by the heating technician or

our customer service. Please read the associated

documentation carefully in order to avoid errors during

operation and maintenance.

Persons who lack experience and knowledge as well

as children may not operate, clean, or maintain the

product.

Display maintenance steps on the screen

With this boiler, the maintenance steps can also be

displayed on the ETAtouch control system screen. The

required activities will be explained to you step-by-step

and supplemented with detailed graphics. Each

maintenance is saved and the details can be viewed at

any time. So you can maintain a long-term overview of

the maintenance carried out. Of course, the

maintenance can also be carried out using the service

guide, without the support of the ETAtouch control

system.

To access maintenance, switch to settings in the boiler

function block ( [Settings] button) and then select

the function [Maintenance].

Fig. 2-1: Overview (example)

You can also access this overview by pressing

the maintenance switch. Also when the message

appears that maintenance of the boiler is required.

In the overview the different maintenance intervals are

listed in the upper area. This includes the maintenance

already carried out. With the button, information

about the selected maintenance is displayed.

Maintenance that you can carry out as an end

customer is labelled with the symbol. All others are

reserved for specialists and require authorisation.

Press the button to start the maintenance. The

individual steps are displayed on the screen. You can

switch to the next or the previous screen respectively

with the arrow keys on the left and right side of the

screen.

Fig. 2-2: Maintenance step (example)