2

INDEX

INDEXINDEX

INDEX

OF CONTENTS

OF CONTENTSOF CONTENTS

OF CONTENTS

1. GENERAL WARNINGS ………………………………………………………

1. GENERAL WARNINGS ………………………………………………………1. GENERAL WARNINGS ………………………………………………………

1. GENERAL WARNINGS ……………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………………………………

……………………………………………………………………………….3

….3….3

….3

2. FUELS…………………………

2. FUELS…………………………2. FUELS…………………………

2. FUELS…………………………..

....

..………………………

………………………………………………

………………………………………

………………………………

………………………………………………………………………………..

………………………………………………………………..………………………………………………………………..

………………………………………………………………..…………………………...3

…………………………...3…………………………...3

…………………………...3

3. SAFETY DEVICES………………………

3. SAFETY DEVICES………………………3. SAFETY DEVICES………………………

3. SAFETY DEVICES………………………..……

..……..……

..…………………………………………………………………………………

…………………………………………………………………………………………………………………………………………………………

………………………………………………………………………………………………………………..4

…………………………………..4…………………………………..4

…………………………………..4

4. TECHNICAL

4. TECHNICAL 4. TECHNICAL

4. TECHNICAL FEATURES

FEATURESFEATURES

FEATURES………………

………………………………

……………………………………………………………………………………………………..

……………………………………………………………………………………..……………………………………………………………………………………..

……………………………………………………………………………………..…………………………….. 5

…………………………….. 5…………………………….. 5

…………………………….. 5

5. INSTALLATION REQUIREMENTS………

5. INSTALLATION REQUIREMENTS………5. INSTALLATION REQUIREMENTS………

5. INSTALLATION REQUIREMENTS……….…

.….…

.………………………………………………………………………..

……………………………………………………………………..……………………………………………………………………..

……………………………………………………………………..…

……

…………………………………. 6

………………………………. 6………………………………. 6

………………………………. 6

5.1. Safety control measures……………………………………………………………………………………………………..…………. 6

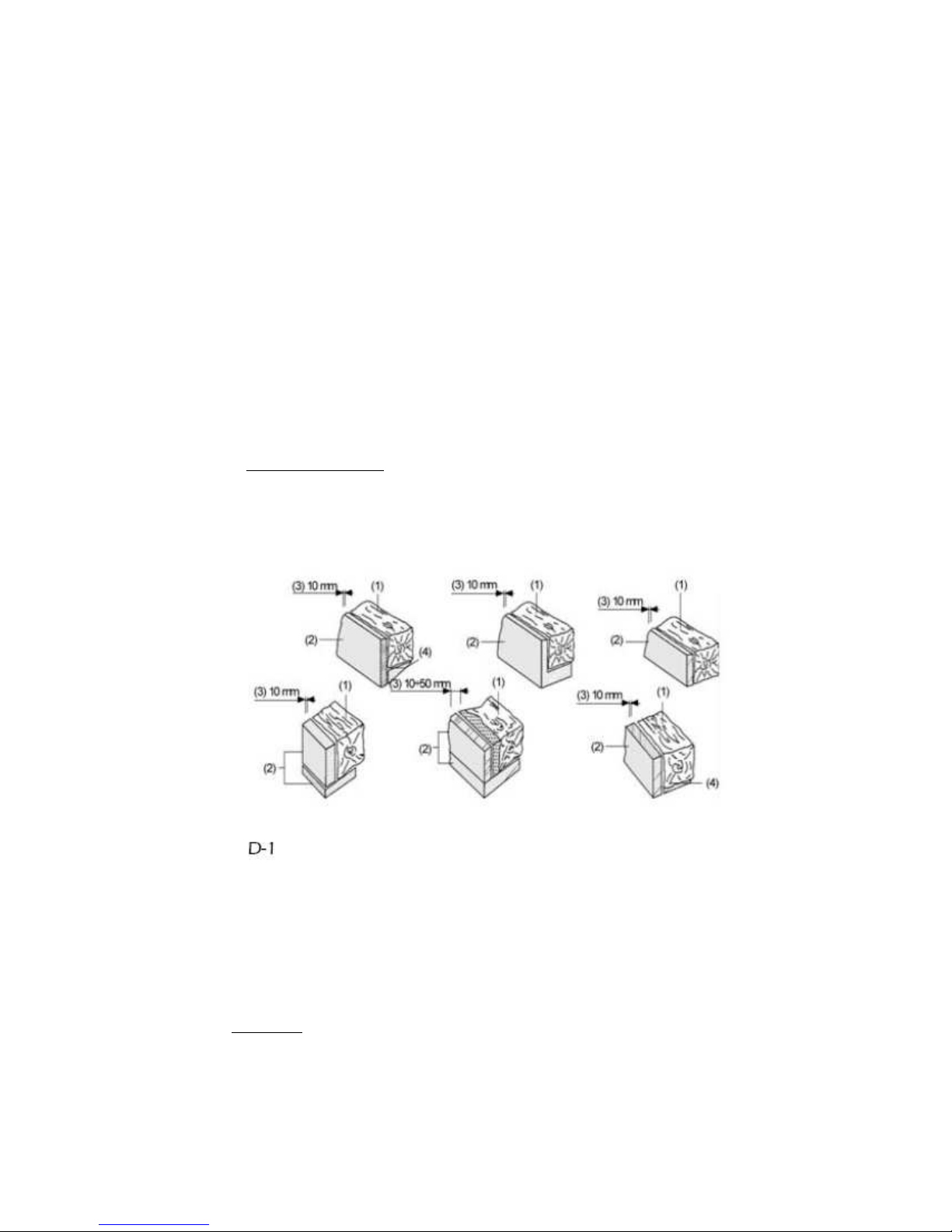

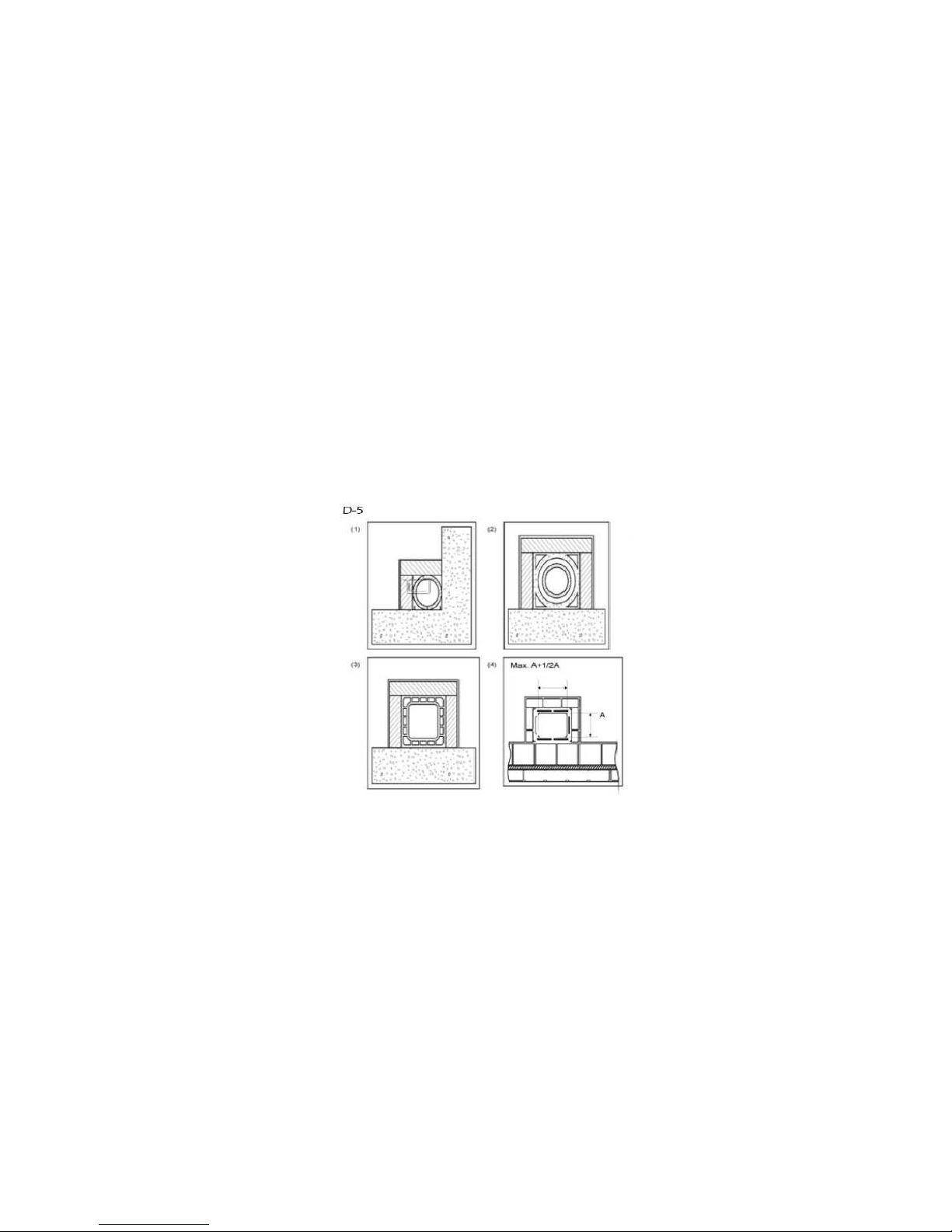

5.2. Beams protection………………………………………………………………………………………………………………..……………7

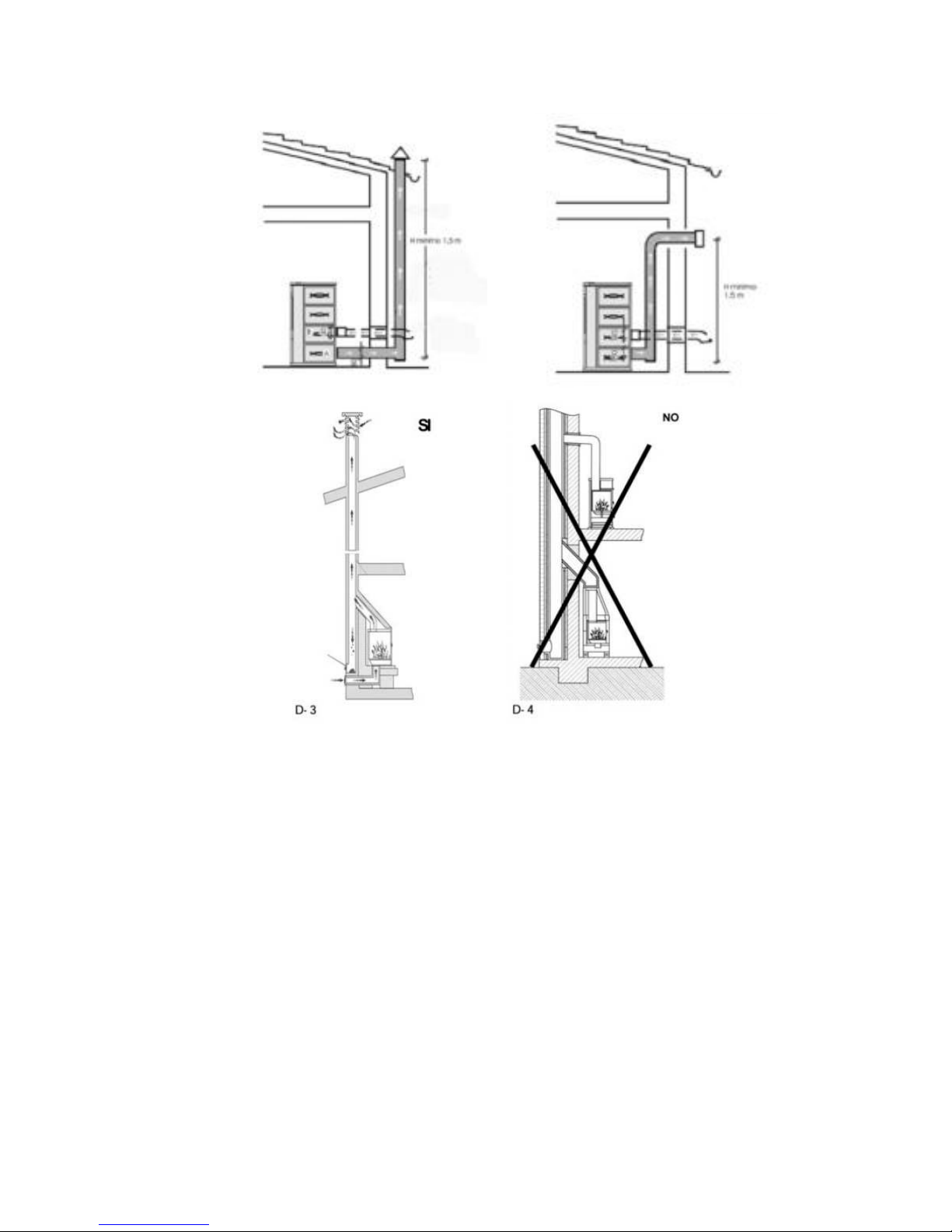

5.3. Chimney………………………………………………………………………………………………………..…………………..……………. 7

5.4. Chimney cowl…………………………………………………………………………………………………………….…………………… 8

5.5. Connection to chimney / Combustion air (air intake)…………………………………………..…………………….8

5.6. Outside air intake………………………………………………………………………………………………………………………….….9

6.

6.6.

6.

STARTING

STARTINGSTARTING

STARTING

U

UU

U …………

……………………

……………

……

…………………

………………………………

…………………..

…..…..

…..……………………………………

…………………………………………………………………………

……………………………………………………

………………………………

…………………………………………………………………………

……………………………………………………………………………………………………………………

……………………………………………………………....

…....…....

…....9

99

9

7.

7. 7.

7. USUAL O ERATION

USUAL O ERATIONUSUAL O ERATION

USUAL O ERATION……………

…………………………

…………………………………………………

…………………………………………………………………………

…………………………………………………………………………………………………………………….

……………………………………………………………………………….……………………………………………………………………………….

……………………………………………………………………………….…….10

…….10…….10

…….10

8. MAINTENANCE AND CARE…………………………………

8. MAINTENANCE AND CARE…………………………………8. MAINTENANCE AND CARE…………………………………

8. MAINTENANCE AND CARE…………………………………………………………………………………………………………

………………………………………………………………………………………………………………………………………………

………………………………………………………………………………

………………

……….…………10

.…………10.…………10

.…………10

8.1. Burn pot cleaning…………………………………………………………………………………………………………..……………..10

8.2. Ash pan cleaning………………………………………………………………………………………………………………………… 11

8.3. Ash pan and burn pot door joints………………………………………………………………………………………….…...11

8.4. Chimney cleaning…………………………………………………………………………………………………..……………….….. 11

8.5. Glass cleaning…………………………………………………………………………………………………………………………….….11

8.6. Exterior cleaning ………………………………………………………………………………………….……………………………....12

8.7. Seasonal shutdowns……………………………………………………………………………………….…………………………….. 12

9

99

9

DIS LAY

DIS LAYDIS LAY

DIS LAY

O ERATION

O ERATIONO ERATION

O ERATION

................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.............................................................

..........................................................

.............................

15

1515

15

9.1

Display general information.................................................................................................................................................... 15

9.2

Display keys running.................................................................................................................................................................. 16

9.3

Remote control general infomation. .................................................................................................................................... 16

9.4

Menu option ................................................................................................................................................................................. 17

9.4.1

User menu ..................................................................................................................................................................... 17

9.4.2

Menu 1. .......................................................................................................................................................................... 17

9.4.3

Menu 2. Clock ............................................................................................................................................................... 18

9.4.4

Menu 3. rogramme Adjustment. ........................................................................................................................ 18

9.4.5

Menu 4. Language selection .................................................................................................................................. 25

9.4.6

Menu 5. Stand-by mode ........................................................................................................................................... 26

9.4.7

Menu 6- Sonorous mode .......................................................................................................................................... 26

9.4.8

Menu 7. Initial charge ................................................................................................................................................ 26

9.4.9

Menu 8- Stove stage ................................................................................................................................................... 26

9.5

User Mode ..................................................................................................................................................................................... 28

9.5.1

Starting up stove ......................................................................................................................................................... 28

9.5.2

Operation stove ........................................................................................................................................................... 28

9.5.3

Consigned ambiance temperature changing .................................................................................................. 29

9.5.4

User fixed temperature reached by the ambiance temperature… ............................................................ 29

9.5.5

Burn pot automatic cleaning .................................................................................................................................. 29

9.5.6

Shutdown stove........................................................................................................................................................... 30

9.5.7

Shutted off stove. ........................................................................................................................................................ 30

9.5.8

Re-starting up stove. ................................................................................................................................................... 30

9.6

What happens if…? ..................................................................................................................................................................... 30