ET&F 610 Operator's manual

INSTRUCTION MANUAL AND SAFETY INSTRUCTIONS

DANGER

Improper and unsafe use of this Nailer will result in death or serious injury!

This Manual contains important information about product safety.

Read and understand this Manual before operating the Nailer.

Keep this Manual available for others before they use the Nailer.

MODEL 610 NAILER

— 2 —

CONTENTS

Page

BEFORE OPERATION .............................................................. 8

WORKING ENVIRONMENT .............................................. 8

AIR SUPPLY ....................................................................... 8

LUBRICATION .................................................................... 9

COLD WEATHER CARE ..................................................... 9

TESTING THE NAILER....................................................... 9

ADJUSTING AIR PRESSURE .......................................... 10

LOADING PINS ................................................................ 10

NAILER OPERATION ............................................................. 12

METHODS OF OPERATION ............................................ 12

ADJUSTING THE FASTENING DEPTH .......................... 13

CHANGING THE EXHAUST DIRECTION ....................... 13

CUTTING OFF THE SHEET ............................................. 13

MAINTENANCE

MAINTENANCE AND INSPECTION ..................................... 14

SERVICE AND REPAIRS ........................................................ 15

PARTS LIST ............................................................................ 18

Page

IMPORTANT INFORMATION .............................................. 2

DEFINITIONS OF SIGNAL WORDS .................................... 2

SAFETY

IMPORTANT SAFETY INSTRUCTIONS

FOR USING NAILERS .................................................... 3

IMPORTANT SAFETY INSTRUCTIONS FOR USING

MODEL 610 .................................................................... 5

EMPLOYER’S RESPONSIBILITIES ...................................... 5

OPERATION

NAME OF PARTS ................................................................. 6

SPECIFICATIONS ................................................................. 7

PIN SELECTION ................................................................... 7

ACCESSORIES ..................................................................... 8

STANDARD ACCESSORIES .......................................... 8

APPLICATIONS .................................................................... 8

IMPORTANT INFORMATION

READ AND UNDERSTAND ALL OF THE OPERATING INSTRUCTIONS, SAFETY PRECAUTIONS AND

WARNINGS IN THIS MANUAL BEFORE OPERATING OR MAINTAINING THIS NAILER.

Most accidents that result from the operation and maintenance of Nailers are caused by the failure to observe

basic safety rules or precautions. An accident can often be avoided by recognizing a potentially hazardous

situation before it occurs, and by observing appropriate safety procedures.

Basic safety precautions are outlined in the “SAFETY” section of this Manual and in the sections which

contain the operation and maintenance instructions.

Hazards that must be avoided to prevent bodily injury or machine damage are identified by DANGERS and

WARNINGS on the Nailer and in this Manual.

Never use this Nailer for applications other than those specified in this Manual.

DEFINITIONS OF SIGNAL WORDS

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury, or

may cause machine damage.

NOTE emphasizes essential information.

— 3 —

SAFETY

IMPORTANT SAFETY INSTRUCTIONS

MMMMFOR USING NAILERSMMlMM

READ ALL INSTRUCTIONS

DANGER

1. ALWAYS WEAR EYE PROTECTOR.

When operating the Nailer, always wear eye protector, and make sure

others in work area wear eye protector, too.

Eye protector must conform to the requirements of American National

Standards Institute, ANSI Z87.1 and provide protection against flying

particles both from the front and side.

The employer must enforce the use of eye protector by the Nailer

operator and others in work area.

2. NEVER USE BOTTLED GASES.

Never use oxygen, combustible gases or any other bottled gases as a

power source for the Nailer.

Use of the above gases is dangerous, as the Nailer will explode.

Use only clean, dry, regulated compressed air.

WARNING

3. DO NOT EXCEED 120 psi.

Do not exceed maximum recommended air pressure 120 psi (8.3 bar

8.5 kgf/cm2).

Never connect the Nailer to pressure which potentially exceeds 200 psi

(13.7 bar 14 kgf/cm2) as the Nailer can burst.

4. NEVER POINT NAILER TOWARD YOURSELF OR

ANYONE ELSE.

Always assume the Nailer contains fasteners.

Never point the Nailer toward yourself or anyone else,

whether it contains fasteners or not.

If fasteners are mistakenly driven, it can lead to severe

injuries.

Never engage in horseplay with the Nailer.

Respect the Nailer as a working implement.

5. NEVER CARRY WITH FINGER ON TRIGGER.

Remove finger from trigger when not driving fasteners.

Never carry the Nailer with finger on trigger since you

could drive a fastener unintentionally and injure

yourself or someone else.

Always carry the Nailer by the handle only.

6. ALWAYS WEAR EAR AND HEAD PROTECTOR.

Always wear ear protector to protect your ears from

loud noise.

Always wear head protector to protect your head from

flying objects.

— 4 —

7. STORE NAILER PROPERLY.

When not in use, the Nailer should be stored in a dry

place. Keep out of reach of children. Lock the storage

area.

8. KEEP WORK AREA CLEAN.

Cluttered areas invite injuries. Clear all work areas of

unnecessary tools, debris, furniture, etc.

9. NEVER USE IN PRESENCE OF FLAMMABLE

LIQUIDS OR GASES.

The Nailer produces sparks during operation.

Never use the Nailer in sites containing lacquer, paint,

benzine, thinner, gasoline, gases, adhesive agents,

and other materials which are combustible or explosive.

10. KEEP VISITORS AWAY.

Do not let visitors handle the Nailer.

All visitors should be kept safely away from work

area.

11. DRESS PROPERLY.

Do not wear loose clothing or jewelry as they can be

caught in moving parts.

Rubber gloves and nonskid footwear are

recommended when working outdoors.

Wear protective hair covering to contain long hair.

12. NEVER USE NON RELIEVING COUPLER ON

NAILER.

If a non relieving coupler is used on the Nailer, the

Nailer can remain charged with air after disconnecting

and thus will be able to drive a fastener even after

disconnecting.

The Nailer and air hose must have a hose coupling

such that all pressure is removed from the Nailer

when the coupling joint is disconnected.

13. CHECK PUSH LEVER BEFORE USE.

Make sure the push lever operates properly. (The

push lever may be called “Safety”.) Never use the

Nailer unless the push lever is operating properly,

otherwise the Nailer could drive a fastener

unexpectedly. Do not tamper with or remove the push

lever, otherwise the push lever becomes inoperable.

14. KEEP ALL SCREWS AND COVERS TIGHTLY IN

PLACE.

Keep all screws and covers tightly mounted. Check

their condition periodically.

Never use the Nailer if parts are missing or damaged.

15. DO NOT LOAD FASTENERS WITH TRIGGER

PULLED OR PUSH LEVER DEPRESSED.

When loading fasteners into the Nailer or when

connecting the air hose,

1) do not pull the trigger;

2) do not depress the push lever; and

3) keep the Nailer pointed downward.

16. KEEP HANDS AND FEET AWAY FROM FIRING

HEAD DURING USE.

Never place your hands or feet closer than 8 inches

(200 mm) from the firing head.

A serious injury can result if the fasteners are

deflected by the workpiece, or are driven away from

the point of entry.

17. PLACE NAILER PROPERLY ON WORKPIECE.

Do not drive fasteners on top of other fasteners or

with the Nailer at too steep of an angle; the fasteners

can ricochet and hurt someone.

18. BE CAREFUL OF DOUBLE FIRE DUE TO RECOIL.

If the push lever is unintentionally allowed to re-contact

the workpiece following recoil, an unwanted fastener

will be driven.

In order to avoid this undesirable double fire,

1) do not push the Nailer on the workpiece with

strong force;

2) take the Nailer completely away from the

workpiece using recoil, and keep the push lever

away from the workpiece until the next desirable

shot; and

3) pull the trigger and release it QUICKLY when

performing intermittent operation (trigger fire).

19. DO NOT DRIVE FASTENERS INTO THIN

BOARDS OR NEAR CORNERS AND EDGES OF

WORKPIECE.

The fasteners can be driven through or away from the

workpiece and hit someone.

20. NEVER DRIVE FASTENERS FROM BOTH SIDES

OF A WALL AT THE SAME TIME.

The fasteners can be driven into and through the wall

and hit a person on the opposite side.

21. CHECK FOR LIVE WIRES.

Avoid the risk of severe electrical shock by checking

for live electrical wires that may be hidden by walls,

floors or ceilings. Turn off the breaker switch to

ensure there are no live wires.

22. NEVER CARRY NAILER BY HOSE.

23. DO NOT OVERREACH.

Keep proper footing and balance at all times.

24. NEVER USE NAILER WHICH IS DEFECTIVE OR

OPERATING ABNORMALLY.

If the Nailer appears to be operating unusually,

making strange noises, or otherwise appears

defective, stop using it immediately and arrange for

repairs by an ET&F authorized service center.

25. DO NOT DISCONNECT AIR HOSE FROM NAILER

WITH FINGER ON TRIGGER.

The Nailer can fire when re-connected to an air supply.

— 5 —

SAFETY — Continued

26. DISCONNECT AIR HOSE FROM NAILER WHEN:

1) doing maintenance and inspection;

2) clearing a jam;

3) it is not in use;

4) leaving work area;

5) moving it to another location; and

6) handing it to another person.

Never attempt to clear a jam or repair the Nailer

unless you have disconnected air hose from the Nailer

and removed all remaining fasteners from the Nailer.

The Nailer should never be left unattended since

people who are not familiar with the Nailer might

handle it and injure themselves.

27. STAY ALERT.

Watch what you are doing. Use common sense.

Do not operate the Nailer when you are tired.

The Nailer should never be used by you if you are

under the influence of alcohol, drugs or medication

that makes you drowsy.

28. HANDLE NAILER CORRECTLY.

Operate the Nailer according to this Manual.

Never allow the Nailer to be operated by children,

individuals unfamiliar with its operation or unauthorized

personnel.

29. NEVER USE NAILER FOR APPLICATIONS OTHER

THAN THOSE SPECIFIED IN THIS MANUAL.

30. HANDLE NAILER CAREFULLY

Because of high air pressure in the Nailer, cracks in

the surface are dangerous.

To avoid this, do not drop the Nailer or strike the

Nailer against hard surfaces; and do not scratch or

engrave signs on the Nailer. Handle the Nailer

carefully.

31. MAINTAIN NAILER WITH CARE.

Keep the Nailer clean and lubricated for better and

safer performance.

32. USE ONLY PARTS, ACCESSORIES OR

FASTENERS SUPPLIED OR RECOMMENDED BY

ET&F.

Unauthorized parts, accessories, or fasteners may

void your warranty and can lead to malfunction and

resulting injuries.

Only service personnel trained by ET&F, distributor or

employer shall repair the Nailer.

Never modify or alter a nailer. Doing so may cause it

to malfunction and personal injuries may result.

SAVE THIS MANUAL AND

KEEP IT AVAILABLE FOR OTHERS!

1. Ensure that this MANUAL is available to operators and

personnel performing maintenance.

2. Ensure that Nailers are used only when operators and

others in work area are wearing EYE PROTECTOR.

3. Enforce the use of EYE PROTECTOR by operators and

others in work area.

4. Keep Nailers in safe working order.

5. Maintain Nailers properly.

6. Ensure that Nailers which require repair are not further

used before repair.

IMPORTANT SAFETY INSTRUCTIONS FOR USING

MODEL 610

WARNING

1. DO NOT REMOVE DUST COVER.

Fragments of wire collating fasteners can fly out.

2. CLOSE NAIL GUIDE AND DO NOT OPEN IT

DURING OPERATION.

If driving fasteners with the nail guide open, the

fasteners can be driven away from the workpiece.

3. DO NOT OPEN MAGAZINE FACING DOWN-

WARD WHILE LOADING FASTENERS.

The fasteners can fall down and result in personal

injury.

EMPLOYER’S RESPONSIBILITIES

— 6 —

OPERATION

NOTE:

The information contained in this Manual is designed to assist you in the safe operation of the

Nailer.

Some illustrations in this Manual may show details or attachments that differ from those on

your own Nailer.

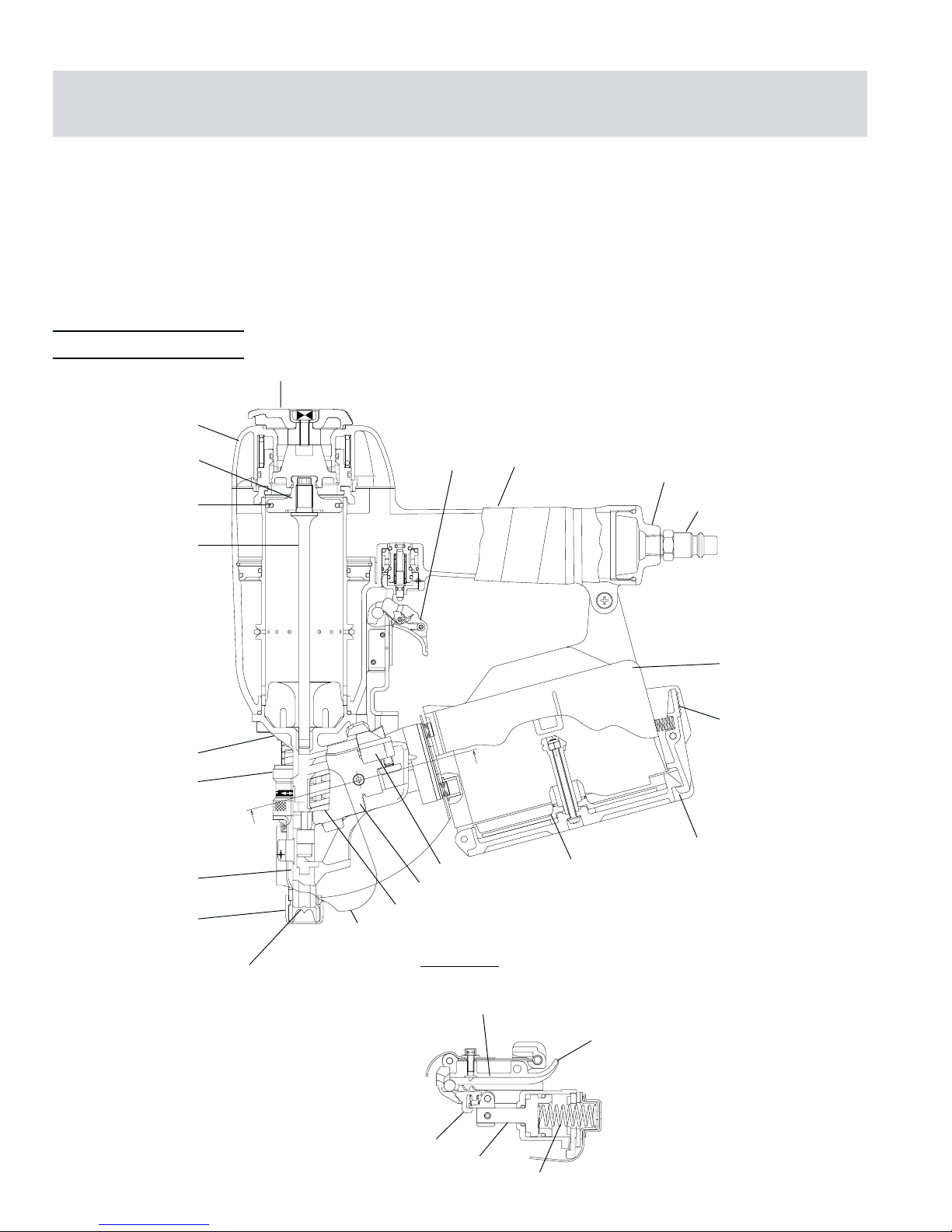

NAME OF PARTS

Feed Spring

Feed Piston

Feeder

Nail Stopper (A)

Nail Guide

Section A-A

Top Cover

Exhaust Cover

Piston

Piston Ring

Driver Blade

Body

Trigger

Cap

Air Plug

Nose

Adjuster

Push Lever

Firing Head (Outlet)

Cover

Feeder

Nail Guide

Knob Nail Holder

Magazine Assembly

Magazine Stopper

Magazine Cover

A

A

Nose Cap

— 7 —

SPECIFICATIONS

Operating pressure 70 – 120 psi (4.9 – 8.3 bar 5 – 8.5 kgf/cm2)

Dimensions 11-1/16" ×11-7/8" ×5-1/8"

Length (without air plug) ×Height ×Width (281 mm ×302 mm ×130 mm)

Weight 5.9 lbs (2.7 kg)

Pin capacity 200 – 300 pins (1 coil)

.052 ft3/cycle at 100 psi

Air consumption (1.5 ltr/cycle at 6.9 bar)

(1.5 ltr/cycle at 7 kgf/cm2)

Air inlet 1/4 NPT Thread

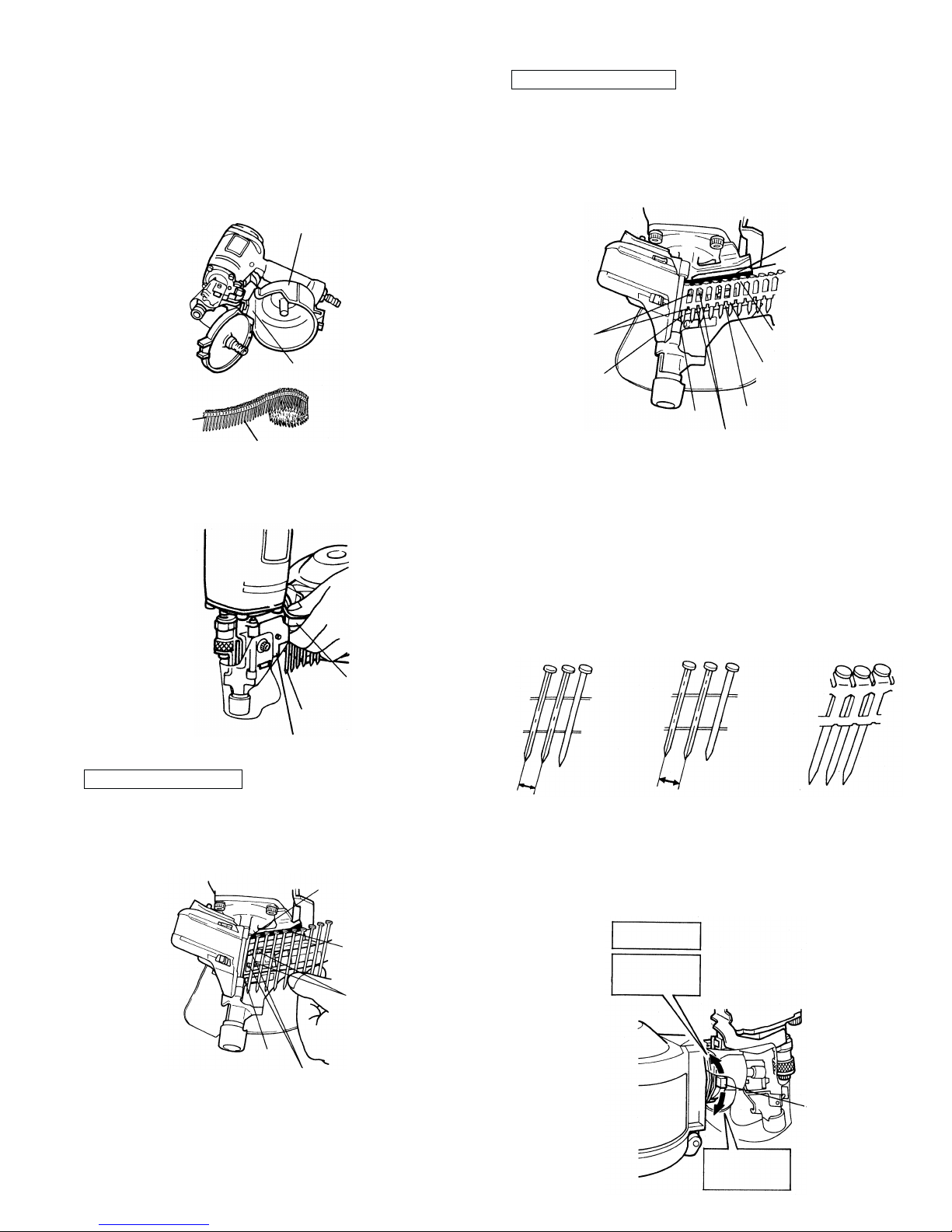

PIN SELECTION

Only pins shown in the Table below can be driven with this Nailer.

NOTE: Use only genuine ET&F pins to assure nail quality and driving ease.

.104"

(2.64 mm)

.240"

(6.1 mm)

1-1/2" (38 mm)

.107"

(2.74 mm)

.252"

(6.4 mm)

2-1/2" (64 mm)

Min. Max.Wire-collated coil pins

.104"

(2.64 mm)

.268"

(6.8 mm)

1-1/4" (32 mm)

.107"

(2.74 mm)

.275"

(7 mm)

2" (50 mm)

Min. Max.

Sheet-collated coil pins

— 8 —

APPLICATIONS

䡬Gypsun wall board to steel studs 12 gauge and lighter

BEFORE OPERATION

Read section titled “SAFETY” (pages 3 – 5).

Make sure of the followings before operation.

WORKING ENVIRONMENT

WARNING

䢇No flammable gas, liquid or other flammable

objects at worksite.

䢇Clear the area of children or unauthorized personnel.

AIR SUPPLY

DANGER

䢇Never use oxygen, combustible gases or any other

bottled gases.

WARNING

䢇Never connect Nailer to pressure which potentially

exceeds 200 psi (13.7 bar 14 kgf/cm2).

䢇Never use non relieving coupler on Nailer.

1. Power source

䡬Use only clean, dry, regulated compressed air as a

power source for this Nailer.

䡬Air compressors used to supply compressed air to this

Nailer must comply with the requirements of the latest

version of ANSI Standard B 19.3 “Safety Standard For

Compressors For Process Industries.”

䡬Moisture or oil in the air compressor may accelerate

wear and corrosion in the Nailer.

Drain daily.

2. Filter-Regulator-Lubricator

䡬Use a regulator with a pressure range of 0 – 120 psi

(0 – 8.3 bar 0 – 8.5 kgf/cm2).

䡬Filter-regulator-lubricator units supply an optimum

condition for the Nailer and extend the Nailer life.

These units should always be used.

Filter ..............The filter removes moisture and dirt

mixed in compressed air.

Drain daily unless fitted with an

automatic drain.

Keep the filter clean by regular

maintenance.

Regulator ......The regulator controls the operating

pressure for safe operation of the Nailer.

Inspect the regulator before operation to

be sure it operates properly.

Lubricator .....The lubricator supplies an oil mist to the

Nailer.

Inspect the lubricator before operation to

be sure the supply of lubricant is adequate.

Use pneumatic tool lubricant.

3. Air hose

Air hose must have a minimum working pressure

rating of 150 psi (10.4 bar 10.6 kgf/cm2) or 150% of the

maximum pressure produced in the system, whichever

is higher.

4. Hose coupling

A female coupler must be on the air hose.

The hose coupling (male plug-female coupler) must

remove all pressure from the Nailer when disconnected.

Never use a non relieving coupler on the Nailer.

5. Air consumption

Using the Air consumption table and the Air

compressor size formula, find a correct compressor size.

ACCESSORIES

WARNING

䢇Accessories other than those shown below can

lead to malfunction and resulting injuries.

STANDARD ACCESSORIES

1Eye protector 1

2Allen wrench for M6 screw 1

3Allen wrench for M5 screw 1

4Allen wrench for M4 screw 1

5Oil feeder 1

6Nose cap 1

24

3

1

Compressor Side

Nailer Side

Filter

Lubricator

Regulator

56

— 9 —

Air consumption table

Air compressor size formula

Amount of air required

=number of Nailers

×average pins driven each minute per Nailer

×air consumption at given air pressure

×safety factor (always 1.2)

Example: 2 Nailers operating at 100 psi driving 30 pins

per minute

Amount of air required

=2 ×30 ×.052 (1.5) ×1.2

=3.7 CFM (ft3/min) (108 ltr/min)

After making the calculations as shown above, you

should find a compressor providing 3.7 CFM of air that

is required.

LUBRICATION

It is important that the Nailer be properly lubricated.

Without proper lubrication, the Nailer will not work

properly and parts will wear prematurely.

䡬Use pneumatic tool lubricant.

Do not use detergent oil or additives. These lubricants

will harm the O-rings and other rubber parts. This will

cause the Nailer to malfunction.

䡬Filter-regulator-lubricator units should always be used.

Keep the lubricator filled with pneumatic tool lubricant.

䡬If a lubricator is not available, supply a few drops

(approximately 2 cc (.12 in3)) of pneumatic tool

lubricant into the air plug on the Nailer twice a day.

COLD WEATHER CARE

䡬Do not store the Nailer in a cold weather environment.

Keep the Nailer in a warm area until beginning the

work.

䡬If the Nailer is already cold, bring it in a warm area and

allow the Nailer to warm up before use.

1Reduce the air pressure to 64 psi (4.4 bar

4.5 kgf/cm2).

2Remove all pins from the Nailer.

3Connect the air hose and free-fire (blank-fire) the

Nailer.

The lowered air pressure will be enough to free-fire

the Nailer.

Slow speed operation tends to warm up the

moving part.

CAUTION

䢇Do not free-fire the Nailer at high pressure.

TESTING THE NAILER

DANGER

䢇Always wear eye protector.

WARNING

䢇Never use Nailer unless push lever is operating

properly.

Before actually beginning work, test the Nailer by using

the check list below. Conduct the tests in the following

order.

If abnormal operation occurs, stop using the Nailer and

contact a ET&F authorized service center immediately.

(1) DISCONNECT AIR HOSE FROM NAILER.

REMOVE ALL PINS FROM NAILER.

䡺ALL SCREWS MUST BE TIGHTENED.

If any screws are loose, tighten them.

䡺THE PUSH LEVER AND TRIGGER MUST MOVE

SMOOTHLY.

psi 80 90 100

Operating pressure (bar) (5.5) (6.2) (6.9)

(kgf/cm2) (5.6) (6.3) (7)

Air consumption ft3/cycle .042 .045 .052

(ltr/cycle) (1.2) (1.3) (1.5)

Trigger

Push Lever

Do not

connect

air hose

— 10 —

Do not pull

Trigger

Depress Push Lever

Pull Trigger

(2) Adjust the air pressure to 70 psi (4.9 bar 5 kgf/cm2).

Connect the air hose.

Do not load any pins in the Nailer.

䡺THE NAILER MUST NOT LEAK AIR.

Hold the Nailer downward and pull the trigger.

䡺THE NAILER MUST NOT OPERATE.

(3) With finger off the trigger, depress the push lever

against the workpiece.

䡺THE NAILER MUST NOT OPERATE.

(4) Without touching the trigger, depress the push lever

against the workpiece.

Pull the trigger.

䡺THE NAILER MUST OPERATE

(5) If no abnormal operation is observed, you may load

pins in the Nailer.

Drive pins into the workpiece that is the same type to

be used in the actual application.

䡺THE NAILER MUST OPERATE PROPERLY.

ADJUSTING AIR PRESSURE

WARNING

䢇Do not exceed 120 psi (8.3 bar 8.5 kgf/cm2).

Adjust the air pressure at recommended operating

pressure 70 – 120 psi (4.9 – 8.3 bar 5 – 8.5 kgf/cm2)

according to the length of pins and the thickness of steel

substrate workpiece.

The correct air pressure is the lowest pressure which will

do the job. Using the Nailer at a higher than required air

pressure unnecessarily over stresses the Nailer.

LOADING PINS

WARNING

䢇When loading pins into Nailer,

1) do not pull trigger;

2) do not depress push lever; and

3) keep Nailer pointed downward.

(1) Press the magazine stopper and open the magazine

cover.

(2) Adjust the position of the nail holder according to the

pin length.

The pin will not feed smoothly if the nail holder is not

correctly adjusted.

1Turn the nail holder about 90 degrees

counterclockwise.

2Move the nail holder up and down to align the top

of the nail holder with a mark on the holder shaft in

accordance with the length of the pins being used.

3Turn the nail holder 90 degrees clockwise until you

hear "click".

Magazine Cover

Magazine Stopper

Nail Holder

Nail Holder Holder Shaft

Holder Shaft

1-1/4" (32 mm)

1-1/2" (38mm)

1-3/4" and 2"

(45,50mm)

Nail Holder

Top of the Nail

Holder

— 11 —

Sheet-collated

pins

8mm pitch

wire-collated

pins

Changeover

lever

6mm pitch

wire-collated

pins

Magazine Opening

First Pin

Magazine

Pin

Knob

Nail Guide

First Pin

First pin

Guide slot 1

Feed pawl 2

Feed pawl 1

Ejection port

NOTE: Before loading pins in the magazine, adjust the

nail holder. If the magazine cover is forcibly closed

without adjusting the nail holder correctly, the nail

holder may be damaged.

(3) Place the pin coil in the magazine.

Insert the first pin into the magazine opening.

(4) Close the magazine cover.

(5) Grip the nail guide and knob with finger.

Press the knob down and swing the nail guide open.

For wire-collated pins

The heads of the row of pins are inserted at guide slot 1

(the upper slot).

The first pin is placed in the ejection port with the second

pin between feed pawl 1and feed pawl 2.

For sheet-collated pins

The heads of the row of pins and the upper extent of the

collating sheet are inserted at guide slot 2(the lower

slot). The lower extent of the collating sheet is inserted at

the sheet guide slot.

The first pin is placed in the ejection port with the second

pin between feed pawl 1and feed pawl 2.

(6) Closing the nail guide

Grip the nail guide and knob with the fingers. While

depressing the knob of the nail guide, rotate the nail

guide to the right until it is completely closed.

(7) Setting the changeover lever

This nailer, as shown in the figure, is able to accommo-

date 6mm pitch wire-collated pins, 8mm pitch wire-

collated pins and sheet-collated pins.

As shown in the diagram, according to the type of pin

used, rotate the changeover lever in the direction of

the arrow until it stops.

If the pitch of the pin to be used is not known, it can be

confirmed by comparing the pins themselves to a

diagram affixed to the reverse side of the magazine.

Guide slot 2

Upper extent of

the collating sheet

Lower extent of

the collating sheet

Sheet guide slot

Feed pawl 2

Ejection port

First pin

Feed pawl 1

6 mm pitch wire-

collated pins

8 mm pitch wire-

collated pins

Sheet-collated

pins

8 mm6 mm

— 12 —

NOTE: Care is advised in the following cases since the

nail guide may not close or pins may not feed

properly:

• Pins and collating sheet are not inserted to the

prescribed position

• Pins rise off of the guide surface

• Collating wire of the pins or the like is deformed

• Changeover lever position is not set according to

the collating system of the pins

(8) Lock the knob completely.

NAILER OPERATION

Read section titled “SAFETY”(pages 3 – 5).

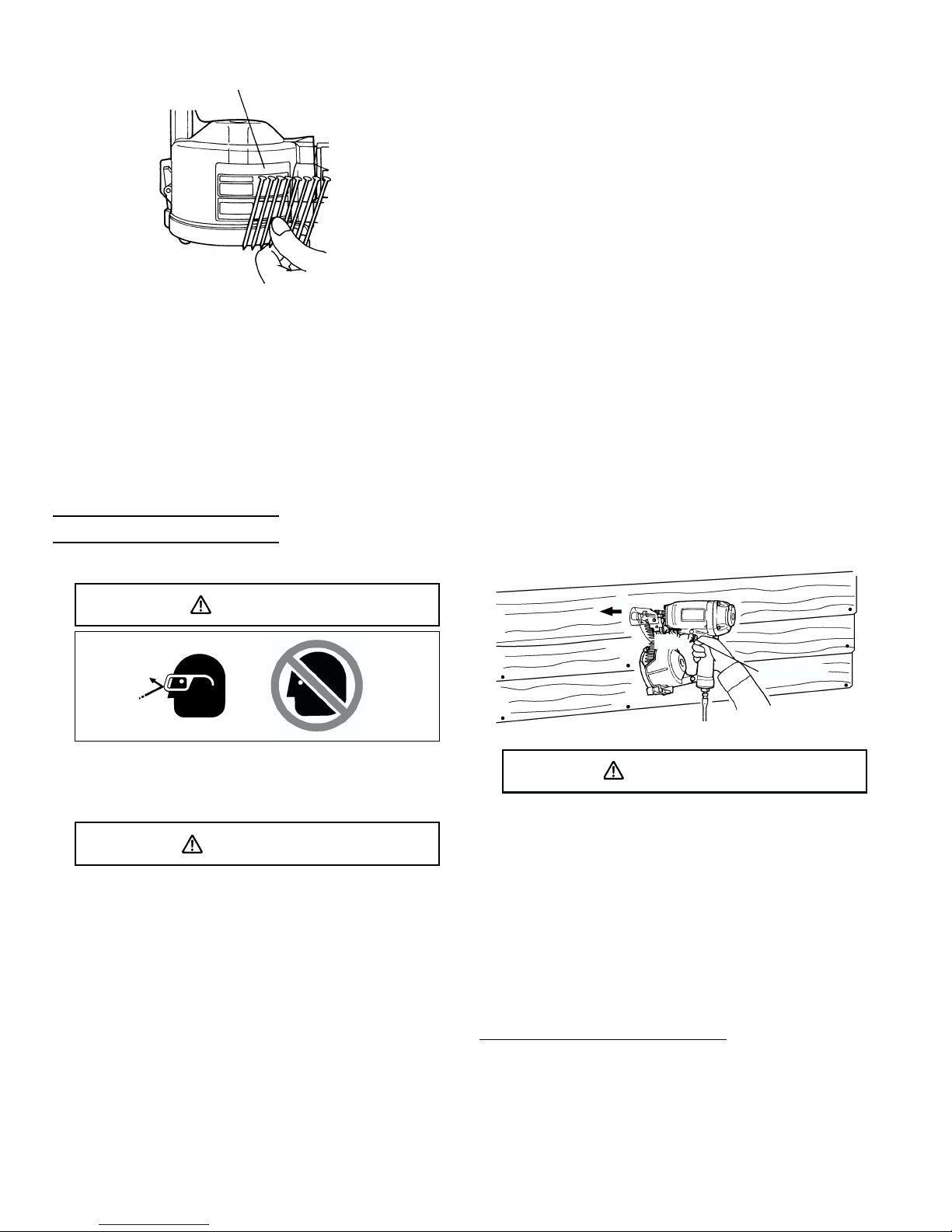

DANGER

䢇Always wear eye protector which conforms to

ANSI Z87.1 specifications.

WARNING

䢇Never point Nailer toward yourself or anyone else.

䢇Never carry with finger on trigger.

Remove finger from trigger when not driving pins.

䢇Never place your hands or feet closer than 8 inches

(200 mm) from firing head when using.

䢇Do not drive pins on top of other pins or with

Nailer at too steep of an angle; pins can ricochet

and hurt someone.

䢇In order to avoid double fire or unwanted ejection

of a nail due to bouncing of the Nailer.

1) do not push Nailer on workpiece with strong

force;

2) take Nailer away from workpiece using recoil;

3) release trigger quickly when performing trigger

fire.

䢇Do not drive pins near corners and edges of

workpiece. Pins can be driven through or away

from workpiece and hit someone.

䢇Never drive pins from both sides of a wall at the

same time. Pins can be driven into and through the

wall and hit a person on the opposite side.

䢇Never use Nailer which is defective or operating

abnormally.

䢇Do not use Nailer as hammer.

䢇Disconnect air hose from Nailer when:

1) it is not in use;

2) leaving work area;

3) moving it to another location; and

4) handing it to another person.

This nailer has a SEQUENTIAL TRIP MECHANISM.

METHOD OF OPERATION

This Nailer is equipped with the push lever and does not

operate unless the push lever is depressed (upward

position).

To drive pins with this nailer:

1Position the outlet on the workpiece with finger off the

trigger.

2Depress the push lever firmly until it is completely

depressed.

3Pull the trigger to drive a pin.

4Remove finger from the trigger.

To drive another pin, move the Nailer along the

workpiece and repeat this procedure.

WARNING

䢇Keep your finger off the trigger except during

fastening operation, because serious injury could

result if the push lever accidentally contacts you or

others in work area.

䢇Keep hands and body away from the discharge

area. The nailer with contact trip mechanism may

bounce from the recoil of driving a fastener and

unwanted subsequent fastener may be driven,

possibly causing injury.

䢇Some types of loaded pins can spark out of the

muzzle during a pin driving operation. Exericise

caution!

THE SEQUENTIAL TRIP MECHANISM (SINGLE SHOT

PARTS) is for use where precision fastener placement is

desired and must be operated in accordance with the

following “Method of Operation”.

You must first depress the push lever (upward posi-

tion) where you want to drive a pin and then pull the

trigger. After the each pin is driven, completely release

the trigger and lift the tool off the work surface. The

SEQUENTIAL TRIP MECHANISM may reduce the

Label showing the pitch of pins

Trigger

2

3

\

— 13 —

possibility of bodily injury to you or others in the work

area. This is because it is less likely to drive an un-

wanted pin if you keep the trigger pulled and acciden-

tally bump the push lever against yourself or others.

NOTE:

䢇Always handle pins and package carefully.

If dropped, the collated pins may break or come loose.

In such cases, do not use the pins because, if used in

that condition, pin feed may become faulty and result

in missed pins or jamming of the pins.

䢇After fastening:

1) disconnect air hose from the Nailer;

2) remove all pins from the Nailer;

3) supply a few drops (approximately 2 cc (.12 in3)) of

pneumatic tool lubricant into the air plug on the

Nailer; and

4) open the petcock on the air compressor tank to

drain any moisture.

ADJUSTING THE FASTENING

DEPTH

To assure that each pin penetrates to the same depth, be

sure that:

1) the air pressure to the Nailer remains constant

(regulator is installed and working properly), and

2) the Nailer is always held firmly against the workpiece.

If pins are driven too deep or shallow into the workpiece,

adjust the nailing in the following order.

1DISCONNECT AIR HOSE FROM NAILER

2If pins are driven too deep, turn the adjuster to the

shallow side.

Adjustments are in half-turn increments.

If pins are driven too shallow, turn the adjuster to the

deep side.

Adjuster

Disconnect

air hose

1 5

Too Deep Turn Adjuster Flush

3Stop turning the adjuster when a suitable position is

reached for a fastening test.

4Connect the air hose.

ALWAYS WEAR EYE PROTECTOR.

Perform a fastening test.

5DISCONNECT AIR HOSE FROM NAILER.

6Choose a suitable position for the adjuster.

CHANGING THE EXHAUST

DIRECTION

The direction of the exhaust vent can be changed by

turning the top cover.

CUTTING OFF THE SHEET

Tear off the output sheet in the direction of the arrow

when using the sheet collated pins.

Too Shallow Turn Adjuster Flush

Exhaust Vent

Top Cover

— 14 —

MAINTENANCE

NOTE:

The information contained in this Manual is designed to assist you in the safe maintenance of

the Nailer.

Some illustrations in this Manual may show details or attachments that differ from those on

your own Nailer.

MAINTENANCE AND INSPECTION

Read section titled “SAFETY” (pages 3 – 5).

WARNING

䢇Disconnect air hose and remove all pins from

Nailer when:

1) doing maintenance and inspection; and

2) clearing a jam.

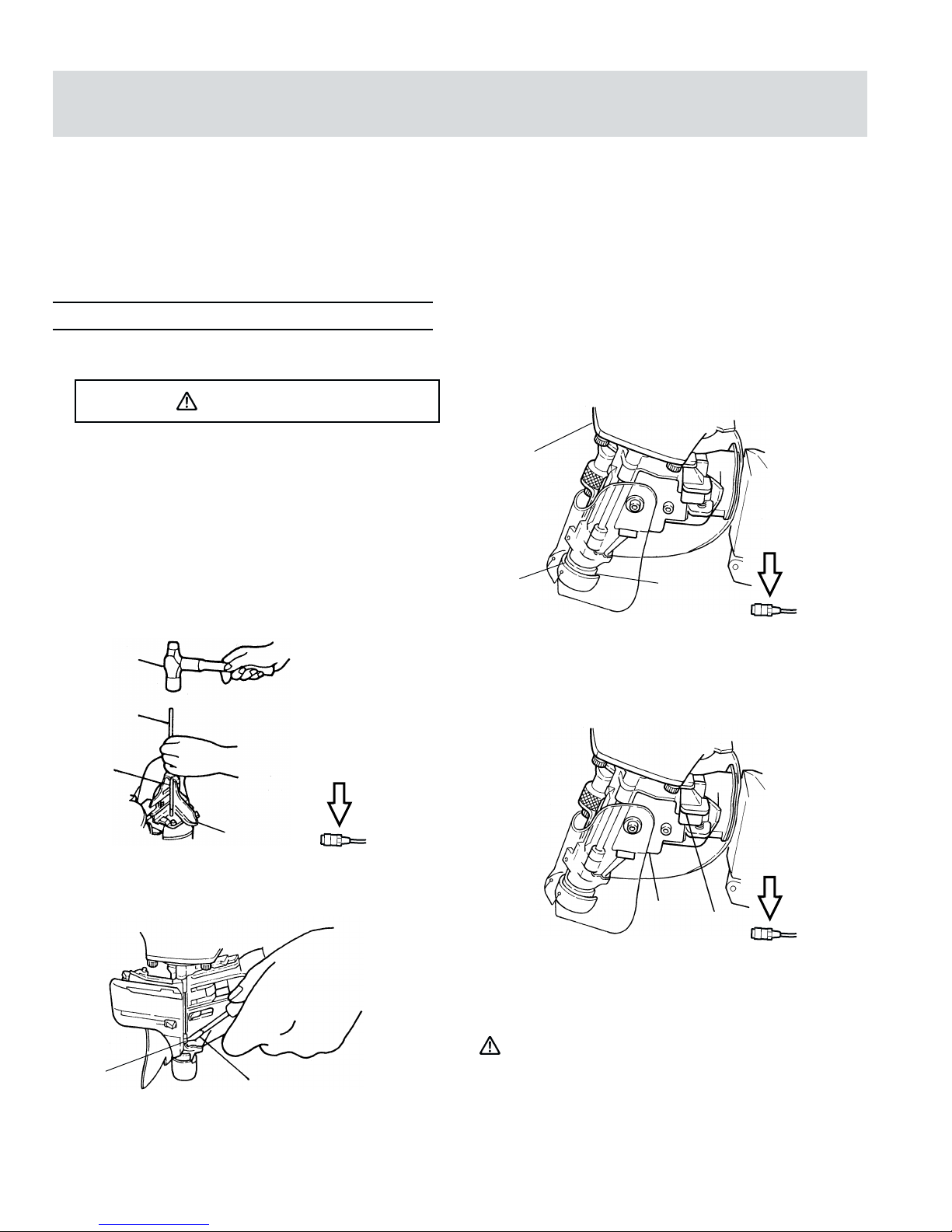

1. Clearing a jam

Remove a jammed pin in the following order :

1DISCONNECT AIR HOSE.

2Open the nail guide.

3Insert a rod into the outlet.

Tap the rod with a hammer.

4Remove the jammed pin with a slotted screw

driver.

5Cut the deformed collated wire with nippers.

Correct the deformation.

6In case of frequent jam, contact an authorized

service center.

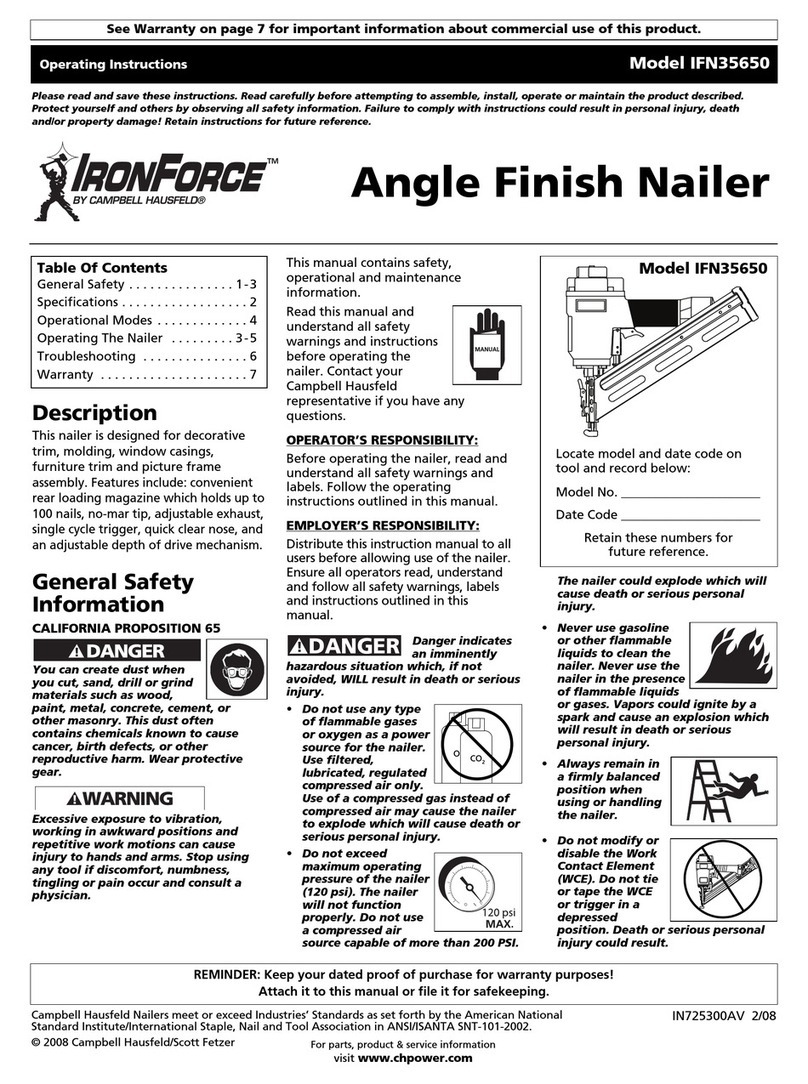

2. Inspecting the push lever

1DISCONNECT AIR HOSE.

2Clean the push lever sliding part.

Lubricate it with pneumatic tool lubricant.

3. Inspecting the feeders

1DISCONNECT AIR HOSE.

2Clean the knob sliding part.

Lubricate it with pneumatic tool lubricant.

3Open the nail guide and remove dust.

Lubricate the sliding groove of the feeder and

shafts.

CAUTION

䢇Check that nail stopper (A) and nail stopper (B) slide

smoothly by pushing them with finger.

If not smooth, pins can be driven at an irregular angle

and hurt someone.

Hammer

Rod

Outlet

Nail Guide

Disconnect

air hose

1

Slotted Screw Driver

Pin

Nose

Push

Lever Lubricate

Disconnect

air hose

1

Knob

Nail

Guide

Disconnect

air hose

1

— 15 —

4Lubricate the feeding surfaces of the nose and the

nail guide after cleaning.

This promotes smooth operation and prevents rust.

4. Inspecting the magazine

1DISCONNECT AIR HOSE.

2Clean the magazine. Remove dust or wooden tips

which may have accumulated in the magazine.

5. Storing

䡬When not in use for an extended period, apply a thin

coat of the lubricant to the steel parts to avoid rust.

䡬Do not store the Nailer in a cold weather environment.

Keep the Nailer in a warm area.

䡬When not in use, the Nailer should be stored in a warm

and dry place.

Keep out of reach children.

6. WARNING LABEL

Change the WARNING LABEL if missing or damaged.

A new WARNING LABEL is available from an

authorized service center.

7. Maintenance chart (See page 16)

8. Operator troubleshooting (See page 16)

SERVICE AND REPAIRS

WARNING

䢇Only service personnel trained by ET&F, distributor

or employer shall repair the Nailer.

䢇Use only parts supplied or recommended by ET&F

for repair.

All quality Nailers will eventually require servicing or

replacement of parts because of wear from normal use.

NOTE:

Specifications are subject to change without any

obligation on the part of ET&F.

Nail guide

Nail Stopper (B)

Nose Feeder

Shaft

Nail Stopper (A)

Warning

Label

— 16 —

Maintenance chart

ACTION WHY HOW

Drain air line filter daily. Prevent accumulation of moisture Open manual petcock.

and dirt.

Keep lubricator filled. Keep the Nailer lubricated. Fill with pneumatic tool lubricant.

Clean filter element — then blow Prevent clogging of filter with dirt. Follow manufacturer’s instructions.

air through filter in direction

opposite to normal flow.

Clean magazine and feeder Prevent a jam. Blow clean daily.

mechanism.

Keep push lever working properly. Promote operator safety and Blow clean daily.

efficient Nailer operation.

Lubricate the Nailer after nailing. Extend the Nailer life. Supply 2 – 3 drops of lubricant

into the Nailer.

Drain air compressor. Keep the Nailer operated properly. Open petcock on air compressor tank.

PROBLEM

Nailer operates, but no pin is driven.

Operator troubleshooting

Most minor problems can be resolved quickly and easily using the table below.

If problems persist, contact an authorized service center for assistance.

CHECK METHOD CORRECTION

Check for a jam. Clear a jam per page 14.

Check function of feeder per Clean and lubricate.

page 14.

Check for proper pins. Use only recommended pins.

Check air pressure. Increase air pressure. (Do not

exceed 120 psi (8.3 bar 8.5 kgf/cm2))

——— Use pneumatic tool lubricant.

Driver blade worn? Contact ET&F for replacement.

Piston ring worn or damaged?

Check air pressure. Reduce air pressure.

(Adjust 70 – 120 psi)

Check for proper pins. Use only recommended pins.

Check function of nail feeder per Clean and lubricate.

page 14.

——— Use pneumatic tool lubricant.

Check position of nail holder in Adjust nail holder to proper position.

magazine per page 10.

Piston ring cut or heavily worn? Contact ET&F for replacement.

Check for proper pins. Use only recommended pins.

Driver blade worn? Contact ET&F for replacement.

Check inside diameter of air hose. Use larger air hose.

Weak drive.

Slow to cycle.

Drives too deep.

Skipping pins. Intermittent feed.

Drives properly during normal

operation, but does not drive fully

at faster fastening speeds.

Pins jam.

Driven pin is bent.

— 17 —

— 18 —

— 19 —

1 610-949755 Hex. Socket Hd. Bolt M6×16 1

2 610-880515 Plate 1

3 610-880514 Top Cover 1

4 610-878854 Hex. Socker.Hd. Bolt (W/Flange) M6×25 4

5 610-882158 Exhaust Cover 1

6 610-878919 Gasket (B) 1

7 610-878912 Spring 1

8 610-878913 O-Ring (I.D 38.5) 1

9 610-878911 Head Valve 1

10 610-878372 O-Ring (I.D 52.6) 3

11 610-878918 Head Valve Rubber 1

12 610-878915 Exhaust Valve Rubber 1

13 610-880513 Retaining Ring 1

14 610-874104 Cylinder O-Ring (I.D 68.3) 1

15 610-880512 Cylinder Plate 1

16 610-878961 O-Ring 1

17 610-880735 Cylinder 1

18 610-878931 Piston Ring 1

19 610-880127 O-Ring 1

20 610-880730 Piston (H) 1

21 610-955479 Retaining Ring (E-Type) For D6 Shaft 1

22 610-881006 Body Ass’y 1

23 610-878933 Piston Bumper 1

24 610-874436 O-Ring (P-4) 1

25 610-880121 Washer 1

26 610-880731 Nose 1

27 610-993068 Nylock High Tension Bolt M7×20 4

28 610-949685 Roll Pin D3×20 1

29 610-878339 Needle Roller 1

30 610-949770 Roll Pin D4×14 1

31 610-878132 Feeder Arm 1

32 610-878340 Feeder Spring 1

33 610-880140 Feeder 1

34 610-876676 Safety Spring 1

35 610-880733 Pushing Lever (B) 1

36 610-880497 Nail Guide Shaft 1

37 610-881974 Adjuster (A) 1

38 610-982454 Spring (C) 2

39 610-959155 Steel Ball D3.97 2

40 610-880130 Pushing Lever (A) 1

41 610-880081 Washer 1

42 610-949657 Hex. Socket Hd. M6×12 1

43 610-881768 Grip Tape (A) 1

44 610-880407 Tape 2

45 610-880183 O-Ring (I.D 37.2) 1

46 610-883590 Cap 1

47 591 Air Plug NPT1/4 1

48 610-880734 Machine Screw (W/Washers) M5×25 1

49 610-949864 Roll Pin D3×22 1

50 610-949865 Roll Pin D3×28 2

51 610-881779 Trigger (A) 1

52 610-881771 Trigger Pin 1

53 610-880361 Pushing Lever Guide 1

54 610-877699 Head Valve O-Ring (I.D 16.8) 1

55 610-878881 Valve Bushing (B) 1

56 610-878885 O-Ring (S-18) 1

57 610-981317 O-Ring (S-4) 1

58 610-880672 Valve Piston (B) 1

59 610-878925 O-Ring (I.D 8.8) 2

60 610-878887 O-Ring (I.D 11) 1

61 610-878884 Plunger Spring 1

62 610-881778 Plunger (B) 1

63 610-878888 O-Ring (I.D 1.8) 1

64 610-880671 Valve Bushing (A) 1

65 ————— Label (C) 1

66 610-872645 O-Ring (P-9) 1

67 610-880128 Feed Piston 1

68 610-876796 O-Ring (P-22) 1

69 610-877144 Feed Spring 1

70 610-880129 Shift Lever 1

71 610-877827 Feed Piston Cover (A) 1

72 610-877713 Feed Piston Cover 1

73 610-949819 Hex. Socket Hd. Bolt M5×10 2

74 610-877479 Magazine Bushing 1

75 610-877360 Magazine Bushing 1

76 610-877371 Nylon Nut M5 1

77 610-880133 Magazine 1

78 610-872971 Retaining Ring (E-Type) For D3 Shaft 2

79 610-877149 Stopper Spring 1

80 610-880146 Magazine Stopper 1

81 610-877150 Stopper Pin 1

82 ————— Label (A) 1

83 610-876465 Nylon Nut M4 1

84 610-880666 Holder Shaft 1

85 610-880398 Ratchet Spring 1

86 610-880665 Nail Holder 1

87 610-880704 Magazine Cover 1

88 610-877152 Hinge Pin 1

89 610-949423 Washer M4 1

90 610-949230 Machine Screw M4×50 1

91 610-880703 Magazine Ass’y 1

92 610-877826 Feeder Shaft Ring 1

93 610-880495 Guide Lock 1

94 610-880446 Spring 1

95 610-880732 Nail Guide 1

96 610-949496 Roll Pin D3×16 1

97 610-880493 Nail Stopper (A) 1

98 610-880494 Stopper Spring 2

99 610-880124 Nail Stopper (B) 1

100 610-880125 Nail Guide Cover 1

101 610-880126 Cover 1

102 610-878614 Nylock Hex. Socket Hd. Bolt M4×81

103 610-878337 Sleeve (B) 1

104 610-880413 Nylock Hex. Socket Hd. Bolt M4×10 1

501 610-880132 Nose Cap (A) 1

502 610-877153 Pneumatic Tool Lubricant 30CC 1

503 610-875769 Eye Protector 1

504 610-944459 Hex. Bar Wrench 5MM 1

505 610-944458 Hex. Bar Wrench 4MM 1

506 610-943277 Hex. Bar Wrench 3MM 1

Code No. Part Name Q’ty

Item

No.

Code No. Part Name Q’ty

Item

No.

111

Code No. C99107062 N

Printed in Japan

29019 Solon Road

Solon, ohio 44139

Table of contents

Popular Nail Gun manuals by other brands

norbar

norbar PneuTorque PTS-52-500 Operator's manual

Campbell Hausfeld

Campbell Hausfeld IronForce IFN35650 operating instructions

Novus

Novus J-102 DA Translation of the original operating instructions

Arrow

Arrow ET200 manual

Paslode

Paslode CF325XP operating manual

Senco

Senco FinishPro 42XP operating instructions