1020 FMD

2

Table of Contents

Introduction......................................................................................................................................3

In the box......................................................................................................................................3

Needed for use .............................................................................................................................3

1Overview ...................................................................................................................................4

2Connections ..............................................................................................................................5

2.1 Power supply .....................................................................................................................5

2.2 Load cell.............................................................................................................................6

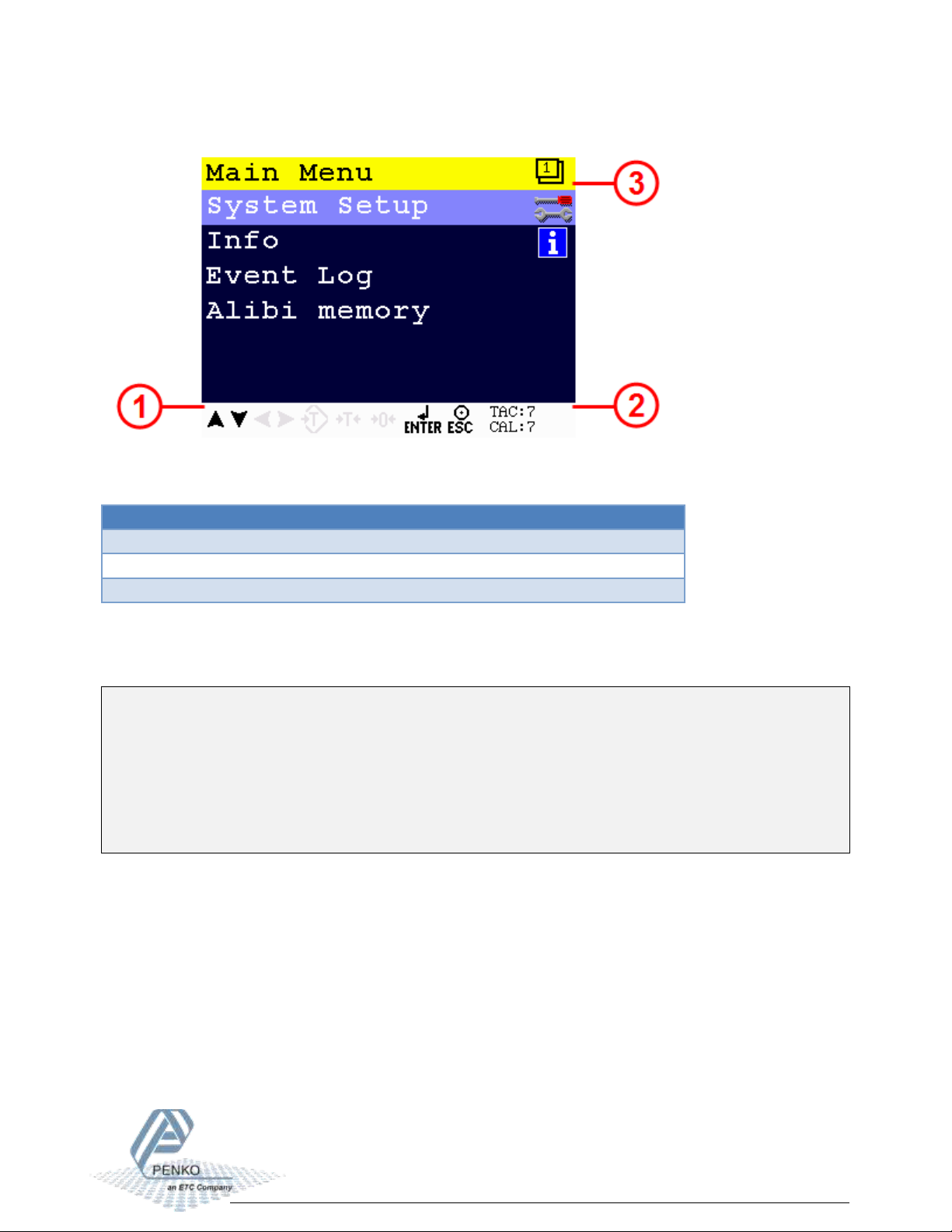

3Display and keypad ...................................................................................................................7

4First use...................................................................................................................................11

5Standard factory settings........................................................................................................20

6Menu structure .......................................................................................................................21