EtherCAT EZ-ZONE RMZ4 User manual

WATLOW®EZ-ZONE®RMZ4 - 1- ETHERCAT® ADAPTER

EZ-ZONE®RMZ4 EtherCAT®

User’s Guide

Adapter

0600-0103-0000 Revision A.7

1241 Bundy Boulevard, Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507, http://www.watlow.com

WATLOW®EZ-ZONE®RMZ4 - 2- ETHERCAT® ADAPTER

1TABLE OF CONTENTS

1 Table of Contents ..................................................................................................................................2

2 Table of Figures .....................................................................................................................................4

3 Overview ...............................................................................................................................................5

4 Mounting and Dimensions ....................................................................................................................6

5 Connections and Wiring........................................................................................................................7

5.1 RMZ4 with up to 48 Control Loops ...........................................................................................7

5.2 RMZ4 with Optical Sensor Card.................................................................................................8

5.3 RMZ4 with Serial Communications Card and Bluetooth...........................................................9

5.4 RM System Connections..........................................................................................................11

5.5 Slot C Power Connection.........................................................................................................12

5.6 Earth Ground...........................................................................................................................13

5.7 EZ-ZONE ST and EZ-ZONE PM Wiring ......................................................................................14

5.8 EtherCAT® Wiring....................................................................................................................15

5.9 USB Wiring...............................................................................................................................15

5.10 Modbus® Wiring......................................................................................................................15

6 Theory of Operation............................................................................................................................17

7 Setting up the System .........................................................................................................................20

7.1 Steps to Implement.................................................................................................................20

7.2 EtherCAT® Master and ESI file ................................................................................................20

7.3 Master instructions .................................................................................................................20

7.4 Explicit Device Identification ...................................................................................................20

7.5 Mapping Loop to CoE Object Indexes .....................................................................................21

7.6 Configuring the RMZ4 .............................................................................................................22

7.7 Identifying the RMZ4 Itself......................................................................................................22

7.8 Setting Addresses on Connected Devices ...............................................................................22

7.9 Identifying Connected Devices................................................................................................22

7.10 Adding Slots.............................................................................................................................25

7.11 Mapping I/O to Loops (Slots) ..................................................................................................26

8 Using Controller Features ...................................................................................................................27

8.1 Sensor and Control Loop.........................................................................................................27

8.2 Optical Sensing........................................................................................................................32

8.3 Open Loop Detect ...................................................................................................................33

8.4 Digital Heat Control Outputs...................................................................................................34

8.5 Over-Temperature Limits........................................................................................................35

8.6 Current Sensing .......................................................................................................................37

8.7 Cooling Digital Outputs ...........................................................................................................38

8.8 Analog Heat Outputs...............................................................................................................39

8.9 Analog retransmit Outputs .....................................................................................................41

8.10 Alarm Outputs .........................................................................................................................42

8.11 Analog Cooling Outputs ..........................................................................................................44

8.12 Direct Digital Input ..................................................................................................................45

8.13 Direct Digital Output ...............................................................................................................46

8.14 Direct Analog Input .................................................................................................................47

WATLOW®EZ-ZONE®RMZ4 - 3- ETHERCAT® ADAPTER

8.15 Direct Analog Output ................................................................. Error! Bookmark not defined.

8.16 Alarm Groups ..........................................................................................................................49

9 Setting Parameters and Running ........................................................................................................54

9.1 Using PDOs ..............................................................................................................................54

9.2 Running ...................................................................................................................................54

9.3 Tuning......................................................................................................................................54

10 EtherCAT® Protocol.............................................................................................................................55

10.1 Device Objects.........................................................................................................................55

10.2 Commands ..............................................................................................................................56

10.3 Default RxPDO.........................................................................................................................58

10.4 Default TxPDO .........................................................................................................................58

10.5 User RxPDO .............................................................................................................................58

10.6 User TxPDO..............................................................................................................................58

11 Control Operation ...............................................................................................................................66

11.1 Network State and Control States...........................................................................................66

11.2 Data Retention ........................................................................................................................66

11.3 Control Loops ..........................................................................................................................66

11.4 Alarms .....................................................................................................................................66

12 Additional Connectivity.......................................................................................................................67

12.1 Bluetooth®...............................................................................................................................67

12.2 Modbus® Slave ........................................................................................................................67

12.3 Modbus® Master.....................................................................................................................67

13 Flash Loading.......................................................................................................................................67

13.1 Over EtherCAT®.......................................................................................................................67

13.2 Over USB .................................................................................................................................67

14 Supporting Documents and Files ........................................................................................................68

15 Troubleshooting Guide........................................................................................................................69

16 RMZ4 Specifications ............................................................................................................................70

17 Optical Adder Card Specifications.......................................................................................................71

18 Serial Communications Adder Card Specifications .............................................................................72

19 Part Numbering...................................................................................................................................73

WATLOW®EZ-ZONE®RMZ4 - 4- ETHERCAT® ADAPTER

2TABLE OF FIGURES

Figure 1 - Dimensions.............................................................................................................................................. 6

Figure 2 –Connections points for RMZ4-__AA-AAAA............................................................................................. 7

Figure 3 –Connections points for RMZ4-xx04-AAAA with Optical Temperature Sensing...................................... 8

Figure 4 –Connection points for RMZ4-xxAA-11AA with serial comms card and Bluetooth................................. 9

Figure 5 - Ground Wire Location........................................................................................................................... 13

Figure 6 - Ground Wire Insertion .......................................................................................................................... 13

Figure 7 –Modbus® Master and Slave RJ-12 Connector Pinout........................................................................... 16

Figure 8 –Connections and Topology................................................................................................................... 18

Figure 9 –RM Control Loop Topology................................................................................................................... 19

Figure 10 –Complete Network Interaction Diagram............................................................................................ 19

Figure 11 –Modular Loop Layout ......................................................................................................................... 21

Figure 12 - Alarm Group Example ......................................................................................................................... 53

Symbol

Explanation

Symbol

Explanation

ESD Sensitive product, use proper

grounding and handling techniques

when installing or servicing product.

Unit protected by double/reinforced

insulation for shock hazard prevention.

Functional earth ground connection

may be present.

Do not throw in trash, use proper

recycling techniques or consult

manufacturer for proper disposal.

Enclosure made of Polycarbonate

material. Use proper recycling tech-

niques or consult manufacturer for

proper disposal.

Unit can be powered with either

alternating current (ac) or direct

current (dc).

Unit is a Listed device per Underwriters

Laboratories®. It has been evaluated to

United States and Canadian require-

ments for Process Control Equipment.

UL/EN 61010-1 and CSA C22.2 No.

61010. File E195611 QUYX, QUYX7.

See www.ul.com

Unit is a Listed device per

Underwriters Laboratories®. It has

been evaluated to United States and

Canadian requirements for Hazardous

Locations Class 1 Division II, Groups A,

B, C and D. ANSI/ASI 12.12.01-2012.

File E184390 QUZW, QUXW7. See

www.ul.com

Unit is compliant with applicable

European Union Directives. See

Declaration of Conformity for further

details on Directives and Standards

used for compliance.

WATLOW®EZ-ZONE®RMZ4 - 5- ETHERCAT® ADAPTER

3OVERVIEW

The Watlow EtherCAT® Adapter allows integration of the EZ-ZONE RM systems into larger EtherCAT®

controlled processes. EtherCAT® is an industrial control network that uses standard 100 Base-T Ethernet wiring

to provide very fast access to controllers and their data points. The Watlow EtherCAT® Adapter conforms to

the EtherCAT® Temperature Controller Specific Device Profile ETG 5003-2060. It has been conformance tested

by an ETG test facility.

EtherCAT® provides access to system parameters using a CAN open interface scheme. The ETG 5003-2060

specification describes the data point organization. The data is accessed via SDO (Service Data Objects) during

startup and configuration and via PDO (Process Data Objects) exchange during operation. SDO access is

transactional in nature, the master asking for or setting a value in the slave device. The device supports

reading and writing an entire index in one transaction. The feature is called SDO complete. PDO data is a

continuous stream of data from the master and back from the devices at high speed.

USB and Bluetooth® interfaces are provided for configuration and system monitoring from a PC or tablet

devices. Bluetooth® is an option so it can be excluded for production equipment where wireless security is

important.

The Watlow EtherCAT® Adapter can also host a legacy communications adder card. This card provides

additional connection points for Modbus®, DeviceNet™and Watlow Standard Bus. These cards are intended

to extend the network beyond RM modules to include displays like Watlow Silver Series and EZ-ZONE EZK and

legacy controllers such as the EHG® SL-10. The Watlow EZ-ZONE ST and EZ-ZONE PM may be integrated from

the “C” connector without requiring a Legacy Communications card.

The Watlow RMZ4 EtherCAT® Adapter operates within a larger RM system. The RMZ4 part number defines the

number of loops supported. The largest system supported is 48 loops. The RMZ4 module does not support ad-

hoc RM modules and function block programming. Function blocks in the RMS and RME I/O modules may be

programmed using EZ-ZONE Configurator software via the USB port.

The RMZ4 supports 4 optical temperature sensors for high RF or voltage environments like plasma, power

distribution transformers, or medical imaging.

Features

ETG Conformance Tested by ETG

ETG.5003.2060 compliant EtherCAT®

Up to 48 control loops with EZ-ZONE RM, ST, or PM controllers

One process and one deviation alarm per loop

USB device serial port emulation supporting EZ-ZONE Configurator and Composer

Bluetooth® serial port emulation serving system information via XML (Optional)

Modbus® Slave RS-485 port to host an HMI touch screen (Optional)

Modbus® Master RS-485 port to monitor up to 16 EHG line heaters (Future Option)

Extra Standard Bus RS-485 port for EZK remote display or PC tools connection (optional)

Optional 4 RF-immune fiber optic sensor.

WATLOW®EZ-ZONE®RMZ4 - 6- ETHERCAT® ADAPTER

4MOUNTING AND DIMENSIONS

FIGURE 1 - DIMENSIONS

Recommended chassis mounting hardware:

1. #8 screw ¾” Long

2. Torque to 10-15 in-lb

3. No washers

WATLOW®EZ-ZONE®RMZ4 - 7- ETHERCAT® ADAPTER

5CONNECTIONS AND WIRING

5.1 RMZ4 WITH UP TO 48 CONTROL LOOPS

FIGURE 2 –CONNECTIONS POINTS FOR RMZ4-__AA-AAAA

RM Module Bus Backplane

Explicit Device ID Switches

EtherCAT® IN

EtherCAT® OUT

USB Configuration Port for PC

EtherCAT® status LEDs

Slot C - Power and Standard Bus

WATLOW®EZ-ZONE®RMZ4 - 8- ETHERCAT® ADAPTER

5.2 RMZ4 WITH OPTICAL SENSOR CARD

FIGURE 3 –CONNECTIONS POINTS FOR RMZ4-XX04-AAAA WITH OPTICAL TEMPERATURE SENSING

The RMZ has an option for using fluorescent decay via fiber optic cable for sensing temperature in high RF

environments. The number of channels of optical sensing is defined in the model number xxxx-xx04-xxxx.

The fluorescent probes are available from Watlow. The range is generally -100 to +200C without special probe

construction. Each probe is connected via a bayonet style ST connectors. To use this input in a control loop

define the bus as Optical (option 4) and select instance 1, 2, 3, or 4.

RM Module Bus Backplane

Explicit Device ID Switches

EtherCAT® IN

EtherCAT® OUT

USB Configuration Port for PC

EtherCAT® status LEDs

Slot C - Power and Standard Bus

WATLOW®EZ-ZONE®RMZ4 - 9- ETHERCAT® ADAPTER

5.3 RMZ4 WITH SERIAL COMMUNICATIONS CARD AND BLUETOOTH

FIGURE 4 –CONNECTION POINTS FOR RMZ4-XXAA-11AA WITH SERIAL COMMS CARD AND BLUETOOTH

RM Module Bus Backplane

Explicit Device ID Switches

EtherCAT® IN

EtherCAT® OUT

USB Configuration Port for PC

EtherCAT® status LEDs

Slot C - Power and Standard Bus

Connection to Modbus slave devices

Connection to HMI Modbus Master

Extra Standard Bus Connection

Bluetooth Connection to Tablet/Phone/ PC

WATLOW®EZ-ZONE®RMZ4 - 10 - ETHERCAT® ADAPTER

5.5 RMZ4 WITH DEVICE NET AND HMI MODBUS

DeviceNet M12

Extra Standard Bus Connection

Explicit Device ID Switches

EtherCAT® IN

EtherCAT® OUT

USB Configuration Port for PC

EtherCAT® status LEDs

Slot C - Power and Standard Bus

Connection to HMI Modbus Master

DeviceNet Address Switches

Bluetooth Connection to Tablet/Phone/ PC

DeviceNet Speed Switch

Extra Standard Bus Connection

WATLOW®EZ-ZONE®RMZ4 - 11 - ETHERCAT® ADAPTER

5.6 RM SYSTEM CONNECTIONS

The RM system controlled by an RMZ4 module can be installed as stand-alone modules or can be

interconnected on the DIN rail as shown below. When modules are connected together as shown, power and

communications are shared between modules over the modular backplane interconnection. Therefore,

bringing the necessary power and communications wiring to any one connector in slot C is sufficient. The

modular backplane interconnect comes standard with every module ordered and is generic in nature, meaning

any of the RM modules can use it.

The modules can also be mounted in different locations and the backplane connected via wires in a Split Rail

configuration as shown in the figure. Notice in the split rail system diagram that a single power supply is used

across both DIN rails. One notable consideration when designing the hardware layout would be the available

power supplied and the loading effect of all of the modules used.

Watlow provides three options for power supplies listed below:

1. 90-264VAC to 24VDC @ 31 watts (Part #: 0847- 0299-0000)

2. 90-264VAC to 24VDC @ 60 watts (Part #: 0847- 0300-0000)

3. 90-264VAC to 24VDC @ 91 watts (Part #: 0847- 0301-0000)

With regards to the modular loading affect, maximum power for each is listed below:

1. RMCxxxxxxxxxxxx @ 7 watts / 14VA

2. RMEx-xxxx-xxxx @ 7 watts / 14VA

3. RMAx-xxxx-xxxx @ 4 watts / 9VA

4. RMLx-xxxx-xxxx @ 7 watts / 14VA

5. RMHx-xxxx-xxxx @ 7 watts / 14VA

6. RMSx-xxxx-xxxx @ 7 watts / 14VA

So in the worst case EtherCAT® integrated system, 48 loops, the maximum current draw on the supply would

be 39 watts.

- 1 RMZ4 consumes 4 watts

- 3 RMS modules consumes 21 watts

- 2 RME modules consumes 14 watts

WATLOW®EZ-ZONE®RMZ4 - 12 - ETHERCAT® ADAPTER

5.7 SLOT CPOWER CONNECTION

Power and Communications

Slot C

Terminal Function

Configuration

98

99

Power Input: AC or DC+

Power Input: AC or DC-

Only needed on one module, shared on backplane

CF

CD

CE

Standard Bus EIA-485 Common

Standard Bus EIA-485 T-/R- (A)

Standard Bus EIA-485 T+/T+ (B)

EIA-485 connection for EZ-ZONE Configurator

CZ

CX

CY

Inter-module Bus

Inter-module Bus

Inter-module Bus

Wire for Split-Rail Configurations

WATLOW®EZ-ZONE®RMZ4 - 13 - ETHERCAT® ADAPTER

5.8 EARTH GROUND

The RJ-45 connector bodies are grounded to earth using the wire traps found on the bottom of the case. To

ground the connector, insert a ground wire into either of the traps as viewed from the case bottom. The

ETG.5003 Semi Standard recommends grounding the jacket. Each jacket is connected to the terminal trap via a

50ohm resistor. This earth ground is not connected to the power.

FIGURE 5 - GROUND WIRE LOCATION

FIGURE 6 - GROUND WIRE INSERTION

Use 18 –26 AWG Solid or Stranded, Trim Length 3.5 ± 0.5mm (0.138 ± .02”).Twist wire to remove.

WATLOW®EZ-ZONE®RMZ4 - 14 - ETHERCAT® ADAPTER

5.9 EZ-ZONE ST AND EZ-ZONE PM WIRING

Connect EZ-ZONE STs or PMs via the CF (Com), CD(A-), and CE(B+) terminals on the Slot “C” connector. This is

the RS-485 Standard Bus connection. The RMZ4 will recognize these devices automatically. View and confirm

discovered devices using the 0xF500 objects.

5.10 DEVICE WIRING

WATLOW®EZ-ZONE®RMZ4 - 15 - ETHERCAT® ADAPTER

5.11 ETHERCAT® WIRING ON RJ-45

EtherCAT® uses standard CAT5 or CAT6 Ethernet cable. The network is wired device to device in series.

Connect a cable from the EtherCAT® master or an upstream device to the IN RJ-45 port. If there are additional

EtherCAT® devices on the network connect the OUT jack to those. If there are none, leave the jack empty.

5.12 DEVICENET WIRING ON M12

5.13 USB WIRING

Connect a USB mini cable from a PC to configure RM features that are outside the EtherCAT® specification.

These could be function blocks such as Logic or Compare blocks. Use the EZ-ZONE Configurator software to

connect via the USB port. All the RM devices in the system should appear when the network is scanned. Use

the Watlow_USB.inf driver located on watlow.com to create a USB serial port on your PC.

5.14 MODBUS®RTU RS-485 WIRING RJ-12 MASTER OR SLAVE

If the RMZ4 has the optional Legacy Communications card, it can be connected to simple Modbus®

temperature controllers and act as a master using the Modbus M port. It can also be connected to graphical

HMIs such as Watlow Silver Series to display system information using the Modbus S port. These are both RS-

485 connections on RJ-12 phone jacks.

The Modbus register table is defined in a supporting spreadsheet RmzParameterMap.xlsx available on

watlow.com.

EtherCAT®

Master

WATLOW®EZ-ZONE®RMZ4 - 16 - ETHERCAT® ADAPTER

FIGURE 7 –MODBUS® MASTER AND SLAVE RJ-12 CONNECTOR PINOUT

WATLOW®EZ-ZONE®RMZ4 - 17 - ETHERCAT® ADAPTER

6THEORY OF OPERATION

EtherCAT® is a protocol that runs on standard Ethernet hardware –CAT5 cable, RJ45 jacks and standard

physical layer transceivers. The Ethernet Media Access Controller (MAC) is a slight variation of a standard MAC

implemented with an ASIC. It allows data to be read and modified on-the-fly as the bits pass through the MAC.

This implies EtherCAT® is a ring topology with each device being part of a single chain. Data frames are not

received and responses formulated. It is more like a train of bytes that does not slow down at the station, data

jumps on and off as the ‘train’ passes though. This allows cycle times around the network in the microsecond

range, even with thousands of data points. This is the PDO (Process Data Object –real-time data) mechanism.

Responsiveness is very important in a large system to keep scan times short. This means products should not

introduce latencies in the system’s data cycle. Therefore the data of interest to the larger system must be

maintained close to the EtherCAT® access port. It is not acceptable to have long latencies while data is

retrieved via the backplane. To assure the required speed, the EZ-ZONE architecture has been modified slightly

to maintain critical data objects in the EtherCAT® module itself rather than each RM module.

EtherCAT® models data as CoE objects. CoE is CANOpen over EtherCAT®. This is the object model developed

for the CAN Open protocol and reused as the EtherCAT data model. It uses objects defined by indexes (0x0000

to 0xFFFF) each containing up to 255 sub-indexes or data elements of simple or complex data type.

EtherCAT® transports data using PDO and SDO methods. PDO is Process Data Object. It is the regular data

shared to and from the master to all the slave devices. The network PDO scan times are very fast, 0.5 to 4ms

typically. The data in the PDO is a selected set of Object:SubIndex parameters. Typical PDO parameters are

process temperature, set point, output power, and errors. PDO data is only exchanged when the system is in

the operational mode (OP mode). As a default, the RMZ4 controller only controls temperature in the

operational mode. The Safe State parameter configures this behavior.

SDO is Service Data Object. This is an asynchronous, on-demand mailbox service that provides access to all the

CoE objects in the device. The SDO method is used to configure the device or tweak settings. Setting PID,

Proportional Integral Derivative control loop parameters or starting an auto-tune would be typical uses for an

exchange. SDO exchanges can occur during normal operation but are secondary to PDO traffic. SDO exchanges

can occur in all modes except boot mode.

The EtherCAT® module holds all the data that is part of the Semi TWG (Technical Working Group) Standard for

all the loops being controlled locally in the EtherCAT® module. The control loops are hosted by the EtherCAT®

module. The EtherCAT® module works in conjunction with RM modules to act as sensor inputs and heater

outputs only. The PV (Process Value Temperature) is produced by an RM and consumed by the EtherCAT®

module via data sharing. The loop power is produced by the EtherCAT® module and consumed by an RM

output via data sharing. The values accessed by the EtherCAT® module are the values held internally. This

includes PV, SP (Set Point), PID values, control mode, percent power, etc.

In legacy product configurations (ST,PM,SL-10) the pertinent data is held locally within the EtherCAT® adapter

for instant access but the control loops still execute in the individual devices due to the lower bandwidth

buses. There means parameter changes made over EtherCAT® can take up to 200ms to be written to the

remote legacy device since they need to be sent by proxy on the legacy communications bus. Input values are

continuously scanned by the RMZ4 and the latest value is available for PDO access.

WATLOW®EZ-ZONE®RMZ4 - 18 - ETHERCAT® ADAPTER

Some configuration data such as sensor type, cycle time, input and output scaling are considered configuration

data by EtherCAT®. It is not part of the EtherCAT®’s fast I/O cycle. These values are written out to each of the

RM modules on power-up or value change to ensure the I/O configuration matches the SDO values. Local

copies in the EtherCAT® module are maintained for immediate access even though a proxy write is required on

change. The configuration values changed will take effect within 200ms.

The RMZ4 models individual control loops as modules or slots as described by the EtherCAT® Modular Device

Profile. Each control loop is mapped to a module or slot. This is a logical association. The EtherCAT® loop

module does not map one to one with physical RM modules. The configuration section describes how to map

the I/O in each RM physical module with the appropriate control loop. Any of the RM family with IO may be

used in conjunction with the RMZ. This includes RMC, RMH, RMS, RML, and RME.

Details and specifications for EtherCAT® are available at: http://www.ethercat.org/

FIGURE 8 –CONNECTIONS AND TOPOLOGY

WATLOW®EZ-ZONE®RMZ4 - 19 - ETHERCAT® ADAPTER

FIGURE 9 –RM CONTROL LOOP TOPOLOGY

FIGURE 10 –COMPLETE NETWORK INTERACTION DIAGRAM

WATLOW®EZ-ZONE®RMZ4 - 20 - ETHERCAT® ADAPTER

7SETTING UP THE SYSTEM

7.1 STEPS TO IMPLEMENT WITH ETHERCAT

1. Mount controllers

2. Wire power, sensors and outputs to heaters

3. Wire CAT5/6 cable to EtherCAT® jacks

4. Set explicit Device ID if needed

5. Verify RM module addresses are set correctly

6. Install Master Software

7. Import the ESI for the RMZ, Watlow_RMZ.xml into the master software.

8. Connect to RMZ4 from Master

9. Configure module/slots for loops needed

10. Setup I/O mapping in 0x4nn0 objects

11. Configure device with 0x4nn1 and 0x8nn0 objects

12. Configure any user specific PDO data beyond the default set

13. Change mode to operational.

14. Program Set Point and Control State in output PDO

15. Monitor system with input PDO

7.2 ETHERCAT® MASTER AND ESI FILE

EtherCAT® systems have a master that configures the network and the devices then manages data interactions

with the devices during operation. Beckhoff®’s TwinCAT® or EtherCAT® Configurator are common master

software programs that run on a standard 32 bit Windows® PC. The Master needs an ESI file to describe the

device and its capabilities. This file is in XML format and provided by Watlow for the RMZ. The ESI file contains

the object dictionary for the RMZ. There is one ESI file regardless of the version of RMZ that contains the

parameter details for all product versions. The master will select the correct version from the ESI based on the

version information reported from the RMZ. If a new version produce is added to the system make sure to

have the master reload the correct definition from the latest ESI file.

7.3 MASTER INSTRUCTIONS

Under I/O Device right click and Scan for Device

Scan for Boxes answer Yes

Start Free Run - Yes

You should see Box 1 (Watlow RM)

We need to add a Module for each control loop by right clicking Append Module

Add the correct number of control loops

Reload Configuration to the RMs under Action

7.4 EXPLICIT DEVICE IDENTIFICATION

Use the two rotary address switches to set the devices Explicit Device ID. The 0x10 switch sets the upper nibble

and 0x01 sets the lower nibble of the unique ID value. This is available over EtherCAT® in register 0x134. This

allows absolute, unique identification of each device in the system.

Table of contents

Popular Adapter manuals by other brands

Schwaiger

Schwaiger PowerLine PLC502M user manual

SeaLevel

SeaLevel COMM+4.cPCI user manual

Simrad

Simrad S-band HSC SRT Installation Guide Addendum

Actron

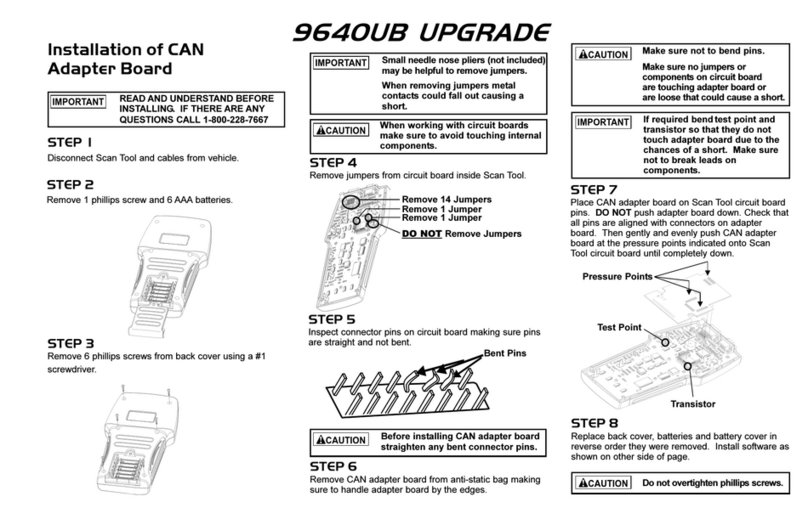

Actron 9640UB Upgrade Upgrade instructions

ZyXEL Communications

ZyXEL Communications ZyXEL ZyAIR B-220 Quick installation guide

Thule

Thule XT 3177 instructions