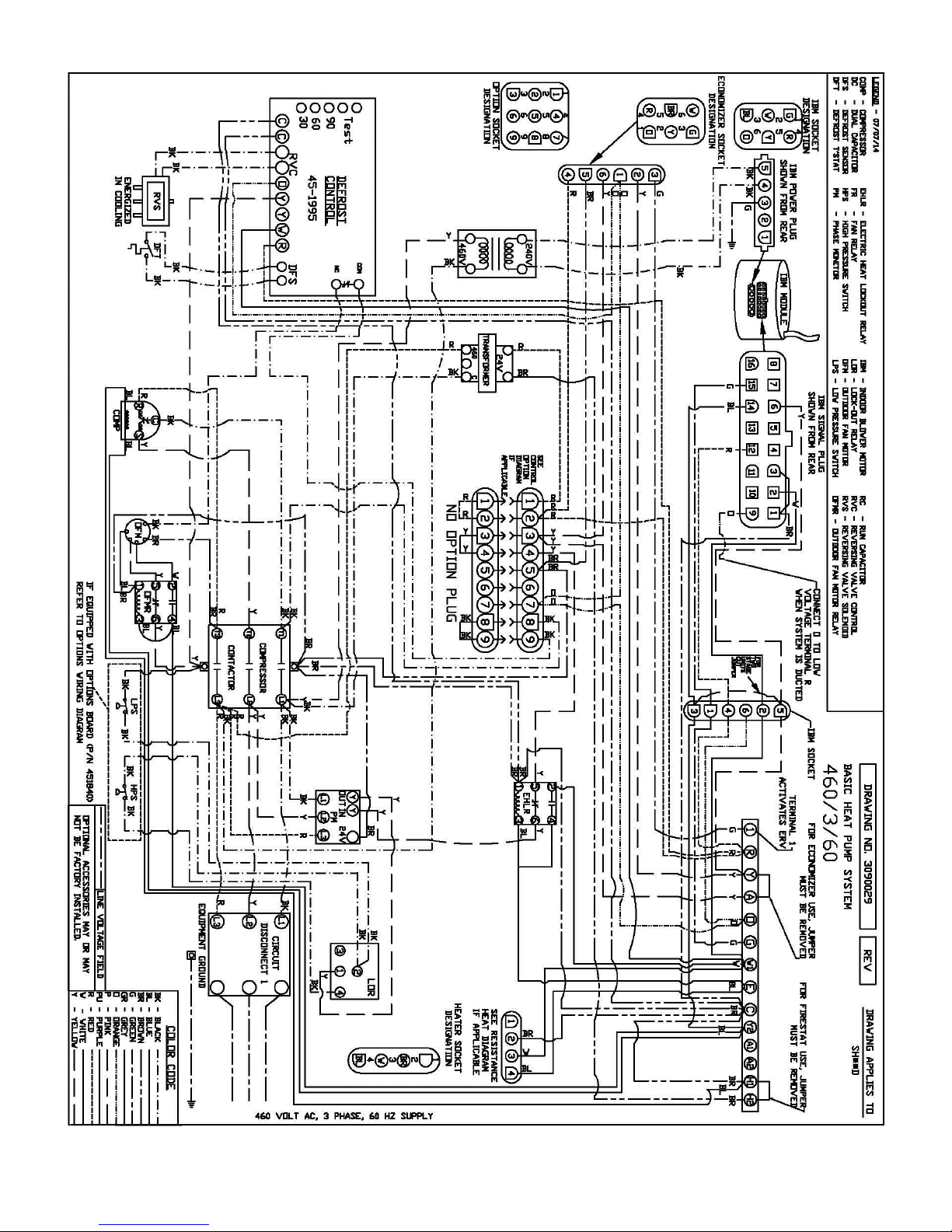

REV. 7/7/14 3 3090032.

TO CLEAN FRESH AIR INTAKE FILTER:

A. Follow steps A and B at left

“TO CHANGE SYSTEM FILTER”.

B. Gently pull out the filter from the bottom.

C. Wash the filter with water.

D. Reinstall the filter, by sliding it into the

retaining rail.

E. Replace the access door and turn the

power on to the unit.

2. Keep the outdoor coil clean. Wash it down

with a garden hose if necessary.

BE SURE THE UNIT DISCONNECT IS IN THE “OFF”

POSITION AND THAT ALL ELECTRICAL POWER TO THE

UNIT IS TURNED OFF BEFORE CLEANING THE SYSTEM.

Remove any loose grass, leaves, papers, etc., from the area

around the condenser coil. These could reduce the air

supply through the coil and reduce the amount of cooling

capacity.

3. Since the heat pump is located outdoors, it is exposed to all

weather elements. Treat it with a good automobile paste wax

twice a year (in the spring and fall).

Check with your contractor if you have any questions regarding

the maintenance or operation of your unit.

INSTALLATION

A. CODES

The installer SHALL comply with all local, state, and federal

codes and/or regulations pertaining to this type of equipment

and its installation. Such codes and/or regulations should take

precedence over any recommendations contained herein.

Installations SHALL be made in accordance with the National

Electrical Code, local codes, and recommendations made by

the National Board of Fire Underwriters.

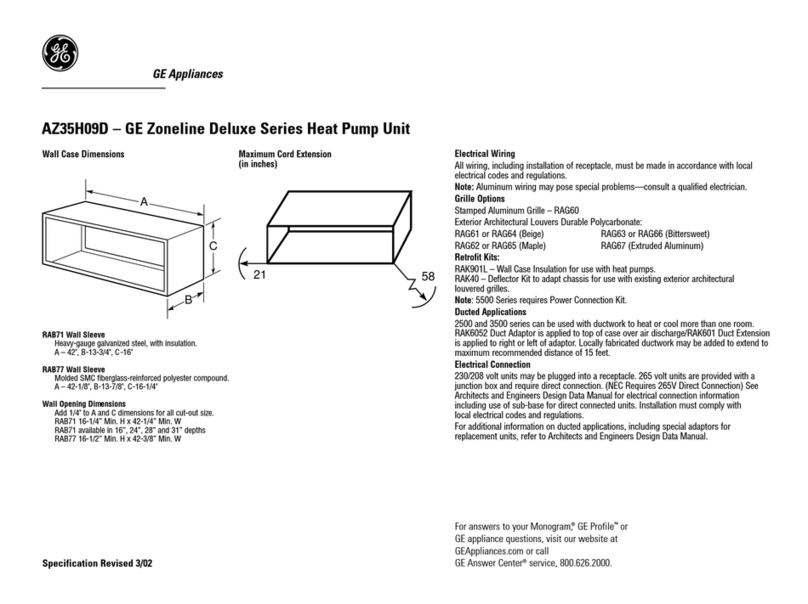

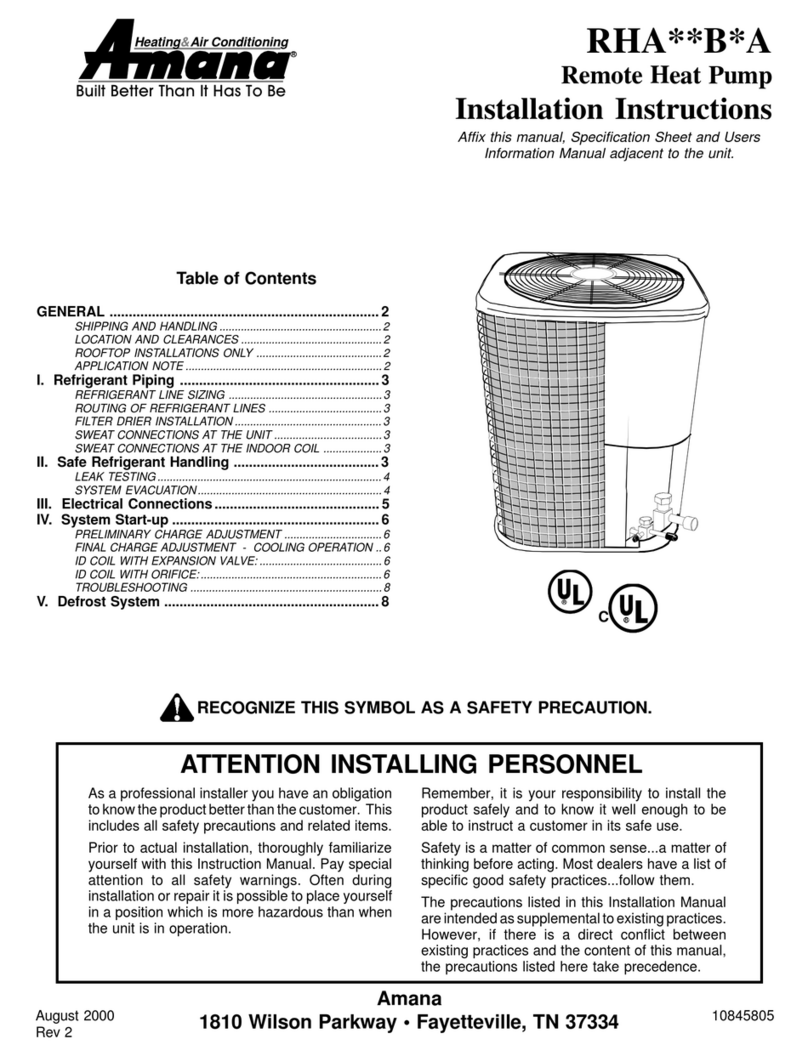

B. UNIT SITE SELECTION

1. To eliminate noise from being transmitted into noise

sensitive areas, the unit should NOT be installed on walls

adjoining bedrooms, sleeping quarters, or adjacent to

windows. To further reduce interior space noise levels,

the unit should be installed in a reinforced location.

2. Locating the unit as close as possible to the main duct

system or area to be conditioned, will prevent lengthy

duct runs and unnecessary thermal and air-pressure

losses.

3. The clearance to combustibles is 0" on all sides, and 1/4"

for the first three (3) feet of supply duct.

4. The condenser air inlets (left, right and bottom inlets)

SHALL be located at least 8" away from walls or other

obstructions for unrestricted airflow.

5. The condenser air outlet should be located at least 6’

away from any obstructions to prevent recirculation of

condenser air.

6. Bottom of the unit SHALL be located at least 12" away

from the ground or other obstructions for unrestricted

airflow.

7. Service clearance is 28" from the electrical box access

panel located on the front of the unit and 28" from the

center, upper, and lower front access panels.

8. The wall selected for unit installation MUST be able to or

be made to safely support the weight of the unit.

9. Do NOT locate where heat, lint or exhaust fumes will be

discharged on the unit (as from dryer vents).

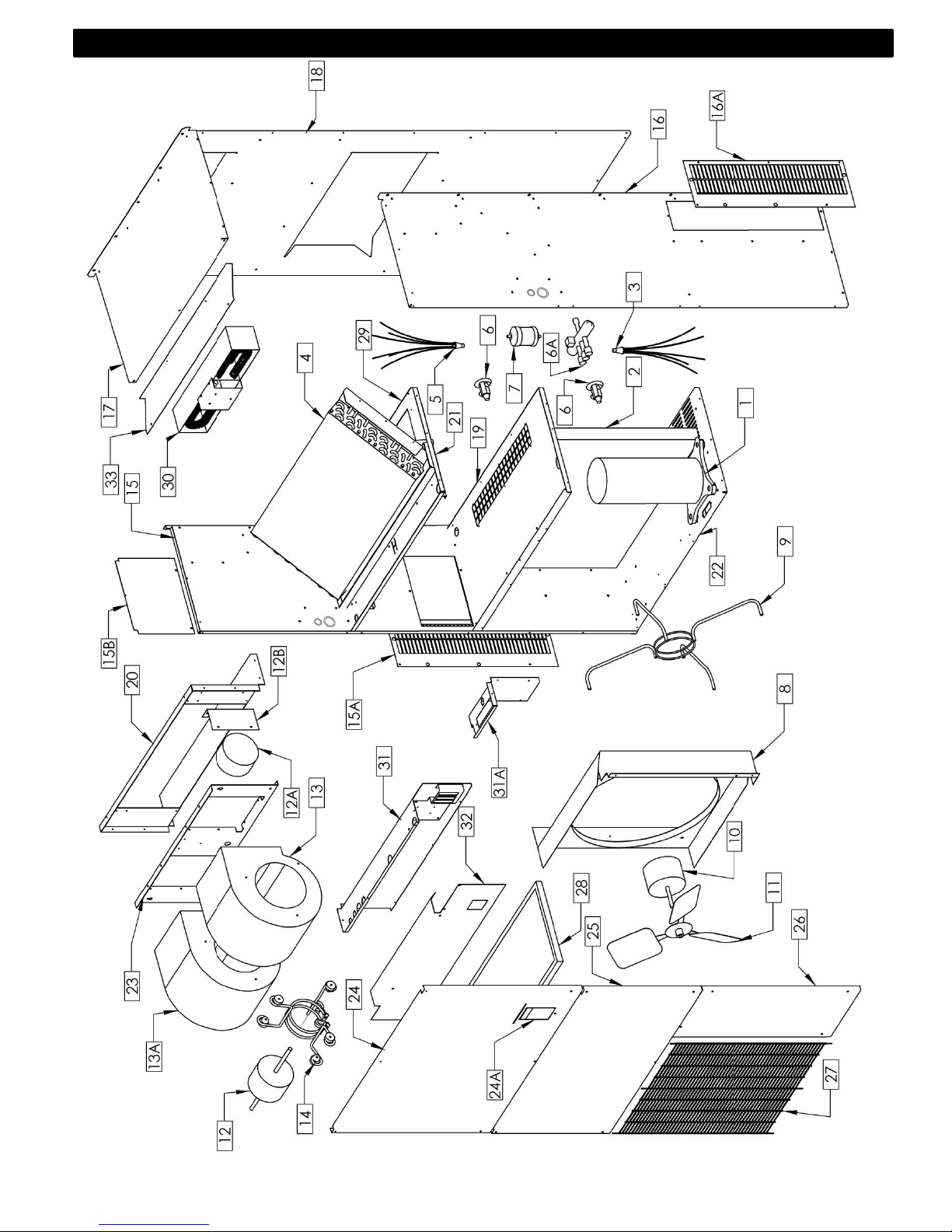

C. UNIT PREPARATION

1. The S Series model units have a separate top rain

flashing accompanying the unit. The bottom-mounting

flange for all models is shipped separately and in place.

(Refer to “Section J. Unit Installation” for the

recommended use of the bottom flange.)

2. Electrical entrances are located on the right side and left

side of all S Series units. Refer to “Section H. Electrical

Hook-up” for details.

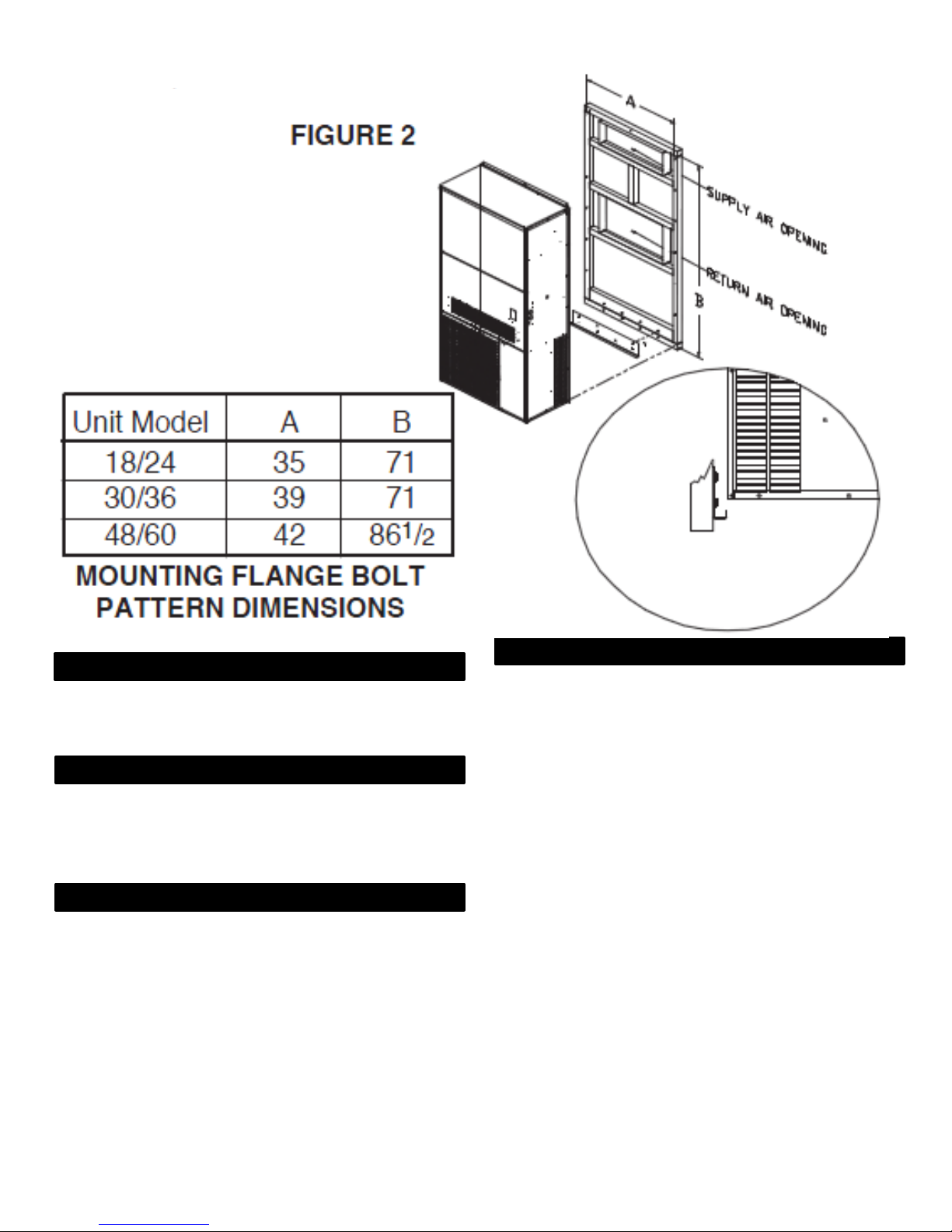

3. Firmly attach return and supply air collars to the wall and

install foam air gaskets.

4. The supply and return air ducts should be checked to be

sure they:

a. Match the openings on the unit to be installed.

b. Have the same distance between them vertically as

the openings on the unit to be installed.

5. Return and supply grilles must be used when the return

and supply are not ducted.

6. If the factory-installed filter is used on your installation,

access to the filter is made through the center panel on

the front of the unit.

IF A REMOTE FILTER IS USED, SUCH AS A FILTER

GRILLE, THE FACTORY-INSTALLED FILTER MUST BE

REMOVED AND DISCARDED.

D. DUCTWORK

1. Properly-sized duct systems are critical for satisfactory

operation of any air conditioning system. All ductwork

MUST be correctly sized for the design air flow

requirement of the equipment.

2. For increased static pressure operation, connect the

orange and red wires on the Indoor Blower Motor (IBM)

Signal Cable.

3. The recommended operation duct static is to deduct

0.07" W.C. for any size of heater 5 kW to 20 kW on

factory or field-installed heaters.

4. Ductwork routed through wall cavities, as well as any

duct not in conditioned space, MUST be insulated.

Supply ducting routed through exterior walls MUST be

insulated with 1" insulation to the back of the unit.

5. Supply and return air ducts should be flush with the

exterior wall and sized to fit over the unit duct collars in

order to compress the collar air gasket.

6. If supply duct is flashed to the exterior of a building

constructed with combustible material, the flashing

MUST be insulated in order to maintain the required

clearances to combustible materials. Required

clearance is 1/4" for the first three (3) feet of supply

duct.

E. FILTERS

1. Filter grilles with one-inch disposable filters are supplied

standard in each unit. A filter grille with two-inch disposable

filters can also be used and are available as an option.

2. If a filter grille (other than the one accompanying the unit) is

used in the installation, the filter should be properly sized to

allow a maximum velocity of 400 FPM.

WHEN A FILTER GRILLE IS USED, THE FACTORY-

INSTALLED FILTER MUST BE REMOVED.