• 7 •

Application Guide /NEOSYS-AGU-1801-E

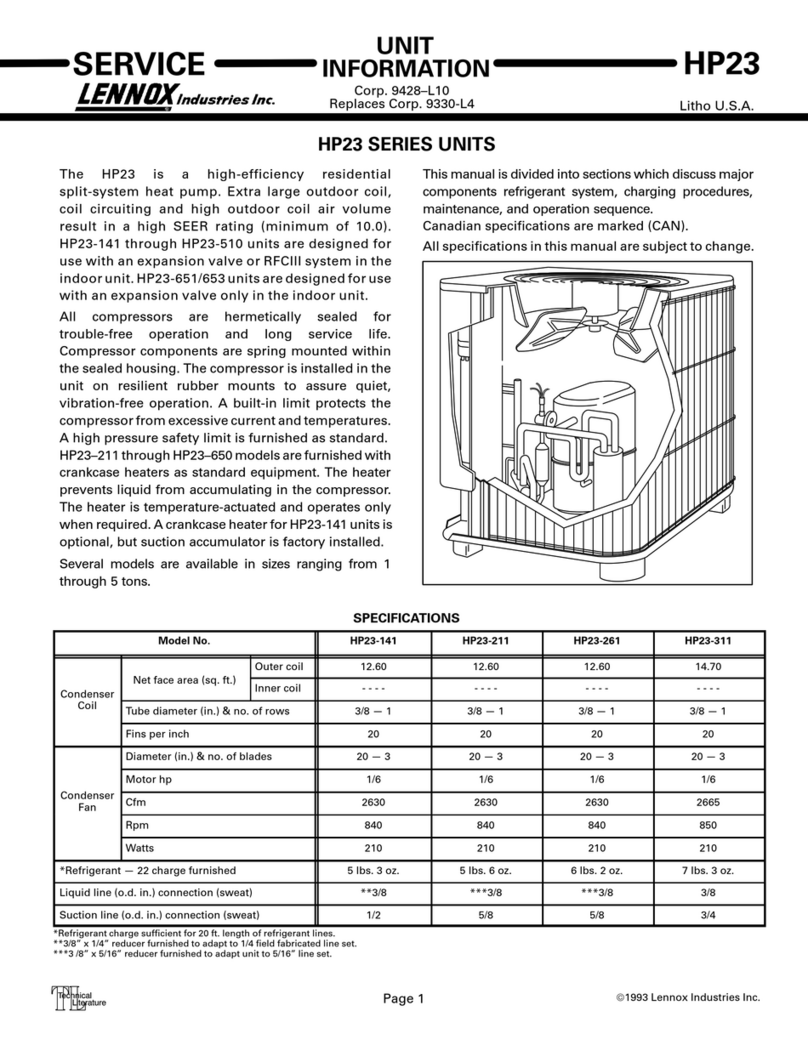

ELECTRICAL BOX

- Unit electrical cabinet, components and wiring in compliance with

EN 60204-1 electrical directive.

- 400V, 50 Hz, 3 phase power supply (without neutral) with a single

point of power connection (except sizes 680 to 1080).

- Bottom entry (through the base) for electrical power.

- IP54 protection class.

- Air spring powered Butterfly electrical panel with top opening

providing protection to the service engineers against rain or snow

during commissioning and maintenance operations.

- Recognized brand electrical components (Schneider) for ease of

maintenance.

- Main on/off switch mounted on the front panel.

- DC60 advanced user interface mounted on the front panel.

- Main disconnect switch with high trip capacity allowing optimized

sizing of the customer power supply.

- 400/24 V transformer to supply the control circuit.

- Numbered electrical wires to facilitate maintenance and diagnostic.

- Variable Frequency Drives (VFD) to control the fan speed.

CONTROL

CLIMATIC microprocessor based control is providing the following

functions:

- 4 scheduling time zones per day over 7 days to allow energy

consumption and sound level management according to the

building use and environmental constraints.

- PI control of the water temperature with operating time equalisation

of the compressors.

- Water set-point offset based on outdoor air temperature.

- Active variable speed control of all fans to optimize the unit

condensing pressure and energy performances at full- and part-

load while meeting authorized maximum noise level in the time

zone (Active Acoustic Attenuation System™ control patented).

- Intelligent advanced control algorithm to protect the compressors

against excessive short-cycling and to allow operationoftheunit

without buffer tank in most comfort air conditioning applications

(e.g. unit with fan-coils). Refer to minimum installation water loop

volume recommendations.

- Dynamic defrost to limit the number and the duration of the

defrost cycles in winter for high performance of the unit (Dynamic

Defrost patented).

- Automatic compressor unloading in case of excessive condensing

pressure allowing the operation of the machine at high outdoor

air temperature (operation extended up to 46°C ambient).

- Water pump control with operating time equalization and automatic

change-over in case of a pump fault (Twin pump only).

- Master/slave or cascade control of two chillers operating in parallel

with operating time equalization and automatic change-over in

case of a unit fault.

CLIMATIC is pre-factory configured with default settings allowing

a fast commissioning on site. The DC60 advanced user interface

with graphical display is easy to use, intuitive. Main customer

parameters can be read or modified without main power shut-off

(Entering/leaving water temperatures, outdoor air temperature, alarm

history, scheduling of the different time zone, water and noise level

set-points, high and low pressure reading).

The DS60 service display (optional) is a “plug and play" controller

that allows service people to read and modify all unit parameters

(Unit settings, operating time and number of compressor starts,

low and high pressure reading, read the history of last 32 faults...).

COMMUNICATION

The control board is equipped with a RS485 serial communication

port to allow remote management through communication bus.

According to the wished communication protocol, our control board

can be fitted with ModBUS®, BacNET®(RS485 or TCP/IP) or

LonWorks® communication interface (options).

The main control board has free dry contacts that allow remote

control of the unit by wired cable:

- Remote on/off of the unit.

- Remote alarm reset to re-start the unit.

- Alarm or alert indications.

- Free customer contact.

With the optional extension board BE60, it is possible to get

additional customized digital or analog inputs / outputs for remote

control of the unit:

- Fault fans or pumps (dry contact).

- Operation indication at 100% on circuit 1 or 2 (dry contact).

- Dual water set-point management (dry contact).

- Force heating or cooling mode (24V AC input).

- Power limitation by disabling circuit 1 or 2 (24V AC input).

- Force unoccupied mode (24V AC input).

- Water set-point offset based on a 4-20mA signal. Note: non

available with heat-pump units.

DIRECTIVES

The unit is built to meet European norms and standards & Eurovent

certification performance standards.

• DI 97/23/CE Pressure Equipment Directive.

• DI 98/37/CE Machinery Directive.

• DI 73/23/CE Low Voltage Directive.

• DI 89/336/CE Electro Magnetic Compatibility Directive

• EN 378-2 Safety and Environmental Directive.

• The European Restriction of the Use of Certain Hazardous

Substances (RoHS).

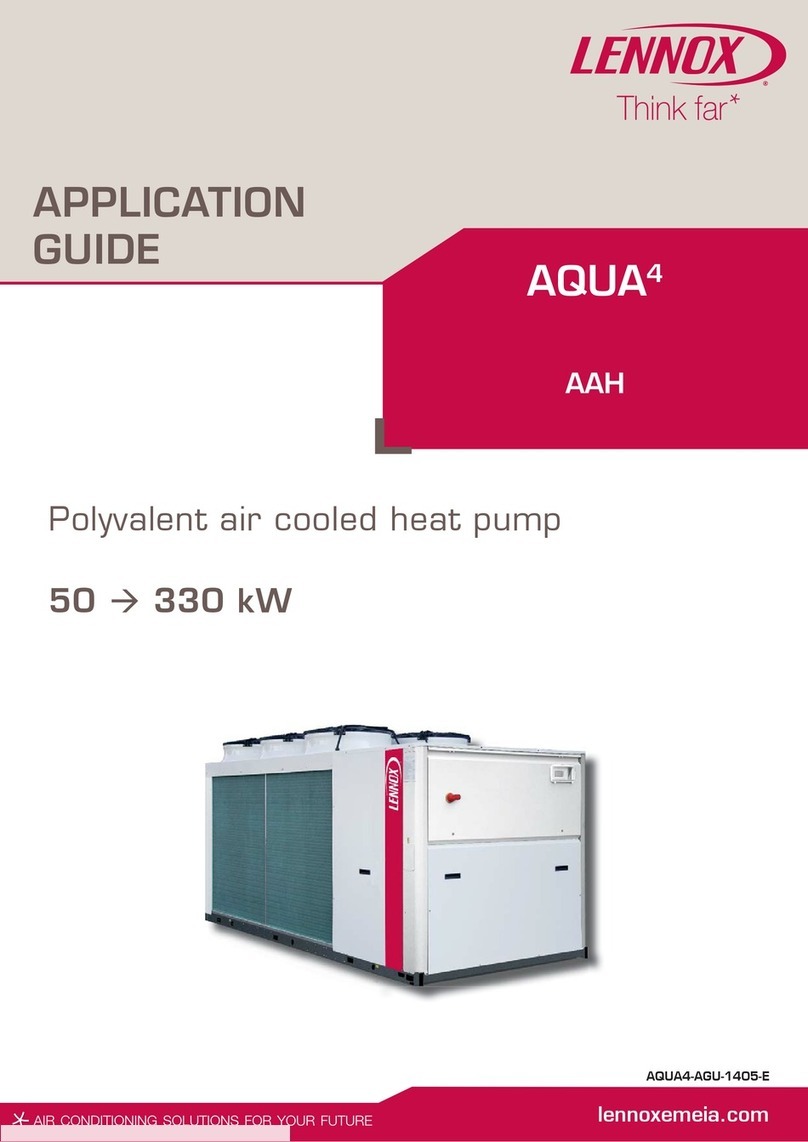

TECHNICAL DESCRIPTION