Operating Instructions

Transponder-Coded Safety Switch CTM-I2-BP/BR

2(translation of the original operating instructions) MAN20001437-01-10/21

Contents

1. About this document............................................................................................. 4

1.1. Scope............................................................................................................................................4

1.2. Target group ..................................................................................................................................4

1.3. Key to symbols...............................................................................................................................4

1.4. Supplementary documents ..............................................................................................................4

2. Correct use .......................................................................................................... 5

3. Description of the safety function .......................................................................... 6

4. Exclusion of liability and warranty ......................................................................... 7

5. General safety precautions ................................................................................... 7

6. Function............................................................................................................... 8

6.1. Guard locking for process protection................................................................................................8

6.2. Monitoring outputs/status bits .........................................................................................................8

6.2.1. Door position signal OD...................................................................................................8

6.2.2. Diagnostic signal OI.........................................................................................................8

6.2.3. Guard locking signal OL ..................................................................................................8

6.2.4. Status signal OM.............................................................................................................8

6.2.5. Locking element signal OLS.............................................................................................8

6.2.6. Communication connection C...........................................................................................8

6.3. Guard locking .................................................................................................................................9

6.3.1. Guard locking on version CTM-I2 and control via control input IMP.......................................9

6.3.2. Guard locking on version CTM-I2 and control via IO-Link communication ..............................9

6.4. Switching states ...........................................................................................................................10

6.4.1. Switching states with control via the control input IMP......................................................10

6.4.2. Switching states with control via IO-Link communication ...................................................10

7. Manual release................................................................................................... 11

7.1. Auxiliary release............................................................................................................................11

7.1.1. Actuating auxiliary release .............................................................................................11

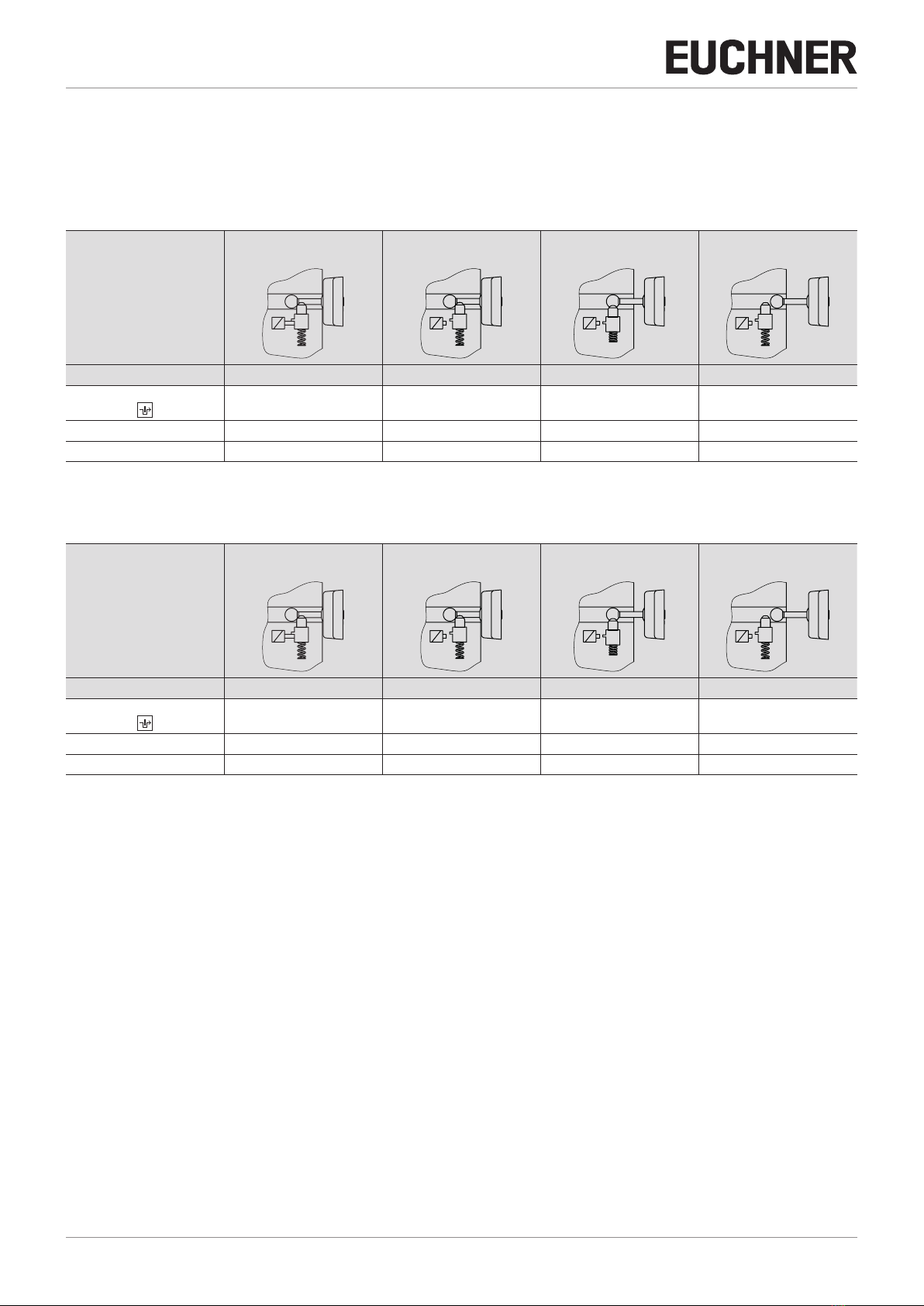

8. Mounting............................................................................................................ 12

9. Electrical connection .......................................................................................... 13

9.1. Notes about .........................................................................................................................14

9.2. Safety in case of faults..................................................................................................................14

9.3. Fuse protection for power supply...................................................................................................14

9.4. Requirements for connecting cables...............................................................................................14

9.5. Connector assignment of safety switch CTM-…-BR-…-SA-…

with plug connector M12, 8-pin......................................................................................................15

9.6. Notes on operation with safe control systems.................................................................................15

9.7. Connection without and with IO-Link communication.........................................................................15

9.7.1. Connection without IO-Link communication......................................................................15

9.7.2. Connection with IO-Link communication...........................................................................15