EURAQUA Duplex Series Instruction manual

9000/9100/9500 Duplex Series

9xDXIOMM\page 1

Installation

Operation

Maintenance

Manual

Duplex Nitrate Removal

With 9000/9100/9500 Series

Downflow Brining Valve

20-350 litres Resin

Inc. Measuring Tank Option

Models:

Mechanical Meter/Timer

SXT Electronic Meter/Timer

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 2

CONTENTS

NOS. PAGE

1.0 GENERAL NOTES 5

2.0 THE SOFTENING PROCESS 6

2.1 In Service 6

2.2 Regeneration 6

2.3 The Regeneration Process 7

2.4 Meter Control of Regeneration Initiation 7

2.5 Duplex Operation 8

3.0 UNPACKING AND PARTS IDENTIFICATION 9

3.1 Basic Packages 9

3.2 Unpacking Notes 9

3.3 Missing or Damaged Goods 9

4.0 TEMPORARY STORAGE 9

5.0 DESCRIPTION OF PLANT COMPONENTS 10

5.1 Nitrate Removal Vessel and Internals 10

5.2 Control Valve 10

5.3 Regeneration Controller and Transformer 10

5.4 Brine System 11

6.0 PRE-INSTALLATION CHECKS 12

6.1 Mechanical 12

6.1.1 Foundations/Drainage 12

6.1.2 Operating Space 12

6.1.3 Incoming Water 12

6.1.4 Pipework 13

6.1.5 Water Supply Company Requirements 13

6.2 Electrical 13

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 3

NOS. PAGE

7.0 ASSEMBLY/INSTALLATION 14

7.1 Mechanical 14

7.1.1 Assembling Vessel, Riser Tube and Internals 14

7.1.2 Charging the Resin 14

7.1.4 Assembling the Control Valve 15

7.1.5 Attatching the Control Valve and Slave Adapter 15

7.1.6 Brine System 15

7.1.7 Pipework 15

7.1.8 Storage tank ball valve 16

7.1.9 Drains and Overflow Connections 16

7.2 Electrical 17

7.2.1 Mains Supply 17

7.2.2 Transformer 17

8.0 COMMISSIONING 18

8.1 Introduction 18

8.2 Controller Setting 18

8.2.1 Setting the Time of Day 18

8.2.2 Site Program –Setting the Capacity 18

8.3 Brine System 19

8.3.1 Brine Tank Filling 19

8.4 Pre Service Flush and Regeneration (MI) 20

8.5 Pre Service Flush and Regeneration (SXT) 22

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 4

NOS. PAGE

9.0 OPERATION 23

9.1 Normal Operation 23

9.2 Refilling with Salt 23

9.3 Manual Regeneration 23

9.4 By-passing the Nitrate Removal 23

9.5 Temporary Shut-down 24

9.6 Changes in Incoming Water 24

9.7 Routine Monitoring 25

10.0 FAULT FINDING AND RECTIFICATION 26

10.1 No Flow to Service 26

10.2 Poor Treated Water Quality 26

10.3 No Regeneration 27

10.4 Unsatisfactory Capacity between Regeneration’s 27

11.0 WARRANTY AND SERVICE 28

11.1 After Sale Warranty 28

12.0 TECHNICAL DATA 29

12.1 Process and Operating 29

12.2 Engineering Data 34

13.0 FACTORY PROGRAMMING

13.1 Regeneration Settings 39

13.2 Nitrate Removal Outputs 40

13.3 Master Programming Setup Summary 9000/9100 41

13.3 Master Programming Setup Summary 9500 43

14.0 DRAWINGS

14.1 Dimensions 45

14.2 General Installation 46

15.0 CE CERTIFICATE 48

APPENDIX I

Resin MSDS

APPENDIX II

Valve manufacturer's manual including parts lists and exploded diagrams

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 5

1.0 GENERAL NOTES

These instructions cover the 9000/9100/9500 Range of Duplex Water

Softeners, which includes models ranging in size from 20-120 litres resin

volume fitter with ¾” – 1.1/2” Mechanical Meter/Timer or SXT Electronic

Meter/Timer.

It is recommended that these instructions are read throughout before

commencing any work on the unit, particularly if you have no previous

experience of installing and using a water Nitrate Removal.

The installation of a Nitrate Removal is very straightforwards, and the only

adjustments to be made to the controller program are setting the water

hardness as detailed in Section 8. However we have tried to make these

instructions as comprehensive as possible to answer any queries you may

have about the functioning of your Nitrate Removal.

This Nitrate Removal will require salt for regeneration. We recommend the

used of proprietary 'pellet' or 'tablet' salt.

Drinking softened water has not been shown to be harmful to normal healthy

children and adults, but softened water contains a higher level of Sodium

than a hard town mains supply. This is of concern to individuals on low

Sodium diets or for babies fed with powder formula milk that already contains

Sodium. It is therefore recommended that a separate un-softened drinking

water supply is left in place or installed on a drinking water faucet. If a

cartridge type water filter is installed on the drinking water line, this must be

fed with un-softened water.

We have also supplied with the system the original valve manufacturer's

handbook. This is written principally for American customers and has a

number of small differences in the setting up instructions from those used in

Europe. In the event of confusion, refer to the data in this manual rather

than in the valve manufacturer's handbook!

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 6

2.0 THE SOFTENING PROCESS

Hardness in water is caused by the presence of dissolved salts of Calcium

and Magnesium. In order to overcome the problems associated with the use

of hard water, these salts must be removed. This process is called

'Softening'. One means of removing the salts is to exchange them for

soluble Sodium salts. This technique is known as 'Ion Exchange Softening'.

2.1 IN SERVICE

In order to soften the water, it is passed through a bed of Ion Exchange resin

beads which are contained inside a vertical cylindrical vessel. these beads

are made of a synthetic material, and are usually amber or dark brown in

colour and between 0.5 and 1.0 mm in diameter.

As the water flows down through the resin, the Calcium and Magnesium in

the hard water are progressively exchanged for Sodium, with the result that

the water which flows out of the unit contains only Sodium salts, which are

not scale-forming. The Calcium and Magnesium remain, attached to the

resin.

The Ion Exchange resin does not have an unlimited capacity for exchanging

Calcium and Magnesium, so to keep the exit water soft it is necessary to

periodically 'Regenerate' the resin to restore its capacity to soften the water.

2.2 REGENERATION

The softening process can be reversed if a strong solution of Sodium

Chloride (i.e. Common salt dissolved in water -'brine') is passed through the

resin.

The high concentration of Sodium allows it to exchange for the Calcium and

Magnesium held on the resin, and these are then carried away to drain. The

resin is left full of Sodium to enable it to soften water again.

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 7

2.3 THE REGENERATION PROCESS

The regeneration process consists of four stages:-

Backwash - Water flows upwards through the resin bed, and out to a drain.

As it does so, it loosens the ion exchange beads, removes any resin 'fines'

(i.e. small pieces of broken beads etc.) and cleans off any particles of dirt or

pipework corrosion products which may have accumulated during the service

cycle.

Brine injection/Displacement Rinse - During the first part of this stage, the

concentrated salt -solution is drawn from the salt storage tank, blended with

water to reduce the concentration to the correct level, and passed down

through the resin. When the required quantity of brine has been drawn in,

the water flows alone to push the remaining brine through the resin at the

correct rate, and ensure that all the resin sees the right amount of

regenerant.

Fast Rinse - This follows the brine injection and displacement rinse stage,

and entails rinsing away the residual brine and Calcium and Magnesium salts

from the resin and re-packing the resin bed down. This is done down with

water flowing through the resin in the direction of service.

Salt Tank Refill - Following the fast rinse, a quantity of water sufficient to

dissolve the correct amount of salt for the next regeneration is returned to the

salt tank. When this has finished, the unit automatically returns to service.

2.4 METER CONTROL OF REGENERATION INITIATION

A water meter is installed in the outlet from the Nitrate Removal, to measure

the volume of water which passes to service. This meter drives a turbine, the

movement of which is measured by a magnetic sensor which sends signals

to the regeneration controller. The controller microprocessor uses this

information to calculate when the unit should be regenerated.

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 8

2.5 DUPLEX OPERATION

A 'Duplex' system is a means of operation to achieve a constant flow of soft

water to service, without the need for extensive treated water storage.

The system is essentially two vessels, which are connected to common inlet

and outlet pipework, and which are in service alternately. Both vessels are

served by a single valve/controller mounted on one of the vessels. This

diverts water to the appropriate tank for treatment or regeneration. One

vessel will be in service at any one time, the other being in its regeneration

cycle, or regenerated and on stand by, ready to enter service.

The vessel in service will operate until the integral water meter reaches its

pre-set volume. At this stage, the stand-by vessel is switched into

service, and the vessel which had been in service enters its regeneration

cycle. At the end of regeneration, this vessel goes into stand by, and waits

for the vessel now in service to complete its pre- set volume, at which point

the vessels swap over again, and the whole cycle starts again.

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 9

3.0 UNPACKING AND PARTS IDENTIFICATION

3.1 BASIC PACKAGES

The Nitrate Removal will be delivered in a number of packages which include

a pair of glassfibre reinforced pressure vessels, a control valve, slave valve

adapter, interconnecting hoses, a brine tank, an even number of 25 litre bags

of resin with possibly two additional part bags, and a funnel to fill the vessels.

The 20 litre system wil be supplied with just two 20 litre bags of resin.

3.2 UNPACKING NOTES

The unpacking of the Nitrate Removal is quite straightforward, and there are

no 'hidden' items. It is advisable to keep the packages sealed until such time

as they are used, to prevent dust or water entry.

Care should be taken in lifting the Nitrate Removal or its parts out of their

cartons. It is advisable to lay large cartons on their side and slide out the

Nitrate Removal or parts prior to standing them up.

3.3 MISSING OR DAMAGED GOODS

Immediately on receipt of the goods, it is advisable to check that all items

ordered have been received. If you have any doubt that goods have been

supplied as requested, please contact your supplier immediately. If any

items are missing or damaged, the carrier and your supplier must be notified

in writing within 3 days of receipt if a claim is to be made.

4.0 TEMPORARY STORAGE

If installation is not to start immediately after delivery, the equipment should

be stored in a clean dry area, where it will not be damaged, or be subjected

to temperatures below freezing.

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 10

5.0 DESCRIPTION OF PLANT COMPONENTS

5.1 NITRATE REMOVAL VESSEL AND INTERNALS

The pressure vessel which contains the ion exchange resin is made from a

fibreglass/epoxy resin outer layer surrounding an inner, seamless shell made from

Polyethylene, Polypropylene or ABS. Vessels below 80 litre resin capacity have a

threaded hole at the top, of 2.5 inch nominal diameter, into which the control valve

fits. Vessels for 100 litres of resin or more have larger 4 inch nominal diameter

hole and an adapter is supplied to reduce the hole to the 2.5 thread on the valve fro

use with 9000 and 9100 valves. The 9500 valve can only be used with 4 inch hole

vessels.

All vessels are equipped with a distribution system. This is attached to a central

riser tube, which is connected to the control valve, and passes water into and out of

the resin bed. On smaller systems this will have a single distributor fitted to the

riser. On larger and high flow systems there will be multiple distributors built up as a

‘hub and laterals’ on the bottom of the riser tube.

5.2 CONTROL VALVE

The control valve is mounted on top of one vessel, and directs the water flow in and

out of the resin beds during the service and regeneration cycles. A manifold

assembly or 'slave valve adapter' is mounted on top of vessel No. 2. This is then

connected to the main control valve via a pair of braided hoses (9000), plastic

interconnect pipes (9100) or copper tubes (9500). The body of the control valve is

a brass casting (9000 & 9500) or injection moulded polymer (9100), containing

operating parts made from Teflon and synthetic rubber.

The valve carries out its various functions by moving pistons backwards and

forwards in a series of seals and spacers contained within the body casting. The

movement of these pistons is controlled by a rotating cam, which is driven from the

controller. Further cams in the controller direct the movement of the valve

controlling the brine system.

5.3 REGENERATION CONTROLLER AND TRANSFORMER

The regeneration controller is attached to the valve, and is contained in a plastic

housing.

The controller is powered by 24v AC electricity, and a separate, wall mounted

transformer is connected to the valve to reduce normal mains voltage down from

240v so that all the electrical supply in and around the control valve runs at a safe

24v.

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 11

5.4 BRINE SYSTEM

The brine system consists of a moulded polyethylene tank into which the

brine well and brine pick up are assembled. The tank forms the salt storage

container.

The brine pick-up tube within the brine well is connected to the pipe from the

control valve which sucks the brine from the tank. At the bottom of the brine

pick-up tube is an air check valve. This serves to prevent air entering the

valve when all the brine has been drawn in. Air in the system could cause

spurting and 'hammering' at the taps or outlets.

BRINE MEASURING SYSTEM

The Brine Measuring System consists of a measuring tank, brine high level

float, brine solenoid and brine pick up. These needs to be fed from a Salt

Storage Tank with fully saturated brine solution.

The brine pick-up tube within the brine well is connected to the pipe from the

control valve which sucks the brine from the tank. At the bottom of the brine

pick-up tube is an air check valve. This serves to prevent air entering the

valve when all the brine has been drawn in. Air in the system could cause

spurting and 'hammering' at the taps or outlets.

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 12

6.0 PRE-INSTALLATION

6.1 MECHANICAL

6.1.1 Foundation/Drainage

The Nitrate Removal will not require any special foundations, provided that a

firm, level area which is capable of supporting the working weight is

available. (See Engineering Data, Section 12.2)

Unwanted water from the regeneration process must flow to drain, and so an

open drain or gully, capable of passing the necessary flow is required (see

Process and Operating Data, 12.1, for relevant flows). The total flow of water

to drain depends on site conditions, but will be approximately 6 times the

resin volume. The drain may be at a level no higher than 500mm above the

Nitrate Removal valve.

A second drain is required for the brine tank overflow. This is a safety drain

which will only discharge water if there is a malfunction in the control valve.

Where possible this should be installed through an outside wall like a cistern

overflow, where it will give a visual indication of any failure.

6.1.2 Operating Space

The space occupied by the Nitrate Removal can be found in the Engineering

Data (Section 12.2).,

Access will be required to refill the brine tank, and to carry out adjustments or

maintenance on the equipment. It is therefore recommended that a

minimum of 500mm clearance be allowed in front of the unit for this purpose.

6.1.3 Incoming Water

The raw water to be fed to the Nitrate Removal must comply with the

following:-

1. Available at all times at a flow equal to the required service flow or

greater, and

2. At a pressure between 1.7 and 5.5 bar

3. Temperature between 0 and 50oC

4. Suspended solids less than 1 ppm

5. Iron less than 0.2 ppm, Manganese less than 0.1 ppm, Free Chlorine

less than 1 ppm if temperature is less than 15oC, less than 0.3 ppm if

temperature higher (up to 30oC)

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 13

6.1.4 Pipework

Pipework to be connected to the Nitrate Removal should not have an

excessive amount of hardness scale deposit. Piping that is heavily built up

with scale (or Iron deposits) should be replaced.

Make sure that the pipework can be connected to the Nitrate Removal in

such a way as to impose no stresses on the control valve, and that it is

properly aligned and supported.

A system for the complete by-passing and isolation of the Nitrate Removal

should be installed (see Section 7.1.6).

6.1.5 Water Supply Company Requirements

It is essential that if the equipment is to be connected directly to a mains

water supply, the local bylaws must be adhered to. These cover both

plumbing and the prevention of backflow into the mains. If there is any

doubt, the local water inspector should be consulted, but in general, the

installation of a 'Double check valve assembly' conforming to BS6282 part 2

will be required in the feed pipework to the Nitrate Removal.

If the pressure available from the mains is not adequate it will be necessary

to install a booster pump arrangement. Such a system would be covered by

additional bylaws, and the water storage tank needed must comply with

these.

6.2 ELECTRICAL

A continuous supply of 24v, 5 VA is required by the Nitrate Removal. A 240v

transformer with an output of 9.6 VA (70 VA if Brine Measuring System used)

is provided, which should be connected to an uninterrupted mains supply,

which is separately 1 Amp fused, and does not have any additional switch.

It is recommended that the transformer be attached to a nearby wall, within

500 mm of the Nitrate Removal in an area free from water spray or excessive

heat or condensation.

A plug is not provided with this Nitrate Removal since the cable should be

connected to fused spur outlet. However if that is not possible then a plug

should be fitted to the cable with a 1 amp fuse. The socket used should be

un-switched to prevent the Nitrate Removal from being inadvertently turned

off.

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 14

7.0 ASSEMBLY/INSTALLATION

7.1 MECHANICAL

Check all the items against the parts list and shipping documents, and

ensure you have them all before starting work. In addition to the Nitrate

Removal you will require installation materials and basic tools, (i.e.,

spanners, screwdrivers etc., and PTFE tape)

7.1.1 Assembling Vessel, Riser Tube and Internals

The larger units are shipped as pre-assembled components to reduce the

risk of transit damage. These need to be assembled on site. Open the

cartons containing the pressure vessels and remove them. Check that the

vessels have not been damaged in transit. Pay particular attention to the

vessel's top hole threads, as this is where the valve will seal. Check that

there is no dirt or swarf inside.

Riser Tube/Bottom Filter

This comprises a length of pipe (the 'riser tube') to one end of which is

bonded a moulded screen or hub and lateral. The other end is fitted into the

bottom of the control valve. To make sure the riser fits properly, and there is

no leakage, it will be supplied to the correct length prior to despatch.

7.1.2 Charging the Resin

The ion exchange resin is supplied in 25 litre bags and/or part bags if

applicable - half for each vessel. All models will be supplied with exactly the

right quantity of resin. It is important that only the correct volume of resin is

put into each vessel or the system will not function properly. (See Section

12.1.2 for data)

Place the vessel in its final location - once filled with resin and water they

should not be moved. Fill the vessel about 1/5 –1/3 full with clean water. A

cover is provided to be slipped over the end of the riser when filling with

resin. This must be carefully removed without disturbing the riser prior to

fitting the control valve. Carefully open the resin bags and pour the resin into

the vessel, using a funnel, keeping the riser tube central and upright. Take

great care not to spill resin on the floor. If any is spilt, make sure it is swept

up immediately, as it is very easy to slip on it. Wash away any loose resin

from the threads of the vessel or adapter collar. Remove the riser cover and

check that the top of the riser is still correctly located

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 15

7.1.4 Assembling the Control Valve

Carefully remove the control valve and the slave tank adapter from their

packing, and check that all parts are present. On the 9000 and 9100 valves,

snap in the bayonet fit distributors to the control valve and slave tank

adapter.

7.1.5 Attaching the Control Valve and Slave Adapter

Carefully fit the control valve on to the right hand vessel, taking care to

ensure that the riser tube locates correctly into the valve base through the

top distributor, and that the threads are not crossed. Also take care to make

sure that the 'O' rings are properly seated and not pinched. Repeat the

process to fit the slave adapter. Connect the two vessels together using the

braided flexible hoses using the swivel coupling end on the slave adapter.

The vessel with the slave adapter must be connected to the left hand side of

the control valve.

Install a suitable service flow controller to the outlet connection of the control

valve if the treated water is to be supplied in to a storage tank at the same

level as the system. This will ensure that there is sufficient back pressure for

regeneration of the standby vessel.

7.1.6. Brine System

Move brine tank into position and connect the outer port of the bulk head

union to the brine draw connection on the valve using the 3/8" or ½” tubing.

Make sure that this connection is also tight to stop air leaking in.

If the brine draw tubing is adjusted for length during installation, ensure that

brass tubing inserts are refitted into tubing end prior to connecting into brine

tank and control valve.

7.1.7 Pipework

Pipework should be assembled incorporating the features shown in the

Installation Diagram, Section 14.1. It is essential that inlet and outlet isolating

valves and a by-pass valve are provided, and that the water main is

protected by a double check valve where appropriate (see Local Water Bye-

laws).

In domestic premises it is recommended that a hard water supply is still used

for drinking water (see General Notes Section 1.0).

Pipework can be constructed from any normally acceptable material (Copper,

Galvanised, Plastic), provided it is properly supported and aligned. Ensure

that the pipe is sufficiently large to accommodate the flow of water required,

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 16

making due allowance for the pressure drop between the Nitrate Removal

and the point of discharge of soft water.

NOTE: IF BRAZED OR SOLDERED FITTINGS ARE TO BE USED, THE

PIPEWORK MUST BE DISCONNECTED FROM THE VALVE DURING

HEATING AND COOLING. EXCESS HEAT CAN CAUSE PERMANENT

DAMAGE TO SOME OF THE VALVE COMPONENTS.

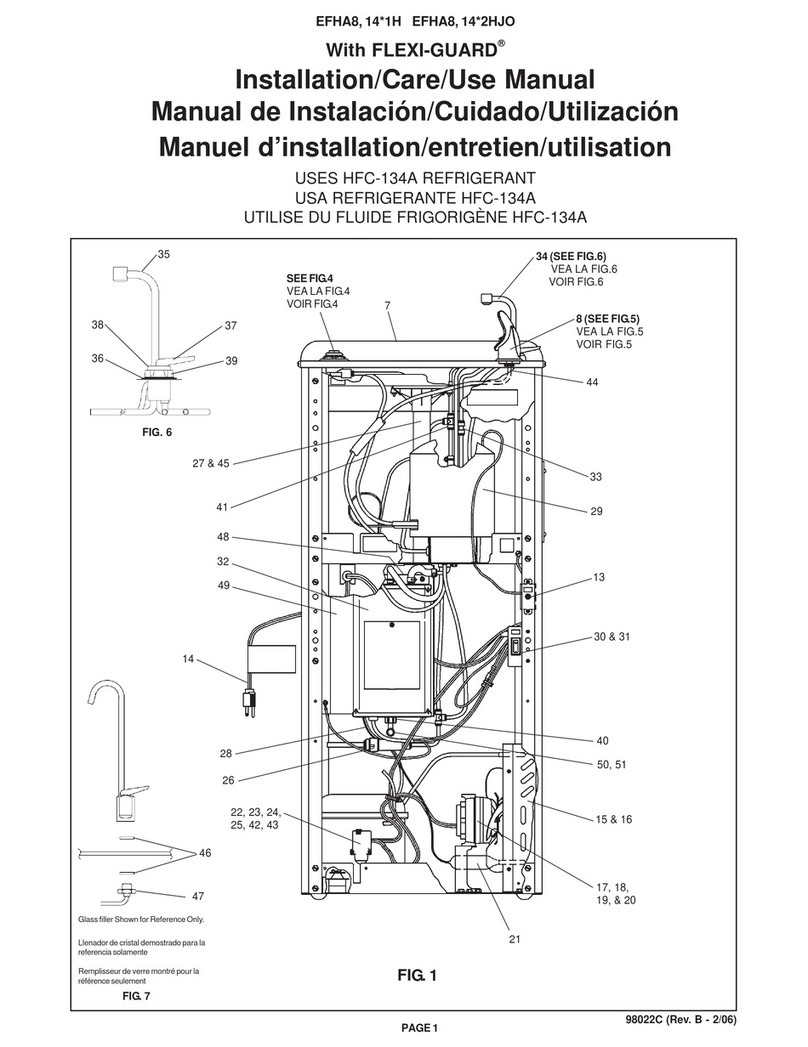

The inlet and outlet pipework should be connected to the horizontal, right

facing connections on the right of the valve manifold (1" BSP Female) (see

Fig 1 in Section 14.1).

7.1.8 Storage tank ball valve

Conventional ball float valves pass water at a slow trickle into storage tanks

and cisterns when they are shutting off. Trickle flow is not recommended for

satisfactory functioning of a water Nitrate Removal since channelling can

occur through the resin bed and the meter may not accurately monitor very

low flows. It is therefore recommended that main storage tanks for softened

water should have the ball valve replaced with a servo type valve such as a

Torbeck, Fluidmaster or Aylesbury which permit full flow until they close off.

These are inexpensive and are a direct replacement for the more common

brass ball float valves.

7.1.9 Drains and overflow connections

Connect the overflow fitting on the brine tank to a suitable drain, using

flexible or rigid tubing. Make sure that there is a clear gap of approximately

50 mm between the end of the tube and the top of the drain tundish or gully

edge.

The drain connection from the valve is a 1/2" hose spigot (9000 & 9100) or

¾” BSPF threaded socket (9500). Flexible tube should be run from this

connection to a drain capable of taking the maximum flow in regeneration

(see Section 12.1), and leaving a similar gap above the drain edge. The

drain must not be at a higher level than the 500mm above the control valve

and preferably should have an air break at the same height as the control

valve.

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 17

7.2 ELECTRICAL

Electrical installation is very straightforward, but should still be carried out by

a competent electrician, and must conform to the appropriate standards of

safety.

7.2.1 Mains Supply

The mains supply should be through a separate, switched supply, fused and

earthed in accordance with Institute of Electrical Engineers Regulations.

Current rating should be 1 Amp.

7.2.2 Transformer

A safety transformer is provided to reduce the voltage to 24 Volts to operate

the controls.

This should be attached to a convenient wall, within 500mm of the Nitrate

Removal. DO NOT SWITCH ON THE ELECTRICAL SUPPLY AT THIS

STAGE

The transformer supply should be connected with the brown cable to the live

(fused) terminal in the supply outlet and the blue cable to the neutral

terminal. The transformer is double insulated and does not require an earth

connection.

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 18

8.0 COMMISSIONING

8.1 INTRODUCTION

It is recommended that the commissioning of the plant is undertaken by a

trained service engineer, who will be able to put the plant into service quickly,

and most efficiently. However, if the services of an experienced engineer are

not available, following the steps outlined below will result in the system

being properly commissioned.

8.2 CONTROLLER SETTING - Site programming mode

All SXT controller settings will require the valve to have a mains supply

switched on. The valve must not be regenerating when controller settings

are adjusted.

8.2.1 Setting the Time of Day

There is no requirement on the Mechanical Initiation valves to set the time of

day

On SXT timers the display alternates between the time of day, the remaining

calculated capacity in litres before regeneration and the vessel on line (U1 or

U2). Wait until the time of day is displayed and the press the up ? and down

? arrow keys until the correct time of day is displayed.

8.2.2 Site programming - Setting the capacity and regeneration override.

The Nitrate Removal regeneration cycles have been factory programmed.

The volume capacity of the resin in litres has also been set up based on a

default hardness of 21 Degrees Clark (300ppm). This may need to be

altered based on local water hardness (see section 13.2).

There is no regeneration override facility on the Mechanical Initiation valves.

On SXT valves, a regeneration override is used to freshen the resin if a

regeneration has not taken place for a number of days.

Press and hold the press the up ? and down ? arrow keys together for 5

seconds. The volume capacity of the resin in litres will be displayed. This

can be adjusted to suit site conditions by pressing the up and down arrows.

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 19

Press the extra cycle button to set the regeneration override. The default is 3

days for duplex softeners. This may be changed to a different interval by

pressing the up and down arrows.

Press the extra cycle button to exit the Site Programming mode.

8.3 BRINE SYSTEM

8.3.1 Brine Tank Filling

Place approximately 100 mm depth of water in the bottom of the brine tank.

Fill with pellet salt (recommended) until the brine tank it is full or with granular

salt until it is 3/4 full.

Overfilling the brine tank with granular salt can result in an overflow of brine.

This cannot happen with pellet salt, which is why it is recommended.

Under no circumstances use cooking salt or Pure Vacuum Dried (PVD) salt

to fill the brine tank as either of these will damage the resin and the internal

components of the regeneration valve and brine draw system.

8.3.2 Brine Measuring System Filling

Connect the solenoid inlet to the outlet of the Salt saturator (3/4” solvent

weld) ensure the middle of the two high level floats (mounted side by side) is

set at the a height above the brine pick up shut off position corresponding to

the following table.

RESIN QUANTITY

(LITRES)

QUANTITY OF BRINE ABOVE PICK UP

(LITRES)

20

8

25

12

50

19

75

34

100

37

120

46

150

61

190

76

200

76

250

106

300

121

350

137

9000/9100/9500 Duplex Watersoftener

Installation Operation Maintenance Manual

9xDXIOMM\page 20

8.4 PRE-SERVICE FLUSH AND REGENERATION –MECHANICAL TIMERS

Set the manual isolating valves so that water will by-pass the Nitrate

Removal. Turn on the main water supply. Open a soft water tap close by

and let the water run for a few minutes to flush out any debris or foreign

matter from the pipework system.

Turn on the power supply to the valve.

Remove the dust cover from the control valve and ensure that the meter

cable is not plugged into the meter on outlet of the valve. Swing 'open' the

timer assembly on the left of the valve by pulling on its right hand edge. Turn

the manual regeneration knob on the front of the timer clockwise until the first

row of pins on the program wheel on the back of the timer lifts the outer

microswitch.

Turn on the power supply. The drive motor on the right of the control valve

will run and will start to slowly drive the internal gearing. The bottom shaft

will move first, followed by the top shaft. When both shafts and all the gears

have finished moving the valve is in the backwash position of the

regeneration cycle. This will take several minutes. Turn off the power

supply.

Slowly open the water inlet valve. Air will be expelled from the drain line,

followed by water once the vessels are filled with water. Open the inlet valve

fully to allow water to run to drain for 4-5 minutes.

Turn on the power supply and index the regeneration knob to the 'brine'

position - the microswitch is in the first (long) gap in the bank of pins.

Water/brine will be drawn in from the brine tank, and water will trickle slowly

down the drain line.

When the gears have stopped moving, index to the rapid rinse section -

second bank of pins - and again wait for the gears to stop moving. Water will

run quickly down the drain line.

Index the knob to the brine refill section - second (short) gap in the pins - and

wait for the gears to stop moving. Water will be refilled into the brine tank.

Finally, index the knob to the 'home' position past the last pair of pins (inner

microswitch drops into the indent in program wheel) and wait for the gears to

stop moving. This has commissioned one vessel.

Leave the power supply on and repeat the sequence in 5) above to

commission the second vessel. However after indexing the knob to the brine

position (iii) leave the timer to drive the program wheel round until the final

pair of pins have lifted the microswitch. This will ensure that the correct

This manual suits for next models

3

Table of contents

Popular Water Dispenser manuals by other brands

Whirlpool

Whirlpool WDAB600XWX Use & care guide

US Water Systems

US Water Systems Ultimate Dual Superfilter FSF-250 owner's manual

Sentencia

Sentencia Volumo Installation & operating instructions

WaterLogic

WaterLogic 4 Firewall user manual

Aqua To Go

Aqua To Go Argento Cleaning instructions

Franke

Franke KEP3CP instructions