EVAPCO Water Saver EWS-22 Instruction manual

WATER SYSTEMS

Installation, Operation &

Maintenance Manual

For EVAPCO Water Saver TM

2

3 Introduction

3 Water Saver System Overview

3 Standard Equipment and Operation

4 Engineering Data

5 Principle of Operation

5 Water Saver Pretreatment System

6 Design Considerations

8 Makeup Water Tank

9 Clean in Place (CIP)

9 Operational Chemical Feed

10 Field Installation Guidelines

10 Moving the EWS

11 Plumbing the EWS

12 EWS Bypass Loop

12 Wiring Power to the Control Panel

13 Wiring the EWLC and Bypass Solenoid

14 Components

15 Water Flow Path

16 Pressure Regulator Valve

16 Water Meters

16 Conductivity Probe

16 Panel Wiring Locations

17 Operation

17 Startup Program

17 Main Program

17 Shutdown Program

17 Five-Probe Electronic Water Level Control

18 EWS Start/Stop

18 EWS Bypass

18 Hi Level Alarm (By Others)

18 User Display

18 Touch Screen Display

18 Home Screen

19 Operating Data Screen

19 Alarms Screen

19 Alarm Configuration

20 Data Logs

20 Startup and Shutdown

20 Startup Procedure

20 Shutdown Procedures

20 Maintenance

21 Troubleshooting

22 Warranty

Table of Contents

3

Thank you for your purchase of EVAPCO’s Water Saver (EWS), a capacitive deionization pretreatment system. Water Saver

systems are constructed using the highest quality materials and workmanship. Evaporative cooling equipment is often the main

water consumer for a building or process. The Water Saver improves an evaporative unit’s water quality and is designed to

provide years of reliable service when properly maintained.

Qualified personnel should use proper care, procedures, and tools when operating, maintaining, or repairing this equipment in

order to prevent personal injury and/or property damage. The warnings listed below are to be used as guidelines only.

The Water Saver is an electrical device. Use caution when working on or near the Water Saver.

Electrical Hazard – Service and troubleshooting to be completed by trained and authorized service

professionals only.

The Water Saver is an environmentally responsible pretreatment system that offers the following benefits:

x

Improves Evaporative Cooling Water Efficiency by Increasing Operating Cycles of Concentration

x

Reduces Blowdown and Treatment Chemicals Sent to Drain

x

Low Cost of Ownership

x

75-85% Recovery Rate

Standard Equipment and Operation

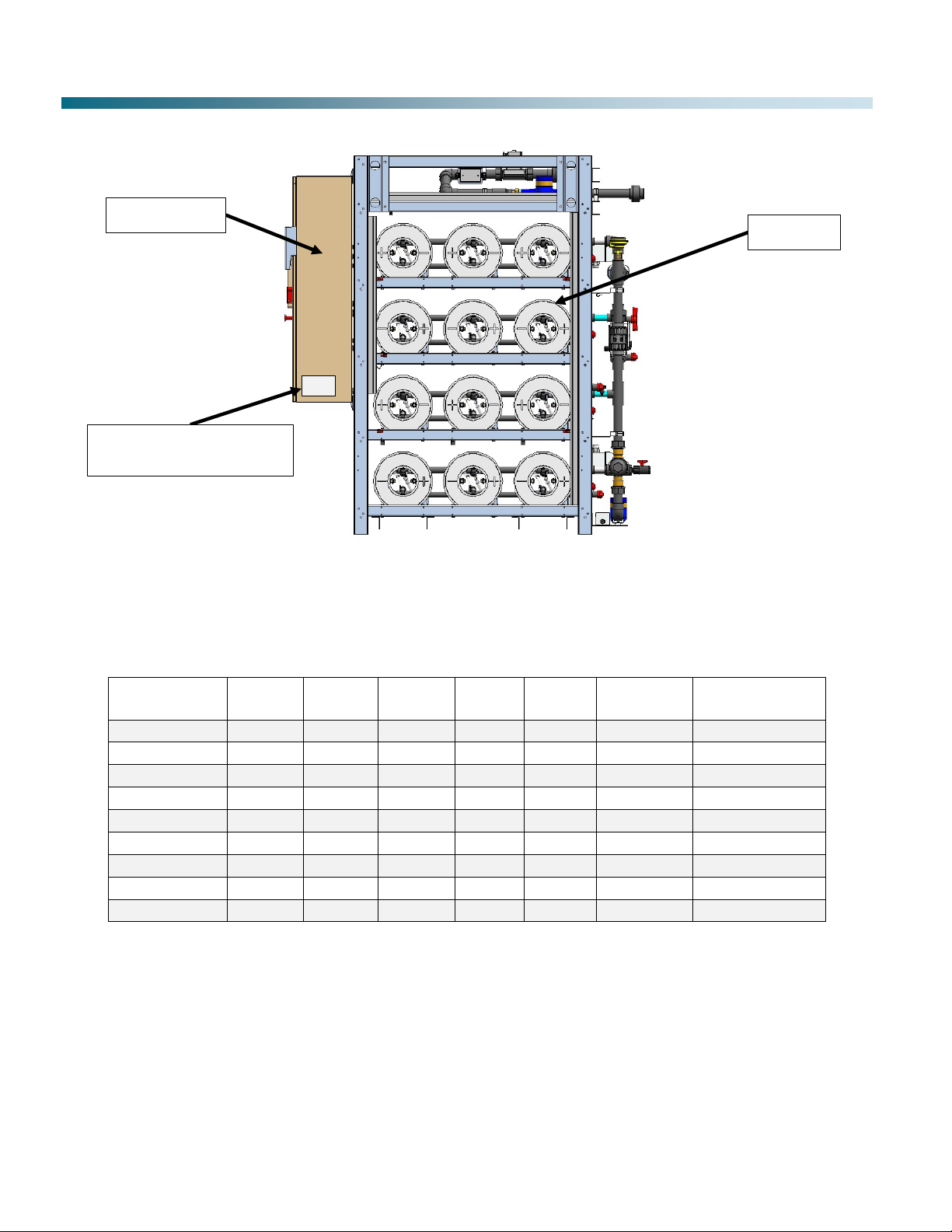

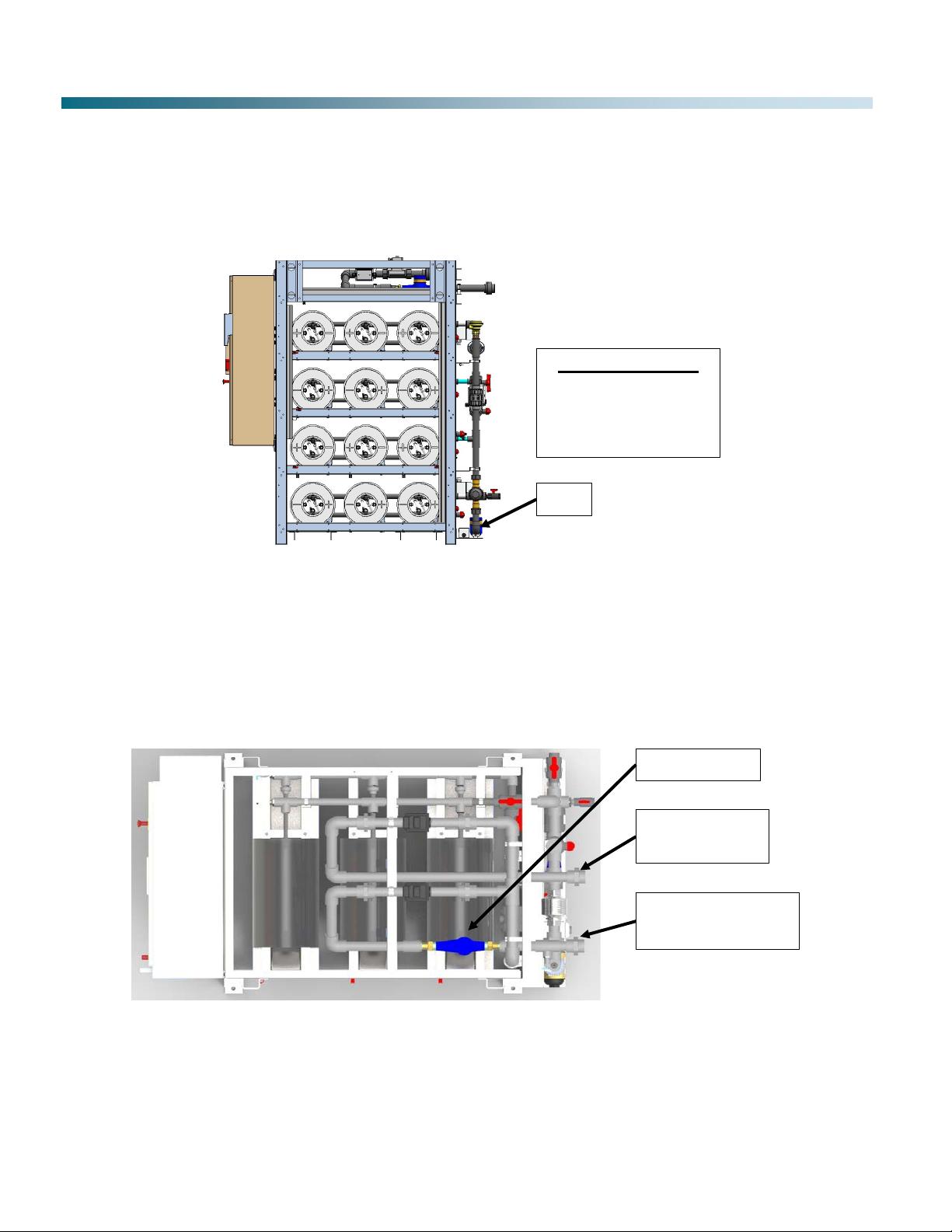

The Water Saver system is comprised of a control panel, ion removal cylinders, flow sensor, conductivity probes and

interconnecting valves and piping. A nameplate indicating the model number, part number, and serial number is located on the

side of the Control Panel. A 12- cylinder Water Saver (EWS-34) is shown in Figure 1.

The Water Saver is available in nine different cylinder arrangements, engineered to produce a target gal/min of lower

conductivity makeup water to the evaporative unit. Systems come in 4, 6, 8, 9, 12, 15, 18, 20, 24-cylinder designs. Available

voltage configurations are 230V, 3-phase, 3-wire (delta), or 480V, 3-phase, 4-wire (WYE). 480V applications may require a

transformer. Refer to Figure 2 for a basic component schematic.

Figure 1: Evapco Water Saver 12-Cylinder Pretreatment Skid

Introduction

Safety Precautions

Water Saver System Overview

4

Introduction (Continued)

Figure 2: Basic Components

Table 1 shows the Water Saver models that are available and their respective mechanical and electrical specifications for field

installed models.

Model Number Length

(in.)

Width

(in.)

Height

(in.)

Voltage FLA # of

Cylinders

GPM Clean

Makeup

EWS-22

64

46-1/2

83-1/4

230/480

21.5/13.1

4

6 - 10

EWS-23 64 46-1/2 83-1/4 230/480 21.5/13.1 6 9 - 15

EWS-24

64

46-1/2

83-1/4

230/480

21.5/13.1

8

12 - 20

EWS-33 79 46-1/2 83-1/4 230/480 21.5/13.1 9 13 - 22

EWS-34

79

46-1/2

83-1/4

230/480

21.5/13.1

12

18 - 30

EWS-53 115 46-1/2 83-1/4 230/480 36.5/23.1 15 22 - 37

EWS-54 115 46-1/2 83-1/4 230/480 36.5/23.1 20 30 - 50

EWS-63

130

46-1/2

83-1/4

230/480

36.5/23.1

18

27 - 45

EWS-64 130 46-1/2 83-1/4 230/480 36.5/23.1 24 36 - 60

Notes:

1. Unit is designed for indoor installation

2. A sanitary drain is required to dispose flush cycle water

3. Inlet water pressure requirement: Min = 65 psi; Max = 120 psi

4. Electrical Service requirement: 230 V, 3 ph, 3 wire (delta) or 480 V, 3 ph, 4 wire (wye)

5. “GPM Clean Makeup” capacity for each model is variable within the flow rate range shown, dependent of raw makeup water quality

Table 1: Factory Assembled Water Saver Models and Specifications

Control Panel

Cylinder

Model and Serial Number

Nameplate

5

Water Saver Pretreatment System

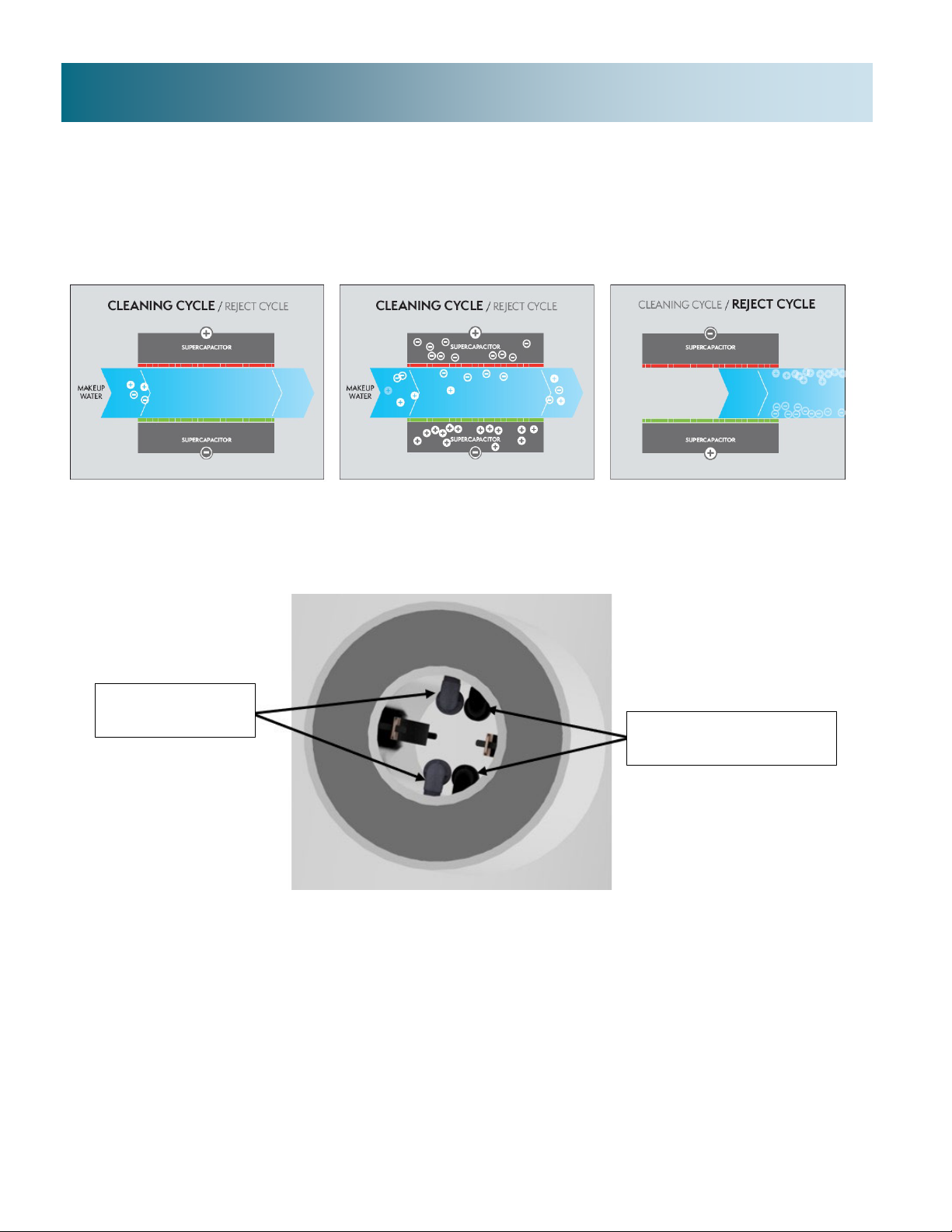

The Water Saver system uses capacitive deionization technology to reduce dissolved ion concentration, thus lowering the makeup

water conductivity prior to use in an evaporative cooling system. Makeup water entering the Water Saver passes through individual

cylinders which contain oppositely charged supercapacitor surfaces. Dissolved ions (except silica) are removed from the water as

they are adsorbed onto the charged capacitor. A 50% ion reduction allows the operating cycles of concentration to be safely

doubled without an increase in scale or corrosion potential. Figure 3 describes the capacitive deionization process. Figure 4

shows an up-close view of a cylinder.

Figure 3: Illustration of EWS Cycles

Figure 4:Illustration of EWS Cylinder

Principle of Operation

Makeup water flows into a cylinder

Supercapacitors attract oppositely

charged ions from the makeup water

Supercapacitors reverse polarity to

reject ions to drain at reduced flow rate

Raw makeup water

enters the cylinder Reduced conductivity

water exits the cylinder

6

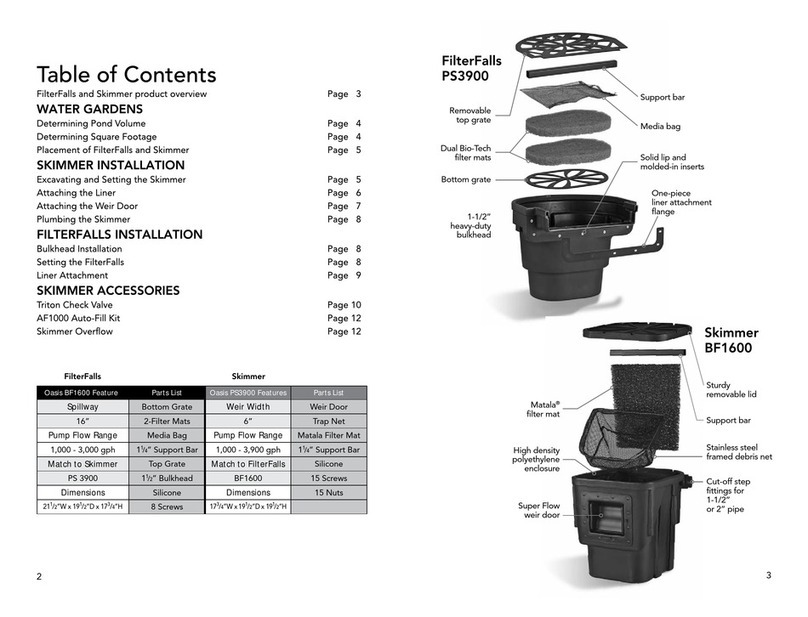

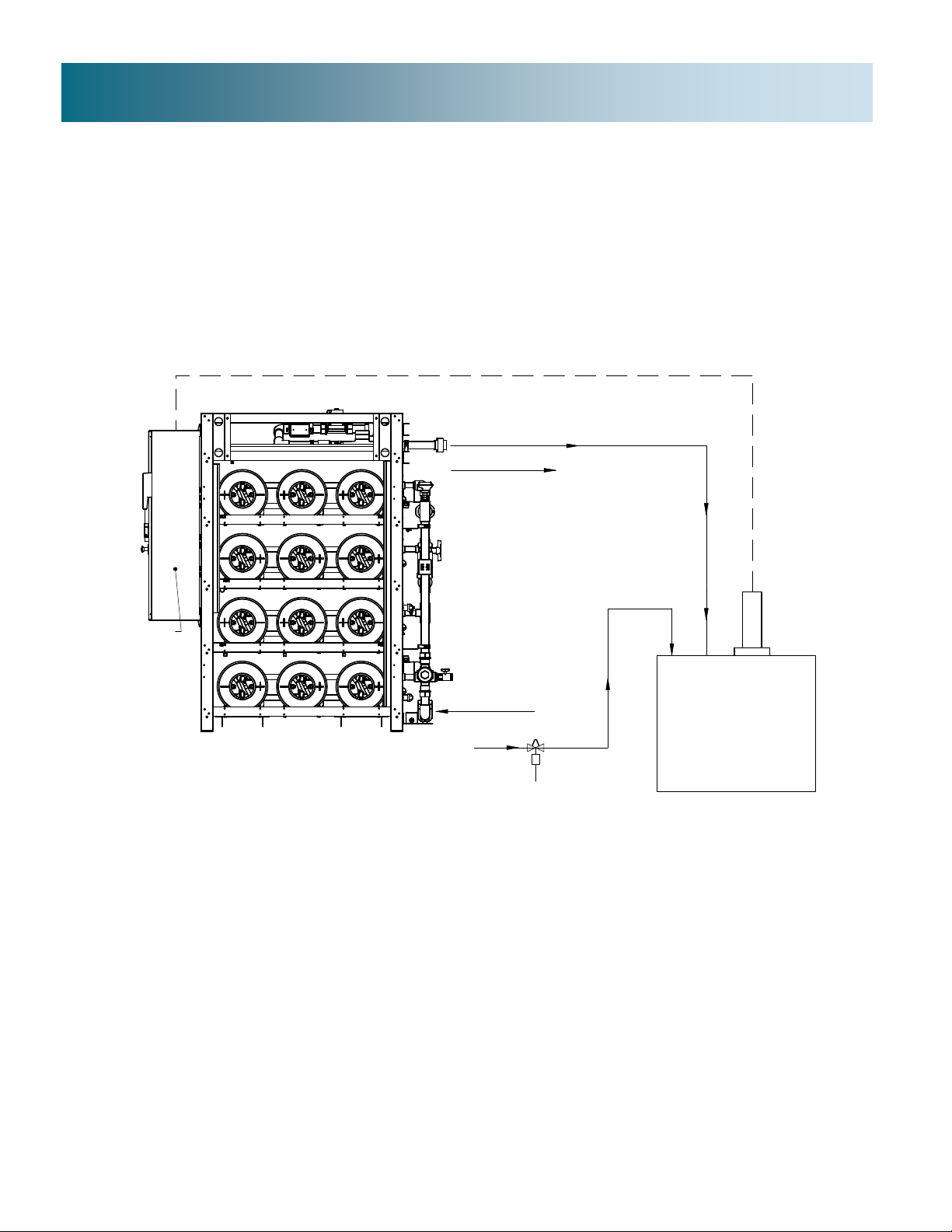

There are multiple standard configurations for field piping and wiring of Water Saver systems based on the evaporative system

design and layout.

xEWS piped directly to a single evaporative unit (see Figure 5)

xEWS piped to a makeup water tank with a single evaporative unit (see Figure 6)

xEWS piped to a makeup water tank with multiple evaporative units (see Figure 7)

Each evaporative unit must be equipped with an Electronic Water Level Controller (EWLC). The EWLC starts Water Saver

operation when makeup water demand is sensed and stops operation when demand is satisfied (see Figure 5). If the system

uses a makeup tank (supplied by EVAPCO), the EWLC (supplied by EVAPCO) on the tank will start and stop Water Saver

operation (see Figure 6 or Figure 7). Makeup water bypass piping and control valve are supplied and field installed (by others)

and are required to ensure the evaporative unit(s) will always have makeup water available.

Figure 5: EWS Field Piping/Wiring for Direct Feed to Single Evaporative Unit

Design Considerations

S

EWS

EVAPORATIVE UNIT

MAKE UP

BYPASS

CLEAN OUTLET, PIPE TO PROCESS

FLUSH OUTLET, PIPE TO DRAIN

(NOT INVIEW)

EWS CONTROL

PANEL

WIRE TO EWLC

POWER AND CONTROL WIRING

E

W

L

C

7

Design Considerations (Continued)

Figure 7:EWS Field Piping/Wiring for Multiple Evaporative Units with Makeup Tank

BOOSTER PUMP REQUIRED

(BY OTHERS)

S

EWS

MAKE UP TANK

MAKE UP

BYPASS

CLEAN OUTLET, PIPE TO PROCESS

FLUSH OUTLET, PIPE TODRAIN

(NOT IN VIEW)

EWS CONTROL

PANEL

P

E

W

L

C

POWER AND CONTROL WIRING

EWLC REQUIRED

EVAPORATIVE UNIT

S

E

W

L

C

POWER AND CONTROL WIRING

WIRE TOEWLC

ON UNIT

EVAPORATIVE UNIT

BOOSTER PUMP REQUIRED

(BY OTHERS)

EWLC REQUIRED

(TYPICAL)

S

EWS

MAKE UP TANK

MAKE UP

BYPASS

CLEAN OUTLET, PIPE TO PROCESS

FLUSH OUTLET, PIPE TO DRAIN

(NOT IN VIEW)

EWS CONTROL

PANEL

WIRE TO EWLC

ON TANK

P

S

E

W

L

C

POWER AND CONTROL WIRING

E

W

L

C

S

E

W

L

C

S

E

W

L

C

WIRE TO UNIT EWLC

POWER AND CONTROL WIRING

POWER AND CONTROL WIRING

POWER AND CONTROL WIRING

EVAPORATIVE UNIT

EVAPORATIVE UNIT

WIRE TO UNIT EWLC

WIRE TO UNIT EWLC

Figure 6: EWS Field Piping/Wiring for Single Evaporative Unit with a Makeup Tank

WIRE TO EWLC

ON TANK

8

Design Considerations (Continued)

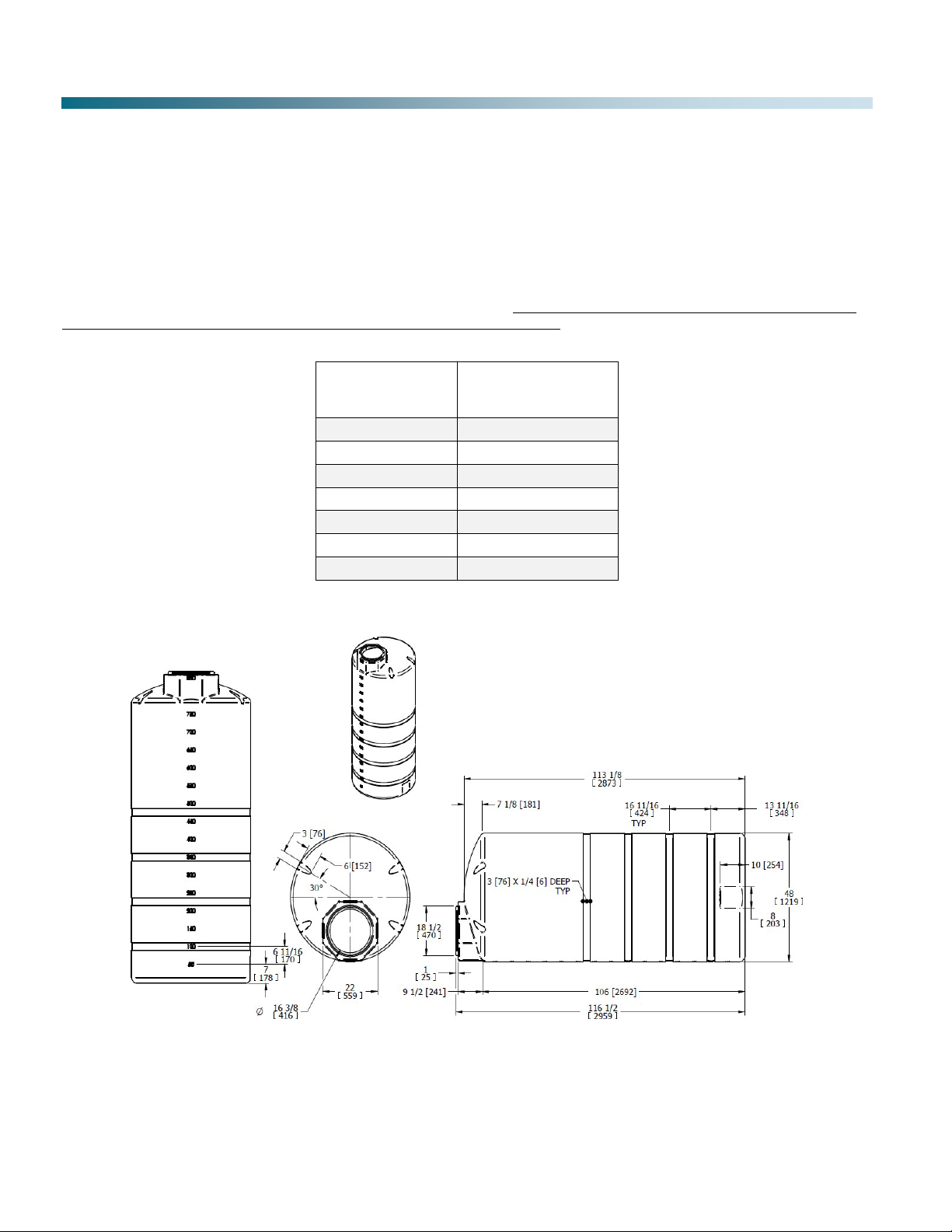

Makeup Water Tank

As determined by system design, the EWS supplies reduced conductivity water to a makeup water tank. A booster pump

(supplied and field installed by others) supplies water from the makeup tank to the evaporative cooling unit(s). Makeup tanks are

sized by evaporative unit demand and supplied by EVAPCO. An 850-gallon tank is shown in Figure 8. All makeup tanks

supplied with the Water Saver(s) have the following connections:

x2” FPT connection at bottom of tank to connect makeup line to evaporative unit

x3” self-aligning connection on top of tank for custom 5 probe EWLC

Clearance above the top of the tank is required for placement of EWLC probes (refer to Table 2 for standard tank sizes). EWS

inlet water should be directed downwards, away from the EWLC probes. Depending upon the height of the mechanical room, the

5-probe EWLC may need to be installed prior to moving the tank into the building. Tank overflow piping is recommended.

Installation and parts for overflow piping is supplied by others.

Make-up Tank

(gallons)

Tank Clearance

(Minimum)

300

79”

500

68”

750

98”

850

112”

1500

110”

2000

120”

2500

82”

Table 2: Minimum Clearance Over Makeup Tank

Figure 8:Makeup Tank 850-gal Capacity

9

Design Considerations (Continued)

Clean-In-Place (CIP)

The Water Saver requires periodic cleaning of the cylinders. CIP equipment supplied with the Water Saver includes a portable

cleaning solution tank, submersible pump, and interconnecting flexible tubing. Water Saver CIP plumbing connections are

integral to the unit. CIP pump discharge is connected to the Water Saver’s CIP inlet. CIP outlet returns to the solution tank. A

sanitary sewer drain will be used during the CIP process. The pump comes equipped with standard 120V maleplug. The Water

Saver has a GFCI utility outlet for this purpose. Refer to Figure 9 for CIP layout.

Figure 9: CIP Equipment

Operational Chemical Feed

The Water Saver may require a chemical feed addition as part of the operating program to maintain performance. A small

chemical feed pump and 5-gallon pail of chemistry is supplied when chemical feed addition is necessary (chemistry is

dependent on makeup water quality and decided by EVAPCO). The pump is powered by the Water Saver.

10

The following needs to be completed in the field prior to starting up the EWS.

Moving the EWS

Forklift Slots

The Water Saver is equipped with forklift slots, hanger brackets, and mounting plates.

If using a forklift,onlyuse the slots marked “FORK HERE” to lift. Equipment damage may result ifEWS islifted from the frame.

Use caution when moving the EWS. The control panel isheavy andcan cause the skid to tip.

Lifting Brackets are located on each corner of the frame.

Mounting Foot Plates

Lagging the Water Saver to the mechanical room floor is recommended. Mounting foot plates with ¾” holes are located on the

EWS frame.

Refer to Figure 10 for lifting and mounting locations.

Figure 10: Lifting and Mounting Locations

Field Installation Guidelines

Lifting Bracket

Mounting Foot

Plate

Forklift Slots

11

Field Installation Guidelines (Continued)

Plumbing the EWS

Inlet (Supply) Piping – see Figure 11

Inlet pipe connections vary by EWS model size. Consult Figure 11 for inlet pipe size. Supply piping (installed and supplied by

others) to EWS inlet must be sized to provide sufficient flow rate and pressure. The minimum inlet pressure is 65 psi. Do not

exceed 120 psi inlet pressure. Schedule 80 PVC supply piping is preferred. Supply piping must not be copper.

Figure 11: Makeup Inlet Plumbing

Clean Outlet

The reduced conductivity (clean) outlet water flow from the EWS is plumbed to either the evaporative unit or the makeup tank.

Due to pressure drop across the EWS (up to 15 psi), some installations may require an inline booster pump (supplied by others)

to get the outlet water flow to the desired destination. A booster pump (supplied by others) is required when a makeup tank is

used to supply makeup to the evaporative unit(s). A totalizing water meter is factory installed prior to shipment.

Flush Outlet

Flush outlet shall be plumbed to a sanitary drain near the EWS. Refer to Figure 12 below for the outlet locations.

Figure 12: Outlet Plumbing (Plan View)

Inlet

Inlet Pipe Diameter

4-12 Cylinders: 1-1/2”

15-24 Cylinders: 2”

Water Meter

Clean Outlet to Unit

or Makeup Tank

Flush Outlet to

Sanitary Drain

12

Field Installation Guidelines (Continued)

EWS Bypass Loop

The bypass engages when the water reaches the “By-Pass On” probe of the EWLC. The EWS system is designed to continue

to operate even if bypass is engaged. Maintaining inlet water pressure and flow during bypass is important.

Install bypass piping around the EWS (piping and valve by others) using the following recommendations.

xThe bypass line shall be separate to the makeup line going to the EWS and the EWS clean outlet line

xBypass piping diameter shall be equal to or smaller than Inlet (Supply) piping diameter

xIn most applications, the recommended cycle time for the bypass valve is 15-25 seconds (line size and pressure may affect

recommended cycle time)

xOn the outlet side, the bypass line must run all the way to the tower for configurations without a makeup tank

See Figure 5-Figure 7 for examples of typical bypass piping configurations. Wire the bypass valve to the 5 probe EWLC as

shown in Figure 14. Bypass operation is controlled by EWLC.

Wiring Power to the Control Panel

The EWS has the following electrical options:

1. 230V, 3 phase, 3 wire (delta)

2. 480V, 3 phase, 4 wire (wye)

Refer to Figure 13A - C for supply voltage connections.

Figure 13A: Supply Voltage 230V, delta

Figure 13B: Supply Voltage 480V, wye Figure 13C: Neutral 480V, wye

Ground

L1 L2 L3

Ground

Neutral

L1 L2 L3

13

Field Installation Guidelines (Continued)

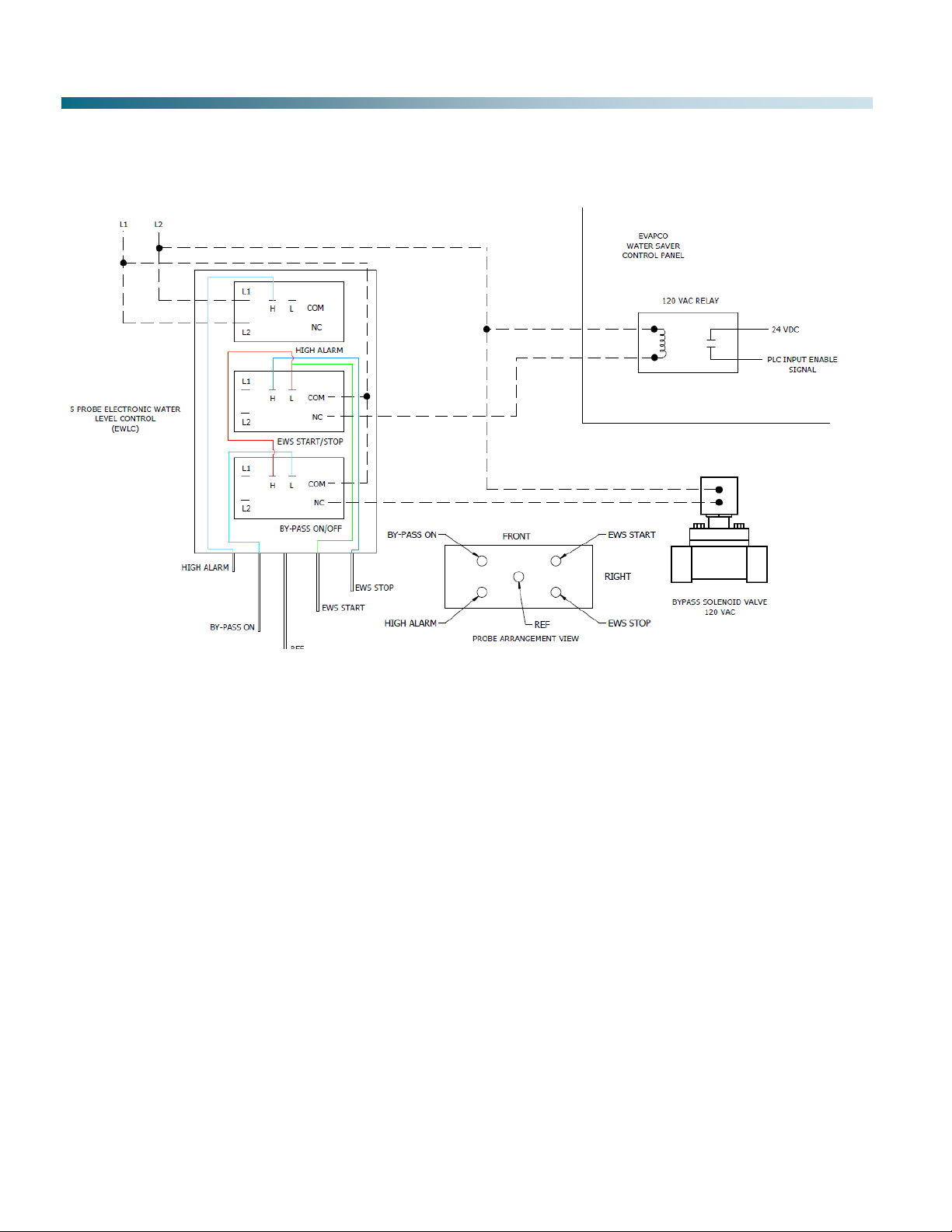

Wiring the EWLC and Bypass Solenoid

Figure 14 shows wiring for a single EWS running off a single EWLC. Internal wiring to be done by others. For other

configurations, please contact your local Evapco Representative.

Figure 14: EWLC Wiring Diagram for a Single EWS Running off a Single EWLC

14

Figure 15 depicts the sensors, valves, and other components on the side of the EWS.

Figure 15: EWS Components

Components

Clean Outlet

Valve

Flush Outlet

Valve

Pressure

Sensor

Magnetic Flow

Meter

Sample Port

Inlet

Conductivity

Probe

Clean Outlet

Water Meter

Outlet

Conductivity

Probe

CIP Inlet

Flow Control

Valve

Pressure

Regulator

Valve

Main Inlet

Isolation

Valve

Drain Isolation

Valves

Makeup (Inlet)

Water Meter

CIP Outlet

15

Components (Continued)

Water Flow Path

Figure 16A-Figure 16B show the water flow path through the EWS. The green dotted arrows show the ion reduced (clean outlet)

water path, and the blue dashed arrows show the makeup (inlet) path.

Figure 16A: EWS Water Flow Path (Cylinder Plumbing)

Figure 16B: EWS Water Flow Path (Inlet/Outlet Piping)

Control Panel

Flush (Outlet) Water

Ion Reduced (Clean

Outlet) Water

Makeup (Inlet) Water

Flush (Outlet) Water

Ion Reduced (Clean

Outlet) Water

Makeup (Inlet) Water

16

Components (Continued)

Pressure Regulator Valve

The valve has been preset at the factory to 45 psi. Inlet supply pressure for your location may require field adjustment of the

regulator valve to achieve desired flow rate. This shall be discussed with the Factory Authorized Service Provider and approved

by EVAPCO to avoid damage to the system. Clean outlet flow rate directly correlates to inlet pressure and flow. Minimum inlet

pressure is 65 psi. Do not exceed 120 psi inlet pressure.

Water Meters

Meter is installed horizontally with register facing up. N/O reed switch set at 10 gallons per count is mounted on the dial face and

connected to the control panel.

Conductivity Probe

The EWS comes with an Inlet Conductivity Probe and an Outlet Conductivity Probe. See maintenance requirements in Table 4.

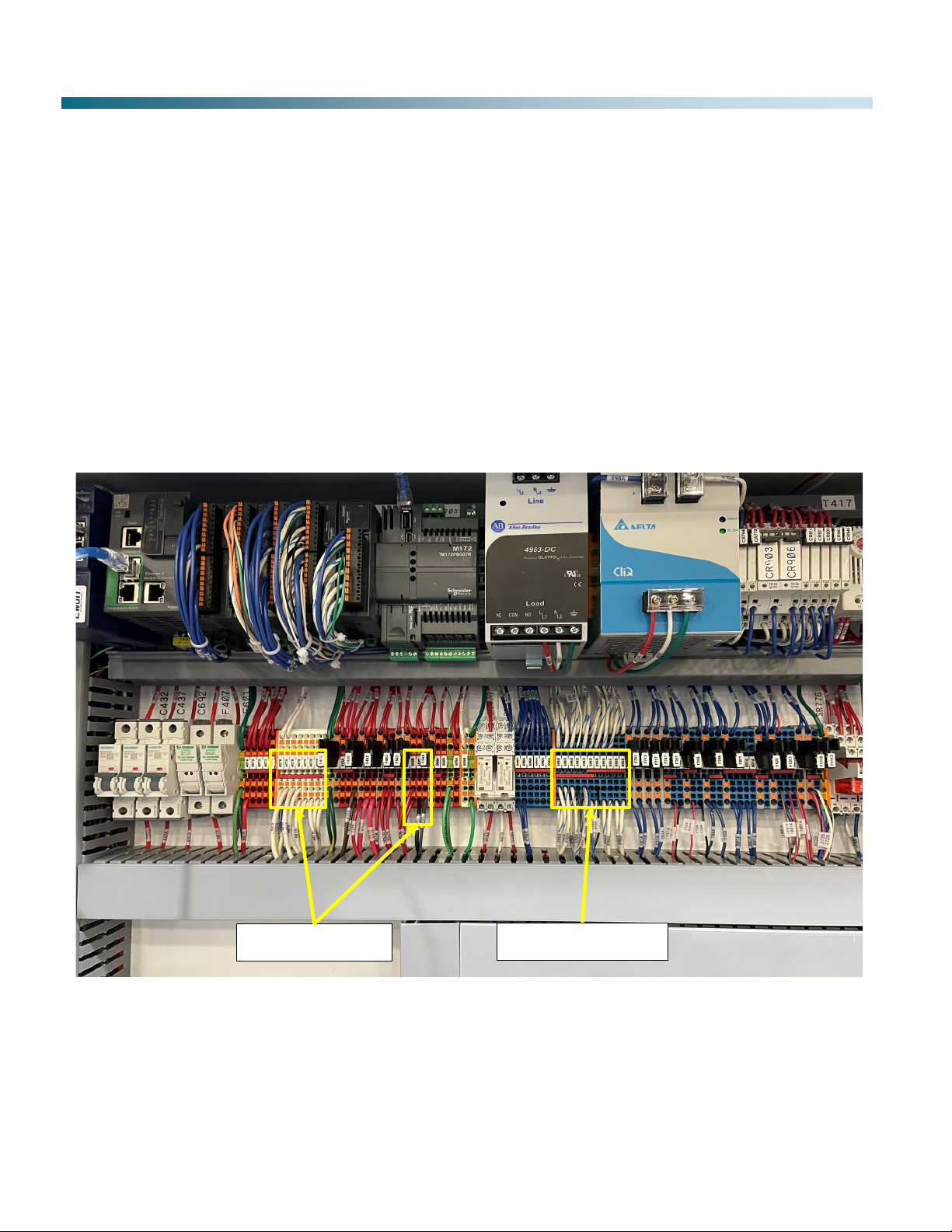

Panel Wiring Locations

In Figure 17, Valve Connections refer to the “Flush Output” and “Clean Output” solenoid valves. Sensor Connections refer to the

Inlet and Outlet Conductivity Probes, the Water Pressure Sensor, and the Inlet Flow Meter.

Figure 17: Inside Panel Wiring

Valve Connections Sensor Connections

17

The Water Saver has three sub programs.

1.

Startup program

2.

Main program

3.

Shutdown program

Each program is comprised of multiple steps. Transition from program to program and step to step is controlled by the PLC.

Programming of individual steps is performed at the factory.

Startup Program

The purpose of Startup is to prepare the cylinder’s conducting capacitors for ion removal. Once Startup program has completed,

the PLC automatically engages the Main program.

Main Program

The Main program supplies ion reduced makeup water to a tank or directly to the evaporative unit’s cold-water basin. The Main

program loops through a series of steps. The two primary steps in the Main program are “Clean” and “Flush”. During the “Clean”

step, ions are removed as water flows through the cylinders. Reduced ion water is directed to the makeup tank or directly to the

evaporative cooling unit. To maintain efficient ion removal, collected ions must be periodically purged. “Flush” step(s) purge the

collected ions. Water flow during the “Flush” step(s) is directed to drain. Other steps are also part of the Main program. These

steps maximize “Clean” water recovery. The Main program repeats until a stop signal is received.

Shutdown Program

The purpose of the Shutdown program is to prepare the superconducting capacitors for Standby status once water demand has

been satisfied. The Shutdown program consists of multiple steps to purge collected ions from the superconducting capacitors. The

Shutdown program automatically engages when the Water Saver receives a signal from the EWLC that water demand has been

satisfied. Once Shutdown steps are complete, the Water Saver awaits a signal to restart (Standby). If a start signal is received by

the Water Saver during the Shutdown steps, the Shutdown program will complete before the Water Saver restarts.

Five-Probe Electronic Water Level Control

Electronic water level control device has five probes and an electrical enclosure. The probes are threaded into connections of

the enclosure. Probes are connected to relay cards that control the operation of the Water Saver and bypass valve.

Water level is sensed in the makeup tank or evaporative unit by the probes. Each probe has a unique length. One probe is used

as reference. Reference probe tip is always submerged. When the tips of the reference and another probe are submerged, an

electrical circuit is completed resulting in a change of relay status. The water level in the tank triggers action of the devices

connected to the level sensor control.

Makeup Tank Size

(gal) [ltr]

Ref Length (in)

[mm]

Bypass On Length

(in) [mm]

EWS Start Length

(in) [mm]

EWS Stop Length

(in) [mm]

High Alarm Length

(in) [mm]

300 [1136] 77 [1956] 62 [1575] 50 [1270] 16 [406] 12 [305]

500 [1893] 59 [1499] 47 [1194] 38 [965] 16 [406] 12 [305]

750 [2839] 89 [2261] 71 [1803] 54 [1372] 17 [432] 13 [330]

850 [3218] 103 [2616] 79 [2007] 63 [1600] 17 [432] 13 [330]

1500 [5678] 101 [2565] 83 [2108] 63 [1600] 19 [483] 15 [381]

2000 [7571] 108 [2743] 105 [2667] 78 [1981] 21 [533] 17 [432]

2500 [9464] 73 [1854] 66 [1676] 51 [1295] 24 [610] 20 [508]

Table 3: EWLC Probe Lengths

Operation

18

Operation (Continued)

EWS Start/Stop

When the water level drops and the EWS START electrode is completely exposed a signal is sent to the EWS to begin

operation. EWS operation continues until the tip of the EWS STOP probe is submerged.

Note: EWS responds to electronic water level control signals only when in Automatic Mode

EWS Bypass

In the event the EWS cannot keep up with water demand, makeup water will flow through the bypass to maintain evaporative

cooling system operation. Bypass valve will open (powered) if the water level falls below the “Bypass On” probe tip. The bypass

valve remains open until water level rises to the EWS Start probe.

Note: Bypass water has not been treated by the EWS and may affect desired cycles of concentration

Hi Level Alarm (By Others)

The 5-probe EWLC is equipped with a high-water level relay and probe. High water level is sensed when the high alarm probe

tip is submerged. The high alarm relay can be connected to a user supplied device such as a warning light or audio alarm.

Note: Refer to Troubleshooting section if high level alarm frequently occurs

Touch Screen Display

A backlit LCD touch screen is mounted under a protective cover on the Water Saver Control Panel. The screen displays

operating status and data. Select the desired item by pressing the icon on the screen.

Home Screen

The Home Screen displays the present operating mode (Auto or Manual), current operating status (Operating, Standby), and

Active program. The display also provides icons to view other screens.

Figure 18: Sample Home Screen

User Display

19

User Display (Continued)

Operating Data Screen

The Operating Data screen can be accessed from the bottom center of the home screen. No login is required to access the

data. It shows conductivity, ion reduction, recovery, water meter, operating mode, system status, and valve status. Return to the

home screen by hitting the “Back” button at the bottom right.

Figure 19: Sample Operating Data Screen

Alarms Screen

The Alarms screen displays alarm history. When an alarm condition occurs a pop-up window alerts the user of a new alarm. To

acknowledge a current Alarm, select the “Acknowledge” icon. The new alarm is added to the Alarm History. Alarms can be reset

by selecting the “Reset” icon.

Figure 20: Sample Alarm Overview Screen

Alarm Configuration

Alarms are preset from the factory for seven operating attributes to alert users of system changes or equipment malfunction: Inlet

Conductivity, Outlet Conductivity, System Pressure, Flow Rate, Water Temperature, Power Supply Current Output (Amps).

Some alarms will shut down the EWS to minimize damage to the system.

20

The EWS records system operational data and stores it on USB drive as a .csv file. Periodically a window will appear indicating

that data is being written to the drive. For most systems the USB drive has enough capacity to record operation data for 2 – 3

years.

Startup Procedure

Contact your Factory Authorized Service Provider two weeks prior to needing Water Saver startup.

Shutdown Procedures

Temporary Layup or Shutdown

The Water Saver must be flushed when it has been idle (standby) for 7 consecutive days.

Extended Layup or Shutdown

For extended periods of inactivity (seasonal) EWS plumbing and cylinders should be flushed to prevent fouling. Cylinders must

be kept wet during layup. DO NOT drain or layup the system dry. Damage to cylinders may result. Contact your Factory

Authorized Service Provider to arrange for extended layup treatment.

Turning Off Power to EWS

To turn off the Water Saver, perform the following:

x

Move the service disconnect handle on the Control Panel to the OFF position

Restarting Power

To restart the Water Saver, perform the following:

x

Move the service disconnect handle on Control Panel to the ON position.

x

Wait for the Home screen to be displayed (~ 20 seconds)

x

Place system in Automatic Mode

o

Select “Begin Auto Operation” icon

Routine maintenance is required to maintain EWS system performance over time. Keep panel, piping and components clean by

wiping with a soft damp cloth, as needed. Do not use solvents or cleaners unless directed.

Description

Service Interval

Control Panel Air Filter Cleaning Quarterly or as needed

Pressure Regulator Valve Cleaning Quarterly or as needed

Inlet Water Meter Cleaning Quarterly or as needed

Outlet Water Meter Cleaning Quarterly or as needed

Verify In-Line Conductivity Probes Monthly

Conductivity Probe Calibration Quarterly or as needed

Clean in Place (CIP) Every 2-4 months

Table 4: Maintenance Requirements

Data Logs

Startup and Shutdown

Maintenance

This manual suits for next models

8

Table of contents

Popular Water System manuals by other brands

Everpure

Everpure QL2-OCS2 Specification sheet

DIG

DIG ST100AS installation instructions

Zip

Zip HydroTap G5 Touch-Free Wave installation instructions

Daikin

Daikin EKSV21P Planning and installation instructions

Halsey Taylor

Halsey Taylor HBW8AQ 1M Series manual

Spectra Watermakers

Spectra Watermakers Newport MkII Deluxe installation instructions