7vwr.com I Instruction manual VWR® G Water System

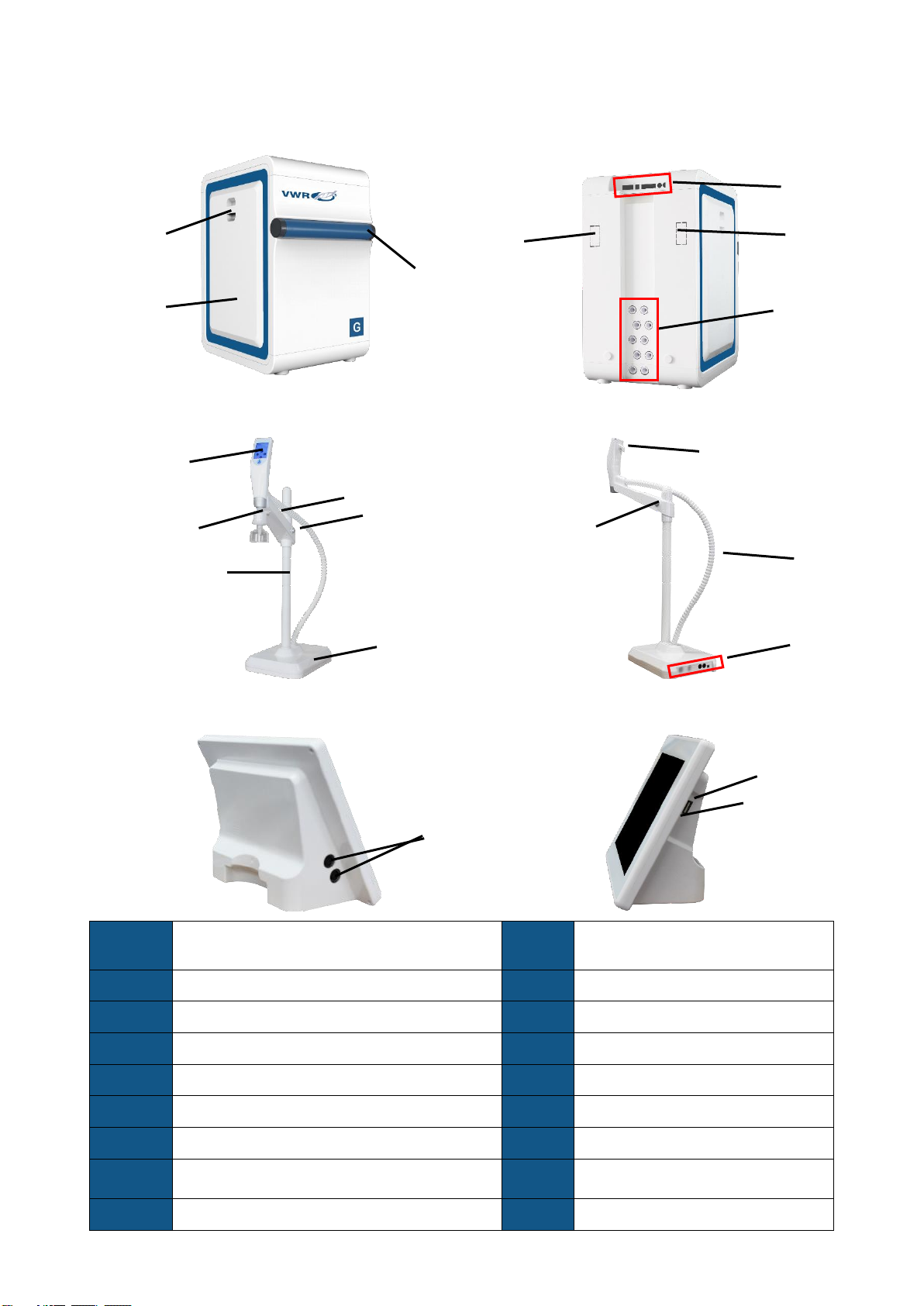

1.2 Product Features

The VWR G ultrapure water system provides an integrated solution for lab water supply. This

system is easy to install, easy to operate and easy to maintain.

This system has the following features:

◆Type I ultrapure water and EDI (Type II) water are produced directly from tap water.

◆The system can be linked to multiple dispensers via cable or wireless.

◆Internal P Pack cartridge removes oxidants, organics, particles and scaling ions to prevent

them from fouling the RO membranes and the EDI module.

◆Alarm will lit if RO permeate does not meet preset quality standard (SP) to protect the EDI

module.

◆The RO drain water is reused to increase the water yield. It is more environmentally friendly.

◆Internal Ion-Pure EDI module removes most ions and organics from RO water.

◆Ultra purification cartridge is filled with media to remove trace ions and organics.

◆Built-in 254 nm lamp kills bacteria and 185/254 nm dual-wavelength lamp reduces TOC level

in ultrapure water.

◆On-line TOC monitor is based on complete oxidation method to obtain a more accurate

measurement of the TOC.

◆Various final filters (optional) can ensure ultrapure water without particles, bacteria or

pyrogen.

◆Tank recirculation mode (optional) from a touch on the monitor guarantees high water quality

in storage.

◆RFID tags ensure perfect placement of consumables and trace their performance.

◆The control console is an 8-inch touchscreen. The console controls system and peripheral

devices (such as dispensers and tank sanitization module). All operations can be done on

the console.

◆Water quality, operation parameters, the status of the system, dispensers, components, and

peripheral devices are stored and displayed on the large colour touchscreen monitor.

◆The console screen and dispenser screens are water-proof. You may operate the console

and dispenser with wet latex gloves on.

◆Signature verification is required for maintenance and service.

◆VWR provides full documents support to meet user’s GMP, GSP, GAP, GCP, GLP

requirements.