EVCO S.p.A. EVDRIVE06 | User manual ver. 1.0 | Code 144EPD4I114

Page 3 of 78

Index

1INTRODUCTION ...................................................................................................................................5

1.1 Introduction ........................................................................................................................................5

1.2 Summarizing table of the main features and available models ...................................................................6

2DESCRIPTION......................................................................................................................................8

2.1 Description..........................................................................................................................................8

3SIZE AND INSTALLATION......................................................................................................................9

3.1 Size....................................................................................................................................................9

3.2 Installation........................................................................................................................................10

3.3 Additional information for the installation ..............................................................................................10

4ELECTRICAL CONNECTION ..................................................................................................................11

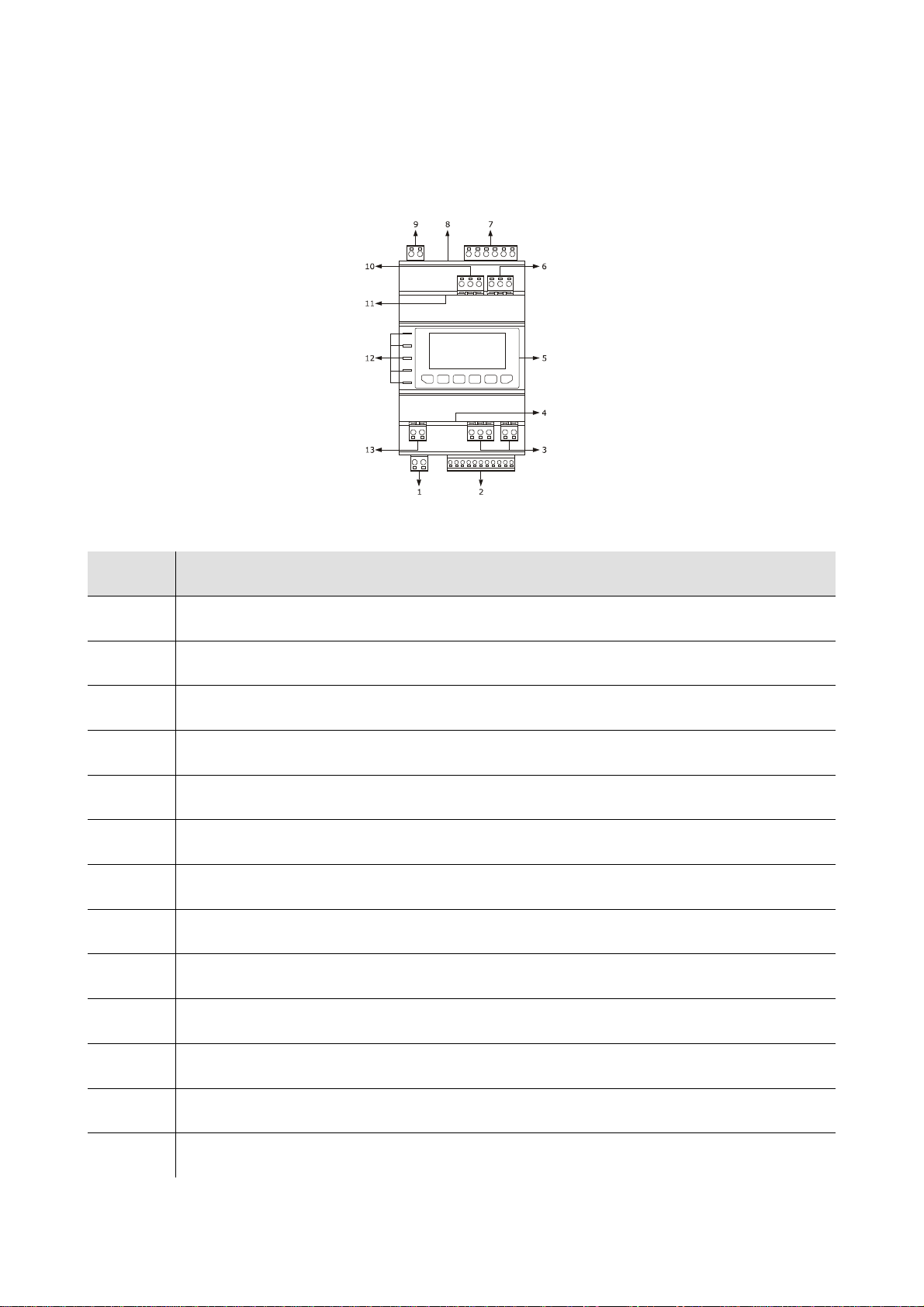

4.1 Meaning of the connectors ..................................................................................................................11

4.2 Example of electrical connection ..........................................................................................................15

4.3 Additional information for electrical connection ......................................................................................16

5USER INTERFACE...............................................................................................................................17

5.1 Preliminary information.......................................................................................................................17

5.2 Keyboard (not available in the blind versions)........................................................................................17

5.3 Signalling LEDs..................................................................................................................................17

6OPERATION.......................................................................................................................................19

6.1 Switch on and resynchronization..........................................................................................................19

6.1.1 Refrigerant selection...................................................................................................................19

6.1.2 Valve selection...........................................................................................................................20

6.1.3 Operation ..................................................................................................................................21

6.2 Operating mode.................................................................................................................................22

6.2.1 Preliminary information ...............................................................................................................22

6.3 Stand-by and operation mode selection ................................................................................................23

6.4 Enabling EVDRIVE06 ..........................................................................................................................23

6.5 Analog inputs ....................................................................................................................................24

6.6 Analog positioner control.....................................................................................................................25

6.7 Algorithm start-up..............................................................................................................................26

6.8 Manual mode.....................................................................................................................................26

6.9 Debugging mode................................................................................................................................27

6.10 Control algorithm ...........................................................................................................................27

6.10.1 Superheat control algorithm ........................................................................................................27

6.10.2 Hot gas bypass algorithm ............................................................................................................29

6.11 Alarm relay....................................................................................................................................30

7CONFIGURATION ...............................................................................................................................31

7.1 Unit of measurements ........................................................................................................................31

7.2 Configuring a built-in version...............................................................................................................31

7.2.1 User menu.................................................................................................................................32

7.2.2 Installer menu ...........................................................................................................................33

7.2.3 Manufacturer menu ....................................................................................................................33

7.3 Configuring a blind version..................................................................................................................35

7.4 Main menu........................................................................................................................................36

7.5 Connecting the device through the set-up software system Parameters Manager .......................................37

7.6 Backup and restore ............................................................................................................................38

7.6.1 Configuring the device through an USB flash drive..........................................................................38

7.7 Reprogramming.................................................................................................................................39