Everhard Industries 82202C Instruction manual

Date

: 21/09/2016

1 of 5

Released/Product Information/Pumpwell

(Poly) V1.0

POLYMER PUMP WELL

1000 L

82202C

Tested to comply with AS/NZS 1546.1 (2008)

Assembly and Installation Instructions

for on-site domestic waste-water treatment and disposal systems

PARTS SUPPLIED WITH EACH POLYMER PUMP WELL:

1: 1 x moulded Plastic Pump Well Assembly

2: 1 x moulded Plastic Access Cover

3: 6 x Stainless Steel Screws

4: 2 x standard elastomeric rubber rings for 100mm uPVC SWV pipe

PARTS SUPPLIED WITH EACH RISER KIT:

5: 1 x 600mm x 630mm dia Ribstruct

6: 6 x Stainless Steel Screws

7: 1 x Black Butyl Joint Tape (97681)

(Complete single pump and duty/standby pumpwell kits are available on request)

* Check with your local authority before selecting any part of a Waste-water disposal system.*

Refer Notes on back page.

The Polymer Pump Well should be located in areas not exposed to any vehicle or regular pedestrian

traffic. It should be installed in an area set aside for garden use, and finally covered with bark or garden

mulch after installation is complete. Where the Pump Well is in a high water table area extra anchorage

may be required. See "ANCHORAGE".

Australian

Standard

AS/NZS1546.1

Lic 1950

Septic Tanks

Date

: 21/09/2016

2 of 5

Released/Product Information/Pumpwell

(Poly) V1.0

PREPARATION

Ensure that –

appropriate approvals have been given by local authorities.

appropriately qualified persons, including electricians and plumbers, are employed to install and connect

the pumpwell.

We recommend that all holes cut in the pumpwell are made leak proof using rubber o-rings (provided), rubber

seals or bulk head fittings.

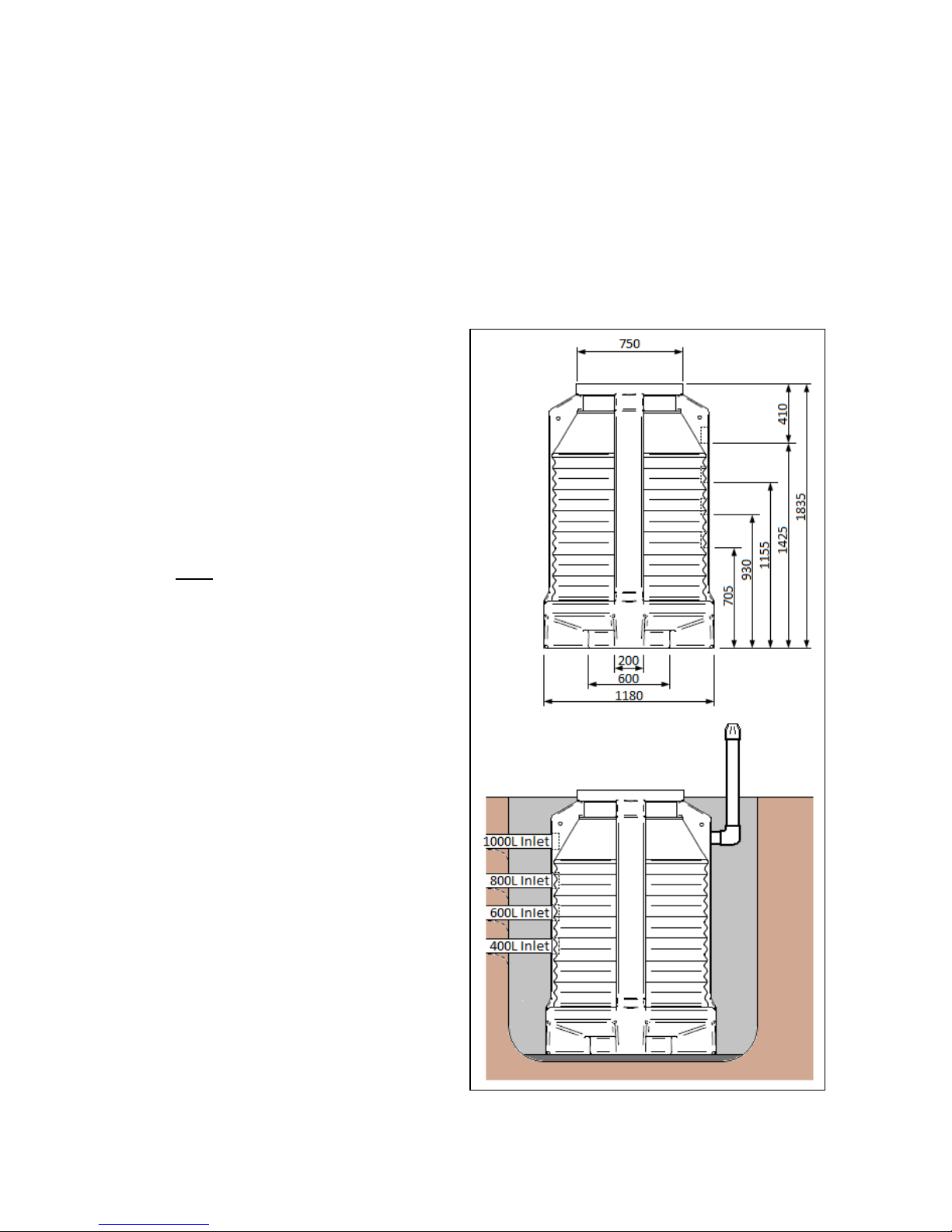

The pumpwell has three additional flat vertical areas that allow inlets to be cut into the pumpwell. These should

be sealed with an appropriate rubber seal or silicon.

SAFETY

Take care when working around excavated holes.

Deep holes can be considered confined

spaces. Consult with local/state laws and

make provisions as appropriate.

An empty pumpwell weights in excess of

70kgs. Take appropriate precautions when

manually handling the pumpwell.

Always use lifting holes to lower the pump

well into the excavated hole

SITE ASSESSMENT

Take note of the invert heights of the available inlets

into the pumpwell and ensure that the incoming

100mm drainpipe is appropriately supported and

allows for wastewater to flow directly into the

pumpwell.

Site MUST be away from areas susceptible to all

vehicular and foot traffic.

THE EXCAVATION

a) Prepare excavation greater than 1500mm

diameter up to 1900mm deep (Deeper holes may be

used when a riser is fitted). Sides and bottom should

be free from all intruding roots, stones, or other

matter.

b) Determine which of the inlet Connection Ports is to

be used. This will depend on the depth of the pipe

from the wastewater source at the point where it

meets the Pump Well.

c) Trench excavation should be widened for

vent connection (see below)

pumped water discharge

electrical connections

d) Line the bottom of the hole with 50mm of sand or

3mm pea gravel

PUMPWELL PREPARATION

a) Cut out the Inlet opening selected using an

appropriately sized hole saw.

b) Venting of the upstream pipe is usually adequate

for most installations. Where needed, a vent port to

suit the required pipe size may be cut in the side of

the pumpwell and may be secured using a bulk head

fitting.

c) Cut hole to accept selected pump discharge hose

or pipe fitting. This hole is normally in any vertical

face of the pumpwell. The size of the hole will be

dependent on the diameter of the discharge pipe

b) Cut the hole to accept the glands selected for the

electrical cable and flexible conduit. This should be

close to the side of the Pump Well to minimise the

exposed electrical conduit.

Date

: 21/09/2016

3 of 5

Released/Product Information/Pumpwell

(Poly) V1.0

POSITIONING AND FITTING OUT THE PUMP WELL

a) Remove the access cover and clear all cuttings from the interior of the pumpwell

b) Fit vent and discharge attachments as required

c) Using the lifting holes, carefully lower the pump well into the excavated hole, seating the base of the pump well

into the sand bed.

d) Connect the 100mm drain pipe to the pump well.

e) Fit out pump as required.

f) Fit access cover ensuring all screws are secure.

BACKFILL

a) Backfill around the pump well, compacting as you go, ensuring that the pump well remains level and the pipe

work is not damaged.

b) In areas that are effected by high water tables, the first 500mm must be backfilled using a concrete.

d) Use excess soil to build a bund above the pumpwell to divert stormwater away from the installation.

FURTHER RECOMMENDATIONS FOR INSTALLATION

Where the required depth to the pipe invert makes the Pump Well lower than normal, a Riser can extend the

access opening to surface level. This is EVERHARD Ribstruct 600mm pipe fitted with a top collar, secured by

screws, which accepts the standard Access Cover. The Pump Well access rim should be cut off with a saw,

leaving a plain upstand of about 20mm. The Ribstruct is trimmed to the required length, leaving a rib-flange at the

lower end. Apply the black butyl joint tape to the rim of the open access hole and push the firmly down over the

upstand. Secure using six equally spaced Stainless Steel self-tapping screws. These must be driven down

through the rib-flange into the top of the Pump Well to secure the Riser.

ANCHORAGE

On most normal sites, the backfill over the Pump Well skirt described above will be adequate. However, where

the location is exposed to regular flooding or has high water table conditions, it may be necessary to provide

extra anchorage to prevent the Pump Well from moving if the soil is saturated and fails to remain as a solid

homogenous mass.

A quantity of concrete may be poured into the excavation and around the Pump Well to encase the vessel.

A concrete tube of 1220mm (outside diameter) and 850mm high around the vessel will have a mass of about

700kg, which will be sufficient to overcome the buoyant effect of a free-floating empty Pump Well.

Date

: 21/09/2016

4 of 5

Released/Product Information/Pumpwell

(Poly) V1.0

IMPORTANT NOTES

"Pump Well" is a generic term for any vessel intended to temporarily store liquid before it is transferred by means

of a pump to another location, perhaps for processing or long-term storage. The EVERHARD Polymer Pump

Well has been tested and found to comply with the Australian/New Zealand standard for vessels such as Septic

Tanks and Collection Wells for use in domestic, and some other, situations.

It may be used to receive treated wastewater from a Septic tank for pumped discharge to a disposal area, or in

applications where site conditions dictate that short-term accumulations of “All-waste”, “Black-water” and/or

“Greywater” (defined by AS/NZS 1546.1) wastes must be delivered to a treatment system by a suitable pump

instead of free-flowing under gravity direct from the source.

Installers MUST check with your local authority to ensure that this pump well and usage will be permitted

in your area before beginning plans for any installation.

The EVERHARD Pumpwell was designed for on-site treatment and disposal applications. It is tested for

Standards Mark approval and does not carry WaterMark certification. Connection to sewer systems, and

installation in sewered properties, may not be permitted by local authorities.

The EVERHARD 250/450L Plastic Pump Well has a number of features which make it an obvious choice for

many installations. It is light and easily handled and worked with, while also being durable and tough. Produced

from a blend of polymer that has been stabilised against ultra-violet light degradation, its physical characteristics

allow the product to exceed the required performance criteria for the applicable tests in AS/NZS 1546.1.

In testing for resistance to lateral load, a critical part of the standard, the EVERHARD Polymer Pump Well was

subjected to side loading equivalent to the vessel being completely buried, a situation which a correctly installed

unit should never encounter. The Polymer Pump Well remained intact and suffered no permanent damage

whatsoever, despite extended exposure to the test load.

EVERHARD Polymer Pump Wells are ideally matched for use with the range of EVERHARD Polymer Septic

Tanks and Collection Wells, all produced in accordance with AS/NZS 1546.1. Other products available for

domestic wastewater applications include the popular EVERHARD Xtra-treat Filter which can be quickly and

easily fitted into the Outlet Fitting inside most Septic Tanks. These help prevent the discharge of solid particles

suspended in the treated fluid. An Xtratreat Filter can greatly extend the service life of the disposal system. The

EVERHARD range of disposal system equipment also includes effluent Distribution Boxes in Concrete and in

durable, tough Polymers. These complement the cost-effective and very efficient Polymer EVERTRENCH Trench

Liner for use in Evapo-Transpiration and Soakage treated waste-water disposal systems.

Date

: 21/09/2016

5 of 5

Released/Product Information/Pumpwell

(Poly) V1.0

HEAD OFFICE –BRISBANE

EVERHARD INDUSTRIES PTY LTD

A.C.N. 009 690 859

405 Newman Rd. Geebung, Brisbane, 4034

PO Box 543 Virginia BC , QLD 4014

Telephone (07) 3637 6444

Fax (07) 3265 2111

EVERHARD products are also available from most reputable building

and hardware suppliers across Australia.

Table of contents

Popular Water Pump manuals by other brands

Wilo

Wilo Stratos Installation and operating instructions

Metabo

Metabo TPF 18 LTX 2200 Original instructions

Ariston

Ariston SOLARcomfort Instructions for installation and servicing

SKF

SKF LAGG 18M Instructions for use

Warren rupp

Warren rupp Sandpiper S15 Service & operating manual

Tunze

Tunze Tucbelle stream 6065 Instructions for use

Oase

Oase FP 1500 operating instructions

Aquascape Pro

Aquascape Pro AquaSurge PRO 4000-8000 Instructions & maintenance

K2 Pumps

K2 Pumps UTS03301K owner's manual

EHEIM

EHEIM 1046 instructions

Becker

Becker KVX 3.80 operating instructions

Grundfos

Grundfos SP Safety instructions and other important information