s15mdl1sm-rev1218

sa ndp ipe rpu mp.c om Model S15 Metallic • 5

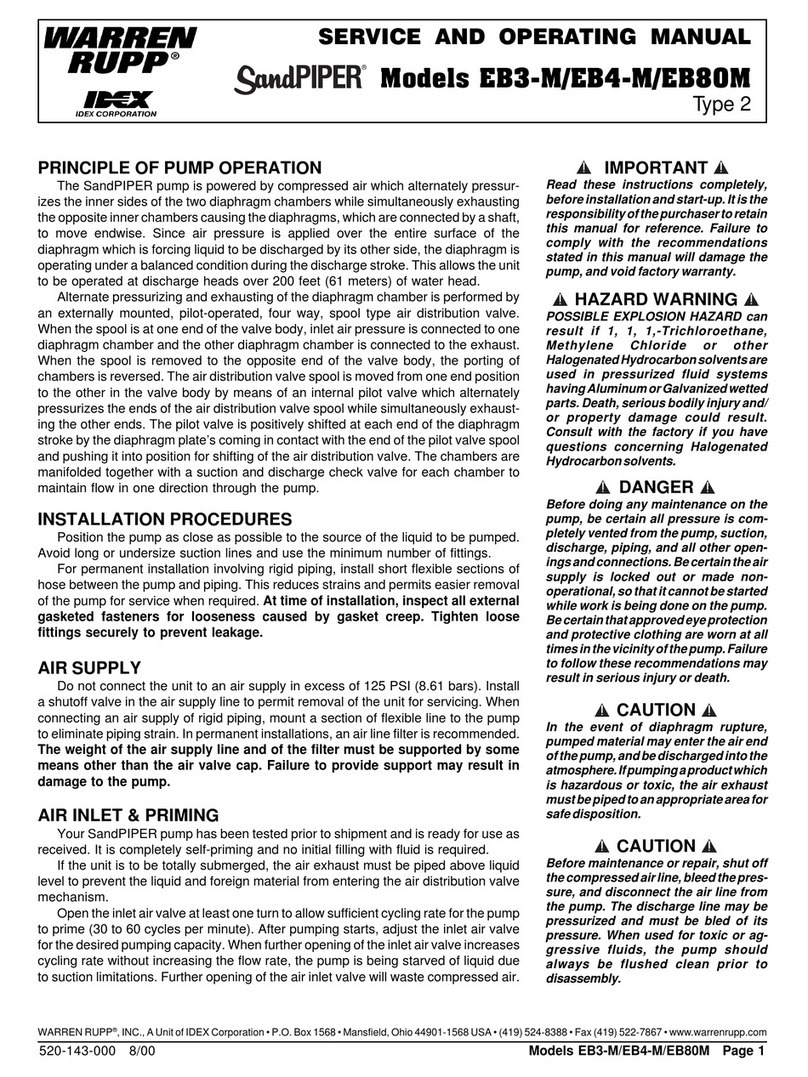

Explanation of Pump Nomenclature

ATEX Detail

Non-Wetted Material Options

A

I

J

S

Y

Z

Porting Options

N

B

R

W

Pump Style

S

Pump Options

0

6

Kit Options

Pump Brand

S ®

Pump Size

15

Check Valve Type

B

W

Design Level

1

Wetted Material

A

I

S

H

X

Diaphragm/Check Valve Materials

1

B

C

E

I

G

M

N

V

Z

Check Valve Seat

A

C

S

T

W

Your Serial #: (ll in from pump nameplate) _____________________________________

Pump Pump Check Design Wetted Diaphragm/

Check Valve

Non-Wetted

Porting Pump Pump Kit

Brand Size Valve Level Material

Check Valve

Seat Material Options Style Options Options

S XX X X X X X X X X X XX

Model #:

S

__ ____ __ __ __ __ __ __ __ __ __ ____

(ll in from pump

nameplate)

Your Model #:

IEC EEX m T4

Pump models equipped with these

explosion-proof solenoid kit options E1, E3,

E5, E7, E8 or E9, are certied and approved

by the above agencies. They are NOT ATEX

compliant.

ATEX Details

Wetted

Material

Options

Non-Wetted

Material

Options

Pump

Options

Options

C

ATEX Details

Wetted

Material

Options

Non-Wetted

Material

Options

Pump

Options

Options

ATEX Details

Wetted

Material

Options

Non-Wetted

Material

Options

Pump

Options

Options

ATEX Details

Wetted

Material

Options

Non-Wetted

Material

Options

Pump

Options

Options

C

C

C

C

ATEX Details

Wetted

Material

Options

Non-Wetted

Material

Options

Pump

Options

Options

C C

C C

C C

C C

ATEX Details Construction Options

CA

CA

ATEX Details

Wetted

Material

Options

Non-Wetted

Material

Options

ATEX Details Construction Options

ATEX Details Construction Options

ATEX Details Construction Options

ATEX Details Construction Options

ATEX Details Construction Options

ATEX Details Construction Options

ATEX Details Construction Options

ATEX Details Construction Options

1: PUMP SPECS