evolution models FUSION3 User manual

0

Instruction Manual

FEATURES

•Precision Laser Cut Parts

•Lightweight Strong Airframe

•Excellent Low Speed Stability

•Comprehensive Instruction Manual

•High Quality Balsa, Ply and Depron Parts

•Excellent Precise Handling Characteristics

•High Quality Comprehensive Hardware Pack

1

Introduction

Evolution Models released the first Fusion in 2008, the Fusion I was designed

with many years of Fun Fly experience. We would like to take this

opportunity to thank all those that have supported us over the last 15

years.

The Fusion III has taken those comments made by our customers and develops them into the New

Fusion package. These comments along with hours of testing and development we have

improved the strength, durability and overall performance of the model. For those who owned the

original Fusion II you will note the changes, some of them are only minor, such as the length of Tail

moment. Other major developments such as the wing section, full length rudder and wing tip

fences take the Fusion III to the next level of Fun Fly design. We listen to our customers to improve

our products, so if you have anything you wish to share, please let us know.

The Evolution Fusion has been designed predominantly for the Fun Fly enthusiast and based on

competition flying. The Fusion III as its predecessors will loop on the spot, roll in the blink of an eye

and inspire confidence as it remains rock solid and stable. This model that has been designed to

be highly manoeuvrable, but also to be attractive with style and flair.

The laser cut parts simply slot together to provide a lightweight structure without compromising

strength. The Fusion is simple and satisfying to build for the amateur and experienced builder.

Each kit contains a comprehensive hardware pack that includes metal clevises, closed loop

systems, hinges, hatch latch, and horns to name but a few.

The Evolution Fusion has been designed to meet the needs of the Fun Fly competition pilot in an

attractive package. We hope that you have as much fun building and flying it as we have had

developing it further!

Building Recommendations

Check all parts from the box to ensure that they are present, if not then please contact us at the e-

mail address at the back of the instructions. We do from time to time make mistakes!!

Ensure that you use a completely flat base on which to build the model, this should be large

enough the build the wing 50” (1270mm) x 16” (400mm) as a minimum.

Read through the instructions before starting to build, understand each step before applying glue.

The glue detailed in the instructions is for a guide only, this is what we used for the prototypes, it is at

the builder discretion which glue is used but ensure that it is suitable for the intended purpose.

Always read the application instructions to ensure you achieve a strong joint. Depron is a foam

material; Standard Cyano will attack and melt it, always use foam safe glue or wood glue. Always

read the safety instructions supplied with the glue.

Balsa is a hardwood and you should make yourself aware of the precautions required when

handling and shaping this type of wood. Always wear an appropriate mask and work away from

others or use a suitable extraction system.

Take your time building the model, build a straight and strong model, this will ensure the model will

fly well!

2

Enjoy. Building is part of aero modelling!

This radio-controlled model is not a toy. It can cause serious injury to the operator, public and

property if misused or abused. Ensure that you read all the instructions supplied with this kit and

instructions provided with the engine/motor and radio control system or any other components

purchased separately carefully. Also, make sure that any parts bought separately are suitable for

their application.

The kit contains small and potentially sharp parts, keep away from children.

Additional Materials Required

Recommended Tools

Standard Thin or Medium Cyano

Aliphatic White Wood Glue

Epoxy Resin

Tinned Copper Wire (For Undercarriage)

Solder

Heat Shrink Covering Material

Engine Mount and Engine or Motor,

Battery and ESC

Radio Gear –4 servo’s, Receiver and

Battery (or BEC)

Modelling Knife

Razor Plane

Set Square

Shaping tools

Blow Torch

Drill

Drill Bits

Building Board –Completely flat 1000 x 400mm

Bradawl

Wood Pack

Hardware Pack

Description

Sheet Size

Quantity

Metric

Imperial

Webbing Sheet

1.5 x 100 x 915mm

1/16 x 4 x 36”

1

Leading and Trailing Edge Sheet

1.5 x 100 x 1220mm

1/16 x 4 x 48”

2

Leading Edge

6 x 20 x 1220mm

¼ x ¾ x 48”

1

Wing Spars and Trailing Edge Spar

6 x 6 x 1220mm

¼ x ¼ x 48”

3

Wing Centre Section and Tip Sheet

1.5 x 75 x 915mm

1/16 x 3 x 36”

2

Fuselage Bottom and Top Deck Sheet

3 x 75 x 915mm

1/8 x 3 x 36”

1

Rib Capping Strips

1.5 x 6 x 915mm

1/16 x ¼ x 36”

5

Aileron/Elevator/Tail Plane Rib Strip

9.5 x 6 x 915mm

3/8 x ¼ x 36”

2

Fin and Rudder Rib Strip

12 x 6 x 915mm

½ x ¼ x 36”

1

Fuselage Triangular Fillet

9.5 x 9.5 x 915mm

3/8 x 3/8 x 36”

4

Description

Quantity

Metal Clevis (M2)

6

Metal Control Rod (M2) and nuts

2

Snap links

2

Control Horns

6

Single Saddle Clamp 10 swg and screws (8)

4

Hatch Latch and Screw

1

Closed Loop Kit (4 adaptors, 4 nuts, 8 ferrules, 2 x 1.8m wire)

1

Mylar Hinge Strip

1

Servo Mount Spruce 6 x 6 x 25mm (¼ x ¼ x 1”)

2

Wing Dowels 8 x 95 and 8 x110mm

1

Captive Nuts (Four for motor mount and four for wing fences)

8

M3 x 10mm Bolts for Wing Fences and Washers

4

10 SWG Elevator Joiner

1

Captive nuts for motor mounting

4

3

Fusion III Part List Laser Cut Sheets

Some parts may be relocated on sheets without notice, please make sure you locate

each part carefully

4

Part No.

Description

Sheet Material

1

Fin Base

6mm (1/4”) Balsa

1a

Fin / Tailplane Interface

6mm (1/4”) Balsa

2

Fin Leading Edge (LE)

6mm (1/4”) Balsa

3

Fin Trailing Edge (TE)

6mm (1/4”) Balsa

4

Rudder LE

6mm (1/4”) Balsa

5

Fin top

6mm (1/4”) Balsa

6

Fin Base

6mm (1/4”) Balsa

7

Fin TE

6mm (1/4”) Balsa

8

Tailplane LE

6mm (1/4”) Balsa

9

Tailplane Centre

6mm (1/4”) Balsa

10

Tailplane Tips (2)

6mm (1/4”) Balsa

11

Tailplane TE

6mm (1/4”) Balsa

12

Elevator LE (2)

6mm (1/4”) Balsa

13

Elevator Inner

6mm (1/4”) Balsa

14

Elevator TE

6mm (1/4”) Balsa

14a

Elevator Tips

6mm (1/4”) Balsa

15

Elevator, Rudder and Aileron Horn Doublers

1.5mm (1/32”) Ply

16

Main Fuselage Side

3mm (1/8”) Balsa

17

Fuselage Wing Fillet

3mm (1/8”) Balsa

18

Fuselage Doublers

1.5mm (1/32”) Ply

19

F2

3mm (1/8”) Ply

20

F1 - Front

3mm (1/8”) Ply

21

F1 - Rear

3mm (1/8”) Ply

22

UC Plate - Front

3mm (1/8”) Ply

23

UC Plate - Separator

3mm (1/8”) Balsa

24

UC Plate - Rear

3mm (1/8”) Ply

25

Hatch Plate

3mm (1/8”) Ply

26

Tail Skid

3mm (1/8”) Ply

27

Aileron Servo Plates (2)

3mm (1/8”) Ply

28

Aileron Leading Edge (2)

6mm (1/4”) Balsa

29

Aileron Horn Support (2)

6mm (1/4”) Balsa

30

Aileron Inner Tips (2)

6mm (1/4”) Balsa

31

Aileron Outer Tip (2)

6mm (1/4”) Balsa

32

Aileron TE

6mm (1/4”) Balsa

33

Wing TE Protector

6mm (1/4”) Balsa

34

Wing Tip Fence (2)

6mm (1/4”) Balsa

35

Wing Tip Fence Doubler (2)

6mm (1/4”) Balsa

W1

Centre Ribs (4)

6mm (1/4) Depron

W2

Inner Servo Mounting Rib (2)

6mm (1/4) Depron

W3

Outer Servo Mounting Rib (2)

6mm (1/4) Depron

W4

Outer Ribs (8)

6mm (1/4) Depron

W4A

Wing Tip Rib (2)

3mm (1/8”Ply

5

Description

Quantity

Undercarriage Front Leg

1

Undercarriage Rear Leg

1

Undercarriage Support

2

Tail Skid

1

Front Leg 10 swg

Rear Leg 10 swg

Piano Wire U/C

Fusion Parts List

Supports 10 swg

Tail Skid 16 swg

6

Building Instructions

The laser is set to the minimum setting to minimise any ‘V’cut in the balsa, please check and run a

knife through any areas that require releasing and the tabs that hold the part in the sheet.

Fin and Rudder

Take the three parts that form the Fin and Rudder (Parts 1, 1a, 2, 3, 4, 5, 6, 7 and 15(2)), trial fit

before gluing together. With the supplied strip of 6 x 12mm (1/4” x 1/2”) cut to length to form the

centre ribbing pieces. Mark a centre line on the Rudder leading edge and chamfer to a 45° angle

with a Razor Plane. Glue the 1/32” (1.5mm) doublers placed to strengthen the horn points where

the chamfered edge ends.

All Parts Laid in Position

Glue applied to form the main structure

Riblets installed using 12 x 6 x 915mm (1/2 x ¼ x

36”) strip.

With a sharp knife cut the slots for four hinges (including one underneath the tailplane) 10mm (3/8”)

from the top and bottom. This gap should be parallel for the full length of the Rudder. Cut 10mm

(3/8”) strips from the supplied Mylar hinge material and insert into the hinge slots; 50% in the Rudder

and 50% into the Fin. Ensure that you get at least 45° free movement either way. Do not glue the

hinges in at this stage! Cover both parts with your chosen covering first.

Shape all parts to a smooth finish and round off the leading edge of the Fin ready for covering.

Glue the 1/32” (1.5mm) doublers placed to strengthen the horn points where the chamfered edge

ends.

Before gluing any hinges in position fully finish the model, the mylar strip surface should be

‘roughened ‘with sandpaper to aid adhesion.

7

Tail Plane and Elevator

Take the pre-cut parts (Parts 8, 9, 10(2), 11, 12(2), 13(2), 14(2), 14a(2) and 15(4)) which form the Tail

Plane and Elevator, trial fit, ensure the tips are at 90° to the leading and trailing edge before gluing.

With the supplied strip of 6 x 9.5mm (1/4” x 3/8”) cut to length to form the fourteen ribbing pieces,

glue in place. The 1/32”(1.5mm) doublers placed to strengthen the horn points. Do not glue the

Elevator to the Tail Plane; theses should be 3 separate pieces!

With a pencil mark the centre line of the leading edge of the Elevator and chamfer to a 45° angle

with a razor Plane ready to receive the hinges. Glue the 1/32” (1.5mm) (Part 15) doublers placed to

strengthen the horn points where the chamfered edge ends.

All Parts Laid in Position

Glue applied to form the main structure

Riblets installed using 9.5 x 6 x 915mm (3/8 x ¼ x

36”) strip.

With a sharp knife cut the slots for three hinges in each elevator 10mm in from either end and

evenly spaced, ensure that the Elevator sits centrally on the Tail Plane. Cut 3/8”(10mm) strips from

the supplied Mylar hinge material and insert into the hinge slots, 50% in the Elevator and 50% into

the Tail Plane. Ensure that you get at least 45° free movement either way. Do not glue the hinges in

at this stage!

With the elevators attached to the tailplane mark

the position if the wire joiner so that it fits centrally.

Remove the two shaded areas to allow the wire

joiner to sit flush with the leading edge of the

elevators.

Drill to holes to accept the wire joiner

Insert the wire joiner and epoxy in position. Make

sure both sides are flat and level.

8

When test fitting the above parts to the fuselage a notch will be required in the rudder there the

wire joiner passes through. Make sure the notch is big enough to allow full movement of the

rudder.

Shape all parts to a smooth Finish and round off the leading edge of the Tail Plane ready for

covering.

Fuselage

Lay the two Fuselage sides (Parts 16(2)and 17 (2)) on the work bench ensuring that you have a left-

and right-hand side. With a thin layer of glue attach the 1mm (1/32”) ply doubler (Part 18(2)).

Weigh down to ensure that the parts cannot ‘curl’ and to allow dry. Glue the reinforcement rails

(Part 18a (2)) to the ply doublers, ensuring there is a 6mm gap to allow F1 to fit between the sides.

Flush with cut out to allow F1

Using the 9.5mm (3/8”) triangular fillet, glue to the outer edge of the Fuselage shown hatched

below, including over the ply reinforcement runners. Make cuts in the fillet to allow it to follow the

bottom curve of the Fuselage.

Check your chosen servo fits in the pre-cut slots and test fit F2 (Part 19) slots into the Fuselage. The

front servo sits on the two pieces of 6 x 6mm (¼ x ¼) spruce supplied in the hardware pack. These

can be glued in place now or when fitting the servo later.

Glue the two parts for F1 (20 and 21) together so that the holes are aligned. The smaller in height F1

(20) faces forward. Drill holes to suit your chosen motor mount and install the supplied captive nuts

9

into the back (inside the fuselage). We suggest gluing the nuts in place to prevent them falling out

when installing the bolts.

F1 should be placed with the three wire holes set towards the bottom of the Fuselage.

With F1 and F2 in place the Fuselage sides should taper back, the gap should be approximately

25mm and the sides should remain straight. Once satisfied that both F1 and F2 fit correctly glue in

place using epoxy. We have found this easier by gluing F2 to one side of the Fuselage first and

allowing to dry before offering the other side and inserting F1. Ensure that F1 is 90° to the centre line

of the Fuselage. We suggest using a Jig such as the SLEC building jig to ensure the fuselage is

straight(www.slecuk.com/building-jig).

We have shown standard servos fitted in the Fuselage but recommend that you use a good quality

mini/micro servo to reduce weight. Ensure the mini/micro servo is of the same or better

specification as a standard servo.

Once the epoxy has set, install the top decking using the 3 x 75 x 915mm (1/8 x 3 x 36”) sheeting

cross grain to the Fuselage, ensuring the rear Fuselage remains square and the cut out for the Fin

remains along the Fuselage centre line.

With epoxy glue the front ply (Part 22), centre balsa separator (Part 23) and rear ply (Part 24)

undercarriage plates into position.

Take the battery hatch floor (Part 25) level the ply U/C mount and mark the ends as shown below.

Remove the section of triangular balsa, leaving the ply reinforcement runners in place, and plank

with the 3mm (1/8”) sheet from this point to the back of the Fuselage.

Hatch tab locates under here Fit hatch latch here

Draw line here

Remove triangular strip

10

Plank the bottom of the hatch floor with 3mm (1/8”) balsa except for the tab Test fit the hatch latch

by drilling a hole in the rear edge of the U/C plate as shown above. Cut the inner bush to allow the

latch to swing with resistance once the screw is fully seated.

Do not place balsa sheet under the tab

Shape the Fuselage to shape rounding off the top and bottom decking and shape the top deck at

the front down to 1mm (1/16”) where it meets the wing.

Lay the Tail skid (Part 26) on the bottom of the Fuselage and mark the distance from the rear, cut a

slot 3mm (1/8”) wide to accept the skid along the centre line of the Fuselage. Repeat this process

to fit the fin. Slot the Fin in from the top and ensure that the parts mate within the Fuselage. Glue

scrap pieces of ply either side of the Tail skid slot to prevent the Tail skid wire rotating as in the

picture below. Ensure that they are not too large to slide into the Fuselage.

Adjust to suit before gluing in the skid with epoxy. Do not glue the Fin in at this stage. Ensure that

the Tail Plane can fit into the Fuselage slot and the Fin slot without fouling.

Wing and Aileron

We recommend building the entire wing with Aliphatic Wood Glue. It is generally fast setting and

can be shaped at the same rate as balsa.

Cut each piece of webbing from the supplied sheet of 1.5mm x 100mm x 915mm (1/16” x 4” x 36”)

as per the spacing shown below, making sure that all the webbing is perfectly square. Each

webbing piece should be approximately 42mm (1 5/8”) high, for example cut 8 No. webbing

pieces 100 x 42mm (4” x 1 5/8”), 2 No. at 25 x 42mm (1” x 5/8”) etc. The excess sheet is to be used

for wing sheeting.

11

The webbing should sit on the front of the spars, do not glue in place now, just use as a guide for rib

spacing. Carefully cut the ribs from the Depron sheet.

Dimensions shown in mm

Pin the main and trailing edge spars 6mm x 6mm x 1220mm (¼” x ¼” x 48”) to the surface. Use a

straight edge to ensure that it is completely straight and both parts are parallel. Mark the centre of

the spar and the centre of the centre webbing; pin the centre webbing to the spar and place

each rib in turn working equally on both sides, separating each rib with a webbing piece previously

cut to size as directed in the drawing above. Push the rib down onto the spar so that the rib is flush

with the board. N.B. It is important that the bottom of the rib sits flush with the bottom of the spar.

Install W1a as you proceed.

As you install W2 take a piece of paper and roll into a tube to carry the servo wires to the centre

section, this is optional, but we Find this makes the installation look tidier. These need to be inserted

as work proceeds as it is impossible to insert after all the ribs are in place. Once the tube is in

position wrap it with Sellotape to seal the edge once in position.

12

Continue to place the ribs, do not glue W4A at this stage. W4A is glued once the sheeting has

been completed and covers the whole of the wing end. Ensure that you place the correct rib in

the correct position as per the diagram above. Once dry, place the upper spar into position and

glue in place. Glue the ribs in place, check to make sure that the ribs are all vertical and at 90°.

Once dry, glue the webbing in place.

Glue the 6mm x 25mm x 1220mm (¼” x 1” x 48”) leading edge (LE) strip on to the front of the ribs.

Pin in place and allow to dry. (Step 1).

Chamfer the LE as shown below (Step 2)

Lay the 100 x 1.5 x 1220 (4 x 1/16 x 48”) sheet over the ribs so that it runs from the centre of the spar

to 1.5mm (1/16”) back from the front of the LE. Mark and cut the sheeting as shown below:

The remaining section is used for the Trailing Edge (TE). The LE sheet should be glued to the LE first

and allowed to fully dry. Lif the sheeting and appt glue to the top of the ribs and spar before rolling

the sheeting back and glue on the TE section (Step 3).

Step 1

Step 2

Step 3

Step 4

(not actual ribs foe illustration reasons only)

Area of the wing to be sheeted shown hatched below, repeat on both sides. Take the 1.5mm x

75mm x 1220mm (1/16” x 3” x 36”) sheeting supplied and sheet across the 4 centre ribs and two

outer panels.

13

Un-pin from the board and repeat the sheeting process to the underside of the wing. Once

completed cut off any excess spar, leading, trailing edge and sheeting, leave flush with the end

depron ribs

Before installing W4a install the supplied captive nuts so when fitted they are on the inside of the

wing. Secure with a epoxy.

Cut a hole in the underside of the sheeting between the two centre ribs to allow the servo leads to

exit.

Cut the 1.5mm x 6mm x 915mm (1/16” x ¼” x 36”) capping strips to length and glue in place.

Ensure good bond with the leading and trailing edge sheeting to prevent these pieces moving

independently as this will cause problems when shaping, repeat to the bottom of the wing.

Take the servo mounting plates (Parts 27(2)) from the birch ply and cut holes to suit your chosen

servos. Once satisfied the servo is a good fit, glue this piece into the wing. With scrap pieces of

9.5mm x 4.5mm (3/8” x 3/16”) glue packing pieces from the servo tray to the wing capping surface

to allow provide a surface for the covering to Finish.

14

Shape the leading edge as step 4 on page 13, continually checking the fit to the Fuselage.

Make up the wing tips/fences using parts 34 and 35 making sure to make a left- and right-hand

pair. Part 35 fits against W4a and Part 34 (the outer rim) slides over the wing as shown below.

The wing tips are removeable and installed using the supplied M3 x 10mm hex bolt and washer.

Shape the entire wing to provide a smooth, blemish free surface ready for covering. Check the fit

with the Fuselage as you go.

At this point if you would prefer you may cut off the front sheeting that passes over the wing and

glue it onto the wing itself. In the event of a hard landing, it is more likely to allow the wing to ‘shift’.

We have not done this with the prototype models, and it is left to the builder’s discretion.

Glue the 1mm (1/32”) ply doubler (Part 33) to the rear of the wing to protect the trailing edge when

the rubber bands are fitted.

Ailerons

Take the five pre-cut parts (Parts 28(2), 29(2), 30(2), 31(2), 32(2) and 15(4)) which form the ailerons,

trial fit, ensure the tips are at 90° to the leading edge, fit the trailing edge, when satisfied glue into

position. With a supplied strip of 6mm x 9.5mm x 915mm (¼” x 3/8” x 36”) cut to length to form the

ten ribbing pieces, glue in place.

Parts 15 are used to provide additional mounting support for the horn and should be glued into

position when the horns are installed.

With a pencil mark the centre line of the leading edge and chamfer to a 45° angle with a razor

Plane. With a sharp knife cut slots for four hinges 10mm in from either end and evenly spaced.

Ensure that the ailerons sit flush with the top surface of the wing. Cut 10mm (3/8”) strips from the

supplied Mylar hinge material and insert into the hinge slots, 50% in the Aileron and 50% into the

wing. Glue the 1/32” (1.5mm) (Part 15) doublers placed to strengthen the horn points where the

chamfered edge ends.

15

Repeat the above stages for the second aileron.

Ensure that you get at least 45° free movement either way. Do not glue the hinges in at this stage!

Cover both parts with your chosen covering first.

Shape to provide a smooth, blemish free surface ready for covering.

Covering

Before covering, seat the wing, Tail Plane and Fin and make sure that all fit. Make any alterations

as necessary. Finally finish all parts to provide a smooth, blemish free surface ready for covering.

This is your chance to express yourself; unlike the ARTF models on the market you can now choose

your own colour scheme. The prototype models were covered in Oracover, but the choice is

yours. Just make sure that you follow the manufactures recommendations when applying the film.

We would recommend applying a surface sealant to the area around F1 so that the film adheres

better in areas where it is likely to be exposed to glow fuel (glow version). We also recommend that

you apply a glow fuel sealant to the radio compartment of the Fuselage. Follow the manufactures

recommendations when applying. Ensure when you cover the model you do not introduce any

warps, cover each section and evenly tighten the covering on both sides. Ensure when you have

Finished covering all parts they are straight and true.

Tail Skid and Undercarriage

Draw two lines on a piece of scrap ply 85mm (3 3/8”) apart (double check this distance by

measuring between the centre of the saddle clamp holes on the front UC plate to the centre of

the holes on the rear UC Plate). Place the front leg and rear leg on each of the lines and screw

down using the supplied 10swg saddle clamps and screws. Make any minor adjustments with pliers

to make sure that the legs are parallel where they are to be bound.

Check measurement

Clean the tops of the legs with sandpaper or wire wool to remove any dirt or lubricants ready to

solder. Pull the legs together so that they join as shown in the photograph. The U/C should also rake

forward as shown in the diagram below. Bind together using tinned copper wire.

Heat the wire using a blowtorch and feed solder into the joint, ensuring that you flood the joint to

make it strong. Clean off the excess with a damp cloth; do not touch the leg as it will be extremely

hot. We advise wearing gauntlets at this point. Repeat for both sides. Once cool remove from the

scrap ply. Save the clamps and screws.

16

Fits best fit, make minor adjustments as before. Bind and solder as before. Repeat for the second

side, ensuring that the supports are positioned symmetrically.

Once the Fuselage has been covered, line the undercarriage up with the centre of the two

mounting plates. Ensure that it is placed square to the Fuselage. Place the saddle clamps over the

wire screw into the pre-drilled holes. Make sure the axles are at 90° to the centreline of the

Fuselage. Minor adjustments can be made with pliers or mole grips, just ensure that you hold the

undercarriage legs when doing this to prevent damaging the Fuselage.

Place your choice of wheel, we use 2” (50mm) wheel followed by 8swg collets. Ensure that the

wheel rotates freely and tighten the second grub screw. Cut off any excess piano wire.

Take the pre-bent 2mm (16 swg) wire and attach to the Tail skid using cotton, looping through each

of the pre-drilled holes several times before securing with Cyano. Ensure the Cyano penetrates

through the cotton.

Final Assembly

If you have any queries about the Final assembly or any other part of the build, then please

contact us at support@evolution-models.com where we will be happy to discuss your problem and

send you a photo to two to illustrate our solution.

Wing

Take the fully covered wing and ailerons, glue the hinges 50% into the aileron using a thin Cyano

and ensure that it penetrates the slots both top and bottom. Slot the hinges into the corresponding

slots on the wing. Move the aileron full travel (min 45°) to ensure that there is no resistance and

17

repeat the gluing process. Repeat this for the second aileron. Due to the large control surfaces we

would recommend pinning the hinges. This is left to the builder’s discretion.

Install the servos into the wing and feed the wires through the tubes. Pull the wires out at the centre

section where the sheeting was cut earlier. Drill pilot holes and securely screw the servos into place

using the fixings supplied with the servo. Centre the servo and attach a single arm horn.

Lay a ruler on the wing lined up with the outermost hole on the servo horn running parallel with the

ribs and mark the position on the aileron LE. Place the supplied control horn centrally on this mark.

Mark the positions of the holes and drill two 1.5mm (1/16”) pilot holes. Place the horn over the holes

and insert 2 No. bolts through to the supplied backing pieces. Screw on the bolts and tighten the

assembly to the aileron, making sure the horn remains at 90° aileron leading edge. Once satisfied

that the horn is secured, cut off the remaining bolt thread and run some Cyano onto the thread to

ensure the nut cannot be loosened.

Repeat this for the second aileron. With the supplied threaded rods, screw on a clevis to allow

equal adjustment up and down the thread and connect to the horn. Mark the rod at the servo

horn hole when the training edge of the aileron in line with the wing tip. Make a 90° bend in the

wire a curt off the excess wire, fix to the horn using the swing keeper supplied.

Fuselage

Take the fully covered parts for the Fuselage and insert the 8mm (5/16”) dowels provided. Glue in

place with white wood glue or Cyano. Fit the wing to the Fuselage and hold in place with an

elastic band so that it is firmly seated, but able to move for adjustment. With a tape measure

check that the Fuselage is square to the wing as per the diagram. Ensure A1 = A2.

Insert the Tail Plane into its slot and check the measurement B1 = B2. Once satisfied that the Tail

Plane is square, mark with a pencil both top and bottom along the edge of the Fuselage. Remove

the Tail Plane from its slot and carefully cut 1.5mm (1/16”) on the inside of the line to remove the

covering film from both the top and bottom.

Take the Fin and insert into the slot. With a pencil mark along the Fuselage as with the Tail Plane,

remove the Fin and remove the covering from 1.5mm (1/16”) below the line.

!!! Warning. Only cut through the film while undertaking the tasks above, do not cut into the balsa

as this will weaken the Fin/Tailplane and may cause it to fail in flight!!!

A2

A1

B2

B1

18

Re-insert the Fin and make sure that the cut-out in the base of the Fin lines up with the Tail Plane

slot. Insert the Tail Plane to confirm. One satisfied with the fit, glue the Fin into position applying

glue on the base where it joins to the Tail skid and at the junction with the top deck. Ensure that the

Fin is vertical, with the wing seated; also, check that the Fin is at 90° by viewing it from the front.

Glue the Tail Plane into position, apply the glue inside the slot, top and bottom, and with help

carefully open the slot while inserting the Tail Plane and release the Fuselage to clamp back down.

Only apply slight pressure so as not to break the rear of the Fuselage. When inserting the Tail Plane

be careful not to get glue onto the covering. Make sure the Tail Plane is parallel to the wing by

viewing from the front as before.

Take the fully covered Fuselage with Fin and Tail Plane fitted and glue the hinges 50% into the

Rudder and Elevator. Glue using a thin Cyano and ensure that it penetrates the slots both top and

bottom. Slot the hinges into the corresponding slots on the Fin and Tail Plane. Move the control

surfaces full travel (min 45°) to ensure that there is no resistance and repeat the gluing process.

Due to the large control surfaces we would recommend pinning the hinges, this is left to the

builder’s discretion.

Fit the Elevator servo (rear servo), Rudder servo (front servo) and 9g Throttle servo (glow version)

using the screws supplied with the servos, if you haven’t already, fit the 6 x 6mm (¼”x ¼”) spruce to

the front servo. Pilot drill the holes first to prevent the ply and spruce splitting.

Using two horns from the hardware pack on both the Elevator and Rudder, install them as

described earlier for the ailerons, except using a horn either side of the control surface. The

Elevator horn is placed at the centre of the Elevator and the Rudder horns are placed at the

bottom of the Rudder parallel with the bottom rail. Ensure that they are tight and sealed with

Cyano as before. For those wishing to get larger Rudder movements move the horn back from the

hinge point by approximately 12.5mm (½”).

With a Bradawl make holes for the closed loop system to exit the Fuselage as shown below in red.

Start by making a hole at 90° to the surface, then increase the angle while twisting the Bradawl to

about 5°. Make the holes in the positions as shown on the diagram. We have found it neater to

insert tubes into the holes and have used old pen inners (Biro) or plastic tube glued in place with

Cyano. Ensure Cyano does not enter the tube, or it will glue the cable fast. The hole for the upper

90o

90o

19

Elevator closed loop cable will be placed centrally on the rear deck but needs to be inserted at an

angle so that the cable can be run past the Fin post.

Make up the closed loop systems to the Elevator and Rudder as shown below.

Ensure the crimps hold the wire tightly, place a drop of Cyano to make sure the wires cannot move.

Motor Mount

Mount the motor using the recommended motor mount ensuring that it is securely attached to the

firewall, do not use screws, only use lock nuts, bolts and washers suitable for this application.

Electronic Speed Controller (ESC)

On the prototypes, we mounted the ESC under the Fuselage between the undercarriage mounts,

this provided constant cooling which is essential to prevent the ESC from overheating. Carefully drill

holes through the bottom of the Fuselage for the wires to pass into the radio bay. Stick the ESC to

the bottom of the Fuselage using double sided tape or hook and loop strips.

Motor Battery

We would recommend using a Lithium Polymer (Li-Po) battery for this model, use extreme caution

when using Li-Po batteries and always read the manufacturers or suppliers instructions when

handling, charging and storing this type of battery. The battery sits at the front of the Fuselage and

can be moved forward or back to alter the centre of gravity (Explained later). Once the centre of

Table of contents

Popular Toy manuals by other brands

LeapFrog

LeapFrog Alphabet Pal Parent guide & instructions

LEGO

LEGO 4439 Building instructions

Rail King

Rail King Work Train operating instructions

Eduard

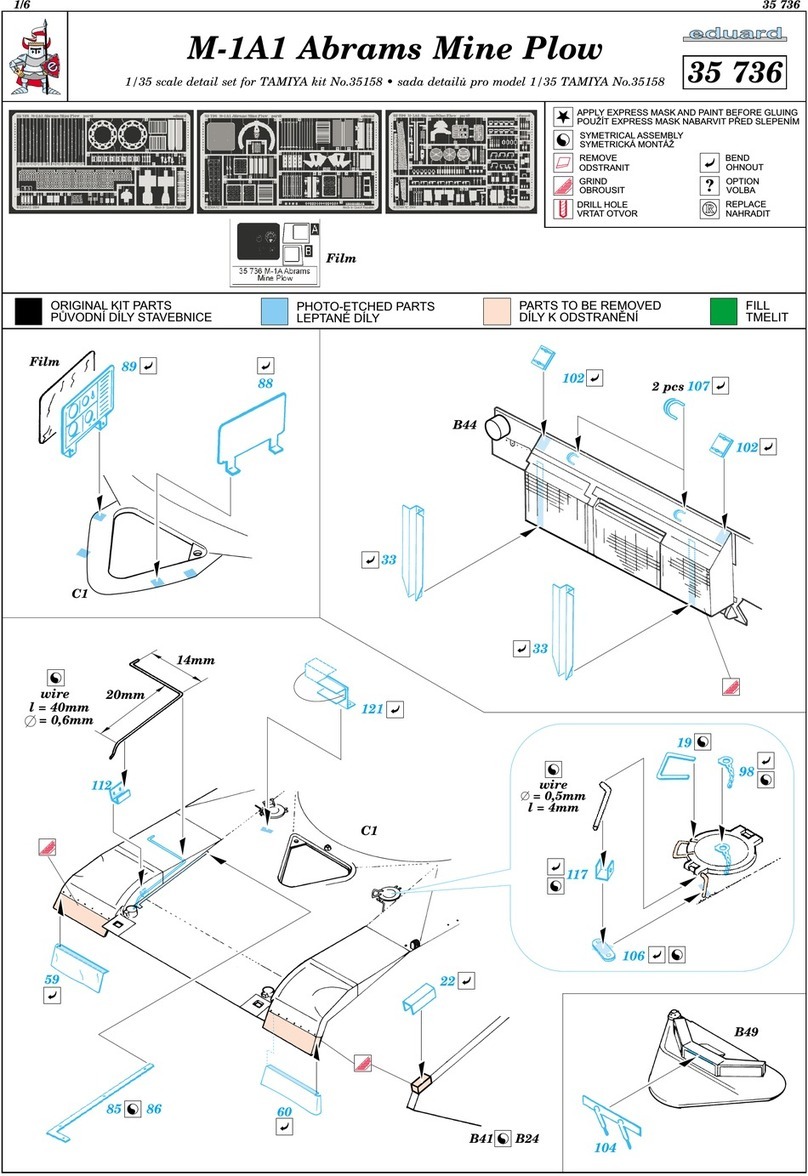

Eduard M-1A1 Abrams Mine Plow quick start guide

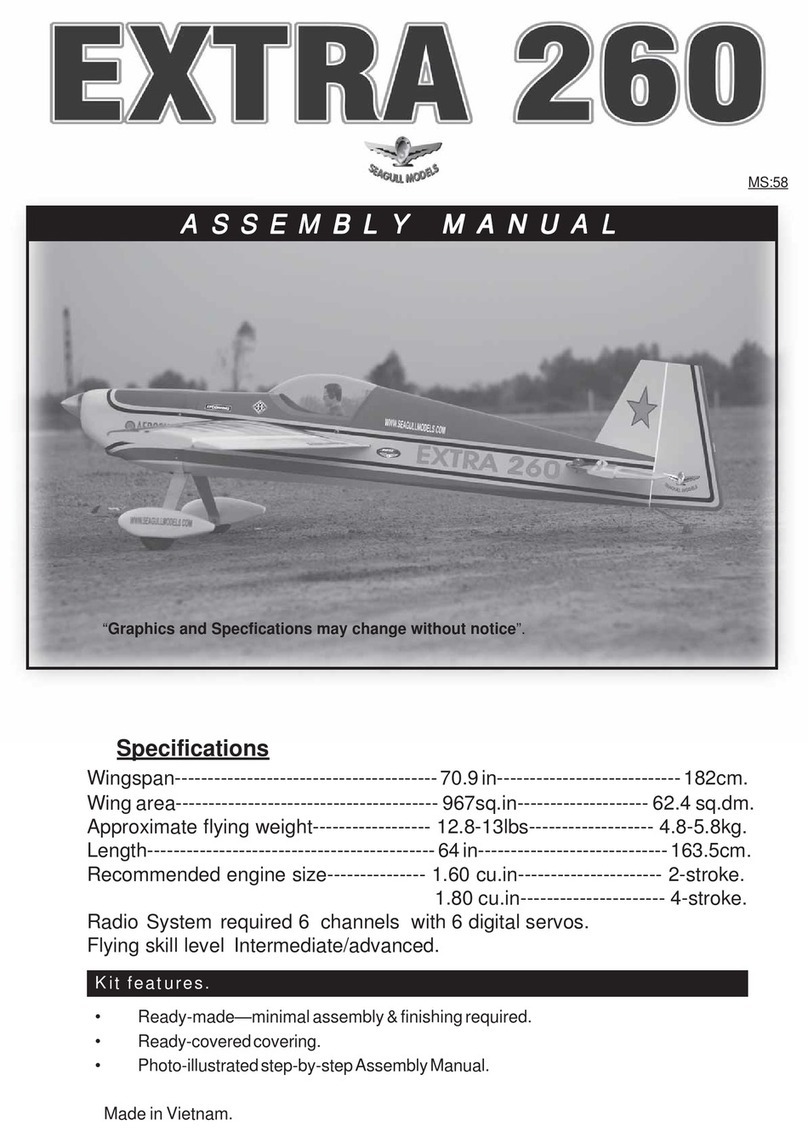

Seagull Models

Seagull Models Little Bunnt P-47D Assembly manual

MGA Entertainment

MGA Entertainment Squezoos Bubble Bus quick start guide