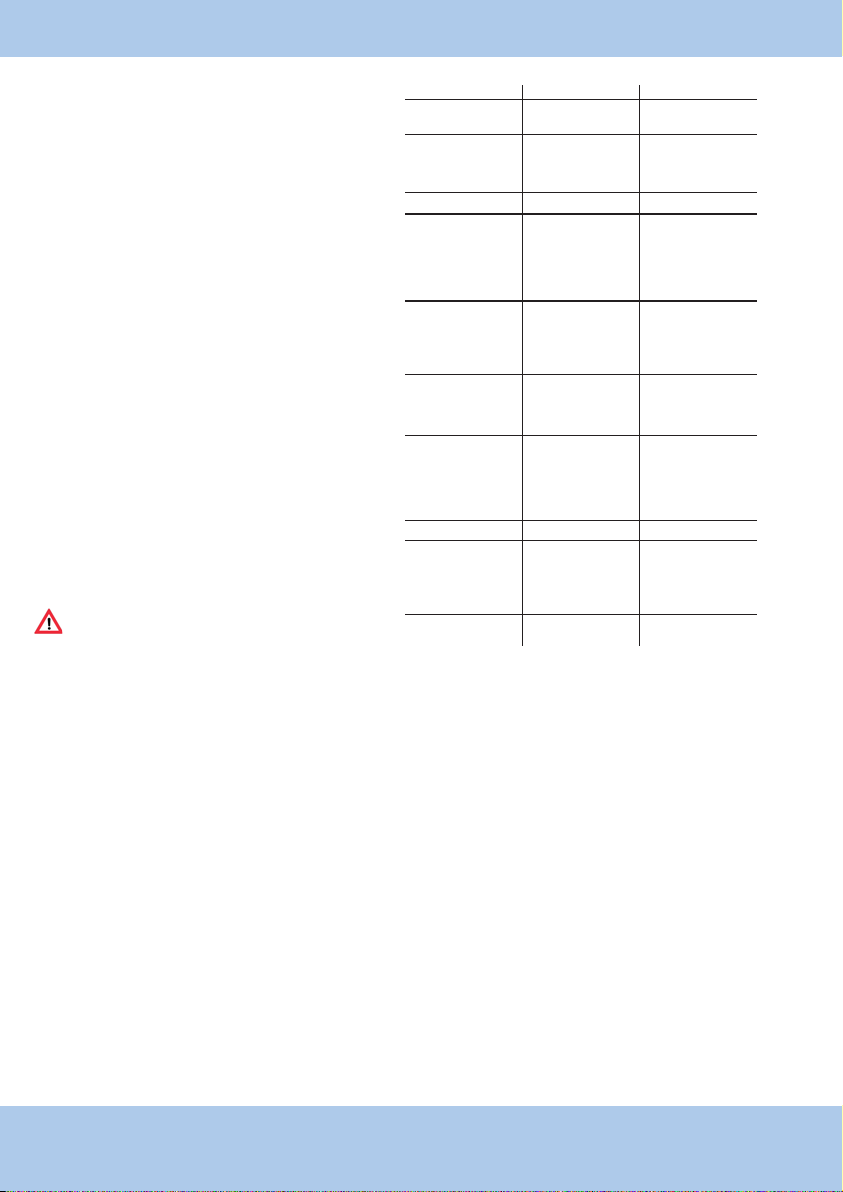

Troubleshooting

Malfunction Possible Cause Solution

The device does not No power source Check electrical cable

switch on available and fuse

Air escapes from the The hoses for input Check hoses and

device (even when it and output are assemble them

is not switched on) attached in reverse of correctly

their proper order

Fill pressure too high Hoses leaking Replace hoses

Fill process does not Connector is not Half-turn to secure

start (even when the attached properly

valve is attached) Connector damaged Replace connector

Valve rod jams Detach and replace

valve rod

Tyres empty Press "flat tyre" button

Fill process functions Connector clogged Remove blockage or

alone, or alarm tone use open design

activated, even though

the connector is not

attached

E00 or E06 is blinking Error in the electrical Shut off the device,

mains or bad contact check the electrical

on the electrical connector, switch on

connector the device once more

E02 is blinking Pressure of compressor Activate or replace

lower than the selected compressor

pressure setting on the

device

Shutoff valve is closed Open shutoff valve

Device error Contact the supplier

E03 or E04 is blinking Device error/malfunc. Contact the supplier

E05 is blinking Error in the electrical Detach connector,

mains. Device under re-start filling process

current after the con-

nector has been

attached to the tyre

E08 is blinking "flat tyre" button pres- Then, briefly touch

sed over 8 seconds the "flat tyre" button

When in doubt, please always phone the manufacturer or its

representative.

– 2 –

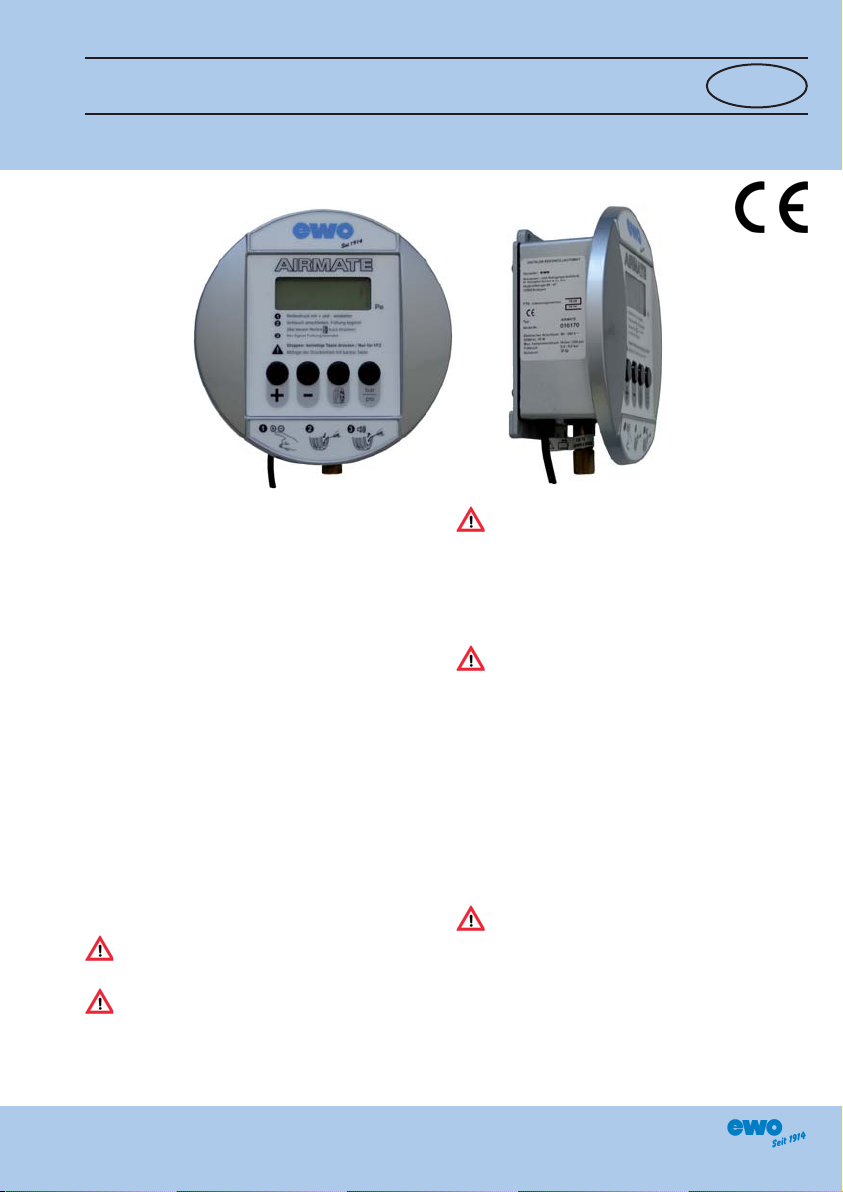

Operation

The manufacturer's pre-set fill pressure amounts to 1.8bar.

1. Set the desired tyre pressure with the plus/minus buttons.

2. Attach the fill hose with a clip connector to the tyre valve and secure it with

a half-turn. The fill process then begins automatically. In Breaks filling it

shows the current pressure.

3. The fill process has ended when the alarm tone sounds and the display

screen is blinking. The connector can now be removed.

4. For empty tyres (tyre pressure <0.2bar), the fill process does not begin

until the "flat tyre" button is pressed. After attaining the value of 0.3bar,

the fill process is automatically continued.

5. With the "bar/psi" button, the pressure check can be performed in anot-

her unit of measure. After this button is released, the reading appears

once again in bar.

• If the same pressure is required for the next tyre, it is sufficient to attach

the connector, and the fill process starts again.

• If the pressure in the tyre exceeds the desired level, the excess amount

of air is discharged.

• When the valve connector is re-attached following the fill process, a slight

drop is pressure occurs. The missing amount of air is then immediately re-

filled.

• After approx. 1 minute rest time, the fill-pressure indicator is reset to 1.8

bar for safety.

Safety Measures During Use

• Check to verify the moment connector is properly attached to the vehi-

cle's valve. After attaching, secure it with a half-turn. Any leakage will lead

to inaccuracies in the fill process.

• The fill process should not be interrupted. If the valve connectors detach

from the valve, first wait fort he air to dissipate, then re-attach the con-

nector.

• The filling process can be interrupted at any time with the "flat tyre" - but-

ton!

• Do not leave the hose on the floor, and do not drop the connector. After

each use, always retract the hose /hang it up

• If the fill process does not start after attaching the valve, check the valve

rod on the tyre and replace it if necessary.

• When the hose or connector leak, they should be replaced promptly.

Preventive Maintenance

Prior to performing any preventive-maintenance work on the electrical com-

ponents, the power supply must be disconnected and the air-shutoff valve

closed.

1. Replacement of hose

Detach the hose-connector fitting with an open-ended wrench. The com-

pressor symbol represents the air intake; the tyre symbol tyre filling. The

hoses must be designed for pressure levels up to 16 bar. When replacing

the hose, always ensure that the plastic sinter filters do not fall out.

Then, seal off the hose connectors (i.e., with Teflon strip) and screw them on

tightly.

2. Replacement of connector

Only use the moment connector supplied by the manufacturer. Other con-

nectors can lead to leakage. Only open design to use. The plug should be

rotated on the hose to be mounted.

3. Replacement of the fuse

Since the fuse is situated on the inside of the device, the tyre-filling machine

must be re-calibrated after it has been opened. The casing may only be ope-

ned by the respective technically trained personnel. Only use those fuses

which have been duly recommended by an accordingly certified testing in-

stitution: 2 mA with delay, and only Type 5 x 20 mm.

Guarantee

The airmate tyre-filling device has a 12-month guarantee period (starting

from the invoice date).

The guarantee applies to potential material defects or manufacturing errors

which occur in the course of proper use and have also been technically ve-

rified and determined by the supplier.

The following are excluded from the guarantee:

• Damage resulting from improper handling of the device or accidents of

any kind, such as i.e., power surges due to lightning strike.

• damages which have occurred due to abnormal electrical fluctuation in the

electrical mains.

• defects caused by the improper assembly of the device.

• expendable parts such as hoses and plugs.

• electrical fuses.

Expiry of the Guarantee Period

The guarantee period will end if and when:

• the term of validity elapses,

• any modifications and the installation of improper components are per-

formed,

• technical servicing has been performed by non-qualified personnel,

• the operation guide has not been observed,

• the seal (lead seal) has been removed or damaged.

Repair

• The device must be sent along with a description of the error/malfunction

to the manufacturer or its representative. Initially, the customer bears the

associated shipping costs.

• For on-site repairs performed by the manufacturer or its representative,

the principal must bear (in addition to the incurred material and labour

costs) the fitter's transportation costs.

• The parts replaced free of charge to the customer due to the warranty

conditions are the property of the manufacturer.

• Due to constant further technical developments, the product's technical

specifications are subject to change.