LIT 6202

©2010 EXAIR Corporation

USING THE REVERSIBLE DRUM VAC (Cont.)

Connect compressed air line (not included) from the filter to the 1/4 NPT shutoff valve. Secure all vacuum connections

to prevent loss of suction.

Upon opening the shutoff valve, it is normal for the drum to make a “popping” sound as the Reversible Drum Vac

begins to fill or empty the drum.

The high powered vacuum can fill the drum in less than 2 minutes. An automatic safety shutoff valve prevents spills or

overfilling.

FLOOR SPILL APPLICATIONS

The Model 6191 Reversible Drum Vac includes a floor tool for spill pick-up. The Floor Tool Picks Up Liquid Only

When It Is Pushed Away From The Operator. Systems using the Model 6091 Spill Recovery Kit work when pulled

toward the operator.

WARNING: Do Not Use With Any Material With A Low Flash Point Or With

Flammable Liquids Such As Fuel Oil, Alcohol, Mineral Spirits, Gasoline Or Kerosene.

TROUBLESHOOTING & MAINTENANCE

Clean air is essential for proper operation of the Reversible Drum Vac. A 10 micron or smaller filter separator must be

used on the compressed air supply in close proximity to the Reversible Drum Vac. If the filter element becomes

clogged with dirt, or a filter with a larger micron rating is us used and passes dirt into the pump, the airflow becomes

restricted and the pump can cease to operate.

For replacement or repair filter and regulator parts, contact EXAIR at 1-800-903-9247 or techelp@exair.com.

Call (513) 671-3322 for outside the US and Canada.

CLEANING

The safety shutoff valve that extends into the drum may require occasional cleaning. Immerse the Reversible Drum

Vac assembly in a mild cleaning or degreasing solvent. After cleaning, be sure the float moves freely. Use an air gun to

remove solution and contaminants.

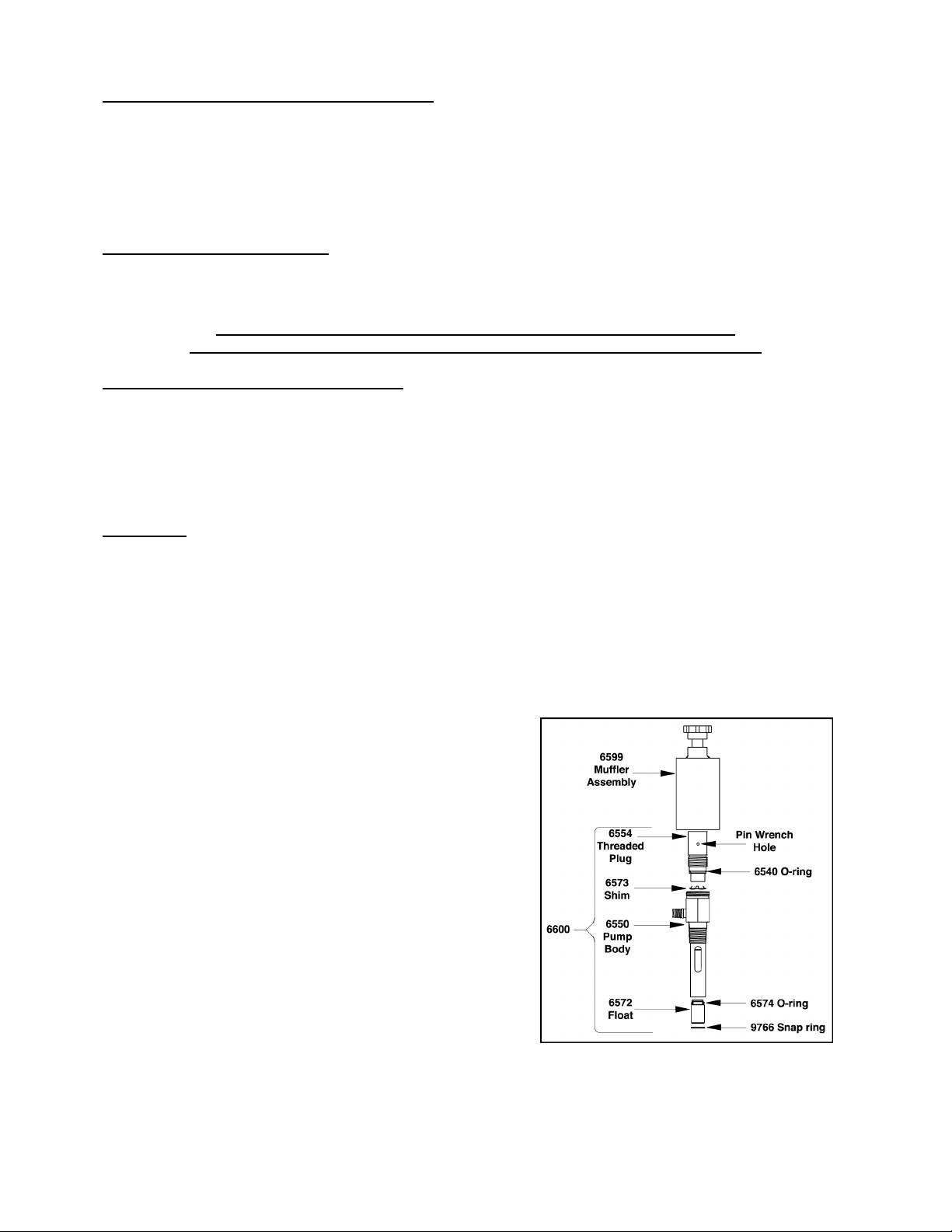

If the Reversible Drum Vac becomes clogged, it can be disassembled for cleaning. Use a wrench to hold the hex body

firm while turning the cylindrical muffler assembly counterclockwise with a strapping wrench. Once the muffler

assembly is removed, use a pin-style spanner wrench to unscrew the threaded plug. Carefully remove the shim and

clean it, the O-ring and the pump body using a mild cleaning solvent. Be sure all components are dry before

reassembling. Note the orientation of the shim as shown in the illustration below and reinstall the threaded plug. Be

careful not to over tighten the threaded plug as this can distort the shim and restrict airflow.

Always clean the vacuum hose and attachments after every use.

If routine cleaning does not solve your performance problems,

please contact:

Henderson Indústria e Comércio Ltda

Av. Álvaro Guimarães 1455 Planalto - CEP: 09890-003

São Bernardo do Campo São Paulo Brazil

Tel: (11) 4399.2992 ▪Fax: (11) 4341.5535

E-mail: Henderson@henderson.com.br