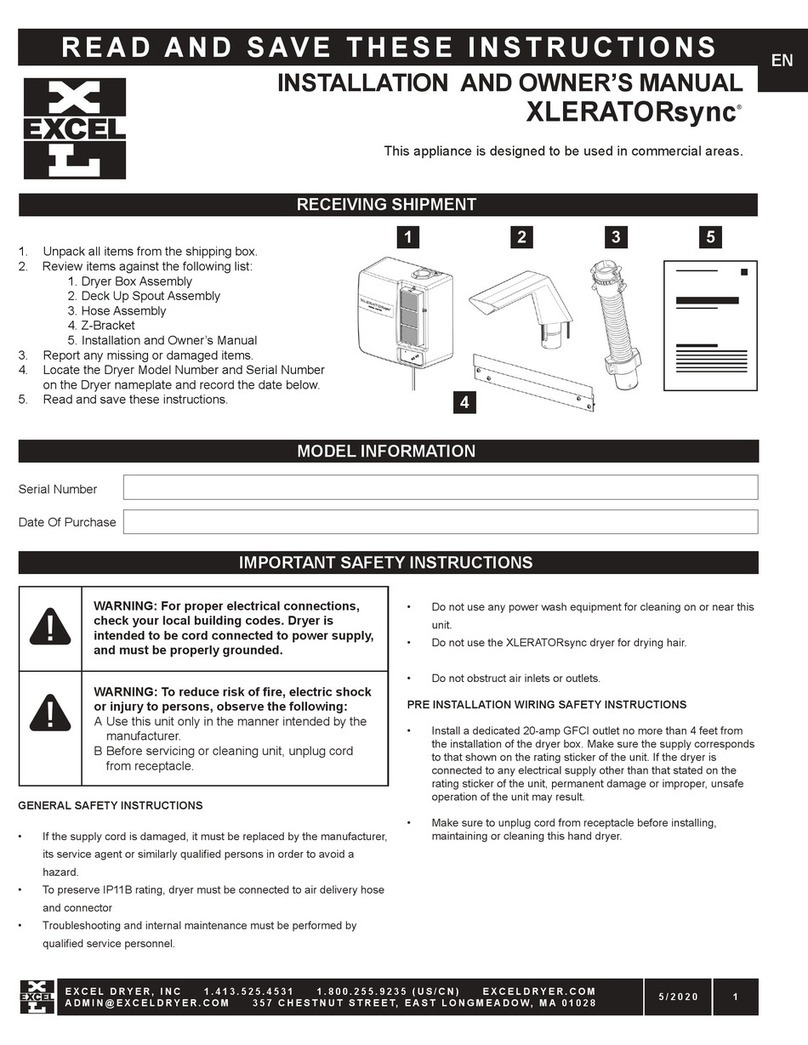

Excel Dryer ThinAir TA-ABS Installation instructions

EXCEL DRYER, INC 1.413.525.4531 1.800.255.9235 (US/CN) EXCELDRYER.COM

ADMIN@EXCELDRYER.COM 357 CHESTNUT STREET, EAST LONGMEADOW, MA 01028 2/2021 1

READ AND SAVE THESE INSTRUCTIONS

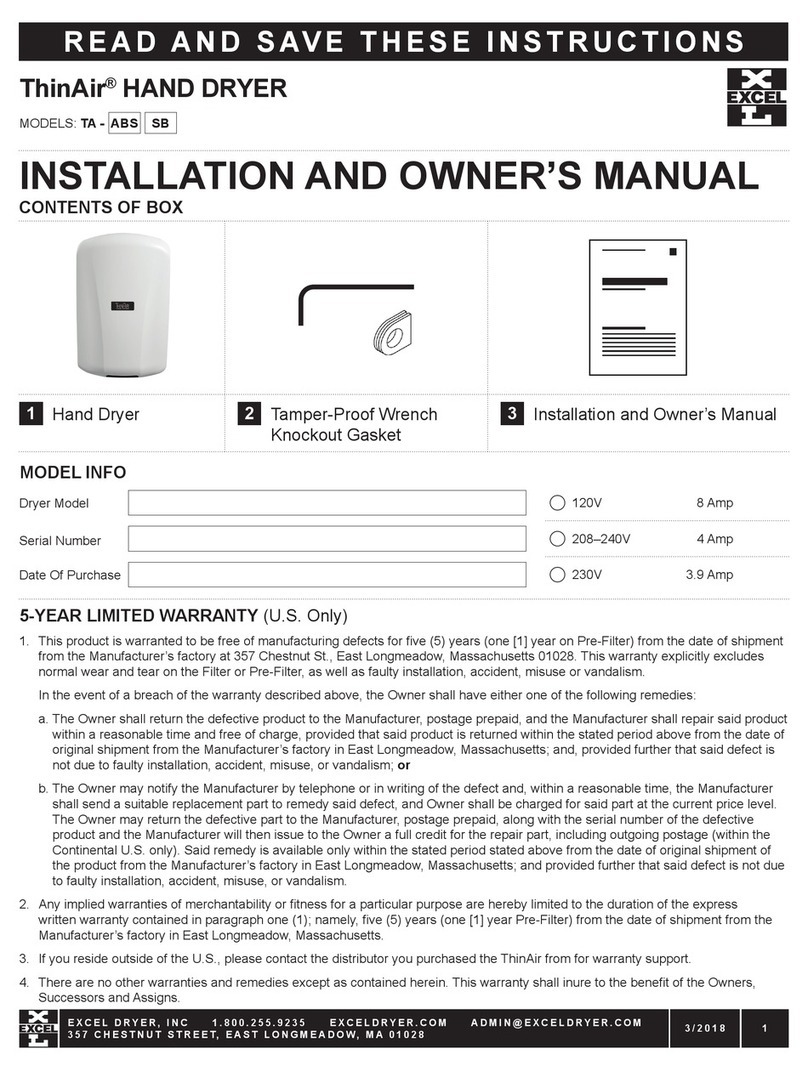

ThinAir®HAND DRYER

INSTALLATION AND OWNER’S MANUAL

Dryer Model

Serial Number

Date Of Purchase

Hand Dryer Tamper-Proof Wrench

Knockout Gasket (included

for use with Model TA-ABS only)

Installation and Owner’s Manual

CONTENTS OF BOX

1 2 3

MODEL INFO

EN

PRE-INSTALLATION WIRING

• Check that the electrical supply corresponds to that shown

on the rating sticker of unit. If the dryer is connected to any

electrical supply other than that stated on the rating sticker of

the unit, permanent damage or improper, unsafe operation of

the unit may result.

• Make sure electricity is switched off at the main panel before

installing, maintaining or cleaning this hand dryer. Dryer

must be installed in accordance with current local wiring and

building regulations.

• Dryer is intended to be permanently connected to power

supply, and must be properly grounded.

SAFETY

• Troubleshooting and internal maintenance must be performed

by qualied service personnel.

• Do not use any power wash equipment for cleaning on or

near this unit.

• Do not use for drying hair.

• Do not obstruct air inlets or outlets.

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended by the manufacturer.

B. Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting means to

prevent power from being switched on accidentally. When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag, to the service panel.

C. For proper electrical connections, check your local building codes. Your unit must be installed by a qualied,

licensed electrician.

MODELS: TA - WITH OR WITHOUT SUFFIX AND/ORABS GR SISB SP W V K H

EXCEL DRYER, INC 1.413.525.4531 1.800.255.9235 (US/CN) EXCELDRYER.COM

ADMIN@EXCELDRYER.COM 357 CHESTNUT STREET, EAST LONGMEADOW, MA 01028 2/2021 2

READ AND SAVE THESE INSTRUCTIONS

1. Disconnect the power source previously brought to the hand

dryer location (see pre-installation wiring above).

2. Use the Tamper-Proof Wrench supplied and remove the

Tamper-Proof Bolt on bottom of cover lifting upwards to

remove cover from base plate.

3. If electrical wiring entry is to be made from the rear, remove

the appropriate pre-formed knockout on the base plate.

If entry is to be made from the side, knock out the preformed

area on the right side of cover for your supply connection

using knockout gasket provided. A rigid conduit must be

used. For models with metal covers, if the side entry for

conduit is required, this must be specied in advance and

the side entry can be pre-cut and proper grommet applied by

the manufacturer.

4. Select the appropriate mounting height for dryer (Table 1)

and fastener, as recommended (Table 2). There should

be no obstruction between the hand dryer and the oor.

If mounting over a countertop, distance from counter to dryer

must be 15” (381 mm) minimum.

CAUTION: Do not use Base Plate as a guide when drilling.

Make sure no pipe work (gas, water, air) or any electrical cables

or wires are located directly behind the area to be drilled.

5. Attach Base Plate at the four corners to smooth wall.

Use one of 2 knockouts provided for service entry on back of

Base Plate. If using surface wiring use knock out in right side

of cover. Use Knockout Gasket supplied around conduit for

water seal. See Mounting Details.

6. Identify the voltage of your dryer from the rating sticker of

the unit. Then connect to a circuit per your local wiring and

building regulations.

7. Secure electrical wiring to terminals as indicated by the

schematic afxed to blower housing. An identied ground

connection point is supplied on the Base Plate for your

equipment ground wire. Dryers should be installed per local

code requirements.

8. In multiple installations, make sure the serial number marked

on the inside matches the cover number. Then carefully

replace Cover by inserting top of cover over bracket and

tilting downward. Use Tamper-Proof Bolt previously

removed in step 2.

9. Restore power and test for proper operation.

10.Return Tamper-Proof Wrench to owner.

INSTALLATION INSTRUCTIONS

SUGGESTED MOUNTING HEIGHT

from oor to bottom of dryer:

Men 45" (114 cm)

Women 43" (109 cm)

Teenagers 41" (104 cm)

Small Children 35" (89 cm)

Accessible 37" (94 cm)

MOUNTING HARDWARE

Recommended Fastener (not supplied):

Masonry Wall ½” Expansion Sleeve with ¼” Lag Bolt

Hollow Wall ¼” Wing Type Toggle Bolt

Wooden Wall ¼” Lag Screw With Washer

12

TABLE 1 TABLE 2

MOUNTING DETAILS CLEANING / MAINTENANCE

Gently wash Cover (including air inlet holes) using a

soft cloth or sponge and a mild soap or detergent with

lukewarm water to loosen dirt and grime.

It is recommended to inspect the inside of the dryer and

clean at least twice per year. Excessive lint, dust or other

particles in the air may require more frequent cleaning.

Lint on the air inlet, the dryer Pre-Filter, HEPA lter (if

so equipped) or other internal parts of dryer will reduce

efciency and shorten the life of the working parts.

Use the Tamper-Proof Wrench supplied and remove the

Tamper-Proof Bolt on bottom of cover, lifting upwards

to remove cover from base plate. Gently clean all

parts using a small soft brush. Remove the PreFilter,

rinse with water and dry. Inspect the HEPA Filter (if so

equipped) for any excessive debris buildup whenever

the Pre-Filter is removed.

DO NOT CLEAN THE HEPA FILTER OR ALLOW IT TO

COME INTO CONTACT WITH WATER. Reinstall the

Pre-Filter, cover and restore power.

Disconnect power to the dryer before cleaning. It is recommended that you refer to the

WHO or CDC for handling guidelines when cleaning the Pre-Filter or replacing the HEPA

lter if either may have been exposed to a contagion.

PLEASE SEE OUR WEBSITE, www.exceldryer.com FOR WARRANTY, TROUBLESHOOTING, AND PARTS INFORMATION

INSIDE:

OUTSIDE:

Gently wash Cover (including air inlet

holes) using a soft cloth or sponge and

a mild soap or detergent with lukewarm

water to loosen dirt and grime.

TO CLEAN:

EXCEL DRYER, INC 1.413.525.4531 1.800.255.9235 (US/CN) EXCELDRYER.COM

ADMIN@EXCELDRYER.COM 357 CHESTNUT STREET, EAST LONGMEADOW, MA 01028 2/2021 3

READ AND SAVE THESE INSTRUCTIONS

TROUBLESHOOTING

Dryer does not turn on

1. Check power to the unit and connections. Verify dryer is receiving

correct voltage at Terminal Block (check Dryer listed voltage).

2. Check RED service LED light for the following:

Light is ON – Place hands under Sensor for 10 sec. If light stays

on, check Sensor connection at control. If OK, replace Sensor or

Control. If light goes off and then ashes a code, see error codes in

CODE chart. If light still stays on, replace Control.

Light is OFF – Check for loose, disconnected or improper wiring

(See wiring schematic inside dryer Cover), or replace Control

Assembly.

Light is FLASHING – See error codes in CODE chart.

SENSOR RANGE ADJUSTMENT: If dryer will not turn on, stays on,

or stops working, it may be mounted too close to a counter or object

and has gone into lockout. If relocating appliance is not possible,

adjust the range of the Sensor. Turn off power to dryer then turn the

range adjustment on the Control Assembly counterclockwise towards

L (-) low to decrease Sensor range.

Dryer does not shut off

1. May be mounted too close to a counter or object (adjust Sensor

range).

2. Check for loose, disconnected or improper wiring (Refer to wiring

schematic afxed to blower housing).

3. Replace Control Assembly.

Dryer does not always turn on or turns on by itself

1. May be mounted too close to counter or object (adjust Sensor

range).

2. Check for foreign material on Optical Sensor next to Air Outlet.

3. Check for loose wires on Control Assembly.

4. Replace Control Assembly.

Dryer heats up but no air comes out

1. Check wire connections to Motor.

2. Replace Motor.

Dryer blows only cold air

1. Check heat setting on control.

2. Check for loose connections to Heating Element.

3. Replace Heating Element.

Dryer has a loss of air volume

1. Check motor speed setting on control.

2. Check for blockage at nozzle air outlet.

3. Check Dryer Pre-Filter for lint buildup. Check HEPA pre-lter

(if so equipped). Clean by removing Pre-Filter and rinse in warm

water then dry before reinstalling. A clogged lter code may be

present in the sensor.

4. After cleaning Pre-Filter, check HEPA Filter (if so equipped).

If dirty, replace HEPA Filter. DO NOT RINSE HEPA FILTER.

ADJUSTING THE HEAT OUTPUT, MOTOR SPEED AND SENSOR RANGE

The dryer is shipped with maximum heat and maximum motor speed. To adjust,

turn the corresponding knob COUNTERCLOCKWISE to reduce.

H = Heat M = Motor R = Range

If problem cannot be resolved with the above, please call the manufacturer at 1-800-255-9235

and one of our trained technicians will be happy to assist you.

CODE CHART

Codes are displayed by ashing the red LED in the sensor behind air outlet. Normal operation will be indicated by the red LED

being on when not drying and off when hands are under the sensor.

Dryer Maintenance Codes

1 Short / 1 Long ash Clogged Pre-Filter, or if

equipped clogged HEPA Filter

Remove and clean Pre-Filter or

if clean, replace HEPA lter

Dryer will still run

1 Short / 2 Long ashes Severely Clogged Filter, or if

equipped clogged HEPA Filter

Remove and clean Pre-Filter or

if clean, replace HEPA lter

Dryer will stop

2 Short / 1 Long ash In lockout mode Remove obstruction or adjust

sensor range

Dryer stops until obstruction cleared or

sensor range is adjusted

Motor Problem Codes

1 Long / 3 Short ashes Motor over current Measure voltage across the

terminal block. If OK, replace

motor

Dryer will stop

1 Long / 4 Short ashes Motor under current Measure voltage across the

terminal block. If OK, replace

motor

Dryer will stop

Heater Problem Codes

2 Long / 3 Short ashes Shorted or incorrect heater Replace heating element Dryer will stop

EXCEL DRYER, INC 1.413.525.4531 1.800.255.9235 (US/CN) EXCELDRYER.COM

ADMIN@EXCELDRYER.COM 357 CHESTNUT STREET, EAST LONGMEADOW, MA 01028 2/2021 4

READ AND SAVE THESE INSTRUCTIONS

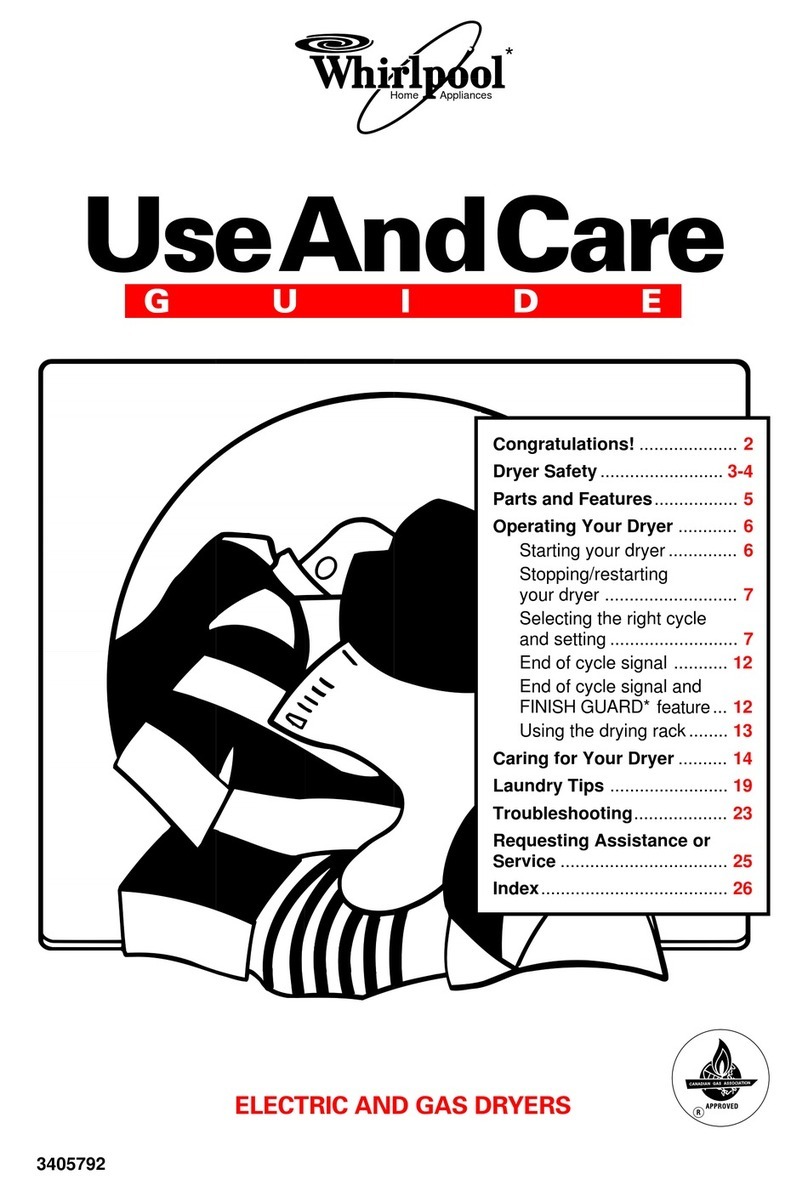

TA-1 Cover (includes nameplate)

TA-2 Tamper-Proof Bolt

TA-3 Tamper-Proof Wrench

TA-4 Knockout Gasket

TA-5 Bracket Cover Hook

TA-6 Nozzle

TA-7 Optic Bracket

TA-8 Optic Assembly

TA-9 Finger Guard

TA-10 Heating Element Assembly

TA-11 Mufer Housing (output)

TA-12 Mufer Foam (output)

TA-13 Motor Gasket Ring

TA-14 Clamshell Upper

TA-15 Bracket Cover

TA-16 Control Assembly

TA-17 Motor

TA-18 Motor Gasket

TA-19 Pre-Filter W/Screen

TA-20 Mufer Foam (input)

TA-21 Mufer Housing (input)

TA-22 Clamshell (lower)

TA-23 Base Plate

TA-24 Nameplate

TA-25 Tube (pressure)

TA-26 Terminal Block

TA-29 HEPA Pre-Filter W/Screen

TA-30 HEPA Filter

PARTS LIST

Ref. No. Description

TIME TO THROW IN THE TOWEL

®

EXCEL DRYER INC • 1.413.525.4531 • 1.800.255.9235 (US/CN) • EXCELDRYER.COM

2021

FEB

19TAM0460

TA-1

TA-23

TA-2

TA-16

TA-15

TA-14

TA-24

TA-25

TA-26

TA-9

TA-7

TA-8

TA-22

TA-19

TA-20

TA-18

TA-21

TA-17

TA-3

TA-6

TA-5

TA-12

TA-13

TA-4

TA-10

TA-11

TA exploded view and BOM 6 R1.cdr 08/14/2020 tek

Combo STD and HEPA

TA exploded view

TA-29

TA-30

FOR HEPA FILTER MODEL

REF # DESCRIPTION

TA-01 COVER TA

TA-02 1/4-20 x 1/2 TAMPERPROOF SCR

TA-03 5/32 HEX KEY TAMPER

TA-04 GASKET KNOCKOUT TA

TA-05 BRACKET COVER HOOK TA

TA-06 NOZZLE TA

TA-07 BRACKET OPTIC TA

TA-08 OPTICS ASSEMBLY HO-I/XL/TA

TA-09 GUARD FINGER

TA-10 HEATING ELEMENT ASSEMBLY

TA-11 MUFFLER OUTPUT TA

TA-12 FOAM OUTPUT MUFFLER TA

TA-13 RING MOTOR GASKET TA

TA-14 BLOWER HOUSING TA FRONT

TA-15 BRACKET COVER TA

TA-16 CONTROL ASSM 110-277V TA SPEED

TA-17 MOTOR TA

TA-18 GASKET MOTOR TA

TA-19 PREFILTER W/SCREEN TA

TA-20 FOAM INPUT MUFFLER TA

TA-21 MUFFLER INPUT HOUSING TA

TA-22 BLOWER HOUSING TA BACK

TA-23 PLATE BACK MOUNTING TA

TA-24 LABEL COVER TA

TA-25 TUBE PRESSURE TA

TA-26 TERMINAL BLOCK TA

TA-29 PREFILTER W/ SCREEN TA HEPA

TA-30 HEPA FILTER TA

5-YEAR LIMITED WARRANTY (U.S. Only)

1. This product is warranted to be free of manufacturing defects for ve (5) years (one [1] year on HEPA Filter & Pre-Filter) from the

date of shipment from the Manufacturer’s factory at 357 Chestnut St., East Longmeadow, Massachusetts 01028. This warranty

explicitly excludes normal wear and tear on the Filter or Pre-Filter, as well as faulty installation, accident, misuse or vandalism.

In the event of a breach of the warranty described above, the Owner shall have either one of the following remedies:

a. The Owner shall return the defective product to the Manufacturer, postage prepaid, and the Manufacturer shall repair said product

within a reasonable time and free of charge, provided that said product is returned within the stated period above from the date of

original shipment from the Manufacturer’s factory in East Longmeadow, Massachusetts; and, provided further that said defect is

not due to faulty installation, accident, misuse, or vandalism; or

b. The Owner may notify the Manufacturer by telephone or in writing of the defect and, within a reasonable time, the Manufacturer

shall send a suitable replacement part to remedy said defect, and Owner shall be charged for said part at the current price level.

The Owner may return the defective part to the Manufacturer, postage prepaid, along with the serial number of the defective

product and the Manufacturer will then issue to the Owner a full credit for the repair part, including outgoing postage (within the

Continental U.S. only). Said remedy is available only within the stated period stated above from the date of original shipment of

the product from the Manufacturer’s factory in East Longmeadow, Massachusetts; and provided further that said defect is not due

to faulty installation, accident, misuse, or vandalism.

2. Any implied warranties of merchantability or tness for a particular purpose are hereby limited to the duration of the express written

warranty contained in paragraph one (1); namely, ve (5) years (one [1] year on HEPA Filter & Pre-Filter) from the date of shipment

from the Manufacturer’s factory in East Longmeadow, Massachusetts.

3. If you reside outside of the U.S., please contact the distributor you purchased the ThinAir from for warranty support.

4. There are no other warranties and remedies except as contained herein. This warranty shall inure to the benet of the Owners,

Successors and Assigns.

This manual suits for next models

5

Other Excel Dryer Dryer manuals