Excel Dryer ThinAir TA-ABS Installation instructions

EXCEL DRYER, INC 1.800.255.9235 EXCELDRYER.COM ADMIN@EXCELDRYER.COM

357 CHESTNUT STREET, EAST LONGMEADOW, MA 01028 3/2018 1

READ AND SAVE THESE INSTRUCTIONS

ThinAir®HAND DRYER

INSTALLATION AND OWNER’S MANUAL

Dryer Model

Serial Number

Date Of Purchase

MODELS: TA - ABS

5-YEAR LIMITED WARRANTY (U.S. Only)

1. Thisproductiswarrantedtobefreeofmanufacturingdefectsforve(5)years(one[1]yearonPre-Filter)fromthedateofshipment

fromtheManufacturer’sfactoryat357ChestnutSt.,EastLongmeadow,Massachusetts01028.Thiswarrantyexplicitlyexcludes

normalwearandtearontheFilterorPre-Filter,aswellasfaultyinstallation,accident,misuseorvandalism.

Intheeventofabreachofthewarrantydescribedabove,theOwnershallhaveeitheroneofthefollowingremedies:

a.TheOwnershallreturnthedefectiveproducttotheManufacturer,postageprepaid,andtheManufacturershallrepairsaidproduct

withinareasonabletimeandfreeofcharge,providedthatsaidproductisreturnedwithinthestatedperiodabovefromthedateof

originalshipmentfromtheManufacturer’sfactoryinEastLongmeadow,Massachusetts;and,providedfurtherthatsaiddefectis

notduetofaultyinstallation,accident,misuse,orvandalism;or

b.TheOwnermaynotifytheManufacturerbytelephoneorinwritingofthedefectand,withinareasonabletime,theManufacturer

shallsendasuitablereplacementparttoremedysaiddefect,andOwnershallbechargedforsaidpartatthecurrentpricelevel.

TheOwnermayreturnthedefectiveparttotheManufacturer,postageprepaid,alongwiththeserialnumberofthedefective

productandtheManufacturerwillthenissuetotheOwnerafullcreditfortherepairpart,includingoutgoingpostage(withinthe

ContinentalU.S.only).Saidremedyisavailableonlywithinthestatedperiodstatedabovefromthedateoforiginalshipmentof

theproductfromtheManufacturer’sfactoryinEastLongmeadow,Massachusetts;andprovidedfurtherthatsaiddefectisnotdue

tofaultyinstallation,accident,misuse,orvandalism.

2.Anyimpliedwarrantiesofmerchantabilityortnessforaparticularpurposeareherebylimitedtothedurationoftheexpress

writtenwarrantycontainedinparagraphone(1);namely,ve(5)years(one[1]yearPre-Filter)fromthedateofshipmentfromthe

Manufacturer’sfactoryinEastLongmeadow,Massachusetts.

3. IfyouresideoutsideoftheU.S.,pleasecontactthedistributoryoupurchasedtheThinAirfromforwarrantysupport.

4.Therearenootherwarrantiesandremediesexceptascontainedherein.ThiswarrantyshallinuretothebenetoftheOwners,

SuccessorsandAssigns.

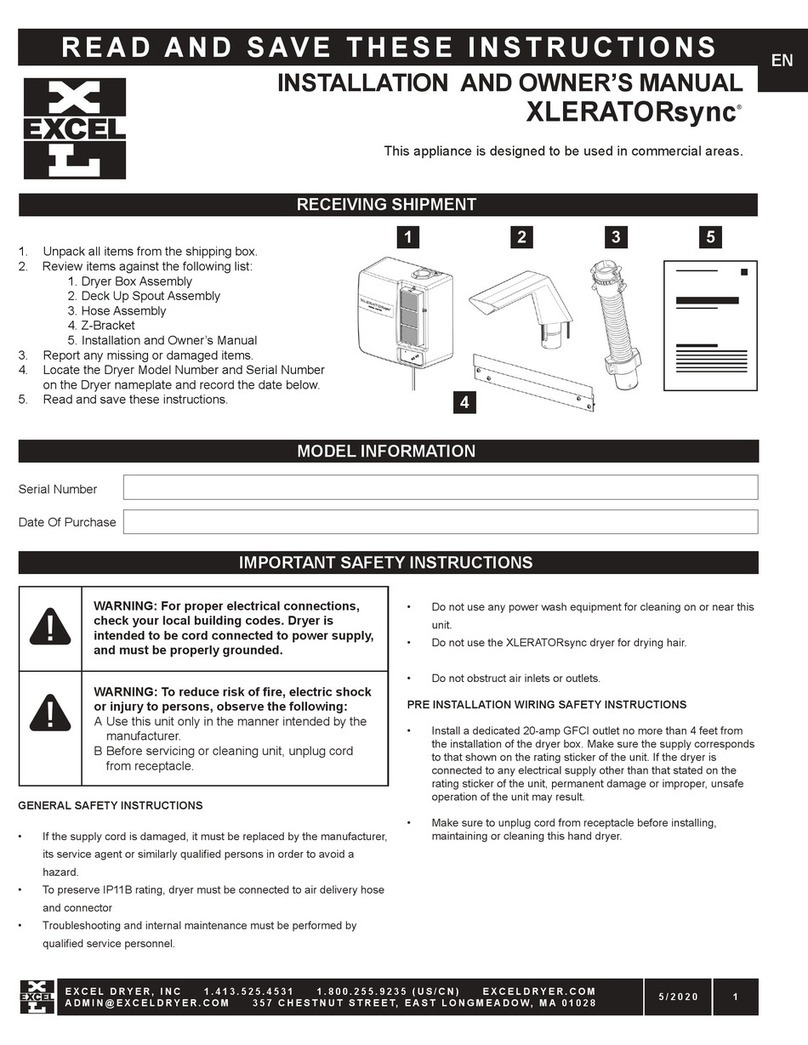

Hand Dryer Tamper-ProofWrench

Knockout Gasket

Installation and Owner’s Manual

CONTENTS OF BOX

1 2 3

120V 8Amp

MODEL INFO

208–240V 4Amp

230V 3.9Amp

SB

EXCEL DRYER, INC 1.800.255.9235 EXCELDRYER.COM ADMIN@EXCELDRYER.COM

357 CHESTNUT STREET, EAST LONGMEADOW, MA 01028 3/2018 2

READ AND SAVE THESE INSTRUCTIONS

WARNING: For proper electrical connections, check your local building codes.

Your unit must be installed by a qualied, licensed electrician.

PRE-INSTALLATION WIRING

• Checkthattheelectricalsupplycorrespondstothatshown

on the rating sticker of unit. If the dryer is connected to any

electrical supply other than that stated on the rating sticker of

theunit,permanentdamageorimproper,unsafeoperationof

the unit may result.

• Make sure electricity is switched off at the main panel before

installing,maintainingorcleaningthishanddryer.Dryer

must be installed in accordance with current local wiring and

building regulations.

• Do not wire this hand dryer into the lighting circuit. It must be

protected by an independent circuit.

• Dryer is intended to be permanently connected to power

supply,andmustbeproperlygrounded.

SAFETY

• Troubleshooting and internal maintenance must be performed

byqualiedservicepersonnel.

• Do not use any power wash equipment for cleaning on or

near this unit.

• Do not use for drying hair.

• Do not obstruct air inlets or outlets.

1. Disconnectthepowersourcepreviouslybroughttothehand

dryerlocation(seepre-installationwiringabove).

2. UsetheTamper-ProofWrenchsuppliedandremovethe

Tamper-ProofBoltonbottomofcoverliftingupwardsto

removecoverfrombaseplate.

3. Ifelectricalwiringentryistobemadefromtherear,remove

theappropriatepre-formedknockoutonthebaseplate.

Ifentryistobemadefromtheside,knockoutthepreformed

areaontherightsideofcoverforyoursupplyconnection

usingknockoutgasketprovided.Arigidconduitmustbeused.

4. Select the appropriate mounting height for dryer (Table 1)

andfastener,asrecommended(Table2).Thereshould

benoobstructionbetweenthehanddryerandtheoor.

Ifmountingoveracountertop,distancefromcountertodryer

mustbe15”(381mm)minimum.

CAUTION: Do not use Base Plate as a guide when drilling.

Make sure no pipe work (gas, water, air) or any electrical cables

or wires are located directly behind the area to be drilled.

5. AttachBasePlateatthefourcornerstosmoothwall.

Identifythevoltageofyourdryerfromtheratingstickerof

the unit. Then connect to a dedicated branch circuit not

exceeding20Amp.

6. Useoneof2knockoutsprovidedforserviceentryonbackof

BasePlate.Ifusingsurfacewiringuseknockoutinrightside

ofcover.UseKnockoutGasketsuppliedaroundconduitfor

water seal. See Mounting Details.

7. Secureelectricalwiringtoterminalsasindicatedbythe

schematicafxedtoblowerhousing.Anidentiedground

connectionpointissuppliedontheBasePlateforyour

equipment ground wire. Dryers should be installed per local

code requirements.

8. CarefullyreplaceCoverbyinsertingtopofcoverover

bracketandtiltingdownward.UseTamper-ProofBolt

previouslyremovedinstep2.

9. Restorepowerandtestforproperoperation.Inmultiple

installations,makesuretheserialnumbermarkedonthe

insidematchesthecovernumber.

10.ReturnTamper-ProofWrenchtoowner.

SUGGETSTED MOUNTING HEIGHT

from oor to bottom of dryer:

Men 45"(114cm)

Women 43"(109cm)

Teenagers 41"(104cm)

SmallChildren 35"(89cm)

Accessible 37"(94cm)

MOUNTING HARDWARE

Recommended Fastener (not supplied):

MasonryWall ½”ExpansionSleevewith¼”LagBolt

HollowWall ¼”WingTypeToggleBolt

WoodenWall ¼”LagScrewWithWasher

1 2

INSTALLATION INSTRUCTIONS

TABLE1 TABLE2

IMPORTANT SAFETY INSTRUCTIONS

EXCEL DRYER, INC 1.800.255.9235 EXCELDRYER.COM ADMIN@EXCELDRYER.COM

357 CHESTNUT STREET, EAST LONGMEADOW, MA 01028 3/2018 3

READ AND SAVE THESE INSTRUCTIONS

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended by the manufacturer.

B. Before servicing or cleaning unit, switch power off at service panel and lock the

service disconnecting means to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service panel.

CLEANING / MAINTENANCE

OUTSIDE: GentlywashCover(includingairinlet

holes) using a soft cloth or sponge and

a mild soap or detergent with lukewarm

water to loosen dirt and grime.

INSIDE: Excelrecommendsinspectingtheinside

of the dryer and cleaning as required at

leastonceperyear,orifperformance

diminishes.Heavierusage,oran

environmentthatcontainsexcessivelint,

dustorotherparticles,requiresmore

frequentcleaning.Lintontheairinlet,the

Pre-Filter,orotherinternalpartsofdryer

willreduceefciencyandshortenthelife

of the working parts.

TO CLEAN: Shutoffpowertodryeratservice

connection.UsestheTamper-Proof

Wrenchsuppliedandremovethe

Tamper-ProofBoltonbottomofcover

liftingupwardstoremovecoverfrom

base plate. Gently clean all parts using

asmall,softbrush.UnclipthePre-Filter,

rinsewithwateranddry.Re-install.

TROUBLESHOOTING

Dryer does not turn on

1.Checkpowertotheunitandconnections.Verifydryeris

receivingvoltageatTerminalBlock.

2. CheckREDserviceLEDlightforthefollowing:

Light is ON–PlacehandsunderSensor.Iflightstayson,

thenreplaceSensor.Iflightgoesoff,checktomakesure

wiringiscorrect.IfOK,checkwireconnectingtoMotor.

IfbothareOK,replaceMotor.

Light is OFF–Checkforloose,disconnectedorimproper

wiring(SeewiringschematicinsidedryerCover),orreplace

ControlAssembly.

Light is FLASHING–SeeerrorcodesinCODEchart.

SENSOR RANGE ADJUSTMENT: If dryer will not turn on,

stays on, or stops working, it may be mounted too close to

a counter or object and has gone into lockout. If relocating

appliance is not possible, adjust the range of the Sensor.

Turn off power to dryer then turn the range adjustment on

the Control Assembly counterclockwise towards L (-) low to

decrease Sensor range.

Dryer does not shut off

1. May be mounted too close to a counter or object (adjust

Sensor range).

2. Checkforloose,disconnectedorimproperwiring(Referto

wiringschematicafxedtoblowerhousing).

3. ReplaceControlAssembly.

MOUNTING DETAILS

Dryer does not always turn on, or turns on by itself

1. May be mounted too close to counter or object (adjust

Sensor range).

2. CheckforforeignmaterialonOpticalSensornexttoAirOutlet.

3. CheckforloosewiresonControlAssembly.

4. ReplaceControlAssembly.

Dryer heats up but no air comes out

1. CheckwireconnectiontoMotor.

2. ReplaceMotor.

Dryer blows only cold air

1. Checkheatsettingoncontrol.

2. CheckforlooseconnectionstoHeatingElement.

3. ReplaceHeatingElement.

Dryer has a loss of air volume

1. Checkmotorspeedsettingoncontrol.

2. CheckforslowrunningMotororburningsmell.

Ifso,replaceMotor.

3. CheckPre-Filterforlintbuildup.Cleanbyremoving

Pre-FilterandrinseinwarmwaterthendryPre-Filter

before reinstalling.

EXCEL DRYER, INC 1.800.255.9235 EXCELDRYER.COM ADMIN@EXCELDRYER.COM

357 CHESTNUT STREET, EAST LONGMEADOW, MA 01028 3/2018 4

READ AND SAVE THESE INSTRUCTIONS

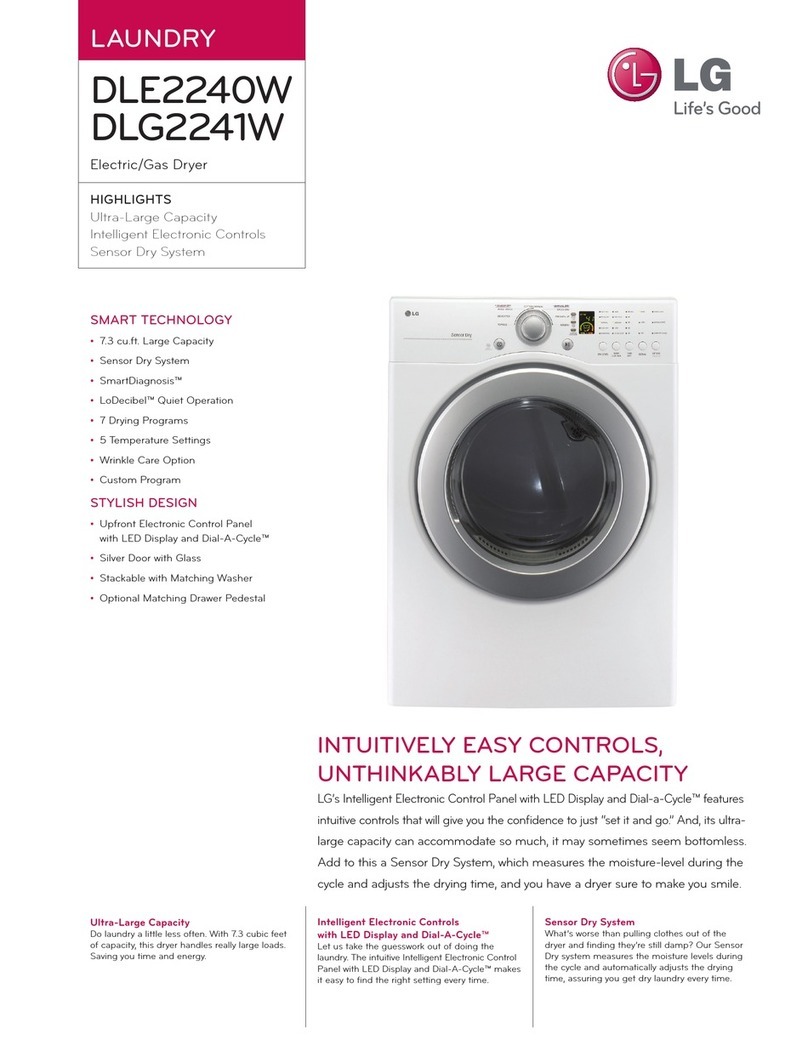

TA-1 Cover(includesnameplate)

TA-2 Tamper-ProofBolt

TA-3 Tamper-ProofWrench

TA-4 KnockoutGasket

TA-5 BracketCoverHook

TA-6 Nozzle

TA-7 OpticBracket

TA-8 OpticAssembly

TA-9 FingerGuard

TA-10 HeatingElementAssembly

TA-11 MuferHousing(output)

TA-12 MuferFoam(output)

TA-13 MotorGasketRing

TA-14 ClamshellUpper

TA-15 BracketCover

TA-16 ControlAssembly

TA-17 Motor

TA-18 MotorGasket

TA-19 Pre-lter(includesscreen)

TA-20 MuferFoam(input)

TA-21 MuferHousing(input)

TA-22 Clamshell(lower)

TA-23 BasePlate

TA-24 Nameplate

TA-25 Tube(pressure)

TA-26 TerminalBlock

PARTS LIST

Ref.No. Description

TROUBLESHOOTING (Continued)

If problem cannot be resolved with the above, please call the manufacturer at 1-800-255-9235

and one of our trained technicians will be happy to assist you.

CODE CHART

Codes are displayed by ashing the red LED in the sensor behind air outlet. Normal operation will be indicated by the red LED

being on when not drying and off when hands are under the sensor.

Dryer Maintenance Codes

1Short/1Longash CloggedPre-Filter CleanPre-Filter Dryer will still run

2Short/1Longash In lockout mode Clearobstruction Dryer stops until obstruction cleared

Motor Problem Codes

1Long/3shortashes Motorovercurrent Replacemotor Dryer will stop

1Long/4shortashes Motor under current Replacemotor Dryer will stop

Heater Problem Codes

2Long/3shortashes Shorted or incorrect heater Replaceheater Dryer will stop

2Long/4shortashes Open/broken heater Replaceheater Dryer will still run

Voltage Problem Codes

3Long/3shortashes Mainpanelovervoltage Checkincomingvoltage Dryer will stop

3Long/4shortashes Mainpanelundervoltage Checkincomingvoltage Dryer will stop

TIME TO THROW IN THE TOWEL

®

EXCEL DRYER INC • 1.800.255.9235 • EXCELDRYER.COM

2018

MARCH

18TAM0343

TA-1

TA-23

TA-2

TA-16

TA-15

TA-14

TA-24

TA-25

TA-26

TA-9

TA-7

TA-8

TA-22

TA-19

TA-20

TA-18

TA-21

TA-17

TA-3

TA-6

TA-5

TA-12

TA-13

TA-4

TA-10

TA-11

TA exploded view 4.cdr 12/13/2016 tek

TA exploded view

This manual suits for next models

1

Table of contents

Other Excel Dryer Dryer manuals