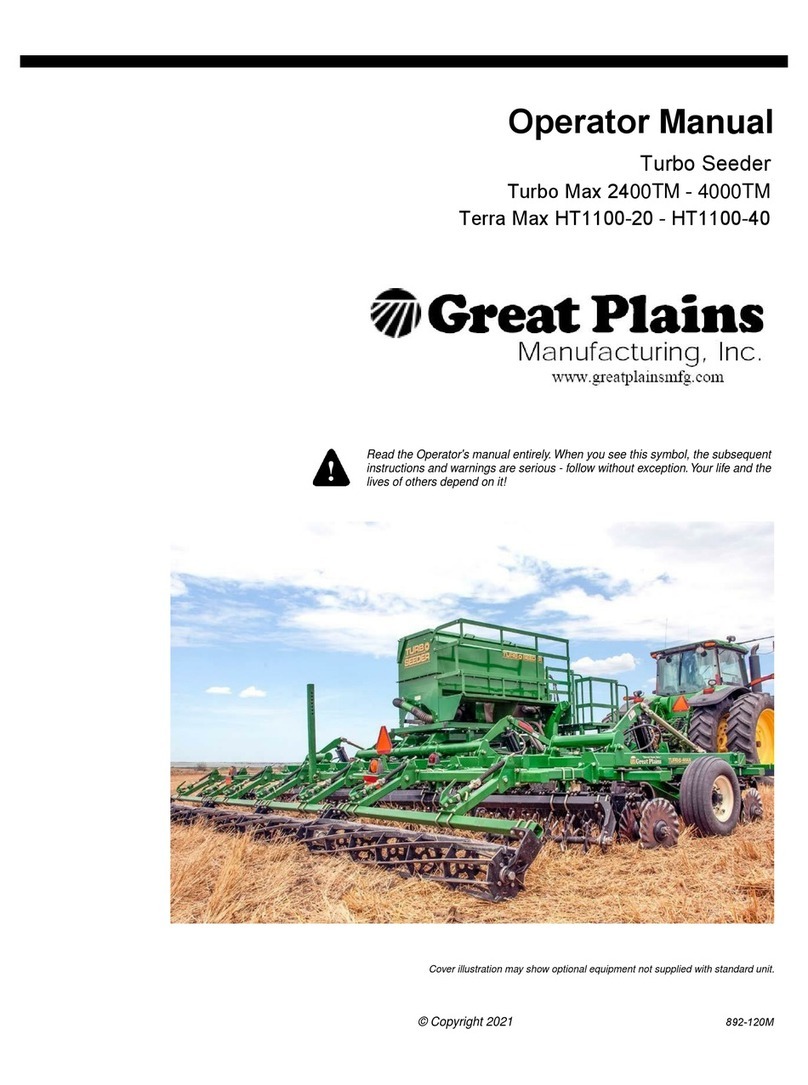

Exmark SD270SB20 User manual

SLICERSEEDER

ForSerialNos.

313,652,088&Higher

PartNo.4501-674Rev.A

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Theengineinthisproductisnot

equippedwithasparkarrestermufer.Itisa

violationofCaliforniaPublicResourceCode

(CPRC)Section4442touseoroperatethis

engineonanyforest-covered,brush-covered,

orgrass-coveredlandasdenedinCPRC4126.

Otherstatesorfederalareasmayhavesimilar

laws.

Toacquireasparkarresterforyourunit,seeyour

EngineServiceDealer.

Thissparkignitionsystemcomplieswiththe

CanadianstandardICES-002.Cesystèmed’allumage

parètincelledevèhiculeestconformeàlanorme

NMB-002duCanada.

TheenclosedEngineOwner’sManualis

suppliedforinformationregardingTheU.S.

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenanceandwarranty.

KeepthisengineOwner’sManualwithyourunit.

ShouldthisengineOwner’sManualbecome

damagedorillegible,replaceimmediately.

Replacementsmaybeorderedthroughthe

enginemanufacturer.

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©2013ExmarkMfg.Co.,Inc.

2101AshlandAve

Beatrice,NE683102

Contactusatwww.Exmark.com.

PrintedintheUSA

AllRightsReserved

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkSlicerSeeder.Thisproducthasbeencarefully

designedandmanufacturedtogiveyouamaximum

amountofdependabilityandyearsoftrouble-free

operation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

SlicerSeeder.

BEFOREOPERATINGYOURMACHINE,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Byfollowingtheoperating,maintenance,and

safetyinstructions,youwillprolongthelifeofyour

SlicerSeeder,maintainitsmaximumefciency,and

promotesafeoperation.

Ifadditionalinformationisneeded,orshould

yourequiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

Exmarkpartsmanualsareavailableonlineat

http://www.Exmark.com

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

3

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals.......................9

Specications........................................................13

ModelNumbers.............................................13

Systems..........................................................13

Dimensions....................................................13

TorqueRequirements.....................................13

Setup.....................................................................14

SetuptheHandle............................................14

ProductOverview.................................................14

Operation..............................................................15

Controls.........................................................15

Pre-Start.........................................................16

OperatingInstructions...................................16

OperatingTips...............................................19

Transporting..................................................20

Maintenance..........................................................21

RecommendedMaintenanceSchedule(s)............21

PeriodicMaintenance........................................22

CheckEngineOilLevel..................................22

ChecktheBlades............................................22

CheckforLooseHardware.............................23

ServiceAirCleaner.........................................23

ChangeEngineOil.........................................23

CheckConditionOfBelts...............................24

LubricateGreaseFittings................................24

CheckSparkPlugs..........................................24

ChangeHydraulicTransmissionFiltersand

Fluid..........................................................25

CheckSparkArrester(ifequipped)..................25

ChecktheSeedGate.......................................25

ThreadLockingAdhesives..............................25

Adjustments......................................................26

AdjustingtheSelf-PropelDrive......................26

AdjustingtheSelf-PropelDriveBelt

Tension......................................................27

AdjustingtheSeedGateClosed

Position......................................................27

Cleaning............................................................28

CleanEngineandExhaustSystem

Area...........................................................28

CleanDebrisBuild-UpUnderUnit.................28

CleaningUndertheBeltCover.......................29

CleaningtheSeedGate...................................29

WasteDisposal...............................................29

Troubleshooting....................................................30

4

Safety

Safety

SafetyAlertSymbol

ThisSafetyAlertSymbol(Figure2)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents.

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

Figure2

SafetyAlertSymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Whitelettering/Redbackground.

Indicatesanimminentlyhazardoussituationwhich,if

notavoided,Willresultindeathorseriousinjury.

WARNING:Blacklettering/Orangebackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Couldresultindeathorseriousinjury.

CAUTION:Blacklettering/Yellowbackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Mayresultinminorormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

SafeOperatingPractices

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)can

notreadEnglishitistheowner’sresponsibilityto

explainthismaterialtothem;otherlanguagesmay

beavailableonourwebsite.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Onlyadultsandmatureteenagersshouldoperate

themachine,andevenmatureteenagersshould

haveadultsupervision.Besureateenager:

1.hasreadandunderstandstheOperator's

Manualandrecognizestherisksinvolved;

2.issufcientlymaturetousecaution;and

3.isofsufcientsizeandweighttooperate

thecontrolscomfortablyandtomanagethe

machinewithouttakingrisks.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,andhearingprotection.Do

Notoperatewhenbarefootorwhenwearingopen

sandals.Longhair,looseclothingorjewelrymay

gettangledinmovingparts.

CAUTION

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

5

Safety

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsonlevelground,

inanopenarea,whentheengineiscold.

Wipeupanygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletelyfull.

Fillthefueltanktothebottomoftheller

neck.Theemptyspaceinthetankallows

gasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengine

oremissionsystem.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoradd

fuelwhenengineisrunningorwhenthe

engineishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelson

theground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.Do

Notuseanozzlelockopendevice.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

•Checkthattheoperatorspresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly.DoNotoperateunlessthey

arefunctioningproperly.

6

Safety

Operation

WARNING

Operatingengineparts,especiallythemufer,

becomeextremelyhot.Severeburnscanoccur

oncontactanddebris,suchasleaves,grass,

brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,to

coolbeforetouching.

•Removeaccumulateddebrisfrommuferand

enginearea.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcankill

you.

DoNotrunengineindoorsorinasmallconned

areawheredangerouscarbonmonoxidefumes

cancollect.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,

DoNotoperatethemachine;seekshelter.

•Starttheenginecarefullyaccordingtoinstructions

withfeetwellawayfromtheblades.

•Neverraisemachinewithbladesrunning.

•Neveroperatethemachinewithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Neverattempttomakedepthofcutadjustments

whiletheengineisrunning.

•Parkthemachineonlevelground.Stopengine,

waitforallmovingpartstostop,andremovethe

sparkplugwire(s).

–Beforechecking,cleaningorworkingonthe

equipment.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspecttheequipmentfor

damageandmakerepairsbeforerestarting

andoperatingthemachine).

–Beforeclearingblockages.

–Wheneveryouleavethemachine.

•Stopengine,waitforallmovingpartstostop:

–Beforerefueling.

–Beforemakingdepthofcutadjustments.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesinplace

andworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•NEVERcarrypassengers.DONOToperate

themachinewhenpeople,especiallychildren,or

petsareinthearea.

•Bealert,slowdownandusecautionwhen

makingturns.Lookbehindandtothesidebefore

changingdirections.

•Stoptheblades,slowdown,andusecaution

whencrossingsurfacesotherthangrassandwhen

transportingtheunittoandfromtheworkarea.

•DoNotoperatethemachineundertheinuence

ofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeOperation

UseExtremecautionwhenoperatingand/orturning

onslopesaslossoftractionand/ortip-overcould

occur.Theoperatorisresponsibleforsafeoperation

onslopes.

7

Safety

DANGER

Operatingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.Lossofcontrol

and/orlossofoperator'sfootingcouldresultina

fallwithanarmorleggettingundertheunitor

enginedeckwhichmayresultinseriousinjury,

deathordrowning.

•Operateacrossslopes,neverupanddown.

•DoNotoperateonslopeswhengrassiswet.

•Useextremecautionwhenoperatingnear

drop-offsorwater

•DoNotslice/seedexcessivelysteepslopes.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromtheworkingarea.Tallgrasscan

hideobstacles.

•Watchforditches,holes,rocks,dipsandrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenoperatinguphill

becausethemachinemaytipbackwards.

MaintenanceandStorage

•Stoptheengineandremovethesparkplug

wire(s).Waitforallmovementtostopbefore

adjusting,cleaningorrepairing.

•Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulate

intheseareas.Thesematerialscanbecome

combustibleandmayresultinare.

•LetenginecoolbeforestoringandDoNotstore

nearameoranyenclosedareawhereopenpilot

lightsorheatappliancesarepresent.

•Shutofffuelwhilestoringortransporting.Do

Notstorefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallow

untrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Removesparkplugwirebeforemakingany

repairs.

•Usecarewhencheckingblades.Wraptheblade(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplacedamagedblades.Never

straightenorweldthem.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,DoNotmakeadjustmentswiththe

enginerunning.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

WARNING

Removalormodicationoforiginalequipment,

partsand/oraccessoriesmayalterthewarranty,

controllability,andsafetyofthemachine.

Unauthorizedmodicationstotheoriginal

equipmentorfailuretouseoriginalExmark

partscouldleadtoseriousinjuryordeath.

Unauthorizedchangestothemachine,engine,

fuelorventingsystem,mayviolateapplicable

safetystandardssuchas:ANSI,OSHAand

NFPAand/orgovernmentregulationssuchas

EPAandCARB.

8

Safety

SafetyandInstructionalDecals

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafety

signsandinstructionlabels.Theyarecriticalto

thesafeoperationofyourExmarkcommercial

SlicerSeeder.

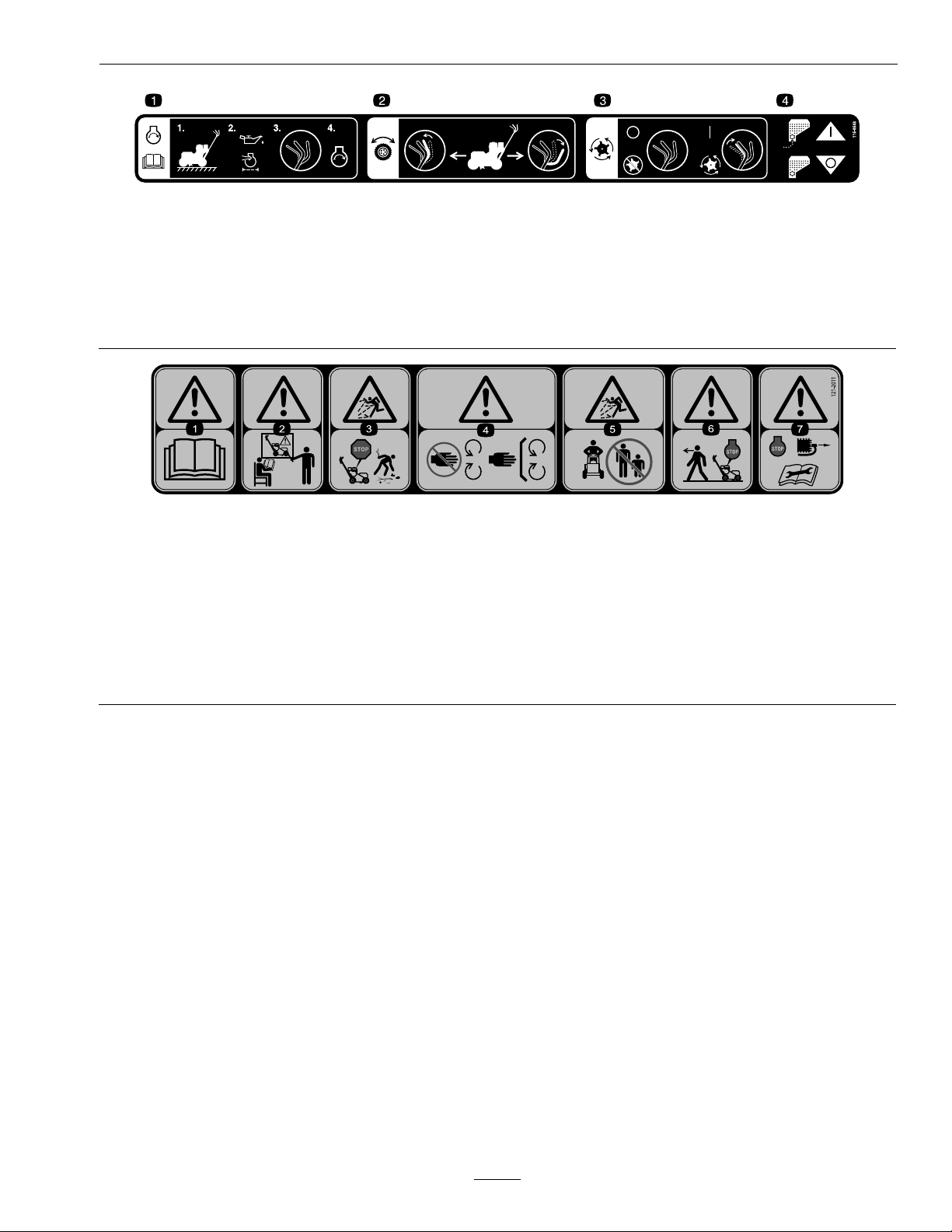

93-7321

1.Cutting/dismembermenthazardofhandsandfeet,

rotatingknives/blades—stayawayfrommovingparts.

115-9625

1.Parking

brake—disengaged

2.Parkingbrake—engaged

116-8535

1.Lowerseedowrate2.Higherseedowrate

116-8536

1.Cuttingblades-pressdownonleverandpullblade

controlbailagainstthehandletoengagethecutting

blades.

9

Safety

116-9985

1.Readandunderstand

theoperator’smanual

beforeservicingthis

machine.

3.ACterminal-orange

wireconnectstoengine

harness

2.Positiveterminal-red

andbluewires

4.Negativeterminal-black

wire

117–2718

117–4979

1.Entanglementhazard,belt—keepawayfrommoving

parts;keepallguardsandshieldsinplace

121-6203

1.Bypassleverpositionfor

operatingthemachine

3.ReadtheOperator’s

manual

2.Bypassleverpositionfor

pushingthemachine

126-0296

1.Readandunderstand

theoperator’smanual

beforeservicingthis

machine

4.Checktransmissionbelt

drivetensionevery25

hours

2.Checktirepressure-13

psi(4x)every50hours

5.Seeengineowner’s

manualforservice

3.Greasetheslicershaft

bearingsevery25hours

10

Safety

116-8648

1.Tostarttheengine,readtheOperator’smanual-(1)Park

themachineonalevelsurface(2)Filltheenginewithoil

(3)Movethecontrolbarstoaneutralposition(4)Start

theengine.

3.Cuttingblades-releasethebladecontrolbail(neutral

position)todisengagethecuttingblades;holdtheblade

controlbailagainstthehandletoengagethecutting

blades.

2.Self-propeldrive-pushtheself-propeldrivebailforwardto

movethemachineforward;pulltheself-propeldrivebail

downwardtomovethemachinebackward.

4.Seedhopperon;seedhopperoff.

121–2011

1.Warning—readthe

Operator’sManual.

3.Thrownobjecthazard;

pickupdebrisbefore

operating.

5.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

7.Warning—stopthe

engineandremove

thesparkplugwire

beforeperformingany

maintenanceonthe

machine.

2.Warning—donotoperate

thismachineunlessyou

aretrained.

4.Warning—keephands

awayfrommovingparts,

keepallguardsand

shieldsinplace.

6.Warning—stopthe

enginebeforeleaving

themachine.

11

Safety

116-8537

12

Specications

Specications

ModelNumbers

SerialNos:313,652,088andHigher

SD270SB20

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’s

Manual

•EngineOilType:Exmark4–CyclePremium

EngineOil

•RPM:FullSpeed:3800±100RPM(NoLoad)

FuelSystem

•Capacity:1.5gal.(5.6L)

•FuelRecommendations:

–Forbestresults,useonlyclean,fresh,unleaded

gasolinewithanoctaneratingof87orhigher

((R+M)/2ratingmethod).

–Oxygenatedfuelwithupto10%ethanolor

15%MTBEbyvolumeisacceptable.

–DoNotuseethanolblendsofgasoline(such

asE15orE85)withmorethan10%ethanol

byvolume.Performanceproblemsand/or

enginedamagemayresultwhichmaynotbe

coveredunderwarranty.

–DoNotusegasolinecontainingmethanol.

–DoNotstorefueleitherinthefueltankor

fuelcontainersoverthewinterunlessafuel

stabilizerisused.

–DoNotaddoiltogasoline.

•FuelShut-OffValve:1/4turnincrements

Transmission

Variable

SpeedsRange:0–4.0mph(6.4km/hr)

TiresandWheels

Pneumatic(Air-Filled)

Quantity4

TreadTurfTL

Size11x4.0-4

PlyRating2

Pressure13psi

(90kPa)

Dimensions

OverallWidth:

30.0inches(76cm)

OverallLength:

54.0inches(137cm)

OverallHeight:

44.5inches(113cm)

TreadWidth:(OutsidetoOutsideof

Tires,Widthwise)

30.0inches(76cm)

CurbWeight:

265lb(120.2kg)

TorqueRequirements

BoltLocationTorque

EngineMountingBolts27-33ft-lb(37-45N-m)

ClutchMountingBolts49-61ft-lb(66-83N-m)

SlicerShaftNut65-85ft-lb(88-115N-m)

13

ProductOverview

Setup

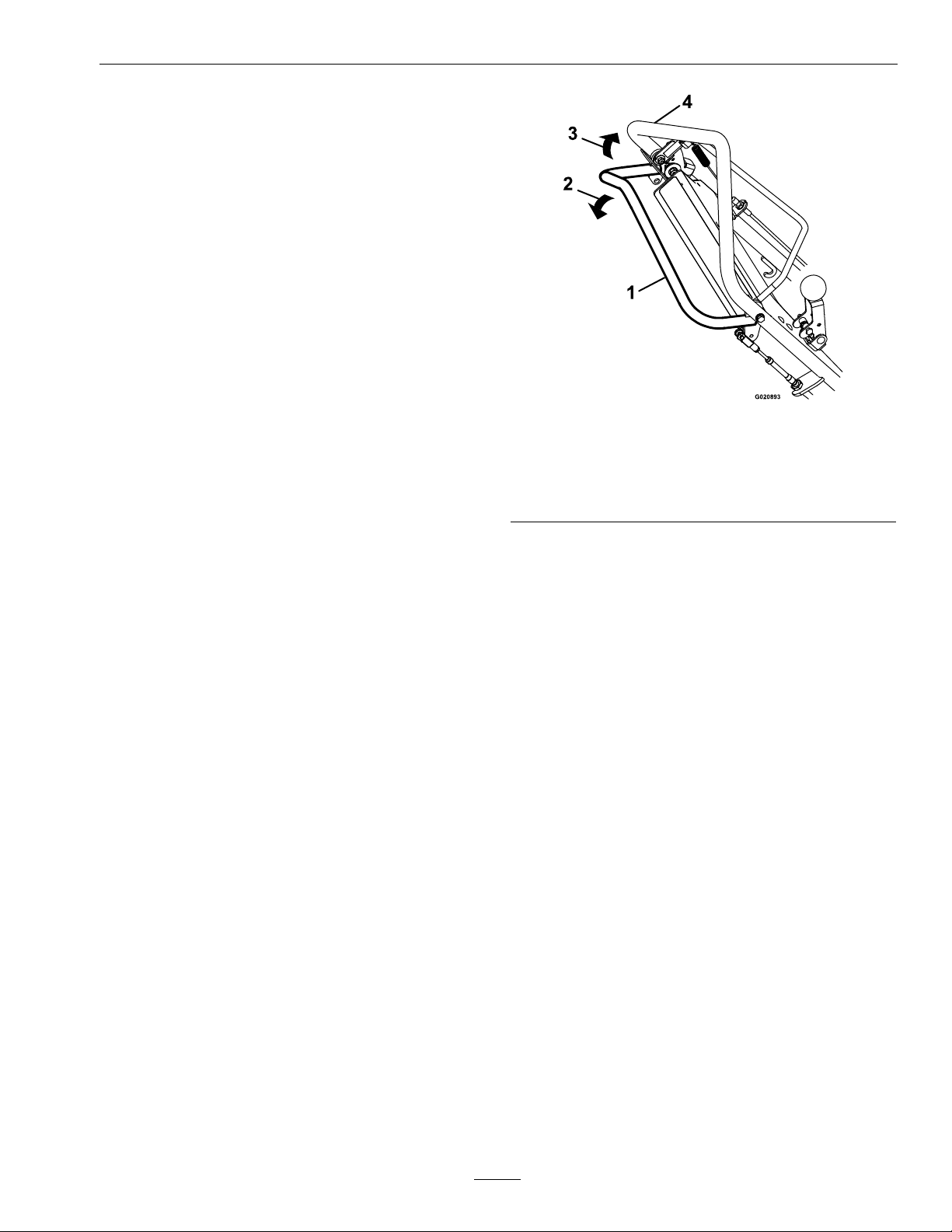

SetuptheHandle

1.Raisethehandletotheoperatingposition.

G016884

Figure3

2.Slidetheovallockingringsdowneachsideofthe

upperhandleoverthelowerhandle,lockingthe

handlesectionstogether.

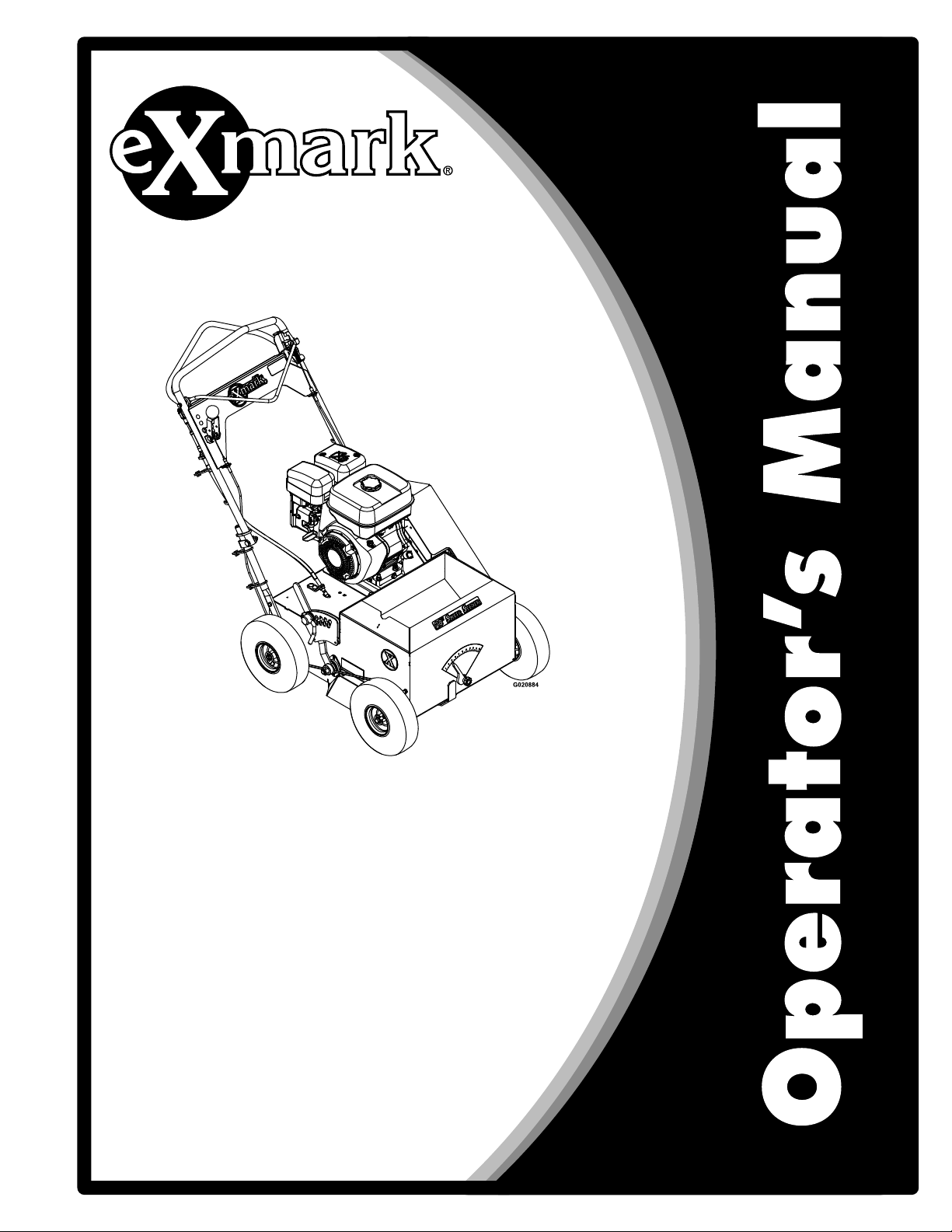

ProductOverview

Figure4

1.Seedercontrollever6.Seedhopper

2.Drivebail7.Seedingrategauge

3.Handle8.Depthcontrollever

4.Bladecontrolbail9.Recoilstarterrope

5.Fueltank

14

Operation

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Controls

ChokeControl

Locatedontheengine.

Thechokeisusedtoaidinstartingacoldengine.

Movingthechokeleverrearwardwillputthechoke

inthe“ON”positionandmovingthechokeleverto

theforwardwillputthechokeinthe“OFF”position.

DoNotrunawarmenginewithchokeinthe“ON”

position.

ThrottleControl

Locatedontheengine.

Thethrottleisusedtocontrolenginespeed.Moving

thethrottleleverrearwardwillincreaseenginespeed

andmovingthethrottleleverforwardwilldecrease

enginespeed.

EngineOn/OffSwitch

LocatedonthefrontRHsideoftheengine.

Rotatetheswitchclockwisetothe“ON”position

beforestartingtheengine.Rotatetheswitch

counterclockwisetothe“OFF”positiontokillthe

engine.

FuelShut-OffValve

Locatedontheengine.

Thefuelshut-offvalveisusedtoshutoffthefuel

whenthemachinewillnotbeusedforafewdays,

duringtransporttoandfromthejobsite,andwhen

parkedinsideabuilding.

Rotatedown90degreestoopen.Rotateup90

degreestoclose.

Self-PropelDriveBail

Theself-propeldrivebail,locatedunderthehandle,

controlstheforwardandreversemotionofthe

machine.

Whentheself-propeldrivebailissqueezedagainst

thehandle,theunitgroundspeedwillchangedbased

onthedistancebetweenthebailandthehandle.

Whenthebailisreleased,theunitwillstopmoving.

Figure5

1.Seedercontrollever4.Self-propeldrivebail

2.Handle5.Bladecontrollocklever

3.Bladecontrolbail

BladeControlBail

Thebladecontrolbail,locatedinfrontofthehandle,

engagesordisengagestheblade.

Iftheengineisrunning,thebladeswillengagewhen

thebladecontrolbailisdepressed.

Whenthebladecontrolbailisreleased,theblades

willstop.

BladeControlLockLever

Thebladecontrollockleverislocatedontheleftside

ofthehandlenexttothebladecontrolbail.

Movingthebladecontrollockleverintothefull

forwardpositionallowsthebladecontrolbailtobe

depressed.

Squeezingthebladecontrolbailagainstthehandle

engagestheblade.Releasingthebladecontrolbail

automaticallydisengagestheblade.Thebladecontrol

lockleverwillresettolockthebladecontrolbail.

SeederControlLever

Theseedercontrolleverislocatedontherighthandle

bar.

15

Operation

Pushtheleverforwardtostarttheseedowandpull

itrearwardtostoptheseedow.

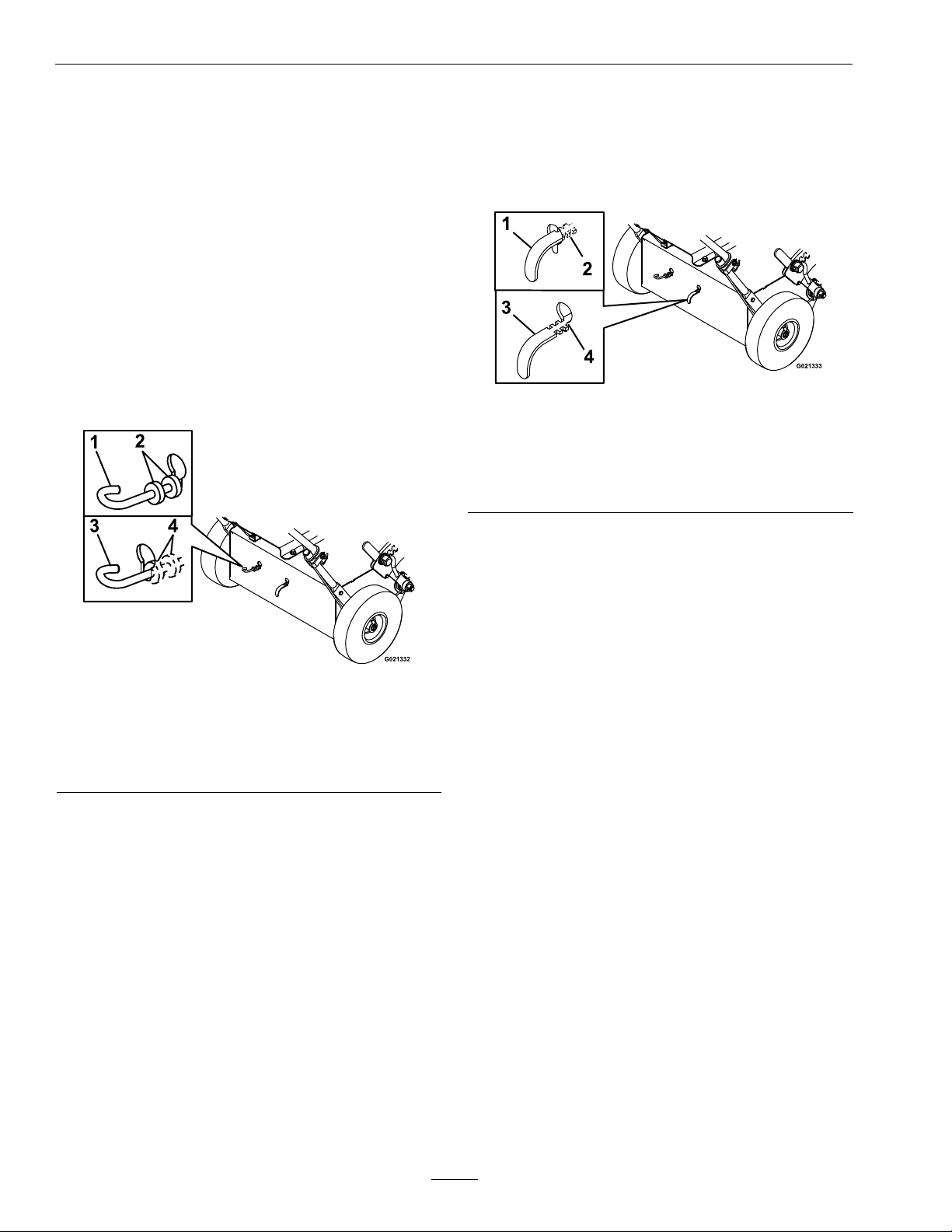

ParkBrakeLever

LocatedonthelowerrearpanelbytheLHreartire.

Thebrakeleverengagestheparkbrakeonthe

transmissionsothedrivetiresdonotrotate.

Toengagetheparkbrake,pulluponthelever,pull

outuntilthetwowashersareoutsidetheframe,and

pushtheleverdownintotheslot.

Todisengagetheparkbrake,pulluponthelever,

pushitinuntilthetwowashersareinsidetheframe,

andpushtheleverdownintotheslot.

Figure6

1.Parkbrakeleverout-engagedposition

2.Twowashersoutsideframe

3.Parkbrakeleverin-releasedposition

4.Twowashersinsideframe

Whenparkingonasteepslope,thewheelsmustbe

chockedorblockedinadditiontothebrakebeing

engaged.Theunitmustbetieddownandbrake

engagedwhentransporting.

DriveWheelReleaseLever

Locatedonthelowerrearpaneltotherightofthe

parkbrakelever.

Thedrivewheelreleaseleverisusedtoreleasethe

hydrostaticdrivesystemtoallowthemachinetobe

movedbyhandwithouttheenginerunning.

Fornormaloperatingposition,pulluponthehandle

andpushthehandleinuntilallthreenotchesare

insidetheframe.

Note:Thelastnotchonthehandledoesnotlatch

ontheslot.

Toreleasethedrivewheels,pulluponthehandle,

pullitoutuntilthelastnotchengagesintheslot.

Pushthehandledown.

Figure7

1.Handlein-normaloperatingposition

2.Allnotchesinsideframe

3.Handleout-drivewheelrelease

4.Lastnotchengagedinslot

Pre-Start

Fillfueltankonlevelground.SeeFuel

RecommendationsintheSpecicationssectionfor

additionalgasolineinformation.

DoNotaddoiltogasoline.

DoNotoverllfueltank.Fillthefueltanktothe

bottomofthellerneck.Theemptyspaceinthe

tankallowsgasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengineoremission

system.

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

OperatingInstructions

OpentheFuelShut-OffValve

Rotatethevalvedown90degreestoopen.

StartingtheEngine

1.Makesurethetractioncontrolleverisinneutral

andthatthecuttingbladecontrolleveris

disengaged.

16

Operation

2.OnthefrontRHsideoftheengine,rotatethe

engineon/offswitchclockwisetothe“ON”

position.

3.OntherearRHsideoftheengine,movethe

chokeleverrearwardtothe“ON”position.On

awarmengine,leavethechokeinthe“OFF”

position.

4.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positionslocatedonrearRHside

oftheengine.

5.Slowlypulltheenginerecoilhandleuntilyoufeel

resistanceandthenstop.Allowtherecoilhandle

toreturnandthensharplypullitstraightout.

Allowtheropetoreturnslowly.

6.Allowtheenginetowarmupforseveralminutes,

movethechoketowardthe“OFF”position.

7.Setthethrottletothedesiredspeed.

StoppingtheEngine

1.Bringtheunittoafullstop.

2.Releasethebladecontrolbail.Thebladesshould

stop;theenginewillcontinuetorun.

3.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

4.Allowtheenginetorunforaminimumof15

seconds,thenturntheengineon/offswitchto

the“OFF”positiontostoptheengine.

5.Waitforallmovingpartstostopbeforeleaving

theoperatingposition.

6.Closethefuelshut-offvalve,locatedbelow

thechoke,byrotatingup90degreeswhenthe

machinewillnotbeinuseforafewdays,when

transporting,orwhentheunitisparkedinside

abuilding.

OperatingtheSelf-PropelDrive

TheSlicerSeederisvariablespeed,themorethe

drivebailissqueezedagainstthehandlethefaster

theunittravels.

1.Starttheengine.

2.Movetheself-propeldrivebailfromtheneutral

position.

•Tomoveforward,squeezetheself-propel

drivebailagainstthehandle(seeFigure8).

Figure8

1.Drivebail(neutral

position)

3.Forward–pulltowards

handle

2.Reverse–pushdownand

awayfromhandle

4.Handle

Note:Thegroundspeedcanbevariedby

increasingordecreasingthedistancebetween

theself-propeldrivebailandthehandle.

Lowerthedrivebail,towardstheneutral

position,todecreasethegroundspeedwhen

makingaturnoriftheunitismovingtoo

fast.Ifthedrivebailisreleased,thedrive

bailreturnstoneutralandtheunitstops

self-propelling.Squeezethegroundspeed

controlbailclosertothehandletoincrease

thegroundspeed.Whenthedrivebailisheld

tightagainstthehandle,theunitself-propels

atthemaximumgroundspeed.Releasethe

drivebailtostopmovingorwheneveryou

leavetheunit.

•Toturnleftorright,decreasethespeed,push

downonthehandles,andturntheunitin

thedesireddirection;thenresumenormal

operation.

•Tomoveinreverse,releasethedrivebailand

allowittoreturntoneutral.Pushthedrivebail

downandawayfromthehandle.Theground

speedwillvaryasthedistanceincreasesor

decreasesfromtheneutralposition.

3.Todisengagetheself-propeldriveandplacethe

unitintotheneutralposition,releasethedrive

bail.

17

Operation

Note:Iftheunitcreepsforwardorrearward

whenthedrivebailisintheneutralposition,stop

theengineandadjusttheself-propeldrivecable

(seeAdjustingtheSelf-PropelDriveinthe

Adjustmentssection).

OperatingtheBladeControlLever

1.Starttheengine.

2.Pushandholdthebladecontrollockleverforward

toreleasethebladecontrolbail(Figure9).

Figure9

1.Bladecontrollocklever

(lockedposition)

3.Bladecontrolbail

2.Push4.Squeezeagainsthandle

3.Squeezethebladecontrolbailagainstthehandle

andreleasethebladecontrollocklever;theblades

willengage.

4.Releasethebladecontrolbailtodisengagethe

blades.Thebladecontrollockleverwillresetto

lockthebladecontrolbail.

OperatingtheSlicerSeeder

DANGER

Therotatingbladesunderthemachineare

dangerous.Bladecontactcancauseserious

injuryorkillyou.

DoNotputhandsorfeetunderthemachine

whenthebladesareengaged.

DANGER

Whenthemachineisinoperation,contactwith

rotatingormovingpartswillseverelyinjure

handsandfeet.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,

stoptheengineandwaitforallmoving

partstostop.Disconnectthewirefromthe

sparkplugandkeepitawayfromtheplugto

preventsomeonefromaccidentallystarting

theengine.

•Staybehindthehandleandawayfromthe

seedmixerandcuttingbladeswhileoperating

themachine.

•Keepface,hands,feet,andanyotherpartof

yourbodyorclothingawayfromconcealed,

moving,orrotatingparts.

1.Ifseeding,lltheseedhopperandsettheseeding

rategauge(seeAdjustingtheSeedingRate

Gaugesection).

2.Adjustthecuttingbladedepthtothedesired

setting(seeAdjustingtheBladeCuttingDepth

section).

3.Starttheengine.

4.Settheenginethrottletothe“FAST”position.

5.Pushdownonthehandletoraisethefrontwheels

slightlyofftheground.

6.Squeezethebladecontrolbailagainstthehandle

toengagetheblades.Slowlylowerthefront

wheelstotheground,allowingthebladesto

graduallyworkintothegrassandsoil.

7.Ifseeding,pushtheseedercontrolleverforward

tostarttheseedow .

Note:Thereisnoneedtoturntheseedow

controlleveroffandonforeachturn.Theseed

owwillslowand/orstopwhenthemachineis

stoppedorslowedforturning.Toreduceseed

loss,raisethefrontwheelsasthemachineis

turned.

Note:Themachinewillseedatthesamerate

goingforwardorrearward.

Note:Ifthereisexcessivethatch,itmaybe

necessarytoremovethethatchpriortoseeding.

8.Engagetheself-propeldrivebailtobegin

operating.

18

Operation

AdjustingtheCuttingBladeDepth

1.Bringtheunittoafullstop.

2.Disengagethecuttingblades.

3.Stoptheengineandwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

Disconnectthewirefromthesparkplug.

4.Unlockthecuttingbladedepthhandlebypulling

upward.

Figure10

1.Unlock3.Lock

2.Cuttingbladedepth

handle

5.Movethelevertothedesiredworkingdepthslot

setting.Rotateandpushthehandledowntolock

thehandle.

6.Thesettingwillneedtobeadjustedasthecutting

bladeswear.

AdjustingtheSeedingRateGauge

1.Bringtheunittoafullstop.

2.Disengagethecuttingblades.

3.Stoptheengineandwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

4.Tochangetheseedingrate,loosentheknobon

theseedingrategaugelocatedonthefrontof

theseedhopper.Movethegaugepointertothe

desiredpositionandretightentheknob.

Figure11

1.Gaugepointer

Note:Refertotheseedinggraph,locatedonthe

machine,todeterminethecorrectgaugesettingfor

thetypeofgrassandthethicknesstobeplanted.

OperatingTips

OverSeeding

Whenoverseeding,setthecuttingbladestobe1/8

to1/4inch(3to6mm)intotheearth.

Important:DoNotputdownmoreseedthan

recommendedbytheseedcompany.Over

seedingcancausethegrasstobetoothickand

causeittobesusceptibletofungus.

Note:Themachinewillseedatthesamerategoing

bothforwardandrearward.

Note:Ifthereisexcessivethatch,itmaybenecessary

toremovethethatchpriortoseeding.

Dethatching

Setthecuttingbladestobe1/8to1/4inch(3to6

mm)pastthethatchlayer,intotheearth.Operatethe

machineovertheyardwiththeseedercontrollever

turnedoff.

PowerRaking/Renovation

Tobreaknewgroundortillanexistinglawn,setthe

cuttingbladestobe1/4to1/2inch(6to12mm)

intotheearth.Goforwardandbackwardsoverthe

areatobeleveled,ormakemultiplepassesfrom

differentdirections.

Themachinewillworkbestwhenthegroundishard

anddryandwillbemostaggressiveinbreakingup

thesoilinreverse.Ifthegroundissoftandcausesthe

19

Operation

enginetobogdown,raisethebladesabitandmakea

fewpassesbeforeloweringthemtothefulldepth.

Transporting

TransportingaUnit

WARNING

Loadingthemachineontoatrailerwithout

strongenoughorproperlysupportedramps

couldbedangerous.Therampscouldcollapse

causingtheunittofall,whichcouldcauseinjury.

•Useproperrampsthataresecuredtothe

truckortrailer.

•Keepfeetandlegsoutfromundertheunit

whenloadingandunloading.

•Ifnecessary,useassistancewhenloading.

Usefullwidthrampswhenloadingthemachine.

Besurethefuelshut-offvalveisclosed.

Useaheavydutytrailertotransportthemachine.

Securelyfastenthemachinetothetrailerwithstraps,

chains,cables,orropes.

Besurethatthetrailerhasallnecessarylightingand

markingasrequiredbylawandusesafetychains.

20

Table of contents