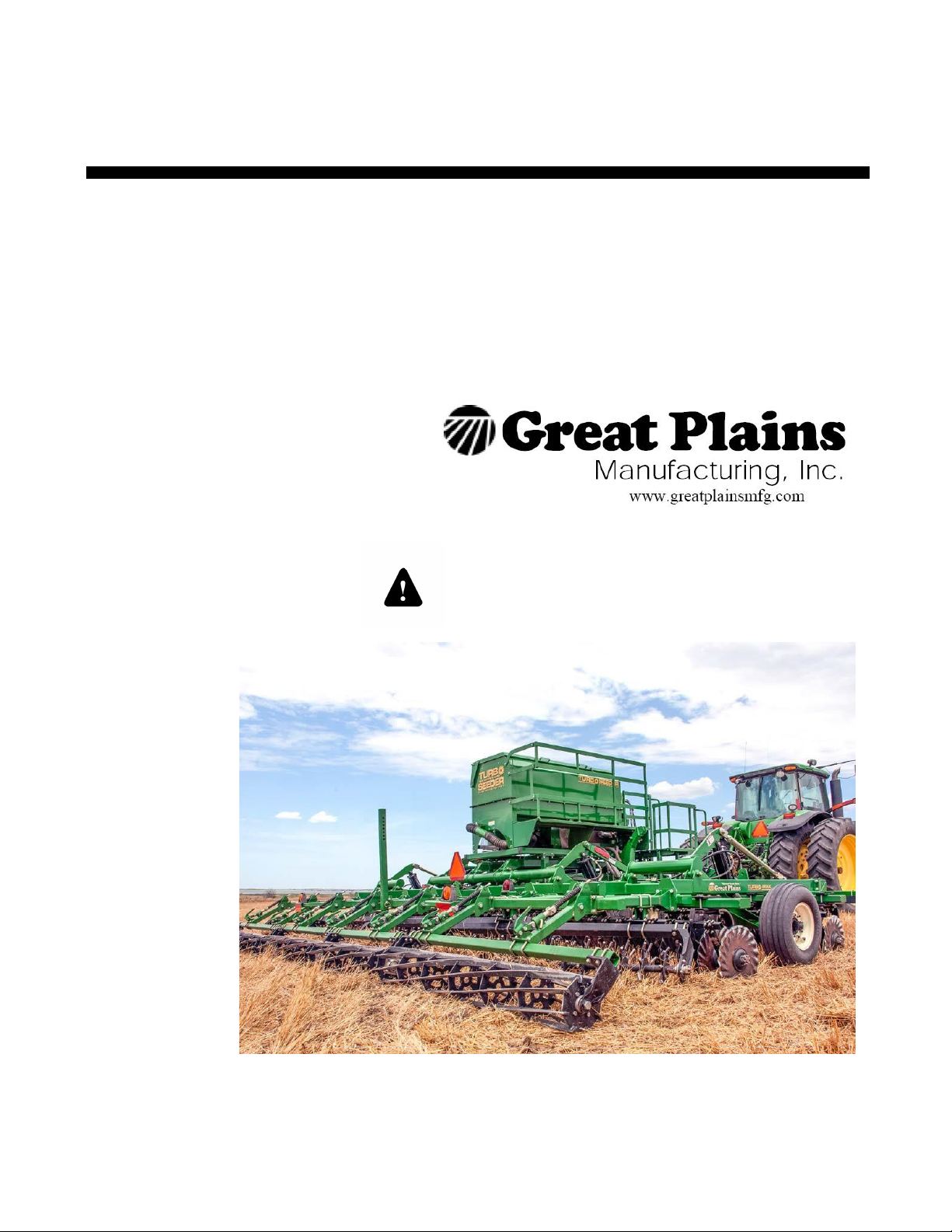

OPERATION MANUAL

Introduction

Great Plains (a division of Great Plains Manufacturing, Inc.) warrants to the original

purchaser that this Great Plains machine will be free from defects in material and work-

manship for a period of one year (Parts & Labor) from the rst use date when used as

intended for personal use; ninety days for custom/commercial or rental use.

Second year limited warranty covers Parts ONLY (personal usage only, excluding labor

and wear items). is warranty is limited to the replacement of any defective part by Great

Plains. Great Plains reserves the right to inspect any equipment or part which are claimed

to have been defective in material or workmanship.

e following items and/or conditions are NOT COVERED UNDER WARRANTY: Fail-

ures resulting from the abuse or misuse of the equipment, failures occurring as a result of

accidental damage or Force Majeure, failures resulting from alterations or modications,

failures caused by lack of normal maintenance as outlined in the operator’s manual, re-

pairs made by non-authorized personnel, items replaced or repaired due to normal wear

(such as wear items and ground-engaging components including, but not limited to, disc

blades, chisel points, tires, bushings, and scrapers), repeat repair due to improper diagno-

sis or improper repair by the dealer, temporary repairs, service calls and/or mileage to and

from customer location, overtime premium, or unit hauling expenses. e warranty may

be voided if the unit is towed at speeds in excess of 20 miles per hour (32 kilometers per

hour), or failures occurring from soils with rocks, stumps, or other obstructions.

Great Plains reserves the right to make changes in materials or design of the product at

any time without notice. e warranty shall not be interpreted to render Great Plains

liable for damages of any kind, direct or consequential or contingent to property. Fur-

thermore, Great Plains shall not be liable for damages resulting from any cause beyond its

control. is warranty does not extend to crop loss, losses caused by planting or harvest

delays or any expense or loss of labor, supplies, rental machinery, or for any other reason.

No other warranty of any kind whatsoever expressed or implied, is made with respect

to this sale; and all implied warranties of merchantability and tness for a particular

purpose which exceed the obligations set forth in this written warranty are hereby

disclaimed and excluded from this sale.

his warranty is not valid unless registered by a certied Great Plains dealer.