ASSEMBLY

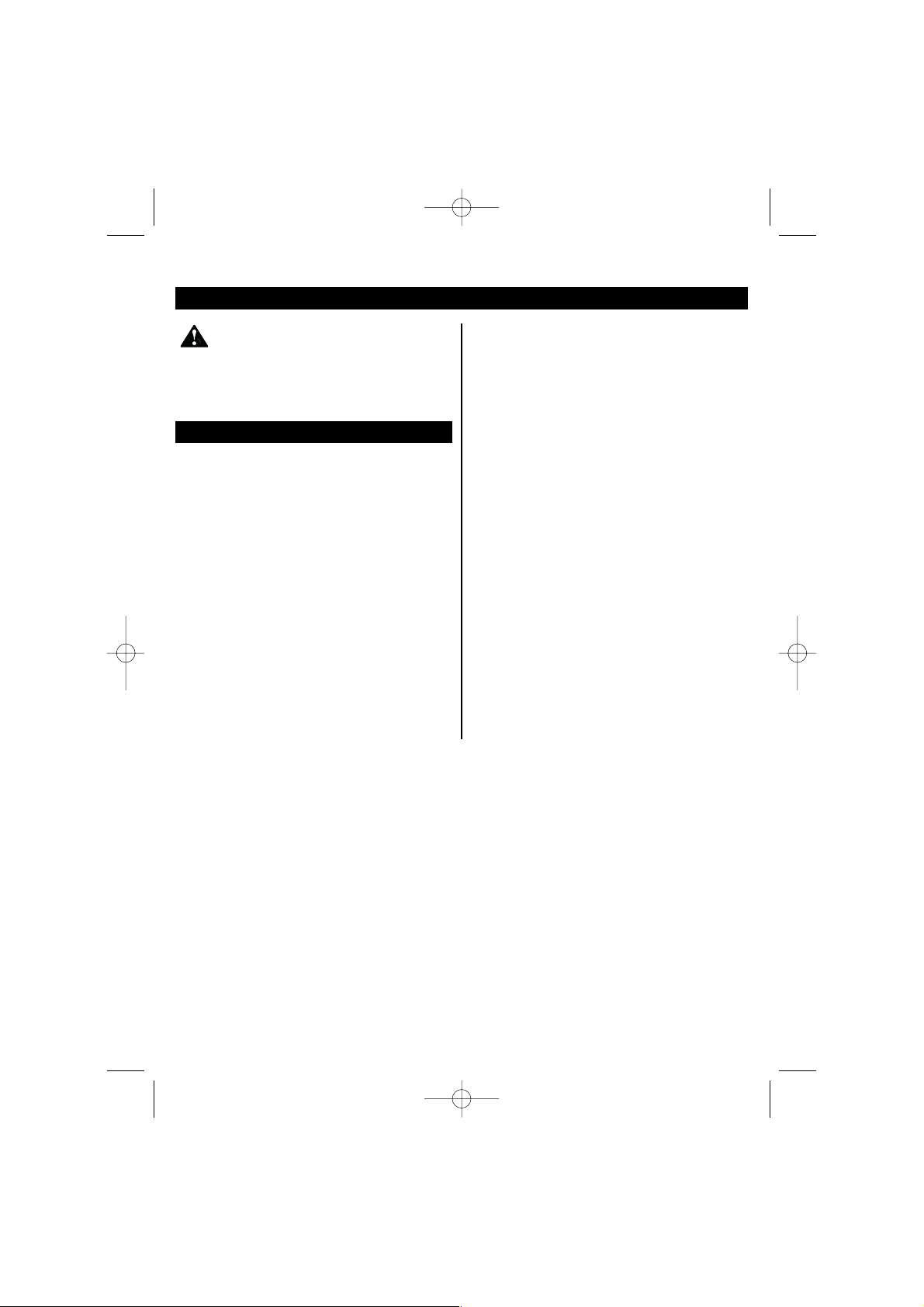

Note: If the button does not release completely in the

positioning hole, the shafts are not locked into place.

Slightly rotate from side to side until the button is

locked into place.

■Tighten the knob securely.

WARNING

Be certain the knob is fully tightened before

operating equipment; check it periodically for

tightness during use to avoid serious injury or

product damage.

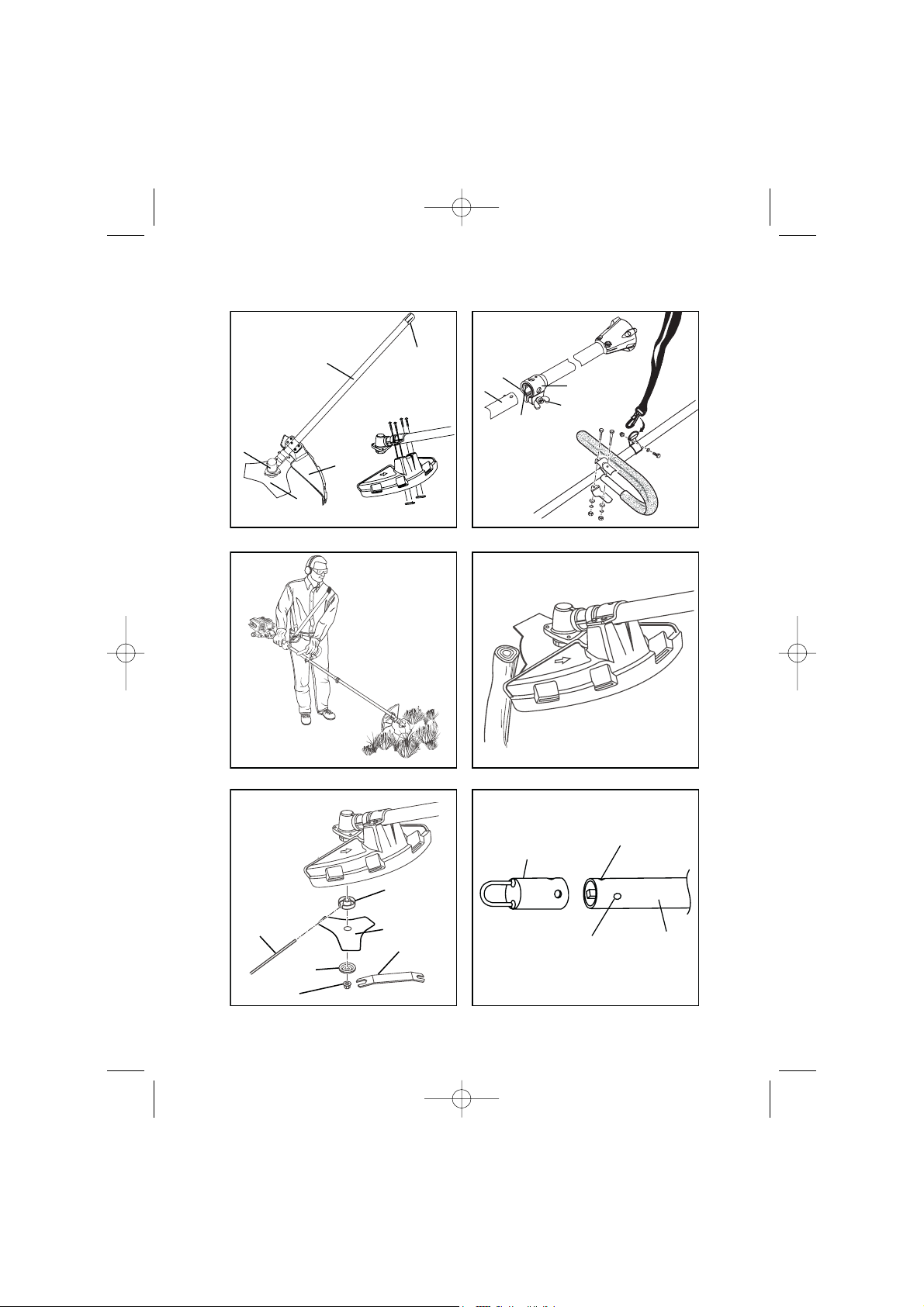

FRONT HANDLE (Fig. 2)

A barrier handle should be used for ensuring the best

control and maximising operator safety.

■Hold the top and bottom clamp snugly in position on

the shaft housing so that handle will be located to the

operator’s left.

■Insert the end of the handle between the clamps.

■Align the bolt holes and push the long bolt (1/4-20 x 1

1/2 in) through the handle side.

■Place short bolt (1/4-20 x 1 in) through opposite side

of clamp. Install flat washer, lock washers and hex

nuts to hold the assembly in place.

■After assembly is complete, adjust the position of the

handle for best balance and comfort.

■Tighten first the long bolt and then the short bolt.

■Connect the shoulder strap to the strap hanger adjust

to a comfortable position.

REMOVING THE ATTACHMENT FROM THE

POWER HEAD

For removing or changing the attachment:

■Loosen the knob.

■Push in the button and twist the shafts to remove and

separate ends.

OPERATION

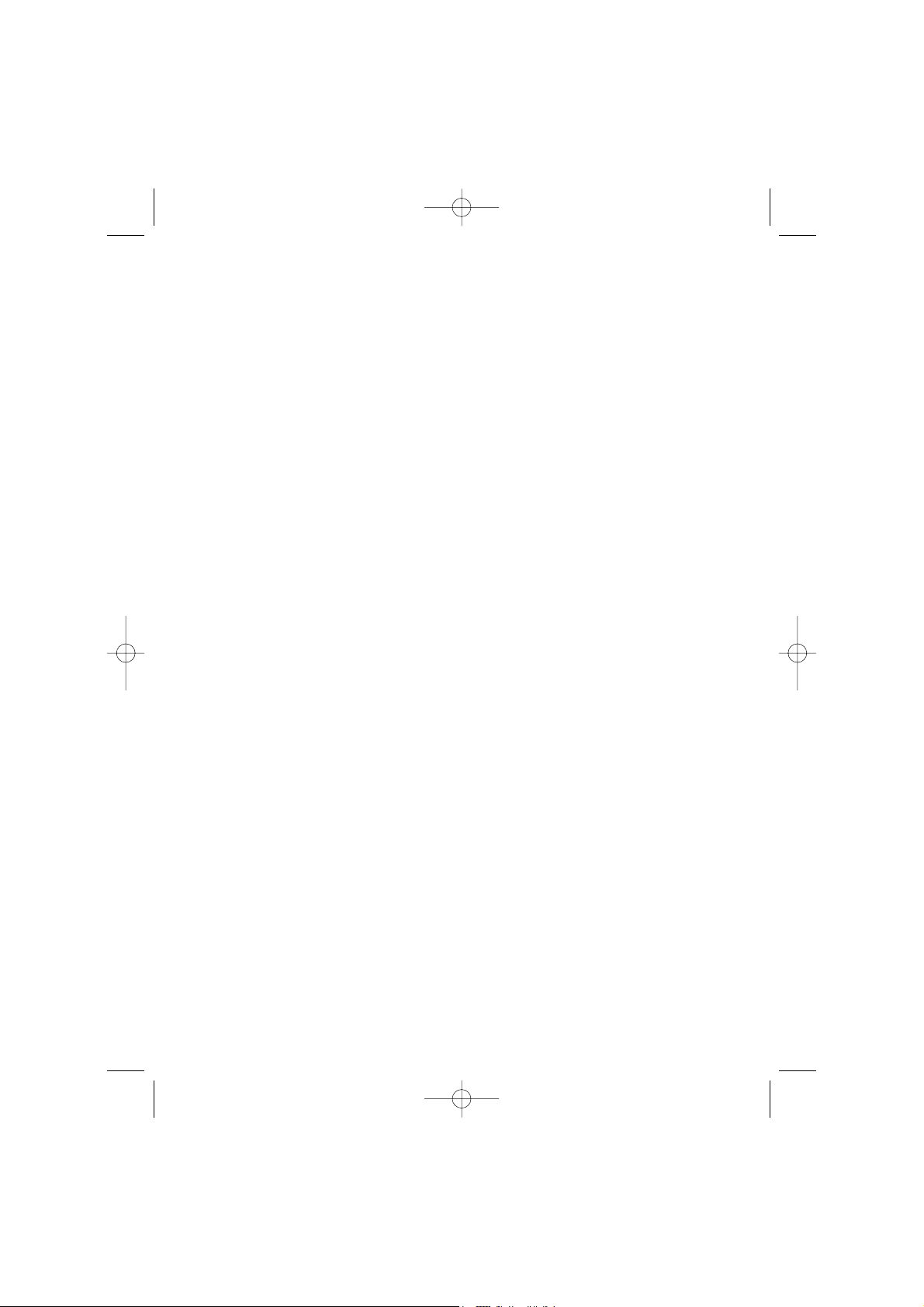

OPERATING THE BRUSHCUTTER (Fig. 3 & 4)

Hold the brushcutter with the right hand on the trigger

handle and the left hand on the front handle. Keep a firm

grip with both hands while in operation. Brushcutter should

be held at a comfortable position with the trigger handle

about hip height. Maintain your grip and balance on

both feet. Position yourself so that you will not be drawn off

balance by the kick-back reaction of the cutting blade.

Exercise extreme caution when using the blade with

this unit. Blade thrust is the reaction which may occur

when the spinning blade contacts anything it cannot cut.

This contact may cause the blade to stop for an instant,

and suddenly "thrust" the unit away from the object that

was hit. This reaction can be violent enough to cause the

operator to lose control of the unit. Blade thrust may occur

without warning if the blade snags, stalls or binds. This is

more likely to occur in areas where it is difficult to see the

material being cut. For cutting ease and safety, approach

the weeds being cut from the right to the left. In the event

that an unexpected object or woody stock is encountered,

this could minimise the blade thrust reaction.

CUTTING TECHNIQUE - BLADE

WARNING

Extreme care must be taken when using blades

to ensure safe operation. Read the safety

information for safe operation using the blade,

refer to "Specific Safety Rules for Brushcutter

and Blade Use" earlier in this manual.

■Always hold brushcutter with both hands when

operating. Use a firm grip on both handles.

■Maintain your grip and balance on both feet. Position

yourself so that you will not be drawn off balance by

the kick-back reaction of the cutting blade.

■Inspect and clear the area of any hidden objects

such as glass, stones, concrete, fencing, wire, wood,

metal, etc.

■Never use blades near footpaths, fencing, posts,

buildings or other immovable objects.

■Never use a blade after hitting a hard object without

first inspecting it for damage. Do not use if any

damage is detected.

WARNING

Do not, under any circumstance, use any

attachment or accessory on this product which

was not provided with the product, or identified

as appropriate for use with this product in the

Operator's Manual.

MAINTENANCE

WARNING

Use only original manufacturer's replacement

parts, accessories and attachments. Failure to do

so may cause poor performance, possible injury

and may void your warranty.

3

English