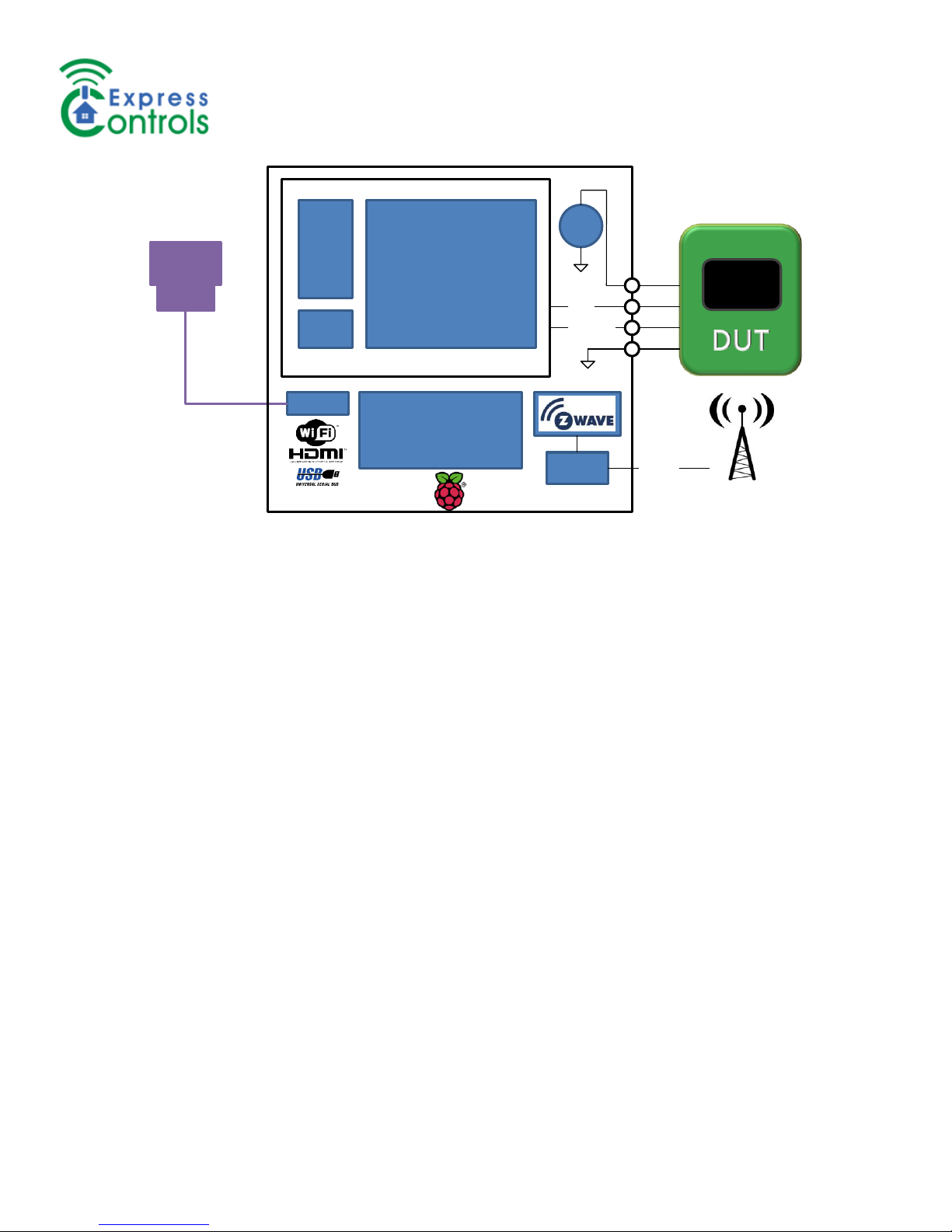

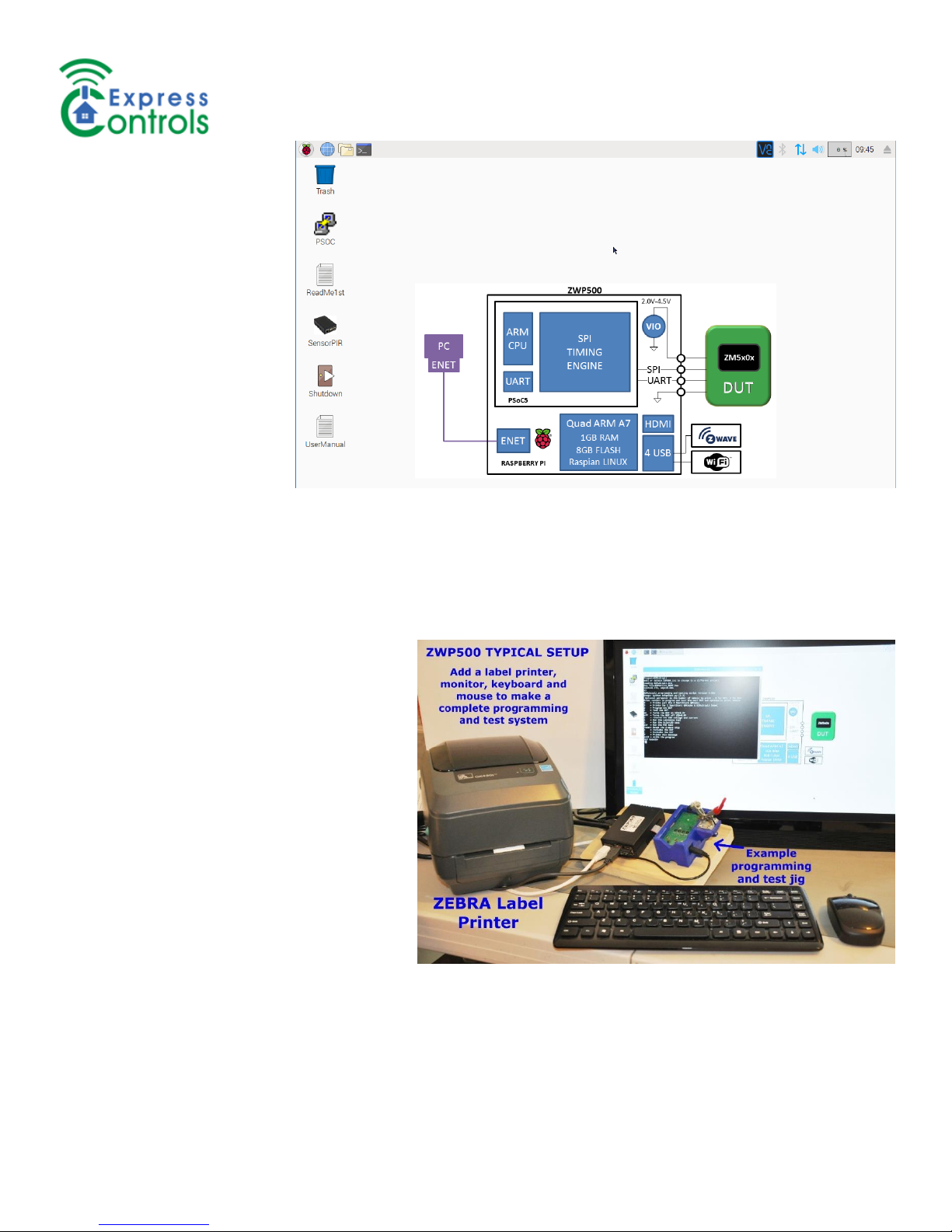

ZWP500™

Z-Wave Production Programmer & Tester

www.ExpressControls.com

February 2018 Bringing the Internet of Things (IoT) to Life 3

Product Validation Example Python Application ...............................................................................................................14

Production Testing ................................................................................................................................................................14

Production Testing Example Python Application...............................................................................................................14

Manufacturing Data Logging .............................................................................................................................................14

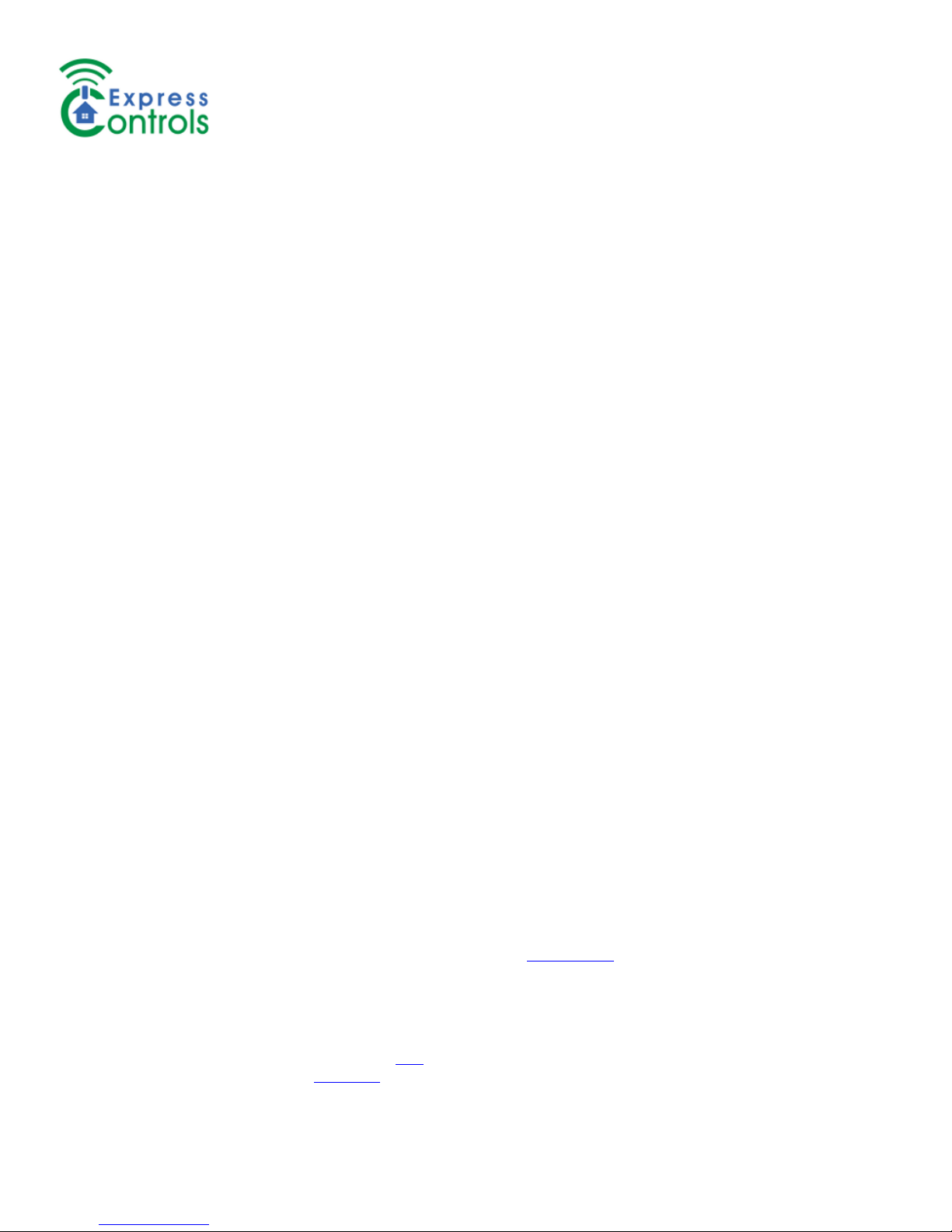

ZWP500 Interface .................................................................................................................................................................14

PSoC Commands..............................................................................................................................................................14

AcquireDUT ...................................................................................................................................................................15

Calibrate.........................................................................................................................................................................15

FirmwareUpdate ............................................................................................................................................................15

FlashDownload ..............................................................................................................................................................16

FlashErase.....................................................................................................................................................................16

FlashWrite......................................................................................................................................................................16

FlashRead 0xxxxx:0yyyyy..............................................................................................................................................17

FlashVerify.....................................................................................................................................................................17

FlashCRC.......................................................................................................................................................................17

GPIOGet ........................................................................................................................................................................17

GPIOSet PS...................................................................................................................................................................17

Help................................................................................................................................................................................18

I2CGet AA LL.................................................................................................................................................................18

I2CProbe........................................................................................................................................................................18

I2CSend AA DD…[p] .....................................................................................................................................................18

LEDSet RGB..................................................................................................................................................................19

NVMGet SSSSSS:EEEEEE ..........................................................................................................................................19

NVMSet AAAAAA=DD...................................................................................................................................................19

NVRGet..........................................................................................................................................................................20

NVRSet AA=DD.............................................................................................................................................................20

ResetDUT [0] .................................................................................................................................................................21

RFAttenuatorSet DD......................................................................................................................................................21

UARTGet........................................................................................................................................................................21

UARTInit BB...................................................................................................................................................................21

UARTSend DD… ...........................................................................................................................................................22

VIOSet............................................................................................................................................................................22

VIOGet...........................................................................................................................................................................22

ZWaveGet [TT] ..............................................................................................................................................................22

ZWaveSend DD… .........................................................................................................................................................22

Troubleshooting ....................................................................................................................................................................23

Firmware Update...................................................................................................................................................................23

Terminal Window Settings with PuTTY.................................................................................................................................23

Python sample application....................................................................................................................................................24