9

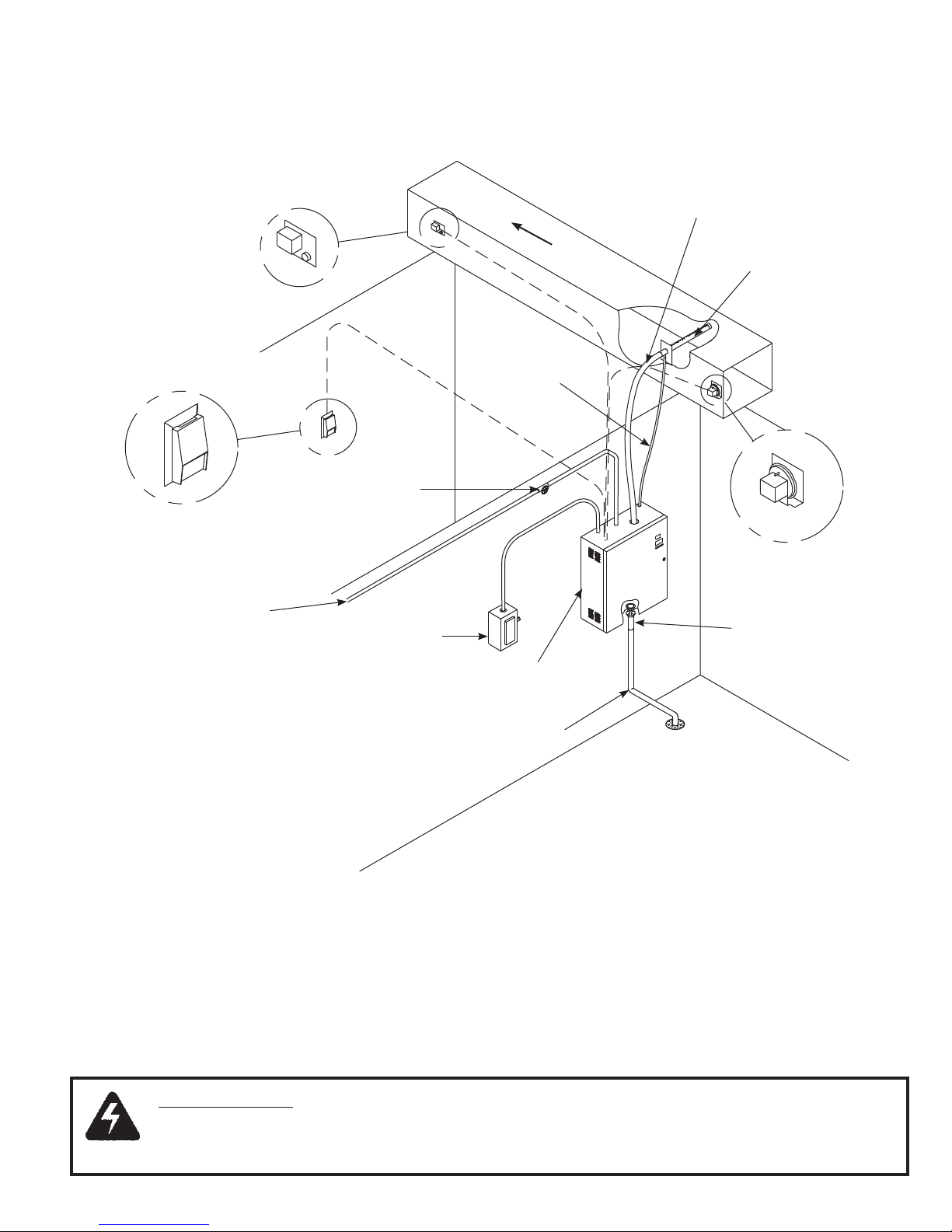

STEAM DISTRIBUTOR PIPE INSTALL

EACH CYLINDER REQUIRES SEPARATE STEAM HOSE,

CONDENSATE RETURN LINE, AND STEAM DISTRIBUTOR

PIPE.

1. The steam distributor pipe must be mounted on a plumb

surface and inclined upward. This is required so the

condensate which forms in the distributor pipe will drain to the

return line and back to the unit, or to a common drain.

2. Insert distributor pipe into duct and secure with four sheet

metal screws (not included).

3. Special distributor pipes are shipped with specific instructions

on how to mount them.

4. If the optional fan distribution unit is to be used, follow the

instructions included with the unit.

CONNECT THE STEAM HOSE

COPPER OR BRASS TUBE IS THE ONLY ACCEPTABLE

SUBSTITUTE FOR CARNES STEAM HOSE OR CONDENSATE

HOSE.

1. The steam hose should be installed so there is a continuous

rise from the humidifier to the distributor pipe. Support the

steam hose at intermediate points to prevent dips, pockets,

sags, or horizontal runs. See Figure I.

2. Any turns should have a minimum radius of 8” to prevent the

hose from kinking. Fasten the steam hose to the distributor

pipe with one of the hose clamps provided.

3. Push the steam hose through the opening on the top of the

humidifier cabinet and slip it over the outlet stub on the top of

the cylinder. Fasten with the hose clamp provided.

4. If long lengths of steam hose or hard tubing are used, the

use of periodic “T’s” to drain condensate should be used.

See Figure D.

CONDENSATE RETURN LINE

1. Fasten the condensate return line to the distributor pipe with

the hose clamp provided.

2. Follow the steam hose to the humidifier cabinet and secure

the return line to the steam hose.

3. Connect the return line to the condensate return inlet with a

hose clamp provided.

4. If it is impossible to maintain a drop to the top of the cabinet,

it is necessary to run the condensate return line directly to the

air gap drain fitting or some other drain.

5. A trap of sufficient size may be necessary to prevent loss of

steam through the return line and reduce the temperature of

condensate water to the common drain. Do not install a trap if

condensate is returned to the top of the cabinet.

STEAM DISPERSION CRITERIA

1. Distributor pipe location must be at a minimum of 6 feet

upstream from any elbows, splits, coils, turning vanes, grilles,

diffusers, etc.

2. If duct temperature is 60°F or less, 10 feet is recommended.

3. Under normal conditions, most absorption distances will be

approximately 4 to 5 feet.

4. If distance recommended is not possible, then a drain pan

may be required.

5. If the air in the duct cannot accommodate the steam output,

the only recourse may be to lower the maximum output of the

unit.

6. If shorter absorption distances are required, 3 feet or less,

multiple distributor pipes could be used. Two pipes split off

one steam hose or two pipes from a dual cylinder unit.

7. If even shorter absorption distances are required, 2 feet

or less, then multi tube short absorption manifolds may be

required.

It is important to keep in mind that there are a lot of variables

involved in proper steam distribution and absorption distances

such as duct length downstream from the dispersion method,

required absorption distance determined by design, capacity of

humidification, velocity of air flow, temperature of air flow, location

of humidifiers, distance between humidifiers to distribution point,

and so on. Proper planning is a prerequisite to good performance.

It is very important that both the steam hose and condensate

return line, whether flexible or hard tubing, be installed so

there are no sags, low points, dips, or horizontal runs. The

steam is at a very low pressure and it cannot overcome any

resistance caused by accumulating water standing in the steam

hose. Accumulation in the condensate return hose will hamper the

flow and may cause water to back up into the duct.

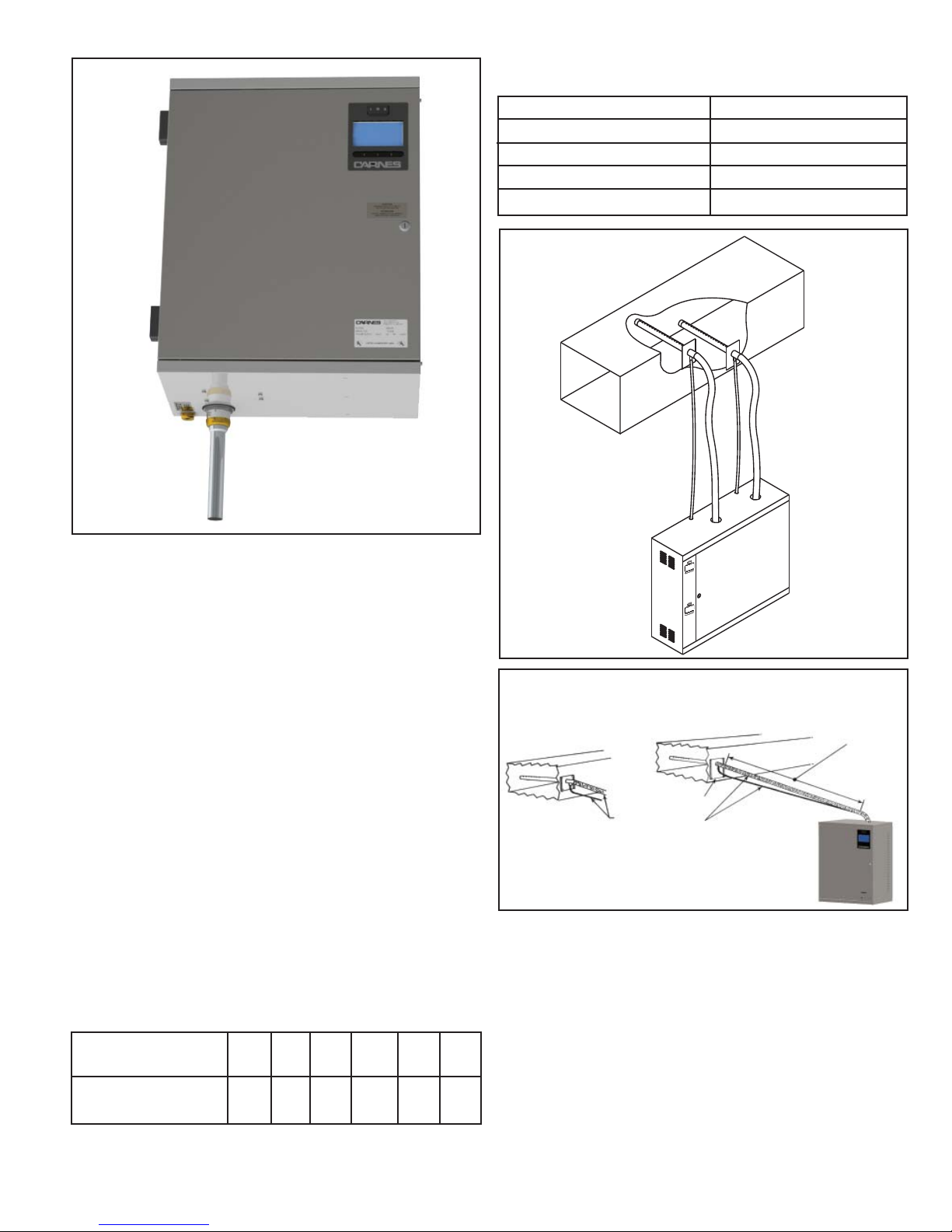

If it is difficult to install the steam hose to prevent sags, it is

recommended that a copper tube be used as a substitute. If a

copper tube is used, a minimum of one inch of insulation must be

applied to prevent excessive condensation (See Figure J). A short

length of steam hose must be used to connect the cylinder in the

humidifier to the copper tube and another short length to connect

the copper tube to the distributor pipe. Size 3/4” copper tube (with

7/8” steam hose) can be used with steam cylinders having output

rates up to 30 pounds per hour. Size 1-1/2” copper tube (with

1-5/8” steam hose) should be used with steam cylinders having

output rates over 30 pounds per hour.

Hose lengths of no longer then 10-20 feet and proper inclines or

routing, as expressed in this manual, will provide the best chance

of having a proper operating humidifier with efficient and effective

steam dispersion.

Figure I Note: Over time and extended

heat, the situations described

in the previous paragraph

can occur. That’s why it is

important to perform monthly

visual inspections to maintain

and correct, improper routing of

steam and condensate lines.

Exaggerated for emphasis.

Figure J

1” Minimum Pipe Insulation

Steam Pipe