-2-

This is a cooling water circulator, which cools water

by means of the refrigerator inside the bath and

circulates cooling water by means of the circulation

pump to the outside to cool the evaporator, reactor,

the heating portion of various mechanical units

This product is of a low-floor type and can be stored

in a space under a table.

This is capable of cooling two 1L type evaporators

simultaneously.

2-2 Specification

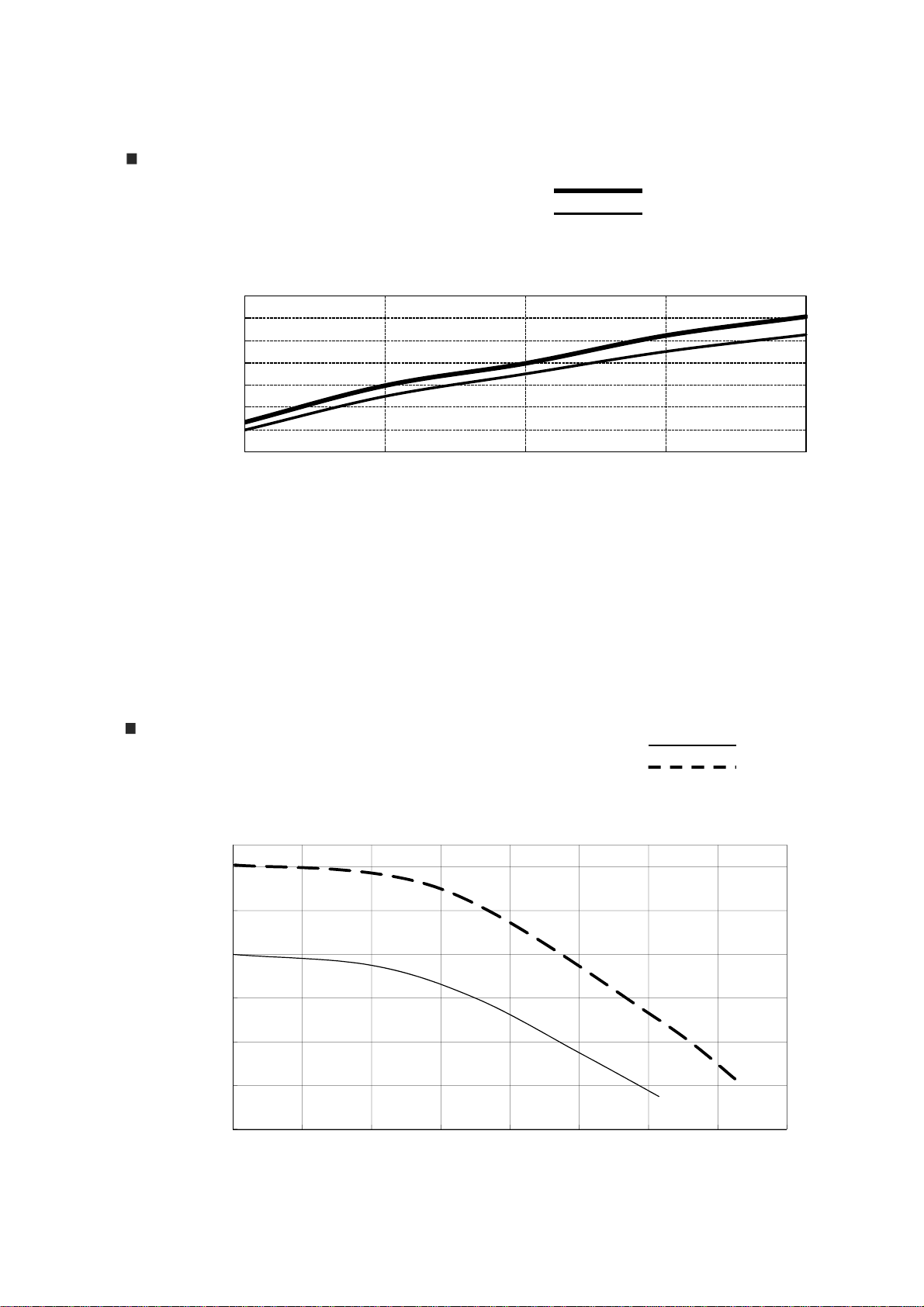

※The performance is for the room temperature of 20℃, the rated supply voltage, 50 Hz, and the no-load state.

※1 For the room temperature of 35℃, the set temperature range can be up to -10℃.

※2 The cooling capacity is ±10%of the listed capacity.

※3 The circulation capacity is ±10%of the listed capacity.

※4 Power cord and other projections not included

2

Product name Low temperature circulator (Cool Ace)

Model CA-1330

Circulation system Circulation for sealed system

Performance

Temperature control range ※1-20℃~+20℃

Accuracy of temperature control ±2.0℃~

Cooling capability※21050Wat10℃

External circulation Capability※3

(50/60Hz) Max. flow volume 12/14L/min

Max. lifting height 9.5/13m

Functions

Temperature control system Refrigeration unit, ON-OFF control

Temperature setting・display Sheet key digital setting , LED digital setting(minimum digit:1℃)

Safety features Residual current device・excess current breaker , Self-diagnosis function

of the temperature controller, Over load relay holding circuit, Protection

timer for refrigeration unit, Thermal protector for circulation pump, High

pressure switch of the refrigeration unit

Optional parts External sensor terminal, communication terminal(for NVC3000)

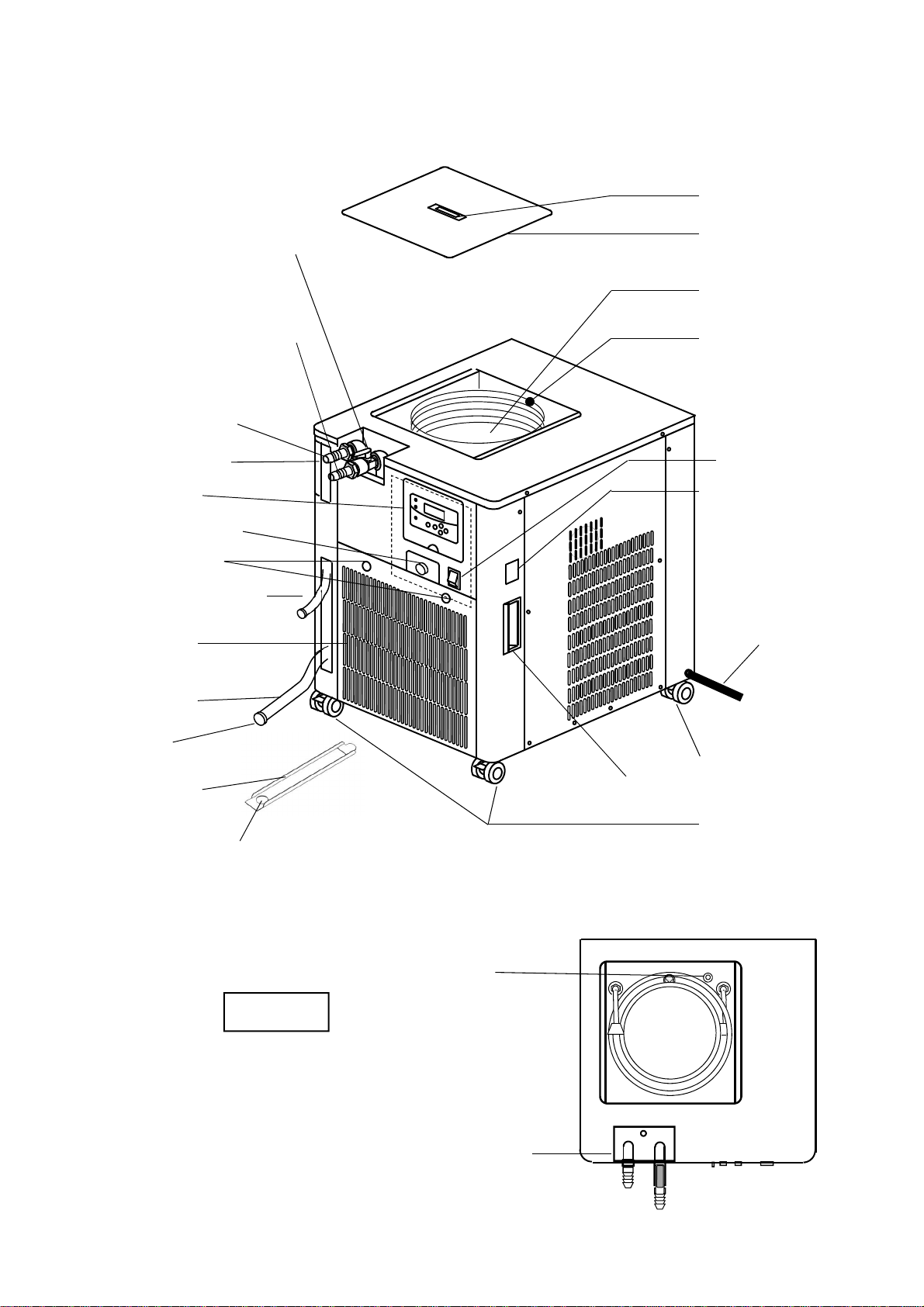

Configuratio

n

Temperature controller Electronic digital setting・digital display

Temperature sensor Pt sensor (Pt100Ω)

Refrigeration unit・refrigerant Air cooling type 650W・R407C

Cooling coil Copper(Nickel coating)

Spec.

External circulation nozzle External diameter:10.5×Bore diameter: 7(R3/8)

Bath material, dimensions and

capacity SUS304, W270×H270×D175[mm], (MAX12.8L, liquid capacity

approx.10L)

Operating ambient temperature 5~35℃

Dimensions (main unit)(mm)※4 W460×D430×H570

Mass Approx. 48kg

Power input・rated power 5A AC220V±10% 50/60Hz

Operation presser max. 2.55MPa

Pollution degree 2

Over voltage category Ⅱ

Operation at a terrestrial altitude Max2000m above sea level

2-1 Applications

Product overview

Never attempt to disassemble or modify the

product.

Do not use the product for any purposes

other than those specified.

Modification or use for purposes other than those

specified may lead to an electric shock or a

malfunction.

Warning