2-1 Use application

2-2 Specification

Do not remodel the product.

Make sure that it should not be used

out of intended use.

Remodeling and improper use may cause

electric shock or breakdown.

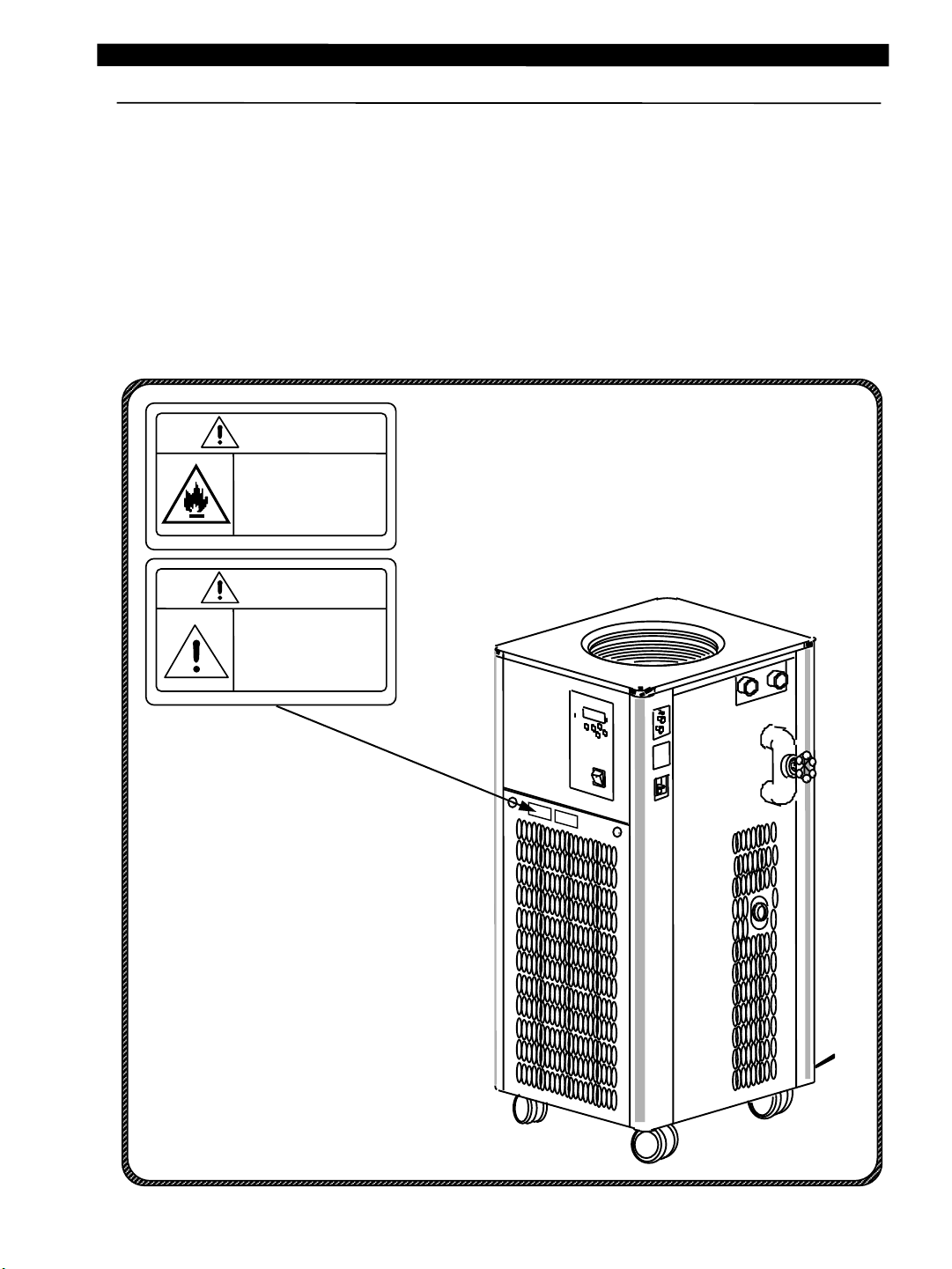

WARNING This is the cool water circulating machine to

cool down the liquid in the bath with using

cooling machine and circulate the liquid

externally by circulating pump, and to cool

down generating heat part of evaporator,

reaction bath and other devices.

Circulation to open system can be performed

when sealing up cover, which is one of the

options, is used.

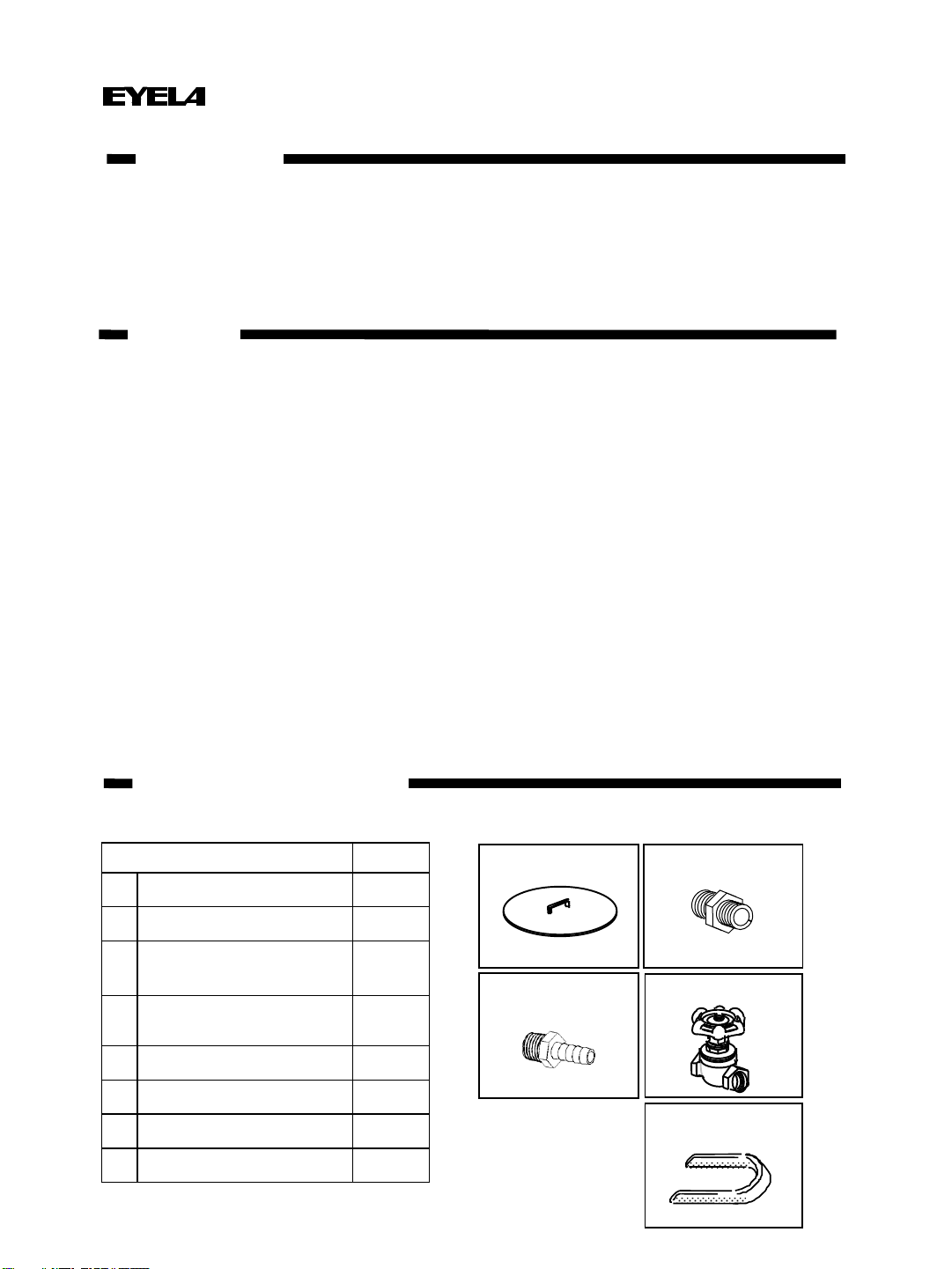

2Outline of the product

Product name Cooling water circulating device (Cool Ace)

Model CA-2610 CA-2610 S

Circulation system Suitable for seal-up circulation

Range of available ambient

temperature 5 to 35⁰C

Range of temperature

control -10 ~35⁰C

Accuracy of temperature

control ±2.0⁰C (Water)

Cooling capacity 3000W at 20⁰C (liquid temperature)

2500W at 10⁰C (liquid temperature)

External

circulation

capacity

Maximum

lifting range 9.5/13m(50/60Hz)

Maximum

flow rate 23.5/27ℓ/min (50/60Hz)

Temperature control

system Caterpillar tube capacity exchanging control + Controlling turning on / off cooling machine

Setting Temp., display Sheet key input・digital display, minimum digit 0.1⁰C

Safety device ad

function

Electric leakage・excess current breaker, self-testing function for temperature controller, Sensor alarm, over load of

cooling machine, high-pressure switch for cooling machine, timer for protecting cooling machine, circulating pump

thermal protector

Included function

Controlling flow amount

function

Alarm out function *5

Output terminal for indictor

External temperature sensor

terminal

Controlling flow amount function

Alarm output function *5

Output terminal for indicator

External temperature sensor terminal

Shutdown switch for emergency case

Remote operation terminal

Optional function Function for detecting pressure abnormality of

circulating water, Function for detecting flow amount decrease of

circulating water

Temperature controller Electronic digital setup・digital display

Temperature sensor Thermistor

Cooling machine・cooling

medium Output: 1100W (Rotary) • R407C

Circulation pump Magnet pump output 41/59W(50/60Hz)

Maximum flow amount: 27/31ℓ/min, Maximum lifting range 9.5/13m(50/60Hz)

Bath Whole capacity Approx. 16.5ℓ Actual capacity Approx. 14ℓ Material SUS304

Cooling coil Copper (Nickel plate)

External circulating nozzle Nozzle, Returning nozzle diameter: Rc1/2

External measurement 450 (W) (bypass valve+10(W)) x 515 (D) x 1010 (H)

Measurement of bath 280 (diameter) x 270 (depth)

Rated supply AC200V single phase 50/60Hz

Power source input 10A 2.0 kVA

Weight Approx. 84 ㎏

*2

*3

*1

*4

-2 -

Features

Functions

Configuration

Spec.