1

I. Brief Introduction

Features

Basic Characteristics

Adopts the design of barren-electrolyte and utilizes AGM (microporous glass

fiber) separator. Thus there is a path existing between the positive and the

negative. Also non-Sb alloy grid is chosen to increase vent hydrogen

over-potential on the negative plate, which prevent generation of Hydrogen,

finally reaches the goal of no water losing. So during the operation life, there’s no

need to add acid and water, neither to adjust the gravity of the solution.

Reliable seal performance, not emission of acid mist, not erosion to equipment.

Long life and low self-discharge.

Compact structure, shock-proof and high energy density design.

Reliable Seal Technology

Container and lid made of ABS flame retardant FV class V-0. Adopt heat seal

technology of ABS container and lid. The technology conquers epoxy’s

weaknesses of aging and brickle. And the amalgamation of the same ABS

material ensures no leakage of solution.

Explosive proof valve with an acid filtering structure. If the pressure inside the

battery exceeds a certain value, the safety valve will automatically open to

decrease the pressure. And it will close till the pressure is normal. The acid

filtering structure in the safety valve prevents emission of acid mist when the

safety valve opens.

Excellent resist characteristics of mechanical impact and heat impact, prolong

the corruption distance of sulfuric acid.

Excellent high rate discharge performance

Unique multiple-segment radial grid

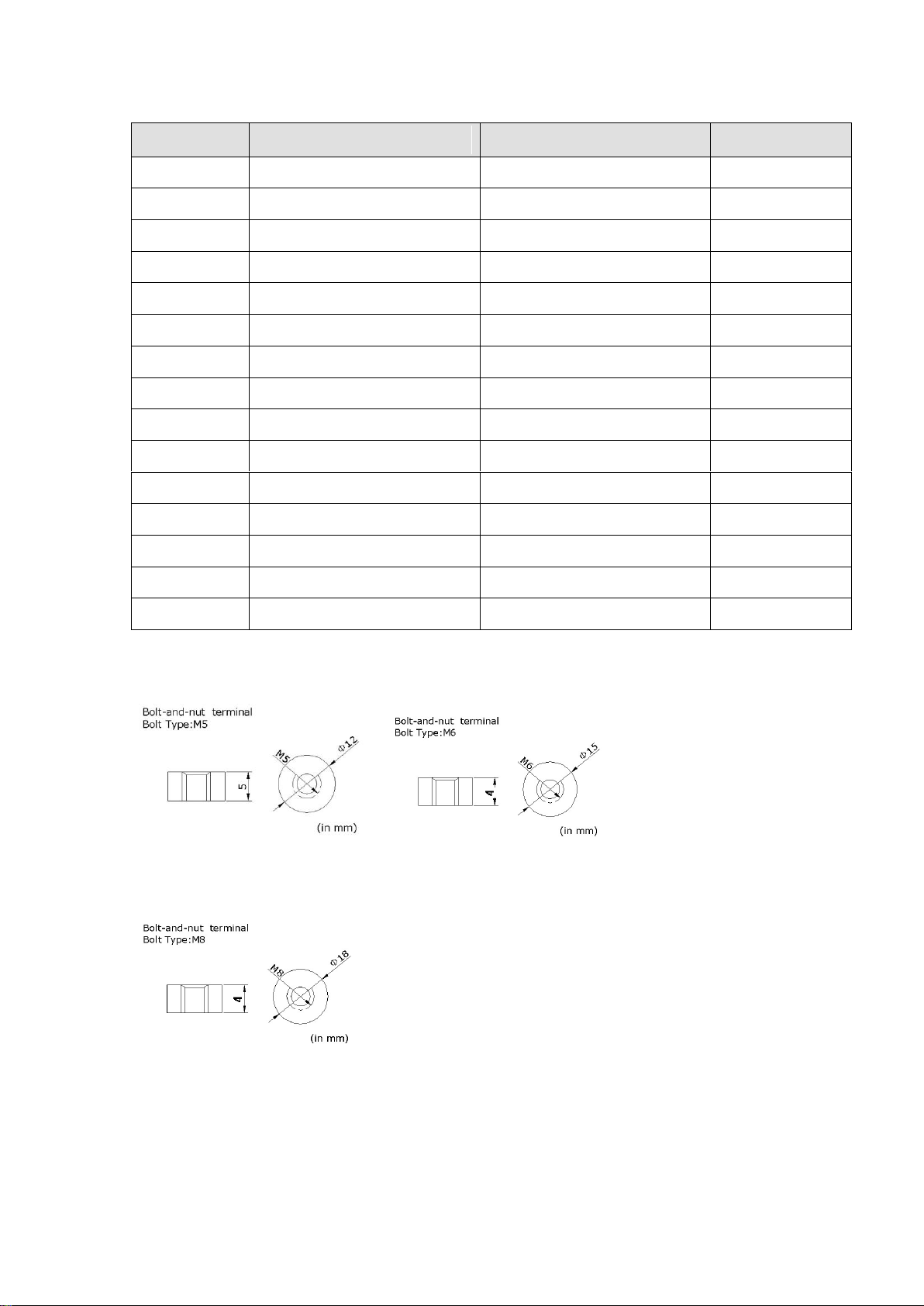

Copper insert pillar, the copper insert’s diameter is as long as 20mm, suitable for

high rate discharge

Silver-coated flexible connector, good electric performance and low

voltage-decrease.

Extremely equalized float charge voltage

A unique homogeneous working procedure ensures homogeneous float charge

voltage of FAAM FLL batteries.