Page 4/11 VISY-ICI 485

1Introduction

The VISY-ICI 485 is a communications adapter to connect VISY-Input 8 and VISY-Out-

put 4 components to the VISY-Command.

The connection is established by an RS-485 interface. The interface is galvanically isolated

from the rest of the circuit, and therefore from the VI-… interface card, by optocouplers

and a DC/DC converter. Galvanic isolation improves the reliability of the communication.

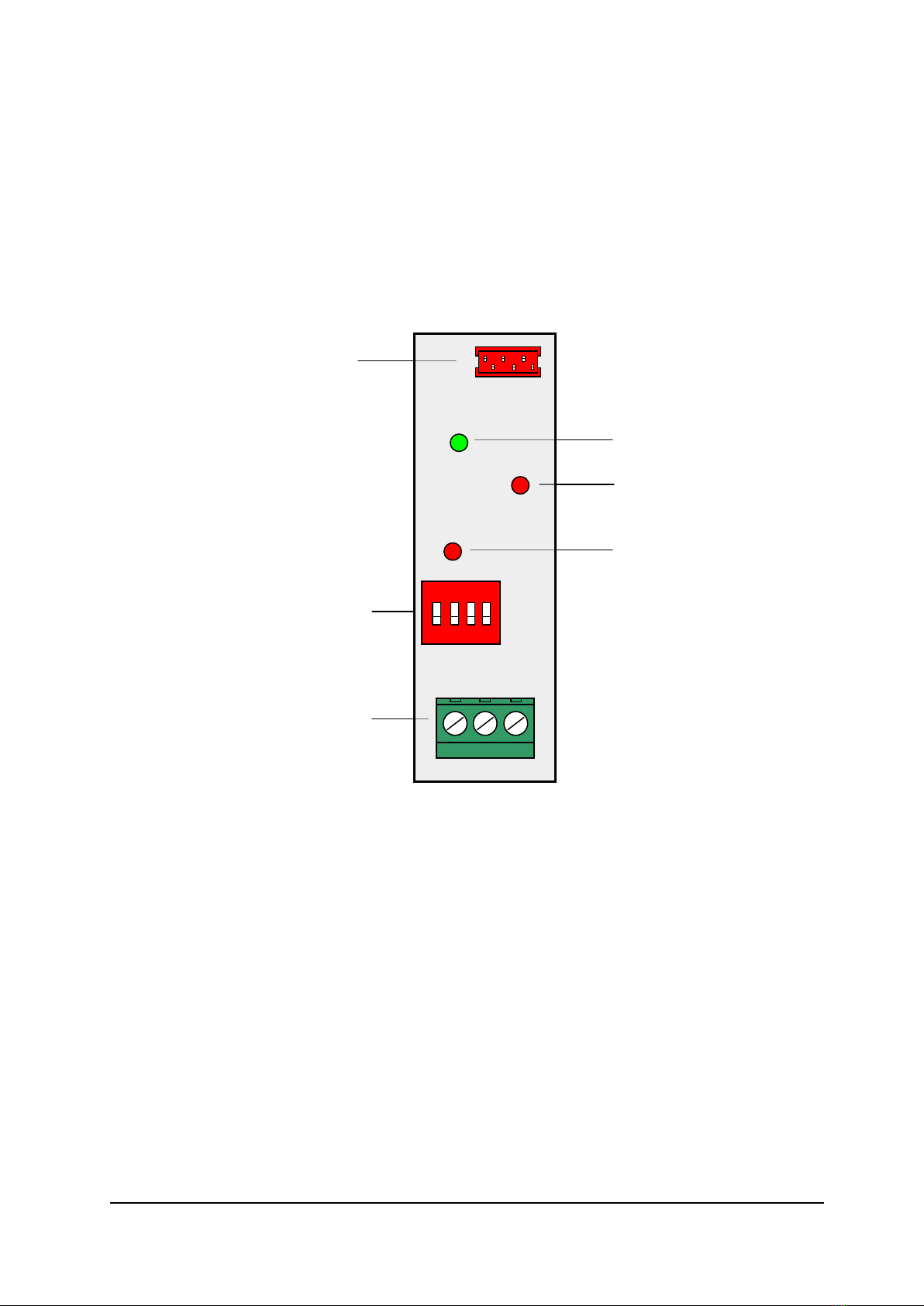

For a convenient integration into VISY-Command, the printed circuit board (PCB) of the

VISY-ICI 485 is mounted on a module carrier for subsequent installation on DIN rails.

2Installation

2.1 Safety precautions

The following safety precautions must be observed during installation of the VISY-ICI 485

communications adapter:

•The VISY-ICI 485 is designed for operation only with the VI-… interface card.

•Modifications to the VISY-ICI 485 are prohibited without the prior consent of the

manufacturer.

•The installation and configuration of the VISY-ICI 485 communications adapter

must be carried out only by expert, authorised personnel. Specialised knowledge

must be obtained by regular training.

•Operators, installers and service technicians must comply with all applicable safety

regulations. This also applies to any local safety regulations and accident

prevention regulations not stated in this technical documentation.

The safety instructions in this manual are labelled as follows:

If you do not observe these safety instructions, the risk of an accident

exists or the VISY-X system could be damaged.

Useful information in these instructions, that should be observed, is

printed in italics and marked with this symbol.